Introduction

Finite element analysis (FEA) utilizes numerical

analysis and minimizes variational calculus to approximate

mathematical and physical problems. Turner et al (1) proposed the basic theory of FEA in

1956. FEA has since been refined to a high level of precision due

to the decline in cost and increase in computing power resulting

from rapid technological development. Belytschko et al

(2) were the first to apply this

technique to understand the mechanical behavior of the human spinal

column. The application of FEA in biomechanics has accomplished

considerable progress and has been widely used in orthopedics,

dentistry and cerebrovascular diseases as an essential,

complementary and effective alternative for in vitro

studies. Models based on computed tomography (CT) imaging

accurately visualize the geometric information of real human

tissues and provide a reliable approach for the biomechanical

analysis of bone tissues. Traditional model construction methods

manually discern and draft the contour of the bone tissue on the

basis of geometrical shape and size, using the initial scanned

sample to construct a model appropriate for FEA study (3). The approach of these methods is

simple and intuitive. However, discriminating and defining complex

and subtle structures under pathological conditions is difficult.

For example, performing 3D reconstruction in elderly patients with

osteoporosis and degenerative osteophytes is challenging since

similar gray and CT values discriminate the margin between the bone

and soft tissues, which are ambiguous to the naked eye.

Nevertheless, discriminating tissue margins in elderly patients is

not difficult when the appropriate computer software is used. At

the beginning of the 21st century, the development of CT imaging

technology, along with FEA, has benefited from advances in computer

power and CT-based modeling has a variety of new medical

applications (4–14).

The present study introduces a 3D modeling method

that applies 3D processing and modeling techniques. In this method,

the margins of various tissues are differentiated automatically by

software that analyzes data according to the intrinsic gray value

of each tissue. The analysis results and the CT imaging data are

then converted into the DICOM file format, which preserves all

tissue density information. Assignment of Young’s modulus to

non-uniform tissue, which is based on the empirical expressions of

the correlations among density, CT value and Young’s modulus,

becomes possible at this stage, particularly in bone tissues. The

data is readily transferrable into other medical image processing

software, including Mimics (Materialise, Leuven, Belgium) or

Simpleware (Simpleware Ltd., Exeter, UK).

A new approach of model construction is proposed.

The method implements automatic 3D tissue discrimination and

incisions using the Siemens syngo® 3D Workplace

(Siemens, Munich, Germany) prior to transferring the data to

Mimics. Converting CT images to a 3D model is fast, thus allowing

more time for conducting FEA. The new model significantly improves

analysis efficiency and research management. A preliminary fracture

risk-evaluation study was performed in elderly individuals,

according to FEA results on the basis of the new 3D modeling

method.

Materials and method

Case selection

A total of 9,670 lumbar CT examination cases were

provided by Jilin University (Changchun, China) between January

2008 and June 2011. The enrollment criterion was restricted to

degenerative lumbar disease, excluding patients with lumbar

fractures and tumors. This study was conducted in accordance with

the Declaration of Helsinki and with approval from the Ethics

Committee of Jilin University. Written informed consent was

obtained from all participants.

CT scan parameters

Patients were examined by 64-slice spiral CT

(Siemens). The scan ranged between thoracic vertebra 11 and sacrum

1 using the following CT scan parameters: Tube voltage, 120 kV;

effective tube current, 60 mV; and reconstruction thickness, 0.6

mm. Data were recorded in the DICOM format.

Model construction by the conventional

Mimics method

One individual in the 20–40-year-old age group was

randomly selected for the preliminary step of the study. First, a

model of the lumbar spine of this individual was constructed using

conventional Mimics software. This case was prepared for the

innovative model construction method in the next step. The average

height of each vertebra (~3 cm) was divided into ~50 consecutive CT

imaging slices. The conventional finite element model was

constructed by discerning the margin of the bone tissue and by

manually cutting the soft tissue slice-by-slice.

Image processing via innovative 3D

modeling method

Raw DICOM data of the lumbar spine of the patient

underwent tissue marking, 3D cutting, home-positioning and

multi-planar reconstruction using syngo software on the Siemens

Workstation.

Tissue marking

Raw DICOM data were transferred to the Siemens syngo

CT Workstation. Slices of 1.0-mm sequence were dragged into the 3D

application and the sagittal frame was activated in the ‘bone

removal’ mode. Region selection, was the first step, where a

default threshold of 175 HU in the body mode was selected to ensure

that pixels with a CT value >175 HU showed blue markings.

Secondly, the image was refined. The segmentation strength value at

this stage was 50 and the noise tolerance was 600 HU. Refinement

was conducted by recalling bone tissue that had been neglected by

the software. Finally, rendering of the marking was completed and

saved to ensure that a browser list of 3D applications remained on

the workstation to allow for the extraction of DICOM data with

processed tissue markings in the future.

3D incision

After tissue marking, the sagittal frame of the

‘bone display’ item was selected in the ‘bone removal’ mode. Next,

the ‘Osseous Transparent metal VP’ of the visual reaction time in

the type work list was selected. The 3D transparent display of the

lumbar spine bone structure facilitated the 3D incision of the

lumbar spine. The lumbar vertebra was incised using the 3D incision

tools of the syngo software and then rotated 360° in the 3D

transparent mode. This action constituted the only step for normal

lumbar vertebra incision and did not necessitate a slice-by-slice

drafting of the contour in Mimics. The ‘Osseous Shaded VP’ mode was

used to recall bone tissue with low density, which had not been

shown clearly in the ‘Osseous Transparent metal VP’ mode. The

aforementioned steps allowed for high-efficiency extraction of the

exact morphology of the lumbar vertebra structure.

3D orientation

The single incised lumbar vertebra was restored into

its original sagittal orientation following selection of ‘the left

to right’ item in oriental mode. The lumbar vertebra was further

restored into its original 3D orientation following the selection

of ‘home zoom/pan’ item in the oriental mode. Proper restoration of

3D vertebrae orientation after 3D incision was a critical step for

achieving exact 3D matching of each data pixel with the raw DICOM

data. The resulting orientations were then processed along the x, y

and z axes.

Multi-plane reconstruction

‘Parallel ranges’ in the setting mode was selected

following a 3D incision to obtain a multi-plane reconstruction of a

single lumbar vertebra. The reconstructed multi-plane horizontal

slices, with 1.0 mm thickness and 1.0 mm interval, were arranged

from the superior to the inferior section of the vertebra. Bone

tissue data was saved in DICOM format after processing.

Data transfer from syngo to Mimics and

further processing

DICOM data of each vertebra were imported into

Mimics for further processing. Only the data of one vertebral body

were left in Mimics since the soft tissue and other vertebral

bodies were eliminated during processing with the Siemens syngo 3D

CT Workplace. All bone tissue information of the selected vertebra

was obtained following the removal of the surrounding soft tissue

by adjusting the threshold of the gray value to the minimum.

Polishing and remeshing

The model was meshed and smoothed using Magics

software included in the Mimics software. It was then remeshed

using the split-based method. Minimum and maximum edge lengths of

the tetrahedral elements were set at 0.7 and 0.9 mm,

respectively.

Congruence between the models constructed

by traditional and innovative 3D modeling methods

Two models were constructed with the same raw DICOM

data of a single vertebra to compare the congruence between the

traditional and innovative methods. The two models were then

transferred into the Mimics software using the same coordinates to

form a merged image.

