Introduction

Metoprolol succinate (MS) is a highly selective

β1-adrenergic receptor blocker typically used for the

treatment of hypertension, coronary heart disease, chronic heart

failure and arrhythmia (1). However,

at higher plasma concentrations, MS may also inhibit

β2-adrenergic receptors located in the vascular and

bronchial musculature. Additionally, when plasma MS concentrations

are greater than required, anesthetic membrane-stabilizing activity

is detected (2,3). Therefore, it is necessary to control

the plasma MS concentration to maximize therapeutic effects and

minimize side effects. Due to the short half-life of metoprolol

(3–4 h) MS must be administered several times a day, leading to

fluctuations in plasma MS concentration (4). Sustained-release (SR) formulations are

able to minimize fluctuations in plasma concentration, hence

minimizing the adverse effects associated with excessively high

plasma concentrations and providing an effective stable dose

(5). This may be achieved through

various formulations, including hydrophilic matrix tablets, SR

pellets, osmotic pump tablets and drug-polymer conjugates. Novel

platforms, such as nano/microcarriers with SR, improved adhesion

and tissue penetration, may be utilized for oral drug delivery

(6).

Microcapsules provide several advantages compared

with conventional dosage forms, including modulated drug release,

enhanced drug stability and reduced gastrointestinal irritation

(7). Microspheres have been

previously used in an SR formulation of MS to provide robust and

consistent control of hypertension and heart rate (8). Recently, metoprolol tartrate

sustained-release capsules, which are polymer-coated metoprolol

tartrate matrix granules, have become commercially available.

Hydrophilic hydroxypropyl methyl cellulose (HPMC) and hydrophobic

ethyl cellulose polymers may also be employed as matrix builders,

and Eudragit® RL/RS as a coating polymer. Microparticles

coated with a film composed of these water-insoluble polymers

exhibit extended release periods of up to 12 h in vitro

(9).

Various encapsulation methods may improve

immobilization, isolation and protection of commercial products and

facilitate control of the transfer rate of pharmacological agents,

nutrients and perfumes (10). The

emulsification-solvent diffusion method is an established method

for the preparation of microcapsules based on an emulsion

technique. This method involves adding capsule material dissolved

in an organic solution to an aqueous solution saturated with

organic solvent to form an emulsion. Removal of organic solvents

induces the formation of microcapsules as a result of phase

separation due to the decreased solubility of the capsule material

in solution. These formulations produce microcapsules with an

evenly rounded shape, a smooth surface and good SR characteristics

(11,12). Ethylcellulose (EC) is a non-ionic,

pH-insensitive cellulose ether, which is insoluble in water but

soluble in numerous polar organic solvents (13), and exhibits SR properties. Dash et

al (14) previously confirmed

that aspirin-loaded EC microcapsules, made using the emulsion

solvent evaporation method, were able to effectively reduce the

drug release rate. Polyethylene glycol (PEG) is a hydrophilic

polymer material and plasticizer. PEG enhances the flexibility and

plasticity of microcapsules, decreases the tendency for aggregation

and adhesion, and improves dispersion. It may also be used as a

porogen for membrane-controlled drug release, and, with a suitable

ratio of polymer semi-permeable membrane and porogenic materials,

is able to reduce the rate of drug release (15).

The objective of the present study was to develop a

method of MS encapsulation to provide microcapsules with high

entrapment efficiency and optimal SR profiles in vitro and

in vivo. The emulsification-solvent diffusion method

(14) was used to prepare

microcapsules of ethyl cellulose and PEG 6,000 and the release of

MS from these capsules was assessed in vitro and in

vivo.

Materials and methods

Preparation of SR microcapsules of

MS

MS (AstraZeneca Pharmaceuticals Co., Ltd., Wuxi

China) was dissolved in water (the internal aqueous phase,

W1) and added to 2 ml ethyl acetate (EA) solution (O)

and ultrasonically emulsified, forming a primary emulsion

(W1/O). The indicated concentration of PEG 6,000

(Sigma-Aldrich; Merck Millipore, Darmstadt, Germany) was dissolved

in EA-saturated water (containing 0.5% SDS; Tianjin Global Chemical

Technology Co., Ltd., Tianjin, China) to constitute the external

aqueous phase (W2). W1/O was slowly added

drop-wise to W2, under continuous stirring until the

emulsion droplets solidified to form a stable

W1/O/W2 complex emulsion. Water was used to

dilute the emulsion 20-fold. The ethyl cellulose phase separated

and condensed into a capsule, and following sedimentation of the

microcapsules, the supernatant was removed and the retentate

centrifuged and filtered to obtain the microcapsules, which were

subsequently washed with water and dried in a vacuum at 40°C.

