Introduction

It is well known that there are numerous factors

that influence the stability of an implant, such as the amount of

bone surrounding the implant and the quality of that bone (1), the size (2) and type (3) of implant and whether it is associated

with one or two bony cortices (4).

Implant length has proved to be an important factor for the success

of implantation, particularly for the atrophied posterior maxilla

area (5,6); however, to the best of our knowledge,

none of these studies have evaluated the association between

implant apex and sinus floor cortical bone. Jeong et al

(7) reported that bicortical

implantation had the potential to increase the initial stability

and reduce the stress of the cortical bone around the implant

neck.

A key factor for the success or failure of a dental

implant is the manner in which stresses are transferred to the

surrounding bone (8), particularly

for immediate loading implantation. It is not difficult to imagine

that the sinus floor cortical bone can provide a support force for

the implant. As the implant apex gets closer to the sinus floor,

the cortical bone will stop the stress distribution and provide a

bigger supporting force for the implant; however this conjecture is

not easily verified by clinical studies.

Finite element analysis (FEA) has been widely used

to predict the effect of clinical factors on the success of

implantation, and also to estimate the biomechanical performance

associated with various alveolar bone and dental implant conditions

(9). FEA allows the prediction of

the stress distribution in the contact area of the implants with

cortical bone, and around the apex of the implants in the

surrounding bone. This method is advantageous for solving complex

structural problems as it divides them into smaller and simpler

inter-related sections through the use of mathematical techniques

(10). Resonance frequency

analysis (RFA) is a nondestructive measurement that has been

extensively used in clinical practice over the last five years

(11). Resonance frequency, as a

type of physical property, can also be simulated by FEA and has

already been used in the biomechanical research of dental

implantation (12,13).

In the present study, three-dimensional (3D) FE

models and an implant were constructed. All factors other than the

distance between the implant apex and the sinus floor cortical bone

were excluded, in order to observe the association between

them.

Materials and methods

Implant system

The standard implant with a diameter of 4.0 mm and a

length of 10.0 mm was modeled and placed in the 3D FE models of the

sinus area. The shape and structure of the implant was modeled

according to the Nobel Biocare® implant system (Nobel

Biocare, Kloten, Switzerland). In order to simplify the analysis,

the implant and the abutment were modeled as a unit.

Sinus geometric modeling

3D-CAD models of the posterior maxilla with 0.3-mm

thick (14) sinus membranes,

different heights of alveolar ridge and different thicknesses of

sinus floor cortical bone were generated using CAD software

(SolidWorks 2012, Fukuoka, Japan). The geometry of the maxilla was

defined by a bucco-palatal section according to the anatomical

aspects of the sinus area (15–18).

Six models (models 1-1 to 1-6) were used to research different

distances between the implant apex and sinus floor cortical bone.

The alveolar ridge heights of these models were between 10 and 14

mm, with 1 mm crestal cortical bone and sinus floor cortical bone.

For model 1-1, the implant apex just broke through the sinus floor

cortical bone (the upper surface of the sinus floor cortical bone

and the apical surface of the implant were at the same level); for

model 1-2, the implant apex broke through half the thickness of the

sinus floor cortical bone; for model 1-3, the implant apex just

made contact with the lower surface of the sinus floor cortical

bone; and for the remaining models the implant apexes gradually

deviated from the sinus floor. The other four models (models 2-1 to

2-4), with the same alveolar ridge height of 11 mm, were generated

to investigate the different depths that the implant was embedded

in different thicknesses of sinus floor cortical bone. The

thickness of the sinus floor cortical bone changed from 0.5 mm to

2.0 mm in increments of 0.5 mm; relative to the sinus floor

cortical bone the implant apex was thus separate, in contact with,

penetrating through one-quarter of the bone thickness or

penetrating through one-half of the bone thickness, respectively.

According to the design of the study, models 2-2 and 1-3 were the

same: Alveolar ridge height, 11 mm; crestal cortical bone

thickness, 1 mm; and sinus floor cortical bone thickness, 1 mm.

Material properties

The material properties of different types of

tissue, as well as the titanium implants in the models, were

assumed to be homogeneous, isotropic and linearly elastic. Young’s

modulus, Poisson’s ratio and the mass density of the materials used

in the analysis were taken from the literature (2,19,20)

and are shown in Table I.

| Table IProperties ascribed to materials used

in the finite element models. |

Table I

Properties ascribed to materials used

in the finite element models.

| Material | Young’s modulus

(MPa) | Poisson’s ratio | Mass density

(g/cm3) |

|---|

| Titanium

implanta | 103,400 | 0.35 | 4.5 |

| Cortical bonea | 13,700 | 0.30 | 2.0 |

| Cancellous bone

(D3)a | 1,370 | 0.30 | 1.0 |

| Sinus

membraneb | 58 | 0.45 | 1.0 |

Interface conditions

The models were prepared with two types of interface

conditions: One represented ideal osseointegration for traditional

loading (loaded onto the body without force), with 100% union

between the implants and maxilla; for the other type, the

implant-bone interface was assumed to be a frictional interface

(prior to osseous integration, i.e. immediate loading). In total,

there were thus four groups: Groups 1 and 2 were based on models

1-1 to 1-6 with interface conditions of either immediate or

conventional loading, respectively; groups 3 and 4 were based on

models 2-1 to 2-4, also with interface conditions of either

immediate or conventional loading, respectively. To ensure initial

stability for the immediate loading condition, the model was

constructed using nonlinear frictional contact elements, which

allowed minor displacements between the implant and bone. Under

these conditions, the contact zone transfers pressure and

tangential forces (i.e. friction) but no tension. The friction

coefficient between the implant and bone was set to 0.3 (21).