Time consumption of the traditional and

innovative 3D modeling methods

The 9,670 lumbar CT examinations in our

institution’s database were divided into the following five age

groups: 20–40, 41–50, 51–60, 61–70 and >70 years old. Five cases

were selected randomly from each age group and models of the entire

lumbar spine (L1–5) were constructed from each patient. Traditional

and innovative methods were used, creating 10 models in total. Time

consumption of each model was recorded and statistical analysis was

performed using SPSS 10 (SPSS, Inc., Chicago, IL, USA). Comparisons

between the two groups were performed by t-tests. P<0.05 was

considered to indicate a statistically significant difference.

Comparative FEA study of the lumbar spine

under flexion and extension between young and elderly patients

The elastic modulus of the bone tissue in the

vertebrae was assigned according to the corresponding gray scale in

Mimics. The relationship between density (ρ) and gray scale is

defined by the following formula: ρ = 1.6 × Hounsfield Unit + 47

(g/mm3).

Elastic moduli of the intervertebral discs were

assigned with reference to the values measured by Gu et al

(15). The anulus fibrosus in the

normal vertebral disc had a water content of ~65%, Young’s modulus

of 12.56 MPa and Poisson’s ratio of 0.4. The nucleus pulposus in

the normal vertebrae disc had a water content of ~85%, Young’s

modulus of 1.0 MPa and Poisson’s ratio of 0.49. By contrast, the

anulus fibrosus in the vertebral disc with Grade IV degeneration

had a water content of ~50%, Young’s modulus of 12.29 MPa and

Poisson’s ratio of 0.39. The nucleus pulposus in the vertebral disc

with Grade IV degeneration had a water content of ~76%, Young’s

modulus of 1.66 MPa and Poisson’s ratio of 0.40. The intervertebral

disc models of young (20–40 years old) and elderly (>70 years

old) individuals were constructed on the basis of the corresponding

Young’s modulus and Poisson’s ratio.

Upper body weight was simulated by a 400 N vertical

downward force on the superior surface of L1. Flexion and extension

were simulated by a 10,000 N.mm bending moment on the superior

surface of L1. Peak stress and stress distribution were observed

through FEA.

Results

Innovative 3D modeling method processed

using Siemens syngo 3D software

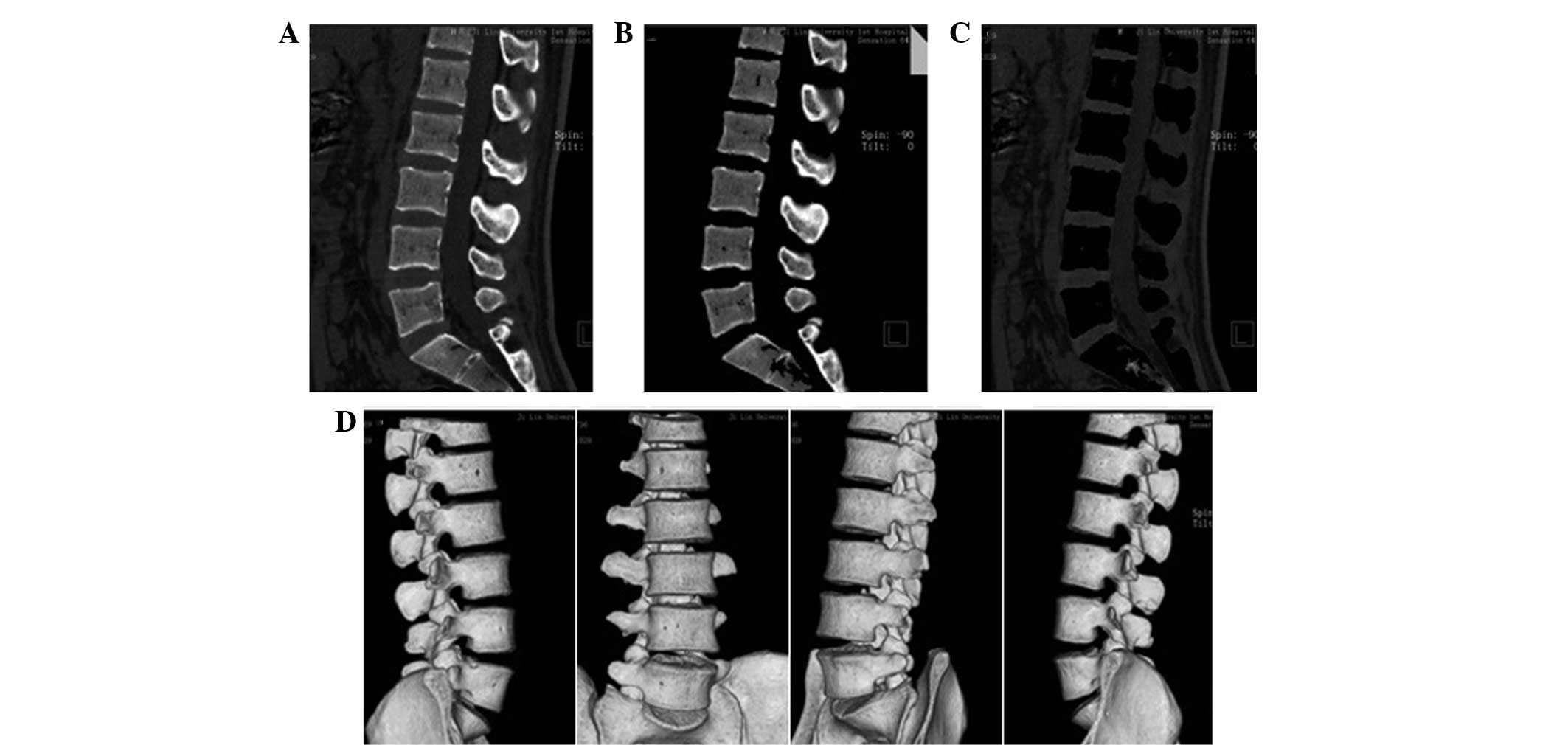

Fig. 1 shows all

the tissue markings with Fig. 1A

showing the sagittal frame of the lumbar spine prior to tissue

marking, Fig. 1B showing the

sagittal frame following bone marking and Fig. 1C showing the soft tissue marking.

Fig. 1D shows the 3D image of the

lumbar spine following tissue marking.

3D incision

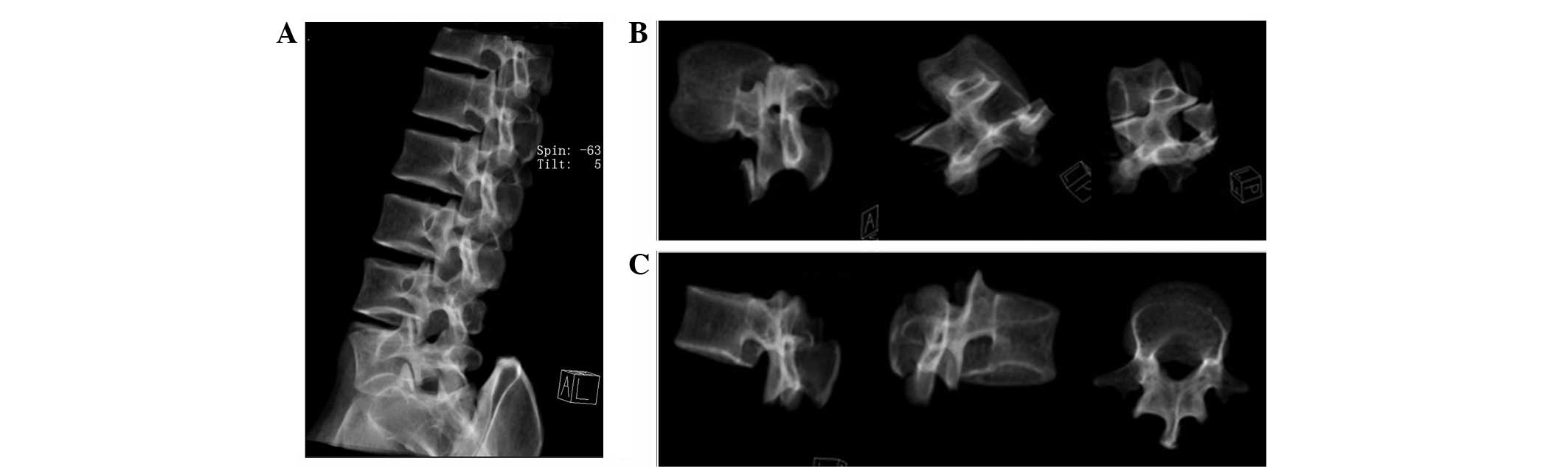

Fig. 2A

demonstrates that the transparency of the bone structure

significantly facilitated the 3D incision of the lumbar spine. The

lumbar vertebra was then rotated 360° in a transparent mode to

facilitate 3D incision (Fig. 2B)

and the construction of L1 (Fig.