Study of microcapsule morphology and

size distribution

Microcapsules were re-suspended in double-distilled

water via ultrasonic dispersion for 20 min. The sample was then

observed under a microscope (Olympus X 51, Olympus Corporation,

Tokyo, Japan; magnification, ×400) and particle diameter was

measured.

Determination of MS drug loading

capacity and encapsulation efficiency

The maximum absorption of MS was previously recorded

at 274 nm when scanned at a wavelength of 200–350 nm (16). Therefore, 274 nm was chosen as the

optimum wavelength for measuring the MS content. A total of 50 mg

of microcapsules were placed in a 100-ml volumetric flask and

dissolved in ethanol. The solution was ultrasonically treated for

30 min and filtered through a 0.8-µm microporous membrane filter.

Of the resulting filtrate, 5 ml was diluted with 20 ml water and

the ultraviolet (UV) absorbance at 274 nm was measured using an

ultraviolet spectrophotometer (Shimadzu UV2550; Shimadzu

Corporation, Kyoto, Japan). MS drug loading capacity was calculated

as: Quantity of agent in microcapsules/microcapsule weight ×100.

Encapsulation efficiency was calculated as follows: Quantity of

agent in the microcapsules/total quantity of agent used ×100.

A linear correlation was obtained with

A=0.0042C+0.0014 (r=0.9997), Where A is the absorbance intensity, C

is the concentration of drug and r is the linearly dependent

coefficient. The intra-day relative standard deviation (RSD) was

0.41% (n=6), and the inter-day RSD was 0.85% (n=6), with the

average recovery being 99.2 and the average RSD being 0.37%

(n=9).

MS microcapsule in vitro release

Artificial gastric fluid was prepared by diluting

16.4 ml hydrochloric acid in 800 ml water and 10 g pepsin (3,800

U/mg; Sichuan Deyang Biochemical Products Co., Ltd., Deyong, China)

and diluting again with water to 1,000 ml. Artificial intestinal

fluid was prepared by dissolving 6.8 g potassium dihydrogen

phosphate in 500 ml water, which was adjusted to pH 6.8 with sodium

hydroxide, to which 10 g trypsin (2,500 U/mg; Sichuan Deyang

Biochemical Products Co., Ltd.) was added, followed by further

dilution with water to 1,000 ml.

Prepared microcapsules were placed in a basket with

1,000 ml of release medium (water, artificial gastric fluid or

artificial intestinal fluid) and the rotation speed was fixed at

100 rpm at 37±0.5°C. A 5-ml sample was taken from the release

solution at predetermined time intervals (0.5, 2, 4, 6, 8, 10, 12,

15 and 18 h) and 5 ml of release medium (water, artificial gastric

fluid or artificial intestinal fluid) was added at 37±0.5°C to

compensate for the volume loss. Following filtration through a

0.8-µm microporous membrane, the UV absorbance of release medium

and microcapsule release medium was measured at 274 nm.

MS release from microcapsule SR tablet

and regular SR tablet in vitro

Excipients, including HPMC (viscosity, 5 cPs),

METHOCEL DC2 K4M (all donated by Shanghai Colorcon Coating

Technology Co., Ltd., Shanghai, China) and microcrystalline

cellulose (MCC; Shanghai Chineway Pharma Tech Co., Ltd., Shanghai,

China) were crushed and passed through a 100-mesh sieve. Weighed MS

microcapsules and excipients were uniformly mixed in a mortar,

passed through a 40-mesh sieve three times and mixed with 85%

ethanol to prepare a soft material. Granules were produced by

passing material through a 16-mesh nylon screen and dried at

50–60°C for 1 h. Dry granules were forced through a 16-mesh sieve

and talcum powder (Shanghai Ju Qian Chemical Co., Ltd., Shanghai,

China) was added, prior to being mixed uniformly and

compressed.

In vitro release of MS microcapsule

SR-tablets was compared with the release from conventional SR

tablets (metoprolol tartrate tablets; AstraZeneca Pharmaceutical

Co., Ltd.) in water. At the indicated time intervals (0.5, 2, 4, 6,

8, 10, 12, 15 and 18 h), samples of release liquid were drawn and,

following filtration through a 0.8-µm microporous membrane, the UV

absorbance of conventional release medium and microcapsule release

medium was measured at 274 nm.

Pharmacokinetic studies of MS

microcapsules in dogs

Six male beagle dogs (age, 8 months; weight, 8–10

kg) were obtained from the Guangzhou General Pharmaceutical

Research Institute Co., Ltd. (Guangzhou, China), housed in

air-conditioned chambers at ambient temperature and humidity, fed a

standard laboratory diet and a 12-h light/dark cycle. Dogs had free

access to food and water. All animal experiments were performed in

full compliance with local, national, ethical and regulatory

principles with the approval of the Institutional Animal Care and

Use Committee of China Pharmaceutical University (Nanjing,

China).