Loading and boundary conditions

An average force of 129 N (22) inclined 30° posteriorly relative to

the implant axis and 30° away from the sagittal plane was dispersed

on the top of the implant abutment. ANSYS 12.1 FE software (ANSYS

Inc., Harbin, China) was used for the FEA. The models were

constrained in all directions at the nodes on the medial and distal

bone surfaces, the top of the simulated sinus, the sinus walls and

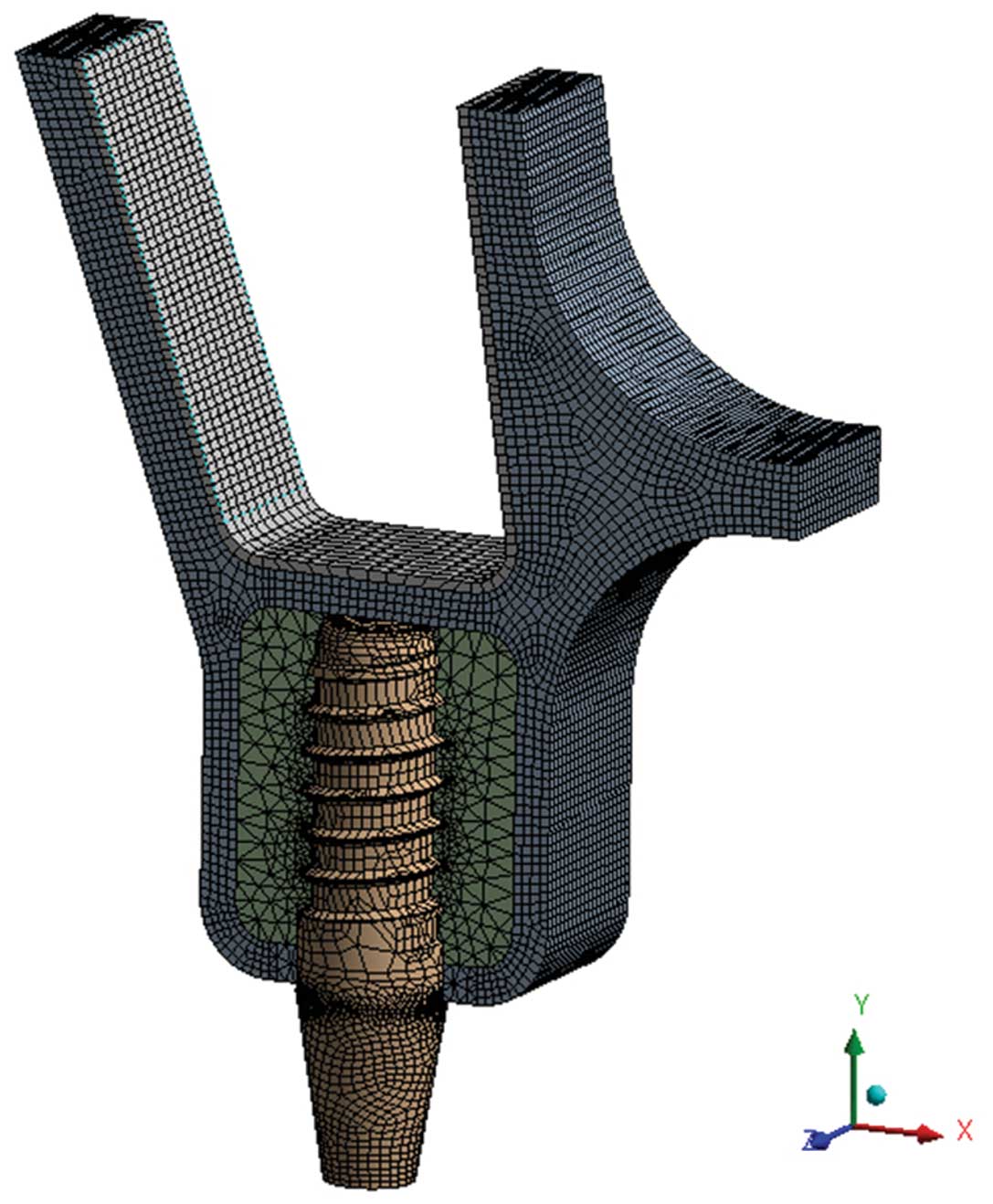

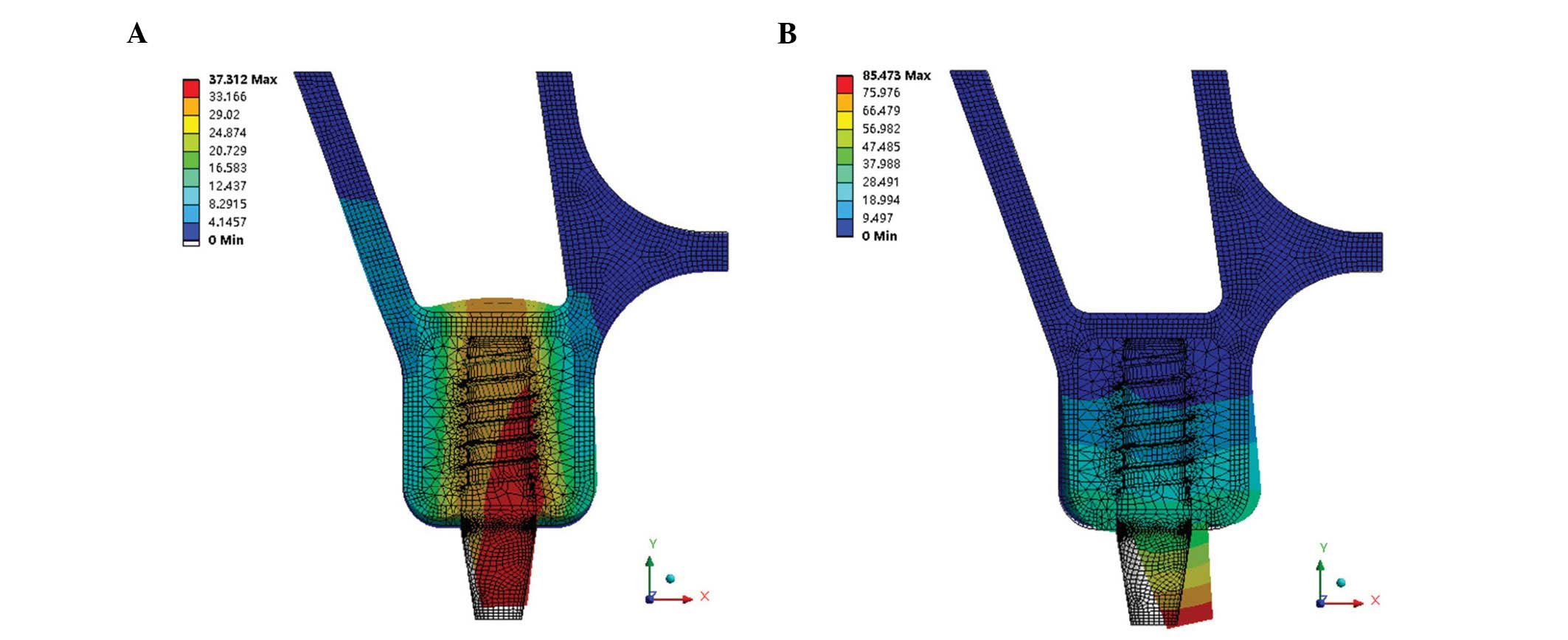

the sinus membrane. The models were meshed with four-node

tetrahedral elements and eight-node hexahedral elements and

composed of total elements varying from 94,453 to 106,347 and total

nodes ranging from 333,087 to 369,874 (Fig. 1). To assess the distribution of

stresses, maximum von Mises stresses were visualized with stress

contour plots. The biomechanical effects were also analyzed by

considering the maximum displacement of the implant neck and apex.

Additionally, buccolingual and axial resonance frequencies of the

implant were analyzed.

Statistical analysis

Data were evaluated by t-tests, and P≤0.05 was

considered to indicate a statistically significant difference.