2C).

Further processing with Mimics

software

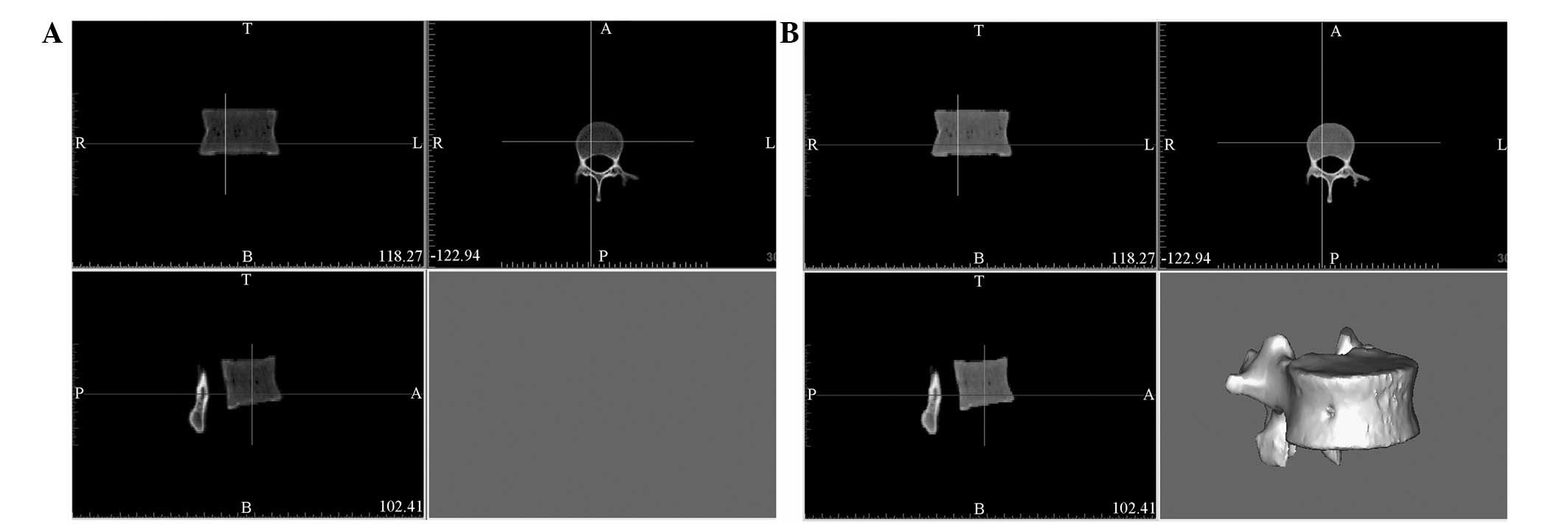

DICOM data of a single vertebra were transferred

into Mimics following processing by Siemens syngo 3D software

(Fig. 3A). The vertebra model was

constructed by further processing in Mimics (Fig. 3B). Following the removal of the

surrounding soft tissue, all bone tissue information of the

selected vertebra was obtained by adjusting the threshold of the

gray value to the minimum. As a result, the information of the

vertebral body bone tissue was completely preserved without extra

information or background (Fig.

3B).

Final model after polishing and

remeshing

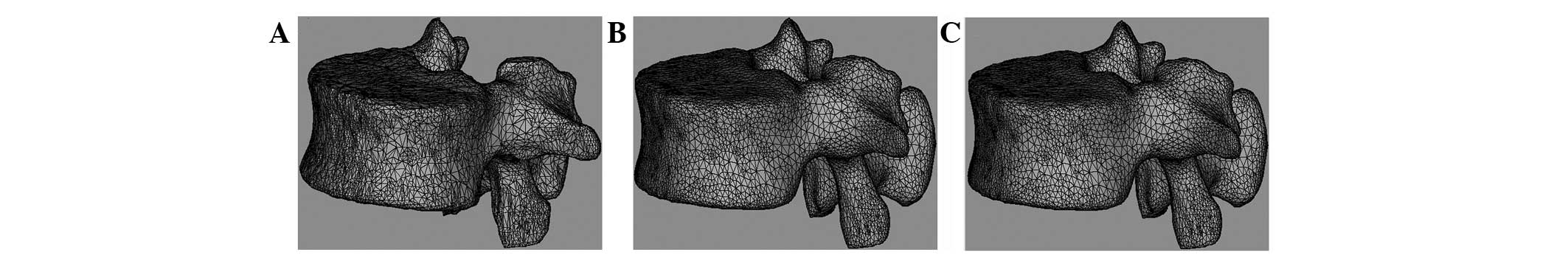

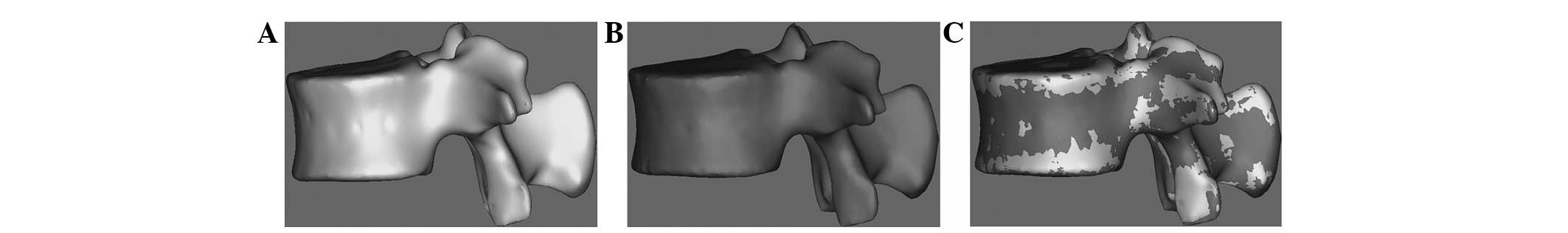

Fig. 4 shows the

meshed, smoothed and remeshed model using the Magics software

included in Mimics. Fig. 4A shows

the raw model prior to polishing, Fig.

4B shows the smoothed model following polishing and Fig. 4C shows the remeshed model.

Congruence comparison between the models

constructed by traditional and innovative 3D modeling methods

Models constructed by the traditional and innovative

methods from the same raw DICOM data of a single vertebra are shown

in Figs. 5A and 5B, respectively.

The merged image of the two models (Fig. 5C) shows striking consistencies,

which indicates the accuracy and reliability of the innovative

method.