Dogs were fasted overnight and randomly divided into

two groups (n=3 in each). Each dog was orally administered 47.5 mg

MS microcapsules or 50 mg metoprolol tartrate tablets (AstraZeneca

Pharmaceutical Co., Ltd.). Prior to administration, 2 ml venous

blood was collected from the dogs, and further samples were drawn

at 0.5, 1, 1.5, 2, 2.5, 3, 4, 8 and 16 h post-administration. Dogs

had free access to food and water after 4 h administration. Samples

were mixed with 1% sodium heparin solution anti-coagulant (Nanjing

King-Friend Biochemical Pharmaceutical Co., Ltd., Nanjing, China),

centrifuged for 10 min at 4,500 × g, siphoned and stored at

−20°C.

The concentration of MS in blood samples was

determined using a Shimadzu 10-Avp high performance liquid

chromatography system (Shimadzu, Kyoto, Japan) with a C18 column

(Inertsil® ODS-SP, 4.6×250 mm; particle size, 5 µm, GL

Sciences, Inc., Tokyo, Japan) and a mobile phase of methanol/water

equal to 6/4 (v/v) (containing 960 mg sodium heptane sulfonate and

82 mg anhydrous sodium acetate, adjusted to pH 4.7 with glacial

acetic acid) at 30°C; Absorbance was measured with an excitation

wavelength of 285 nm and an emission wavelength of 316 nm, with a

sample injection volume of 50 µl.

Statistical analysis

Statistical analysis was performed with SPSS 13.0

software (SPSS Inc., Chicago, IL, USA). Values are expressed as the

mean ± standard deviation. Multiple regression was used to

determine the optimal conditions for preparation of MS

microcapsules. Statistical significance was determined using a

two-tailed Student's t-test. Fisher's Least Significant Difference,

Sidak and Tukey's post hoc analysis were applied as the post hoc

analysis following one-way analysis of variance for the homogeneity

variance data. Statistical significance was set at P<0.05.

Results

Optimization of microcapsule

preparation

Microcapsules were prepared using the

W1/O/W2 double emulsification-solvent

diffusion method, with W1 being an MS solution, O being

EC dissolved in EA and W2 being PEG 6,000. The impact of

the following factors on the encapsulating efficiency was analyzed:

Volume ratio of W1:O, MS content in W1, EC

concentration, power and duration of ultrasonic emulsification, PEG

6,000 concentration, W1/O:W2 volume ratio,

stirring speed and time, and diffusion time (Table I).

| Table I.Levels of single factor analysis. |

Table I.

Levels of single factor analysis.

|

| Level |

|---|

|

|

|

|---|

| Factor | 1 | 2 | 3 | 4 | 5 |

|---|

| W1:O | 1:20 | 1:15 | 1:10 | 1:5 | 1:1 |

| MS content (mg) | 1 | 2 | 3 | 4 | 5 |

| EC concentration

(mg/ml) | 5 | 10 | 20 | 40 | 80 |

| Power of ultrasonic

emulsification (W) | 40 | 80 | 120 | 160 | 200 |

| Duration of

ultrasonic emulsification (sec) | 30 | 60 | 90 | 120 | 180 |

| PEG 6,000

concentration (%) | 1 | 2 | 3 | 4 | 5 |

|

W1/O:W2 (v/v) | 1:5 | 1:10 | 1:15 | 1:20 | 1:25 |

| Mixing speed of

multiple emulsion (rcf, × g) | 450 | 750 | 1,050 | 1,350 | 1,650 |

| Multiple emulsion

mixing time (min) | 0.5 | 1 | 2 | 3 | 4 |

| Diffusion time

(h) | 0.5 | 1 | 2 | 3 | 4 |

As demonstrated in Table

II, single factor analysis indicated that microcapsule loading

capacity was influenced by W1:O, MS content in

W1, EC, W1/O:W2 volume ratio and

multiple emulsion mixing time.

| Table II.Analysis of single factors affecting

microcapsule loading capacity. |

Table II.