Results

Stress distribution and maximum von Mises

stress

Cortical bones of the alveolar ridge

and sinus floor

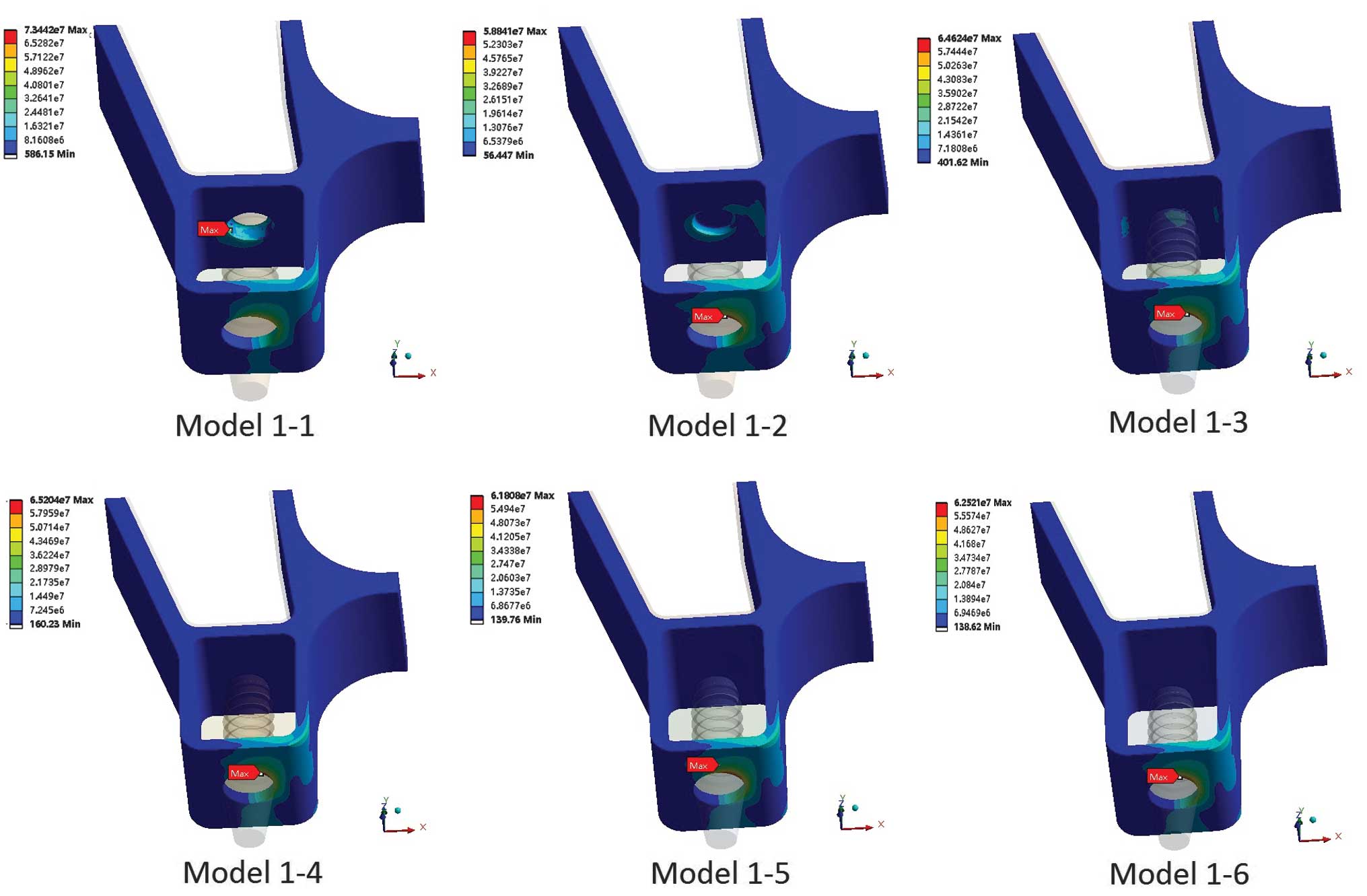

The stress distributions of the cortical bone in

immediate loading are shown in Fig.

2 (groups 1 and 2) and Fig. 3

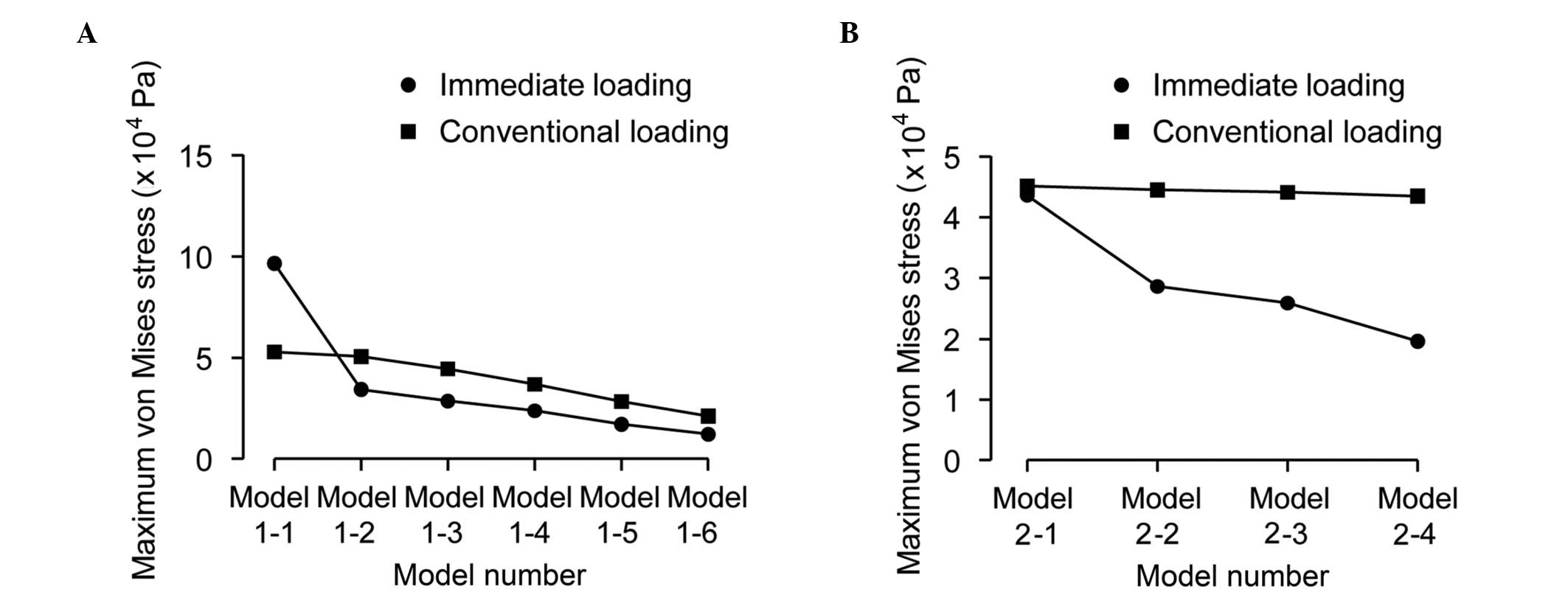

(groups 3 and 4). Maximum von Mises stresses were also analyzed and

are shown in Fig. 4A (groups 1 and

2) and Fig. 4B (groups 3 and

4).