Comparison of time consumption between

traditional and innovative 3D modeling methods

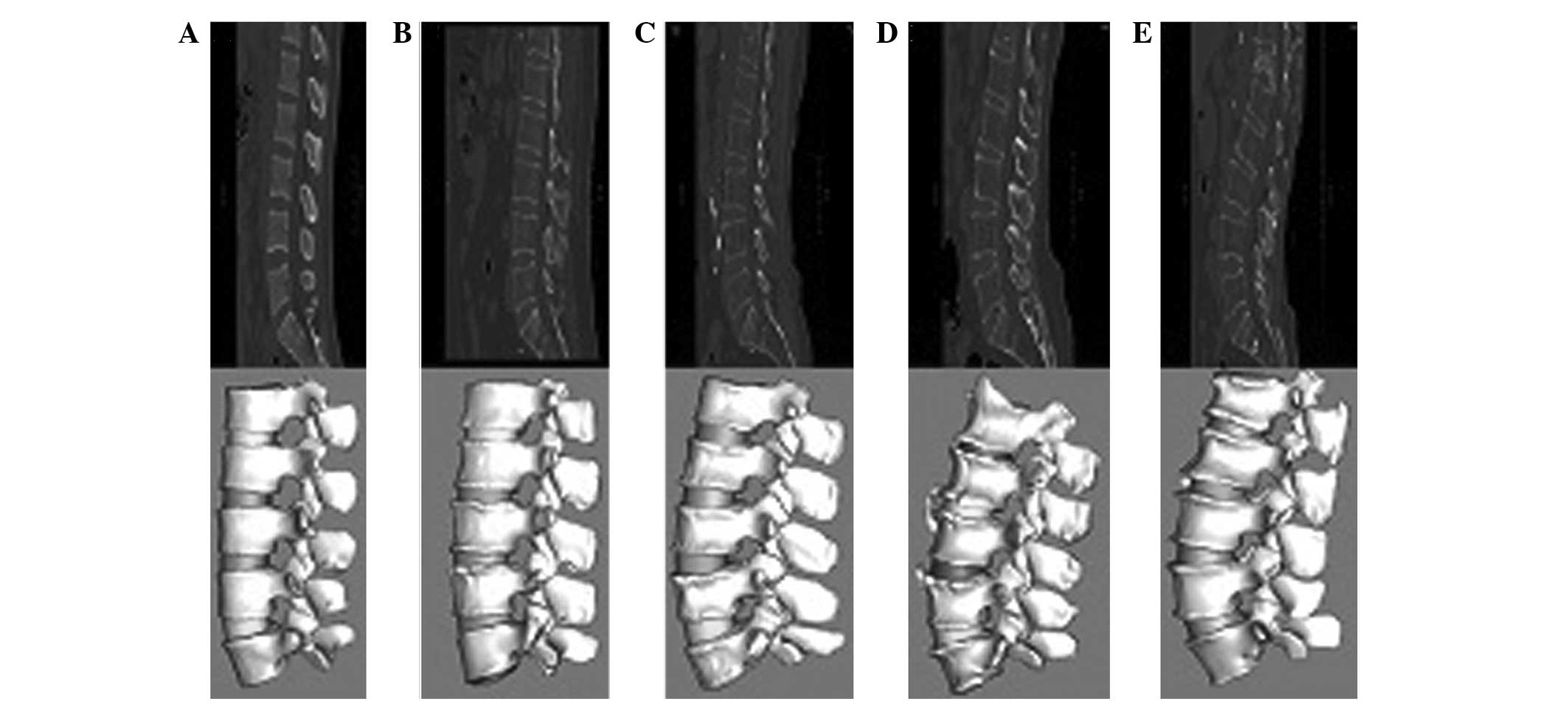

Fig. 6 shows the

lumbar spine models constructed for five age groups by the

innovative method. A significant difference was observed in time

consumption of the two model construction methods. Table I shows that the time spent to

produce a contour image of five age groups using the new 3D

modeling method was generally shorter compared with that using the

traditional method. Time consumption was longer for the elderly age

groups than for younger groups, particularly when using the

traditional method. Therefore, the results indicate that the

difficulty of model construction increases with increasing age, and

time saved by the innovative method increases as the age group

increases. Constructing the model of a lumbar spine for five

consecutive vertebrae (L1–5) of an elderly osteoporotic patient

took ~24 h to complete using the traditional manual method, whereas

~2 h was spent to finish the same work with the new 3D modeling

method. Therefore, the processing time of the innovative method was

~10-times shorter than that of the traditional method. The

innovative approach markedly simplified the manual margin

discrimination and slice-by-slice incision between the vertebral

body and surrounding soft tissues. The new method also saved much

time and greatly improved the efficiency of the analysis.

| Table IComparision of time consumption

between traditional and new methods of model construction. |

Table I

Comparision of time consumption

between traditional and new methods of model construction.