Analysis of single factors affecting

microcapsule loading capacity.

|

| Drug loading amount

(%) |

|---|

|

|

|

|---|

| Factor | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|

|

W1:O | 8.45±0.36 | 8.57±0.71 | 8.69±0.45 | 8.73±0.38 | 8.76±0.32 |

| MS content |

7.14±0.28a |

7.52±0.17b |

8.68±0.31c |

9.31±0.34d |

9.72±0.51e |

| EC content | 7.89±0.21 | 8.53±0.19 | 8.71±0.47 | 7.84±0.51 | 7.16±0.15 |

| Power of ultrasonic

emulsification | 7.99±0.36 | 8.65±0.43 | 8.71±0.25 | 8.91±0.78 | 8.72±0.13 |

| Time of ultrasonic

emulsification | 8.40±0.82 | 8.68±0.20 | 8.69±0.27 | 8.72±0.71 | 8.62±0.50 |

| Concentration of

PEG 6,000 | 8.35±0.67 | 8.39±0.58 | 8.43±0.17 | 8.41±0.13 | 8.36±0.41 |

|

W1/O:W2 | 7.87±0.52 | 7.91±1.16 | 8.06±0.39 | 8.01±0.36 | 7.95±0.27 |

| Mixing speed of

multiple emulsion | 8.42±0.34 | 8.67±0.28 | 8.69±0.23 | 8.75±0.51 | 8.71±0.39 |

| Multiple emulsion

mixing time |

8.39±0.36f | 8.78±0.47 | 9.02±0.68 | 9.06±1.08 | 9.14±0.38 |

| Time of

diffuser | 8.56±0.43 | 8.59±0.30 | 8.61±0.77 | 8.58±0.50 | 8.55±0.12 |

Uniform design is an algorithm used to test the

influence of multiple factors with fewer experiments by evenly

distributing the tested factors in the experimental design

(17). Uniform design was applied to

determine the optimal conditions for the preparation of

microcapsules. Each factor was tested at five levels, using the

principle of the intended level (repeating the same level multiple

times without adding new levels), so that the number of levels

reached more than twice the number of factors. A total of 15 level

experiments were designed, using the U15

(155) uniform design table (18) and the resultant drug loading is

illustrated in Table III.

| Table III.Assessment of the influence of

multiple factors on drug loading capacity using the uniform design

algorithm. |

Table III.

Assessment of the influence of

multiple factors on drug loading capacity using the uniform design

algorithm.

| Level,

W1:O, (v/v) | Level, MS content

(mg) | Level, EC

concentration (mg/ml) | Level,

W1/O:W2 (v/v) | Level, multiple

emulsion mixing time (min) | Drug loading

(%) |

|---|

| 1

(1:20) | 4

(2) | 7

(20) | 11 (1:20) | 13 (4) |

6.27±1.46 |

| 2

(1:20) | 8

(3) | 14 (80) | 7

(1:15) | 11 (3) |

7.18±1.39 |

| 3

(1:20) | 12 (4) | 6

(10) | 3 (1:5) | 9

(2) |

8.61±1.08 |

| 4

(1:15) | 1

(1) | 13 (80) | 14 (1:25) | 7

(2) |

4.31±0.73 |

| 5

(1:15) | 5

(2) | 5

(10) | 10 (1:20) | 5

(1) |

5.74±0.97 |

| 6

(1:15) | 9

(3) | 12 (40) | 6

(1:10) |

3 (0.5) |

6.86±1.33 |

| 7

(1:10) | 13 (5) | 4

(10) | 2 (1:5) |

1 (0.5) |

9.69±1.55 |

| 8

(1:10) | 2

(1) | 11 (40) | 13 (1:25) | 14 (4) |

4.88±0.89 |

| 9

(1:10) | 6

(2) | 3 (5) | 9

(1:15) | 12 (3) |

6.17±1.29 |

| 10 (1:5) | 10 (4) | 10 (40) | 5

(1:10) | 10 (3) |

8.77±1.76 |

| 11 (1:5) | 14 (5) | 2 (5) | 1 (1:5) | 8

(2) | 10.06±2.21 |

| 12 (1:5) | 3

(1) | 9

(20) | 12 (1:20) | 6

(1) |

4.45±0.62 |

| 13 (1:1) | 7

(3) | 1 (5) | 8

(1:15) | 4

(1) |

7.66±1.92 |

| 14 (1:1) | 11 (4) | 8

(20) | 4

(1:10) |

2 (0.5) |

8.84±1.57 |

| 15 (1:1) | 15 (5) | 15 (80) | 15 (1:25) | 15 (4) | 10.63±1.86 |

Using mean drug loading as an index, multiple

regression analysis was performed for each factor. At α=0.05, the

regression equation revealed that it was possible to calculate mean

drug loading according to the formula 2.865+0.597

(W1:O)+1.341 (MS content of W1) + 0.194

(multiple emulsion mixing time) (F=328.265; P<0.001;

r2=0.990). Regression analysis indicated that

W1:O, MS content of W1 and multiple emulsion

mixing time were significantly correlated with drug loading

(P<0.05), whereas EC or the W1/O:W2 volume

ratio were not. The optimal microcapsule preparation conditions

were determined as follows: Internal W1:O, 1:1; MS

content of W1, 5 mg; EC, 20 mg/ml;

W1/O:W2 volume ratio, 1:15; and multiple

emulsion stirring time, 4 min. The microencapsulated drug loading

capacity predicted using a regression equation under optimal

conditions was 10.94%. Consistent with this predicted value, the

three batches of microcapsules prepared were determined to have an

average drug loading capacity of 10.91%, as well as an

encapsulation efficiency of 83.16%.