The von Mises stress was concentrated on the surface

of the crestal cortical bone around the implant neck, with the

exception of that in model 1-1 (immediate loading) (Figs. 2 and 3). In model 1-1 (bicortical

implantation), the implant apex broke through the sinus floor

cortical bone, which resulted in the sinus floor cortical bone

suffering more stress (73.44 MPa) than the crestal cortical bone

(58.69 MPa) (Fig. 4A). The results

of Fig. 4A show that the maximum

von Mises stress of immediate loading was ~18% lower than that of

conventional loading. The maximum von Mises stress of the crestal

cortical bone increased with the increasing distance between the

implant apex and the upper surface of the sinus floor cortical

bone. Until the implant apex separated from the lower surface of

the sinus floor cortical bone (model 1-4), the stress reached a

peak value and then decreased with increasing distance, whether the

loading was immediate or conventional. The stress of the sinus

floor cortical bone was higher with immediate loading than that

with conventional loading prior to the implant apex and sinus floor

cortical bone separating. When there was cancellous bone between

the implant apex and the sinus floor cortical bone, the stress of

the sinus floor cortical bone was approximately the same in

immediate and conventional loading.

The results of Fig.

4B show that the different penetration distances of the implant

apex into the sinus floor cortical bone had little effect on the

maximum von Mises stress of the crestal cortical bone (P>0.05);

however the stress of the sinus floor cortical bone with immediate

loading was affected, and the maximum von Mises stress increased

from 6.01 to 34.48 MPa.

Sinus membrane

Maximum von Mises stresses of the sinus membrane

were analyzed and are shown in Fig.

5A (groups 1 and 2) and Fig.

5B (groups 3 and 4). Fig. 5A

shows that, as the distance increased between the implant apex and

the upper surface of the sinus floor cortical bone, the maximum von

Mises stress decreased significantly, particularly between models

1-1 and 1-2, with immediate loading. Fig. 5B shows that changing the distance

that the implant apex pierced into the sinus floor cortical bone

had little effect in reducing the maximum von Mises stress of the

sinus membrane in conventional loading (P>0.05) but showed a

marked effect in immediate loading; in immediate loading, the

maximum von Mises stress decreased from 4.36×104 to

1.96×104 Pa.