| Group | Traditional method,

h | SD traditional | New method, h | SD new | P-value |

|---|

| 20–40 years | 4.4 | 0.65 | 1.00 | 0.14 | <0.001 |

| 41–50 years | 13.0 | 1.58 | 1.58 | 0.13 | <0.001 |

| 51–60 years | 15.0 | 0.71 | 2.02 | 0.15 | <0.001 |

| 61–70 years | 20.4 | 1.14 | 2.12 | 0.08 | <0.001 |

| >70 years | 24.2 | 1.48 | 2.50 | 0.35 | <0.001 |

Peak stress in the lumbar spine of young

and elderly patients

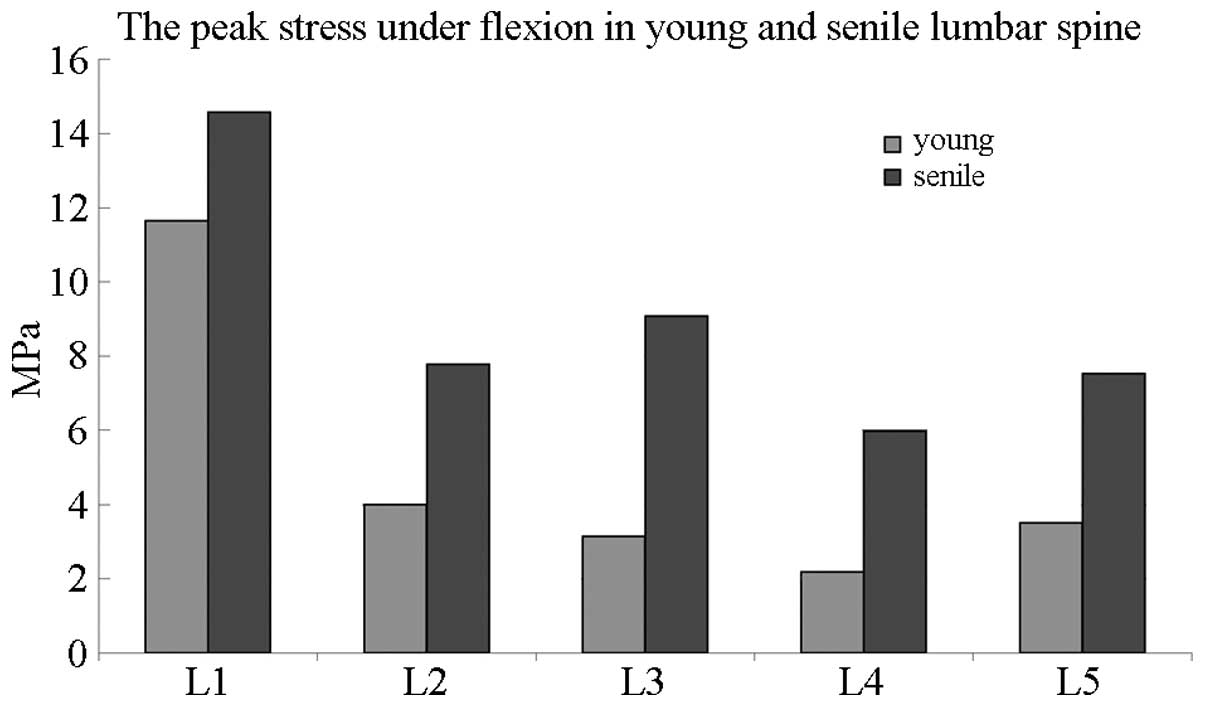