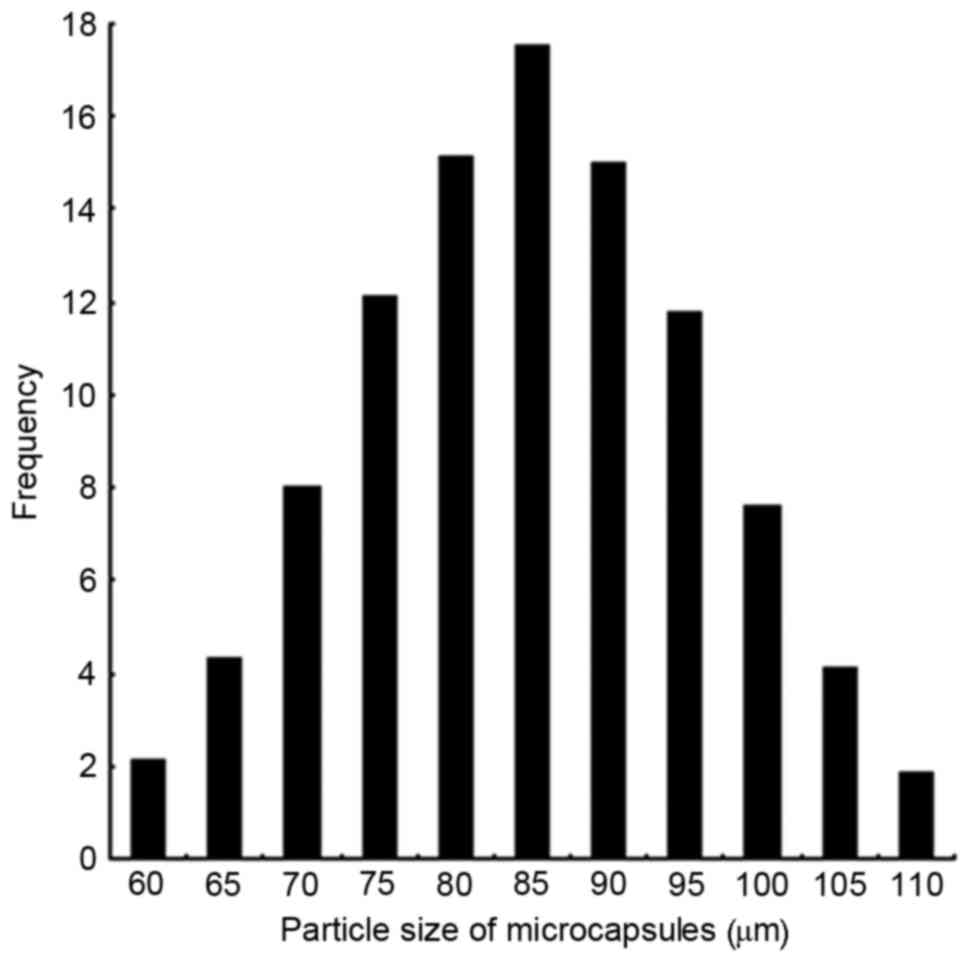

Microcapsule morphology and size

distribution

Prepared microcapsules were spherical, with

relatively uniform size, and did not adhere to one another

(Fig. 1). Microcapsule wall

integrity was maintained for 20 h prior to rupture when suspended

in distilled water, indicating a 20-h period of

diffusion-controlled drug release. Microcapsule size was relatively

narrowly distributed, with 86% of capsules being 70–100 µm in

diameter, and a mean particle size of 85 µm (Fig. 2).

In vitro release

The in vitro drug release profiles of the MS

microcapsules in various dissolution media are presented in

Fig. 3. The release equations of MS

microcapsules in water, artificial gastric fluid, and in artificial

intestinal fluid were determined to be

Q=22.346t1/2+1.6068 (r=0.992);

Q=26.438t1/2+2.5376 (r=0.990); and

Q=22.553t1/2-1.3337 (r=0.997), respectively. The

cumulative release was found to fit the Higuchi equation (19), indicating that MS was released from

microcapsules via diffusion. The MS microcapsules demonstrated a

good SR profile in all three media, with a mean release of 96.1%

within 18 h.

| Figure 3.Drug release from MS microcapsules

in vitro. Prepared microcapsules were placed in a basket

with 1,000 ml of release medium (water, artificial gastric fluid or

artificial intestinal fluid). Samples were taken from the release

solution at pre-determined time intervals (0.5, 2, 4, 6, 8, 10, 12,

15 and 18 h) to detect the released drug concentration. The total

percentages of MS released at different time-points are plotted.