Implant displacement

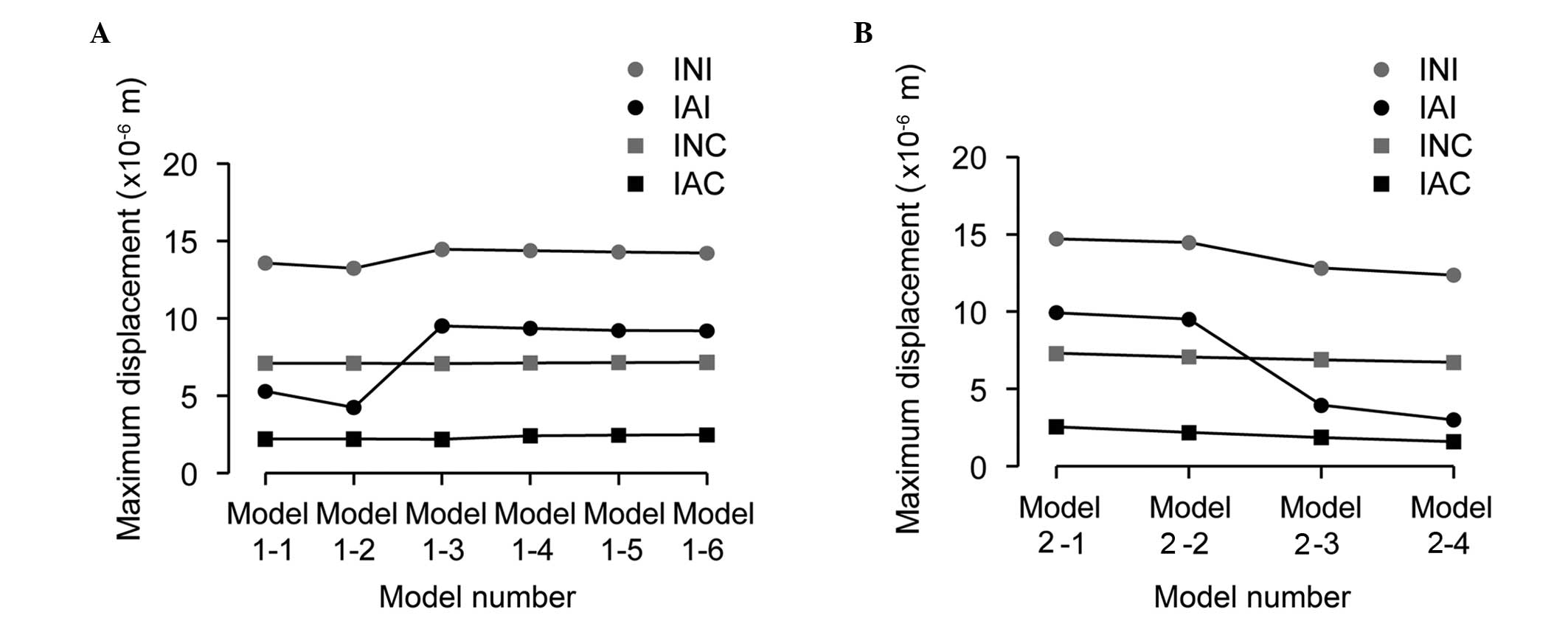

The data of the maximum displacements of the implant

neck and apex are shown in Fig. 6A

(groups 1 and 2) and Fig. 6B

(groups 3 and 4). The implant displacement cloud chart of group 3

is shown in Fig. 7 as an example.

The results showed that the maximum displacement of the implant

neck was bigger than that of the implant apex in all the models.

For immediate loading, when the implant apex broke through or

inside the sinus floor cortical bone, the implant maximum

displacements, particularly for the implant apex, were smaller than

those for the other conditions (Fig.

6A). As the depth the implant apex reached into the sinus floor

cortical bone increased, the maximum displacements decreased

(Fig. 6B). For conventional

loading, as the distance between the implant apex and the sinus

floor cortical bone increased, the maximum displacements of the

implant neck and apex increased, although inconspicuously. As the

depth the implant apex reached into the sinus floor cortical bone

increased, the maximum displacements of the implant apex decreased

significantly.

Implant resonance frequencies

Fig. 8 shows the

two vibrational modes of the implant-bone system. The data of

implant axial resonance frequencies are shown in Fig. 9A (groups 1 and 2) and Fig. 9B (groups 3 and 4), and implant

buccolingual resonance frequencies are shown in Fig. 10A (groups 1 and 2) and Fig. 10B (groups 3 and 4). As the

distance between the implant apex and the sinus floor cortical bone

lengthened (Fig. 9A), the values

of the axial resonance frequencies increased significantly between

models 1-1 and 1-2 in immediate and conventional loading. The

resonance frequencies subsequently increased slowly. As the depth

the implant apex penetrated into the sinus floor cortical bone

increased, the axial resonance frequencies exhibited a linear

upward tendency (Fig. 9B). The

buccolingual resonance frequencies imperceptibly decreased as the

distance between the implant apex and sinus floor cortical bone

lengthened. No significant changes in frequency were observed when

the penetration depth into the sinus floor cortical bone was

adjusted (Fig. 10).

Discussion

Mechanical analysis using the FE method has

previously been utilized to reliably and accurately reveal the

biomechanical behavior around dental implants without the risk or

expense of implantation (2). The

sinus area of the posterior maxilla is complex and it is not easy

to establish an accurate and valid 3D FE model. In FEM research of

a maxilla sinus area implant, Okumura et al (24) found no marked difference between

conventional simplified 3D FE models and the full maxilla model

created from computed tomography (CT) Digital Imaging and

Communications in Medicine data. In order to exclude the influence

of the anatomical variations of bone and to improve the

comparability of the models, as suggested by Akca and Cehreli

(25), the models used in the

present study required a change in the height of the alveolar bone

and the thickness of the sinus floor cortical bone. It was decided

not to use an anatomical model of the maxilla provided by cone beam

CT data; instead, 3D CAD models based on the anatomical data of the

sinus area have been developed in this study.

Due to the poor quality and size of the alveolar

ridge, the success rate of sinus area implantation is relatively

low. Numerous studies have been conducted into dental implantation

in the posterior maxilla (26,27),

and clinical studies, animal experiments and FEM studies (28–30)

have been carried out regarding the influence of bone quality and

size on implants; however, to the best of our knowledge, no study

concerning the association between an implant and the sinus floor

cortical bone has been conducted. Sinus floor cortical bone has a

tendency to be thin, which has made it less important in the

research of dental implantation in the sinus area.

The results of the present study showed that the

association between the implant apex and the sinus floor cortical

bone affected the stress distribution of the cortical bone, the

implant micromotion and the implant resonance frequencies. In the

clinic, it is usual to select an implant that is a little shorter

than the height of the alveolar ridge to keep the implantation

safe. The study showed that if the height of the alveolar ridge is

much longer than the implant length, it may not benefit the

stability of the implant. This was particularly true when the

implant apex made contact with or broke into or through the sinus

floor cortical bone, when the maximum von Mises stress of the

crestal cortical bone around the implant neck was reduced and

whether loading was immediate or conventional. When the implant

apex just broke through the sinus floor cortical bone in immediate

loading (bicortical implantation), the sinus floor cortical bone

suffered more stress than the implant neck cortical bone, which may

increase the success rate of implantation. Although, the maximum

von Mises stress of the sinus membrane was significantly increased

in bicortical implantations, the sinus membrane was not supposed to

be aggravated. Clinical and animal studies have shown that sinus

membrane contact with the implant apex in sinus floor elevation

without bone grafts also has a good success rate, without

inflammation of aggravation of the sinus membrane (30,31).