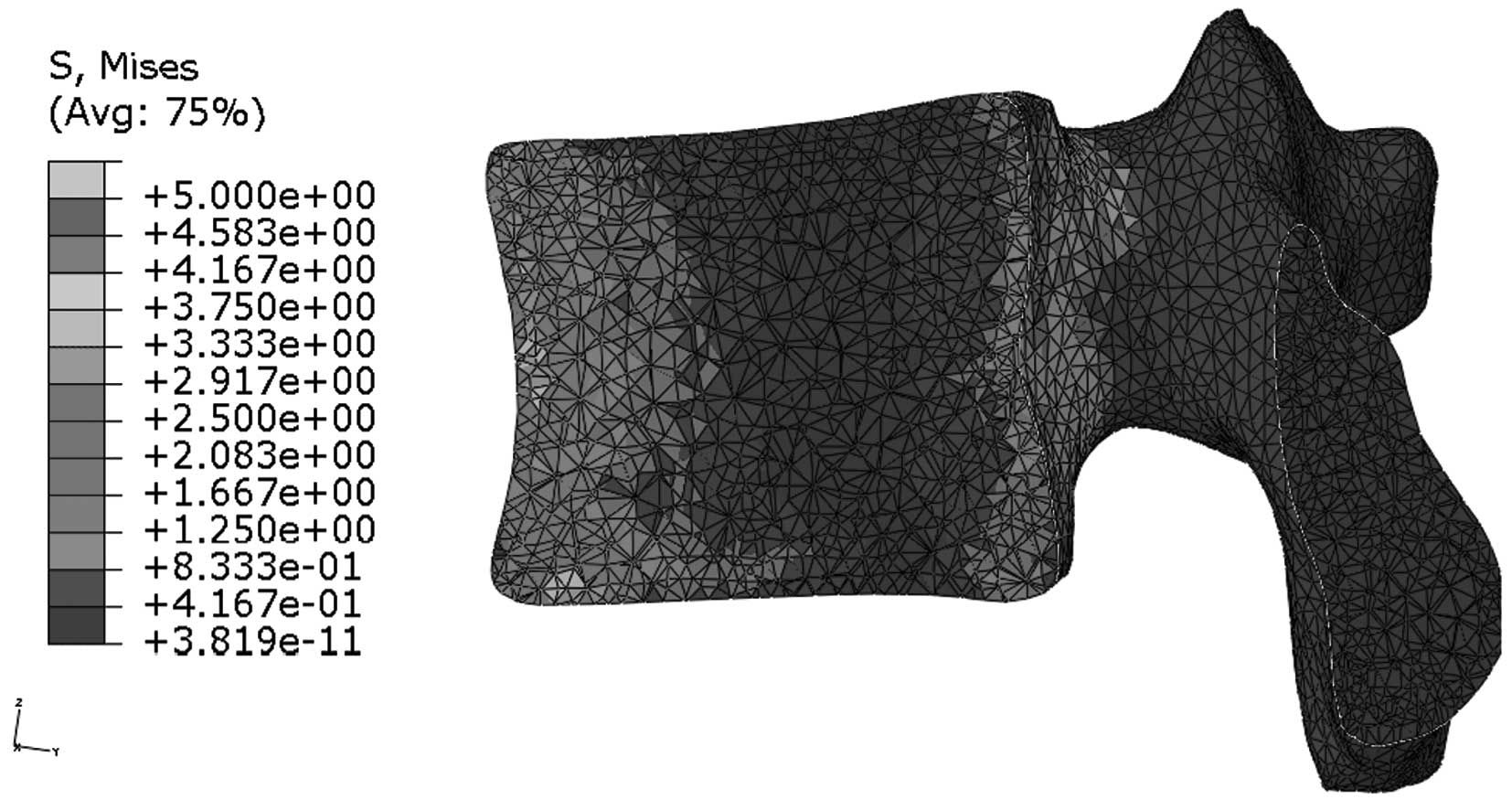

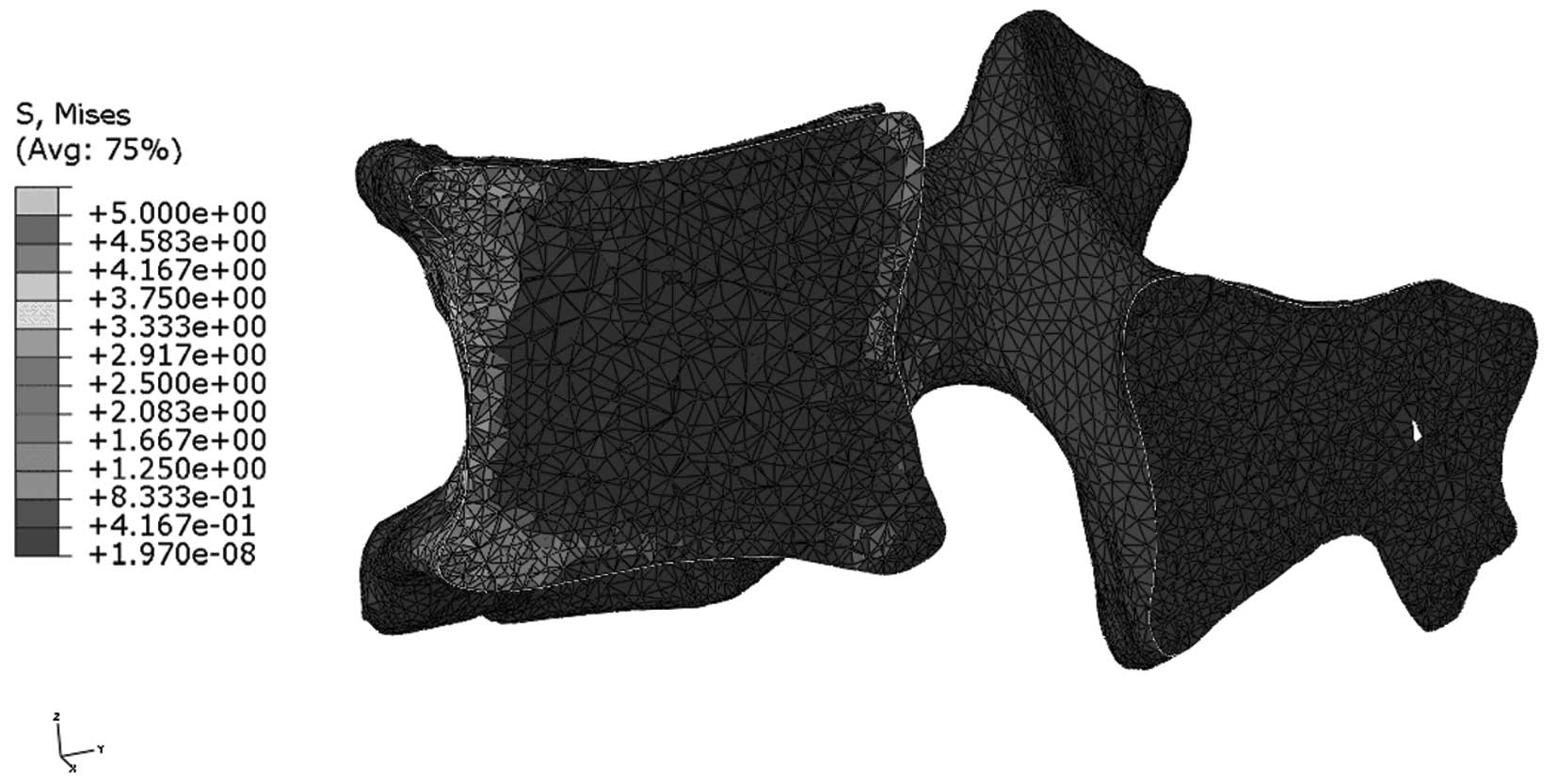

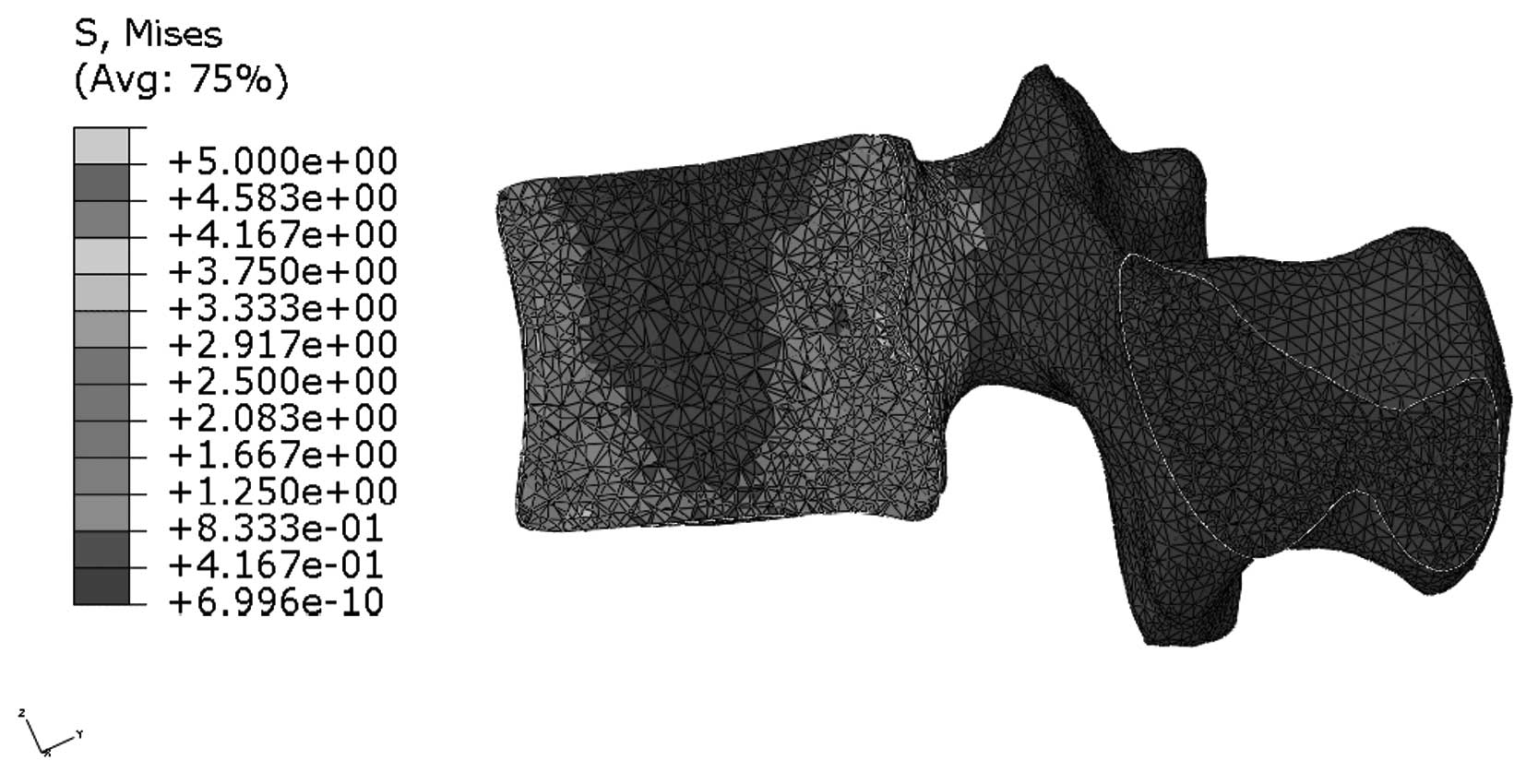

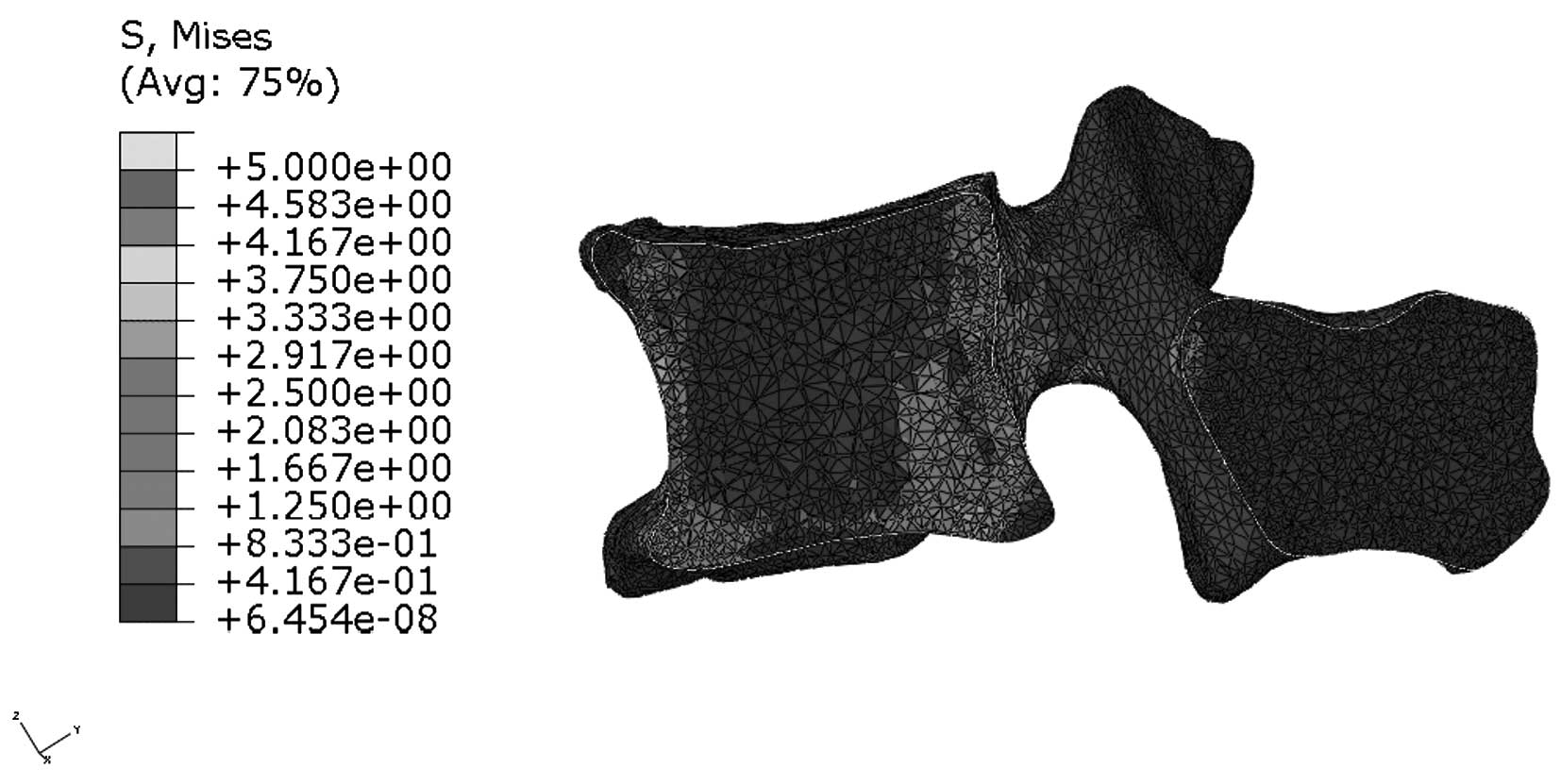

Fig. 7 compares the

peak stress between elderly and young individuals in the lumbar

spine under flexion elevation. The most evident variations between

the age groups were observed from L2 to L5, with the peak stress of

elderly patients being twice as high as that of young

individuals.