Values are expressed as the mean ± standard deviation (n=12). ■,

water; ●, artificial gastric fluid; ▲, artificial intestinal fluid.

MS, metoprolol succinate. |

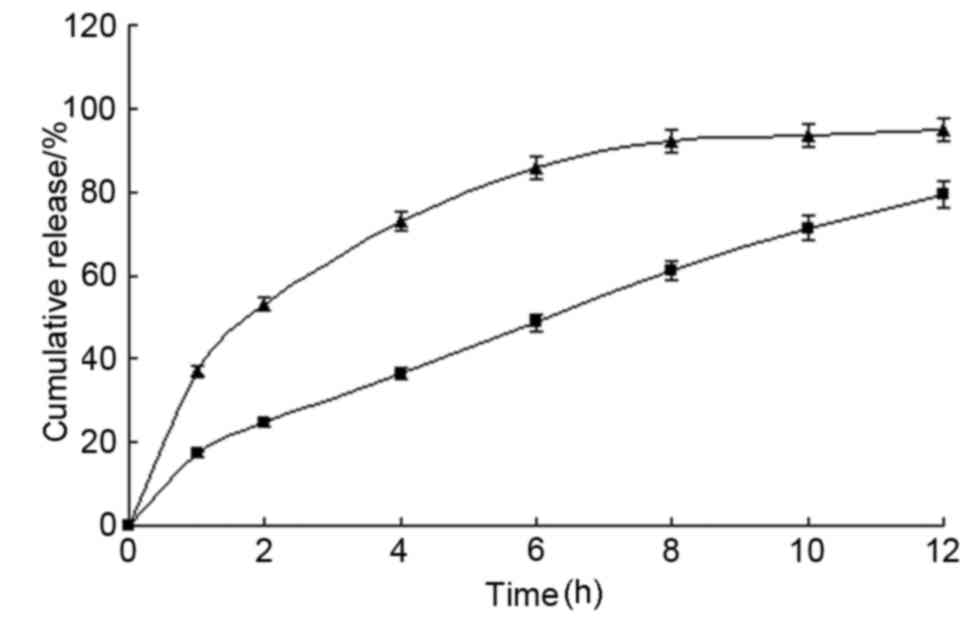

When submerged in water, conventional SR-tablets

exhibited a burst of release with >50% released in 2 h.

Conversely, the MS microcapsule SR-tablets exhibited an almost

linear SR in a 12-h test period (Fig.

4).

Pharmacokinetic studies in vivo

Pharmacokinetic studies of MS microcapsules and

conventional SR tablets were performed in dogs to evaluate the

in vivo performance of these formulations (Fig. 5). The results indicated that

conventional tablets and microcapsules fitted a single-compartment

model. The pharmacokinetic parameters are presented in Table IV. Both formulations exhibited a

similar area under curve; however, the microcapsules exhibited a

significantly longer half-life and time to peak, and a markedly

lower maximum drug concentration (Cmax).

| Figure 5.Microcapsule drug release profile

in vivo. Six dogs were fasted overnight and administered

47.5 mg MS microcapsules or 50 mg metoprolol tartrate tablets

(conventional SR tablets). Venous blood samples harvested prior to

and following administration at 0.5, 1, 1.5, 2, 2.5, 3, 4, 8 and 16

h were used to detect MS concentration by HPLC analysis. Values are

expressed as the mean ± standard deviation (n=3). ■, SR

microcapsules; ▲, conventional SR tablets. MS, metoprolol

succinate; SR, sustained-release; HPLC, high-performance liquid

chromatography. |

| Table IV.Pharmacokinetic parameters. |

Table IV.

Pharmacokinetic parameters.

| Parameter | Conventional

SR-tablets | SR

microcapsules |

|---|

| t1/2

(h) | 0.84±0.09 |

2.84±0.37a |

| Ka (1/h) | 0.88±0.12 |

0.255±0.10a |

| Tmax

(h) | 1.17±0.27 |

4.01±0.53a |

| Cmax

(ng/ml) | 216.13±48.79 |

86.69±27.71a |

| CL (l/kg) | 0.42±0.07 | 0.43±0.09 |

| AUC (ng·h/ml) | 738.50±150.82 | 710.71±131.64 |

Discussion

SR formulations of MS may minimize fluctuations in

plasma concentration, avoiding the adverse effects associated with

excessively high plasma concentrations and providing a stable

effective dose. Microspheres have been previously used in SR

formulations of MS to provide robust and consistent control of

hypertension and heart rate (20).