With regard to implant micromotion in the condition

of immediate loading, when the implant apex made contact with the

lower surface of the sinus floor cortical bone or broke into the

sinus floor cortical bone, implant displacements of the neck and

apex decreased significantly. This result indicated that the sinus

floor cortical bone was beneficial to the initial stability of the

implant. In particular, when the implant apex was inside the sinus

floor cortical bone, implant micromotion was reduced, and not too

much stress passed to the sinus membrane; thus, a situation where

the sinus floor cortical bone is thick enough to insert the implant

apex inside it but without breaking through may be a better design

of surgical treatment. For conventional loading, due to good

osseointegration, the bone around the implant apex may not greatly

affect the implant stability.

RFA as a nondestructive measurement has been widely

used in clinical practice in the last five years (11) but only buccolingual resonance

frequencies are checked. There are, in fact, numerous types and

directions of resonance frequencies that cannot be examined,

particularly the axial resonance frequency. In an FEA study, both

buccolingual and axial resonance frequencies can be tested. The

present results showed that, as the implant apex moved closer to

the sinus floor cortical bone and within it, the implant axial

resonance frequency increased but a change in the buccolingual

resonance frequency was not evident. This suggests that the sinus

floor cortical bone was beneficial in reducing implant axial

resonance frequency, particularly when the implant apex was inside

the sinus floor cortical bone. This means that the sinus floor

cortical bone can improve implant stability in the axial direction

but not the buccolingual direction.

In conclusion, this FE study of the association

between the implant apex and the sinus floor cortical bone showed

that the sinus floor cortical bone is beneficial for implant

stability, particularly for immediate loading. In the situation

where the implant apex contacts with, breaks into or breaks through

the sinus floor cortical bone a significant reduction in the

maximum von Mises stress of the sinus floor cortical bone, implant

displacement and axial resonance frequencies can be observed.

Further research concerning bicortical dental implantation in the

posterior maxilla is required.

Acknowledgements

This study was supported by the National High

Technology Research and Development Program of China (Program 863,

2011AA030107) and the Young Scholars Foundation (School of

Stomatology, China Medical University, Shenyang, China) (grant

K101593-12-34). The authors would like to thank the Regenerative

Dentistry and Implant Center, and the Section of Removable

Prosthodontics (Division of Oral Rehabilitation, Faculty of Dental

Science, Kyushu University, Fukuoka, Japan) for their support and

permission to use their facilities.

References

|

1

|

Winter W, Krafft T, Steinmann P and Karl

M: Quality of alveolar bone - structure-dependent material

properties and design of a novel measurement technique. J Mech

Behav Biomed Mater. 4:541–548. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Ding X, Zhu XH, Liao SH, Zhang XH and Chen

H: Implant-bone interface stress distribution in immediately loaded

implants of different diameters: a three-dimensional finite element

analysis. J Prosthodont. 18:393–402. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Meredith N, Books K, Friberg B, Jemt T and

Sennerby L: Resonance frequency measurements of implant stability

in vivo. A cross-sectional and longitudinal study of resonance

frequency measurements on implants in the edentulous and partially

dentate maxilla. Clin Oral Implants Res. 8:226–233. 1997.

View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Mohammed Ibrahim M, Thulasingam C, Nasser

KS, Balaji V, Rajakumar M and Rupkumar P: Evaluation of design

parameters of dental implant shape, diameter and length on stress

distribution: a finite element analysis. J Indian Prosthodont Soc.

11:165–171. 2011. View Article : Google Scholar :

|

|

5

|

Lee JH, Frias V, Lee KW and Wright RF:

Effect of implant size and shape on implant success rates: a

literature review. J Prosthet Dent. 94:377–381. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Toniollo MB, Macedo AP, Rodrigues RC,

Ribeiro RF and de Mattos Mda G: Three-dimensional finite element

analysis of stress distribution on different bony ridges with

different lengths of morse taper implants and prosthesis

dimensions. J Craniofac Surg. 23:1888–1892. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Jeong CM, Caputo AA, Wylie RS, Son SC and

Jeon YC: Bicortically stabilized implant load transfer. Int J Oral

Maxillofac Implants. 18:59–65. 2003.PubMed/NCBI

|

|

8

|

Geng JP, Tan KB and Liu GR: Application of

finite element analysis in implant dentistry: a review of the

literature. J Prosthet Dent. 85:585–598. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Van Staden RC, Guan H and Loo YC:

Application of the finite element method in dental implant

research. Comput Methods Biomech Biomed Engin. 9:257–270. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Bozkaya D, Muftu S and Muftu A: Evaluation

of load transfer characteristics of five different implants in

compact bone at different load levels by finite elements analysis.

J Prosthet Dent. 92:523–530. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Chang PC, Lang NP and Giannobile WV:

Evaluation of functional dynamics during osseointegration and

regeneration associated with oral implants. Clin Oral Implants Res.