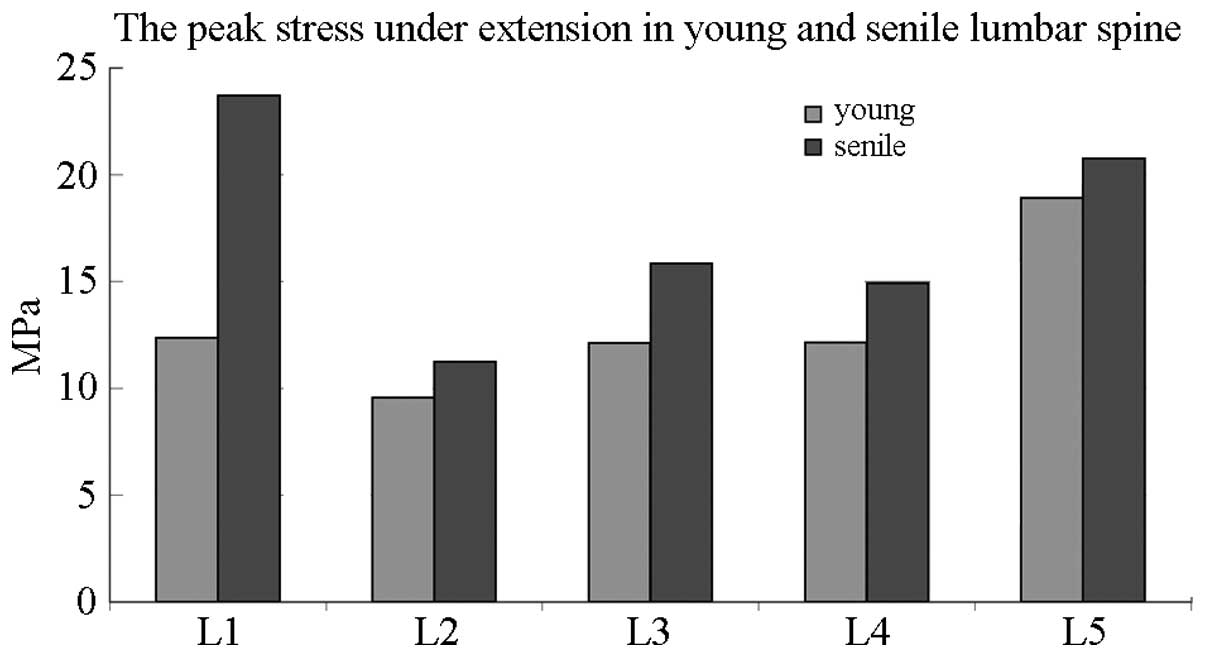

Fig. 8 compares the

peak stress between elderly and young individuals in the lumbar

spine under extension elevation. The most evident variation was

observed in the L1 of elderly patients, which showed a peak stress

twice as high as that of young patients.

Therefore, peak stress was elevated in each lumbar

vertebra under flexion and extension in elderly people.

Stress distribution in the median

sagittal plane of L1

Figs. 9 and

10 indicate that stress is evenly

distributed in the entire L1 of young individuals, without stress

concentration under flexion. By contrast, the stress redistribution

in the L1 of older patients indicates stress-concentration in the

anterior cortex under flexion. Similarly, Figs. 11 and 12 show the stress redistribution in the

L1 under extension in young and elderly patients, respectively.

Stress redistribution in older patients resembles stress

concentration in the anterior cortex, whereas that of young

individuals resembles evenly distributed stress.

Discussion

In the last decade, significant development of

biomechanics has occurred. Joint application and finite element

techniques have greatly contributed to the improved understanding

of biomechanical behavior in the human body, particularly the

musculoskeletal system (16–18).

However, the modeling process remains complex. The

current method used for constructing models from a CT scan dataset

for FEA study is time-consuming and the number of samples that may

be analyzed is limited (19). The

traditional model construction method for processing a CT image

using Mimics is meticulous and tedious work since it requires the

extraction of tissues by manually drafting the contour of the

vertebrae slice-by-slice (20,21).

In addition, the application of FEA in objects with pathological

changes has resulted in difficulties with tissue-margin

discrimination for irregular pathological structures, thereby

affecting the accuracy and efficiency of the traditional method.

Manual discrimination of the contour of delicate osteoporotic

structures and irregular osteophytes in elderly patients with

typical pathological changes is ambiguous and time-consuming

(22). Subsequently, miscutting of

vertebral bone tissues often occurs (23). Stress distribution is greatly

affected by subtle alterations in anatomical structures in

pathological conditions (24).

Accordingly, bias in the stage of model construction often results

in unexpected deviations of the stress distribution in FEA, as the

final stage of biomechanical study.

Furthermore, studies have attempted to explain

stress redistribution with models based on normal anatomical

configurations in pathological conditions in the early stage of FEA

(3,6,7).

However, these studies have failed to determine the true stress

distribution in pathological conditions, particularly in cases such

as osteoporosis and irregular osteophytes, which often cause more

systemic errors. Moreover, margin-determination using a

conventional manual model construction method is extremely

time-consuming (~20 h).

In summary, the results obtained using the

traditional biomechanical FEA model construction method under

pathological conditions and the challenging manual determination of

the contours of typical pathological changes in morphology make the

traditional method tedious and prone to errors. The establishment

of an accurate and efficient method of model construction has

become an critical requirement for further FEA study under

pathological conditions. A new 3D modeling method, that pertinently

utilizes excellent multiple image post-processing with 3D

processing functions of the Siemens syngo software, was developed

to perform automatic tissue margin selection with high efficiency

and accuracy. With the post-processing of syngo software before

model construction, the soft tissue could be eliminated and the

bone tissue could be extracted both accurately and effectively.

This method also reduces the major limitations encountered when

using the traditional construction method in creating models from

pathological cases, including those encountered with elderly

patients. Following multiple image post-processing to automatically

select tissue margins, data are transferred from DICOM to Mimics,

in which the last step of model construction for FEA study is

performed. Using the new method eliminates the time-consuming

slice-by-slice processing step.

A lumbar vertebra is easily rotated 360° and may be

conveniently observed, incised and marked from any angle using the

‘Osseous Transparent Metal VP’ and ‘Osseous Shaded VP’ modes of the

new 3D modeling method. The previously cumbersome, challenging and

time-consuming task of model construction for elderly patients with

osteoporosis and degenerative osteophytes has been simplified. In

such cases, margin discrimination between the bone and soft tissues

was formerly equivocal and misleading to the naked eye due to

similarities in CT and gray values, as well as the irregular margin

of the osteophytes. However, discrimination is simple when using

the Siemens syngo 3D software, which removes the surrounding soft

tissues to show the vertebral body alone and facilitates the final

model construction in Mimics.