The objective of the present study was to develop a method of MS

encapsulation to provide microcapsules with high entrapment

efficiency and optimal sustained-release profiles in vitro

and in vivo.

EC was employed as the capsule material and EA as a

solvent to prepare multiple emulsions. At room temperature, the

emulsion was added to distilled water to cause phase separation and

condensation of microcapsules. The solvent was removed with excess

water, avoiding the elevated temperatures usually employed in

solvent evaporation methods, which may have negatively affected the

stability of the encapsulated compound. Water-insoluble EC was

employed as a blocker film coating.

Increased ultrasonic power and time during

emulsification may increase drug loading; however, excessive

emulsification may lead to excess evaporation of EA in the primary

emulsion. In the current study, when agitated too quickly,

excessive foam was produced and the primary emulsion particle size

decreased, reducing the dose loaded per particle. Emulsification at

<160 W with a mixing time of <120 sec and 1,350 × g

using PEG 6,000 as a plasticizer in the W2 phase

produced microcapsules with favorable mechanical properties, as

walls were less prone to rupture and drug leakage was reduced. An

excess of PEG may reduce the amount of drug loading and accelerate

drug release, and may also cause microcapsules to aggregate into

larger clumps, with oil leach induced by mechanical impact

adversely affecting the process of preparation (21). As such, the optimal PEG 6,000

concentration was determined to be 3%. It was also necessary to

determine the optimum diffusion time, as excessively long diffusion

periods may result in loss of the pharmacological agent (20). The optimum diffusion time was

determined to be 2 h.

Given the complexity of the microcapsule preparation

process, numerous variables may be adjusted to optimize the drug

loading capacity. By using a single factor method and applying a

uniform design to assess the contribution of individual parameters,

and subsequently performing multiple regression analysis to select

the optimal conditions, the loading capacity of MS microcapsules

was optimized (22). The MS

microcapsules prepared under optimal conditions exhibited good

morphological characteristics, a high encapsulation efficiency and

good reproducibility.

It is difficult to achieve prolonged SR of

water-soluble pharmacological agents with conventional tablets

(23). Microcapsules formed with EC

and PEG 6,000 exhibited SR of MS in vivo and in

vitro. The 18-h release behavior followed the Higuchi equation

in water (19), and release rates in

artificial gastric and intestinal fluid were similar and

reproducible, with a release of ~80% of the encapsulated MS within

12 h. Furthermore, the novel microcapsule formula developed in the

present study exhibited slower in vitro release of MS than

the conventional tablet formula. These novel microcapsules are

advantageous, as they achieve a more even SR in various

environments, including water, artificial gastric fluid and

artificial intestinal fluid.

When dogs were orally administered microcapsules and

conventional tablets, the plasma half-life of MS with the

microcapsule tablet formulation was longer than with the

conventional tablet and the peak plasma concentration was

significantly lower (P<0.05). MS microcapsule SR tablets may

provide additional advantages by reducing the dose frequency and

minimizing adverse effects associated with Cmax.

In conclusion, the present study reported on the

development of microcapsules with high entrapment efficiency and

desirable SR properties in vitro and in vivo. An

entrapment efficiency of 83.16% was achieved and 96.1% of MS was

released in vitro within 18 h. Pharmacokinetic studies of MS

microcapsules in dogs indicated a superior SR profile compared with

conventional SR tablets. These findings suggested that the use of

microcapsules in tablets may provide therapeutic benefits over

conventional tablets by SR of pharmacological agents.

Acknowledgements

The authors would like to thank Professor Liu at

Guangzhou General Pharmaceutical Research Institute for providing

the animal models used in the present study.

References

|

1

|

Papadopoulos DP and Papademetriou V:

Metoprolol succinate combination in the treatment of hypertension.

Angiology. 60:608–613. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Reiter MJ: Cardiovascular drug class

specificity: Beta-blockers. Prog Cardiovasc Dis. 47:11–33. 2004.

View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Frishman WH and Saunders E: β-Adrenergic

blockers. J Clin Hypertens (Greenwich). 13:649–653. 2011.

View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Bengtsson C, Johnsson G and Regårdh CG:

Plasma levels and effects of metoprolol on blood pressure and heart

rate in hypertensive patients after an acute dose and between two

doses during long-term treatment. Clin Pharmacol Ther. 17:400–408.