21:1–12. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Huang HM, Lee SY, Yeh CY and Lin CT:

Resonance frequency assessment of dental implant stability with

various bone qualities: a numerical approach. Clin Oral Implants

Res. 13:65–74. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Pattijn V, Van Lierde C, Van der Perre G,

Naert I and Vander Sloten J: The resonance frequencies and mode

shapes of dental implants: Rigid body behaviour versus bending

behaviour. A numerical approach. J Biomech. 39:939–947. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Pommer B, Unger E, Sütö D, Hack N and

Watzek G: Mechanical properties of the Schneiderian membrane in

vitro. Clin Oral Implants Res. 20:633–637. 2009.PubMed/NCBI

|

|

15

|

Underwood AS: An inquiry into the anatomy

and pathology of the maxillary sinus. J Anat Physiol. 44:354–369.

1910.PubMed/NCBI

|

|

16

|

Ulm CW, Solar P, Gsellmann B, Matejka M

and Watzek G: The edentulous maxillary alveolar process in the

region of the maxillary sinus - a study of physical dimension. Int

J Oral Maxillofac Surg. 24:279–282. 1995. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

van den Bergh JP, ten Bruggenkate CM,

Disch FJ and Tuinzing DB: Anatomical aspects of sinus floor

elevations. Clin Oral Implants Res. 11:256–265. 2000. View Article : Google Scholar

|

|

18

|

Gosau M, Rink D, Driemel O and Draenert

FG: Maxillary sinus anatomy: a cadaveric study with clinical

implications. Anat Rec (Hoboken). 292:352–354. 2009. View Article : Google Scholar

|

|

19

|

Rues S, Lenz J, Schierle HP, Schindler HJ

and Schweizerhof K: Simulation of the sinus floor elevation. Proc

Appl Math Mech. 4:368–369. 2004. View Article : Google Scholar

|

|

20

|

Huang CC, Chen LW, Wu DF and Chen YC:

Finite element simulations of the contact stress between rotary

sinus lift kit and sinus membrane during lifting process. Life Sci

J. 9:167–171. 2012.

|

|

21

|

Mellal A, Wiskott HW, Botsis J, Scherrer

SS and Belser UC: Stimulating effect of implant loading on

surrounding bone. Comparison of three numerical models and

validation by in vivo data. Clin Oral Implants Res. 15:239–248.

2004. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Morneburg TR and Pröschel PA: Measurement

of masticatory forces and implant loads: a methodologic clinical

study. Int J Prosthodont. 15:20–27. 2002.PubMed/NCBI

|

|

23

|

Lekholm U, Zarb GA and Albrektsson T:

Tissue Integrated Prostheses: Osseointegration in Clinical

Dentistry. Quintessence Publishing; Chicago, IL, USA: pp. 199–209.

1985

|

|

24

|

Okumura N, Stegaroiu R, Nishiyama H,

Kurokawa K, Kitamura E, Hayashi T and Nomura S: Finite element

analysis of implant-embedded maxilla model from CT data: comparison

with the conventional model. J Prosthodont Res. 55:24–31. 2011.

View Article : Google Scholar

|

|

25

|

Akca K and Cehreli MC: Biomechanical

consequences of progressive marginal bone loss around oral

implants: a finite element stress analysis. Med Biol Eng Comput.

44:527–535. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Cannizzaro G, Felice P, et al: Early

implant loading in the atrophic posterior maxilla: 1-stage lateral

versus crestal sinus lift and 8 mm hydroxyapatite-coated implants.

A 5-year randomised controlled trial. Eur J Oral Implant. 6:13–25.

2013.

|

|

27

|

Doan N, Du Z, Crawford R, Reher P and Xiao

Y: Is flapless implant surgery a viable option in posterior

maxilla? A review. Int J Oral Maxillofac Surg. 41:1064–1071. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Wang D, Künzel A, Golubovic V, et al:

Accuracy of peri-implant bone thickness and validity of assessing

bone augmentation material using cone beam computed tomography.

Clin Oral Investig. 17:1601–1609. 2013. View Article : Google Scholar

|

|

29

|

Chou IC, Lee SY, Wu MC, Sun CW and Jiang

CP: Finite element modelling of implant designs and cortical bone

thickness on stress distribution in maxillary type IV bone. Comput

Methods Biomech Biomed Engin. 17:516–526. 2014. View Article : Google Scholar

|

|

30

|

Sul SH, Choi BH, Li J, Jeong SM and Xuan

F: Histologic changes in the maxillary sinus membrane after sinus

membrane elevation and the simultaneous insertion of dental

implants without the use of grafting materials. Oral Surg Oral Med

Oral Pathol Oral Radiol Endod. 105:e1–e5. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Pjetursson BE, Rast C, Brägger U,

Schmidlin K, Zwahlen M and Lang NP: Maxillary sinus floor elevation

using the (transalveolar) osteotome technique with or without

grafting material. Part I: Implant survival and patients’

perception. Clin Oral Implants Res. 20:667–676. 2009. View Article : Google Scholar : PubMed/NCBI

|