Comparative FEA study of the lumbar spines between

young and elderly patients, on the basis of the models constructed

by the new bionic modeling method, shows peak stress elevation in

each lumbar vertebra of the elderly. Stress was evenly distributed

throughout the vertebrae in young people, whereas stress

redistribution in the vertebrae of elderly patients was

concentrated in the anterior cortex, which explains the high

fracture risk in the elderly. The FEA results were consistent with

clinical observations, which indicated that the most common site of

lumbar vertebral fracture was generally located in the anterior

cortex of L1.

A fast and efficient method of CT image-based

modeling of the lumbar spine for FEA is described in the present

study. The model provides a 10-fold reduction in the average

processing time and utilizes automatic tissue margin discrimination

with Siemens syngo software in a 3D mode, instead of manual

discrimination with the naked eye. In addition, 3D cutting is used

instead of slice-by-slice cutting. The low speed and equivocal

margin discrimination of the traditional model construction method

does not allow the pathological analysis of a large number of

specimens. By contrast, the new 3D modeling method achieves high

efficiency and accuracy, allowing for large sample sizes and

multivertebrae analysis, thereby enabling the application of

significant statistical power in all future biomechanical studies.

The new 3D modeling method was used to simulate the genuine

mechanical situation of the lumbar spine in elderly patients, thus

explaining the high fracture risk and common fracture site

mechanism in this age group. Application of this method in FEA is

likely to greatly contribute towards the accurate establishment of

the typical characteristics of stress redistribution in any

pathological condition, thereby allowing for faster and improved

data accumulation for further fracture risk studies.

Acknowledgements

The study was supported by grants from the Leading

Multi-Disciplinary Innovation Project Basic Science Foundation of

Jilin University (nos., 450060445234 and 3R210H143428).

References

|

1

|

Turner MJ, Clough RW, Martin HC and Topp

LJ: Stiffness and deflection analysis of complex structures. J Aero

Sci. 23:805–823. 1956. View

Article : Google Scholar

|

|

2

|

Belytschko TB, Andriacchi TP, Schultz AB

and Galante JO: Analog studies of forces in the human spine:

computational techniques. J Biomech. 6:361–371. 1973. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Wang JL, Parnianpour M, Shirazi-Adl A and

Engin AE: Rate effect on sharing of passive lumbar motion segment

under load-controlled sagittal flexion: viscoelastic finite element

analysis. Theor Appl Fract Mec. 32:119–128. 1999. View Article : Google Scholar

|

|

4

|

El-Rich M, Arnoux PJ, Wagnac E, Brunet C

and Aubin CE: Finite element investigation of the loading rate

effect on the spinal load-sharing changes under impact conditions.

J Biomech. 42:1252–1262. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Hakim NS and King AI: A three dimensional

finite element dynamic response analysis of a vertebra with

experimental verification. J Biomech. 12:277–285. 1979. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Schmidt H, Heuer F, Simon U, et al:

Application of a new calibration method for a three-dimensional

finite element model of a human lumbar annulus fibrosus. Clin

Biomech (Bristol, Avon). 21:337–344. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Renner SM, Natarajan RN, Patwardhan AG, et

al: Novel model to analyze the effect of a large compressive

follower pre-load on range of motions in a lumbar spine. J Biomech.

40:1326–1332. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Rohlmann A, Bauer L, Zander T, Bergmann G

and Wilke HJ: Determination of trunk muscle forces for flexion and

extension by using a validated finite element model of the lumbar

spine and measured in vivo data. J Biomech. 39:981–989. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Zander T, Rohlmann A, Burra NK and

Bergmann G: Effect of a posterior dynamic implant adjacent to a

rigid spinal fixator. Clin Biomech (Bristol, Avon). 21:767–774.

2006. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Zeng XL, Peng L and Bai J:

Three-dimensional finite element modeling and analysis of human

L3–L4 lumbar segment based on CT data. Beijing Biomed Eng.

26:266–269. 2007.(In Chinese).

|

|

11

|

Jiang HB: Static and dynamic mechanics

analysis on artificial hip joints with different interface designs

by the finite element method. J Bionic Eng. 4:123–131. 2007.

View Article : Google Scholar

|

|

12

|

Chevalier Y, Charlebois M, Pahra D, et al:

A patient-specific finite element methodology to predict damage

accumulation in vertebral bodies under axial compression, sagittal

flexion and combined loads. Comput Methods Biomech Biomed Engin.

11:477–487. 2008. View Article : Google Scholar

|

|

13

|

Kim TY, Kang KT, Yoon do H, et al: Effects

of lumbar arthrodesis on adjacent segments: differences between

surgical techniques. Spine (Phila Pa 1976). 37:1456–1462. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Gong H, Wu W, Fang J, Dong X, Zhao M and

Guo T: Effects of materials of cementless femoral stem on the

functional adaptation of bone. J Bionic Eng. 9:66–74. 2012.

View Article : Google Scholar

|

|

15

|

Gu WY, Mao XG, Foster RJ, Weidenbaum M,

Mow VC and Rawlins BA: The anisotropic hydraulic permeability of

human lumbar anulus fibrosus. Influence of age, degeneration,

direction, and water content. Spine (Phila Pa 1976). 24:2449–2455.

1999. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Nadzadi ME, Pedersen DR, Callaghan JJ and

Brown TD: Effects of acetabular component orientation on

dislocation propensity for small-head-size total hip arthroplasty.

Clin Biomech (Bristol, Avon). 17:32–40. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Lu S, Xu YQ, Zhang YZ, et al: A novel

computer-assisted drill guide template for lumbar pedicle screw

placement: a cadaveric and clinical study. Int J Med Robot.

5:184–191. 2009. View

Article : Google Scholar : PubMed/NCBI

|

|

18

|

Xiao Z, Wang L, Gong H, et al:

Establishment and verification of a non-linear finite element model

for human L4–L5 lumbar segment. Biomedical Engineering and

Informatics (BMEI), 2010 3rd International Conference on IEEE.

3:1171–1175. 2010.

|

|

19

|

Francis A, Nareliya R and Kumar V:

Three-dimensional finite element analysis of human femur: A

comparative study, proceedings of all India seminar on biomedical

engineering 2012 (AISOBE 2012). Springer India. 37–48. 2013.

|

|

20

|

Sun W, Starly B, Darling A and Gomez C:

Computer-aided tissue engineering: application to biomimetic

modelling and design of tissue scaffolds. Biotechnol Appl Biochem.

39(Pt 1): 49–58. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Kuo CS, Hu HT, Lin RM, et al:

Biomechanical analysis of the lumbar spine on facet joint force and

intradiscal pressure-a finite element study. BMC Musculoskelet

Disord. 11:1512010. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Xiao Z, Wang L, Gong H and Zhu D:

Biomechanical evaluation of three surgical scenarios of posterior

lumbar interbody fusion by finite element analysis. Biomed Eng

Online. 11:312012. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Harrysson OL, Hosni YA and Nayfeh JF:

Custom-designed orthopedic implants evaluated using finite element

analysis of patient-specific computed tomography data:

femoral-component case study. BMC Musculoskelet Disord. 8:912007.

View Article : Google Scholar

|

|

24

|

Niemeyer F, Wilke HJ and Schmidt H:

Geometry strongly influences the response of numerical models of

the lumbar spine - a probabilistic finite element analysis. J

Biomech. 45:1414–1423. 2012. View Article : Google Scholar : PubMed/NCBI

|