1975. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Guan G and Li Z: Evaluation of the effect

on metoprolol succinate sustained release tablets in reducing blood

pressure. Jian Yan Yi Xue Yu Lin Chuang. 6:1989–1990. 2009.(In

Chinese).

|

|

6

|

Chirra HD and Desai TA: Emerging

microtechnologies for the development of oral drug delivery

devices. Adv Drug Deliv Rev. 64:1569–1578. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Lu B, Wen R, Yang H and He Y:

Sustained-release tablets of indomethacin-loaded microcapsules:

Preparation, in vitro and in vivo characterization. Int J Pharm.

333:87–94. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Frishman WH, Hainer JW and Sugg J; M-FACT

Study Group, : A factorial study of combination hypertension

treatment with metoprolol succinate extended release and felodipine

extended release results of the Metoprolol Succinate-Felodipine

Antihypertension Combination Trial (M-FACT). Am J Hypertens.

19:388–395. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Siddique S, Khanam J and Bigoniya P:

Development of sustained release capsules containing ‘coated matrix

granules of metoprolol tartrate’. AAPS PharmSciTech. 11:1306–1314.

2010. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Gong X, Lu Y, Xiang Z and Luo G:

Preparation of polysulfone microcapsules containing 1-octanol for

the recovery of caprolactam. J Microencapsul. 26:104–110. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Zhang X, Zhu Y, Wang J, Sun Y, Li S and

Pan W: Preparation of sustained-release microspheres of

clarithromycin by quasi-emulsion solvent diffusion method. Zhongguo

Yao Ye. 18:39–40. 2009.(In Chinese).

|

|

12

|

You J, Cui FD, Han X, Wang YS, Yang L, Yu

YW and Li QP: Study of the preparation of sustained-release

microspheres containing zedoary turmeric oil by the

emulsion-solvent-diffusion method and evaluation of the

self-emulsification and bioavailability of the oil. Colloids Surf B

Biointerfaces. 48:35–41. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Jelvehgari M and Montazam SH: Comparison

of microencapsulation by emulsion-solvent extraction/evaporation

technique using derivatives cellulose and acrylate-methacrylate

copolymer as carriers. Jundishapur J Nat Pharm Prod. 7:144–152.

2012. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Dash V, Mishra SK, Singh M, Goyal AK and

Rath G: Release kinetic studies of aspirin microcapsules from ethyl

cellulose, cellulose acetate phthalate and their mixtures by

emulsion solvent evaporation method. Sci Pharm. 78:93–101. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Saringat HB, Alfadol KI and Khan GM: The

influence of different plasticizers on some physical and mechanical

properties of hydroxypropyl methylcellulose free films. Pak J Pharm

Sci. 18:25–38. 2005.PubMed/NCBI

|

|

16

|

Huang G, Deng S, Wang R and Xi Y:

Preparation and in vitro-in vivo correlation in dogs of metoprolol

succinate sustained-released tablets. Zhongguo Yi Yao Gong Ye Za

Zhi. 36:412–414. 2005.(In Chinese).

|

|

17

|

Xu W, Li N and Gao C: Preparation of

controlled porosity osmotic pump tablets for salvianolic acid an

doptimization of the formulation using an artificial neural network

method. Acta Pharm Sin B. 1:64–70. 2011. View Article : Google Scholar

|

|

18

|

Shen LN, Zhang YT, Wang Q, Xu L and Feng

NP: Enhanced in vitro and in vivo skin deposition of apigenin

delivered using ethosomes. Int J Pharm. 460:280–288. 2014.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Saurí J, Millán D, Suñé-Negre JM, Colom H,

Ticó JR, Miñarro M, Pérez-Lozano P and García-Montoya E: Quality by

design approach to understand the physicochemical phenomena

involved in controlled release of captopril SR matrix tablets. Int

J Pharm. 477:431–441. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Albin P, Markus A, Ben-Zvi Z and Pelah Z:

A new slow release formulation of metoprolol: In-vitro and in-vivo

evaluation in dogs. J Control Release. 23:1–11. 1993. View Article : Google Scholar

|

|

21

|

Liu Y, Feng Y and Xu D: Influence of

excipients on the mechanical properties of microcapsules. Chin

Traditional Pat Med. 29:1602–1605. 2007.

|

|

22

|

Zhao W: Uniform design application in

pharmaceutics. Anhui Med Pharm J. 14:610–612. 2010.

|

|

23

|

Pradhan R, Kim YI, Chang SW and Kim JO:

Preparation and evaluation of once-daily sustained-release coated

tablets of tolterodine-L-tartrate. Int J Pharm. 460:205–211. 2014.

View Article : Google Scholar : PubMed/NCBI

|