Introduction

Common implant materials, including titanium alloys,

stainless steel and cobalt-chromium alloys, have considerable

advantages in terms of their load-bearing capabilities and

resistance to fatigue, wear and corrosion (1–3).

However, these traditional materials also have multiple

disadvantages. For instance, their mechanical properties differ

from those of natural bone, which may cause stress shielding

(4–6). A second surgery is often required to

remove the implant after the tissues have healed, which markedly

increases the risk and costs of healthcare (7,8).

Furthermore, implant materials release cytotoxic ions and may cause

physical irritation due to their rigidity (9,10).

Recently, magnesium and its alloys have attracted

increasing interest as innovative biodegradable materials,

particularly due to their potential use as temporary orthopedic

implants (11,12). The fundamental properties of

magnesium make it relatively suitable for this application

(13); it has low density and

elastic modulus, both of which are close to that of natural bone,

thus preventing stress shielding during fracture consolidation

(14,15). In addition, magnesium is

biocompatible and essential for human metabolism as a cofactor for

many enzymes (16). Notably,

magnesium ions that are produced as a result of implant degradation

have been reported to aid in the growth and healing of tissues

(17,18). Magnesium is well tolerated by the

human body and does not induce systemic inflammatory reactions or

negatively affect the cellular blood composition (19). It also degrades in aqueous solutions,

and is prone to degradation in body fluids (20); thus, follow-up surgery to remove the

implant is not required (21).

Finally, due to its functional roles and presence in bone tissue,

magnesium may exert stimulatory effects on the growth of new bone

tissue (21–23).

Despite these advantageous properties, magnesium and

its alloys have not been widely used as human body implants to

date. A major drawback is that magnesium alloys tend to corrode

rapidly in chloride solutions, including the physiological

environment, leading to a loss in their mechanical integrity before

their expected service life (1,23,24). One

method of altering the surface and degradation properties without

adding a coating material, and thus inducing other potentially

irritating materials, is micro-arc oxidation (25,26).

This method of surface modification, which is based on the

principle of plasma-electrolytic oxidation, produces an increased

oxide layer at the surface (27).

Micro arc-treated magnesium surfaces exhibit improved resistance to

corrosion in various environments (28,29).

In vitro tests in simulated body fluid have repeatedly

confirmed the favorable behavior of surface-treated magnesium

alloys regarding reduced dissolution and enhanced biocompatibility

(30).

There has been much research on degradable implants

for applications in orthopedics (31–34),

such as those made of polylactic-co-glycolic acid and magnesium

alloys. It has been reported that the degradation of implant

material and formation of new bone, and notably, the balance

between these two processes, are important evaluation indices

(35). Traditional methods of

assessing degradation have unavoidable disadvantages, and the

evaluation of new bone formation generally relies on images

obtained from histology and radiography, which are imprecise and

difficult to analyze quantitatively (36,37).

Thus, the present study used images and data from micro-computed

tomography (micro-CT), as a non-traumatic, in vivo,

quantitative and precise process (38,39).

Over the past decade, the number of orthopedic

studies that have used micro-CT imaging has increased (40–49).

Higher spatial and temporal resolution are key technical advances

that have enabled researchers to capture increasingly detailed

anatomical images of small animals and monitor the progression of

orthopedic disease in small animal models (38,50).

Furthermore, a range of data may be derived from micro-CT,

including bone volume (BV), bone mineral content (BMC), bone

mineral density (BMD), bone volume fraction (BVF), bone

volume/tissue volume (BV/TV), bone surface/bone volume (BS/BV),

trabecular thickness (Tb.Th), trabecular number (Tb.N) and

trabecular separation (Tb.Sp). With the development of radiography

methods for the evaluation of implants, measuring the weight loss

of implants and histological analysis, as ‘traumatic’ methods, and

micro-CT imaging, as a ‘non-traumatic’ method, have become

mainstream (51); however,

quantitative analyses and methods that evaluate the association

between implant material degradation and new bone formation are

still lacking (52,53).

In the present study, micro-CT images and data were

used to assess the degradation of micro arc-oxidized AZ31 magnesium

alloy implants in vivo. Changes in the volume of the AZ31

implants were assessed, and the application of the degradable

implant for bone-regeneration was evaluated. By applying micro-arc

surface treatment, the initial intention was to decrease the

degradation rate of the magnesium implants in the initial

post-implantation period and reduce the impact of degradation

products on the postoperatively irritated surrounding tissue, then

to slow dissolution of the implant material once the implant's

function became redundant. Generally, a cylinder of the same size

and position of the pin was selected as the region of interest

(ROI) to analyze the degradation of the material, and a new larger

ROI in the same shape and position was selected to observe new bone

formation and assess the stimulatory effects of magnesium alloys on

bone growth.

Materials and methods

Implants

Micro arc-oxidized cylindrical pins (n=60; diameter

2.0 mm, length 6.0 mm, weight 0.500 g) made of AZ31 material were

used (Trauson Medical Instrument Co., Ltd., Changzhou, China). AZ31

is a fast-degrading alloy of magnesium with 3 wt.% Al, 1 wt.% Zn

and 0.15 wt.% Mn.

Experimental design

All animal experiments were conducted following

ethical guidelines by Ethics Committee of Chinese PLA General

Hospital (Beijing, China), obtained international standard

authentication-SIDCER (54) and were

authorized by the Institutes for Food and Drug Control of China and

KEYU Animal Experiment Center.

A total of 60 male New Zealand white rabbits (body

weight 2.2–2.5 kg, 3 months old) were purchased from KEYU Animal

Experiment Center (Beijing, China; accreditation number SCXK(Jing)

2012-0004, certification no. 11400800001109) for the present study.

Experiments were performed under standard conditions throughout the

study (temperature, 23±2°C; relative humidity, 60±10%; with access

to a 12-h light/dark cycle). Rabbits had been ensured adequate food

and water. Each rabbit had an AZ31 pin implanted into its right

femoral condyle. Rabbits were randomly divided into six groups

(n=10), and were sacrificed after 1, 4, 12, 24, 36 or 48 weeks (1

group per time-point). Each pin was weighed prior to implantation

and following sacrifice. Micro-CT, 3D reconstruction and

histological examinations were performed following sacrifice.

Surgical procedure

Rabbits were fasted for 12 h prior to surgery and

then anesthetized with an intraperitoneal injection of 3% sodium

pentobarbital (Sigma-Aldrich; Merck KGaA; Darmstadt, Germany) with

a dosage of 24 mg/kg. Surgery was performed under sterile

conditions. First, full-thickness lesions were created with 2.0 mm

Kirschner pins (Beijing Fule Science & Technology Development

Co., Ltd., Beijing, China). AZ31 alloy cylindrical pins were

implanted into the defects in the right femoral condyles. All pins

were γ-ray-sterilized with 29 kGy of 60Co radiation

prior to surgery. All rabbits received an intramuscular

anti-inflammatory injection with penicillin (Sigma-Aldrich; Merck

KGaA) with a dosage of 400,000 U/day following surgery and were

housed individually. Postoperatively, the rabbits were allowed to

move freely in their cages without external support and with

unrestricted weight bearing. Daily clinical observations were made

throughout the study period.

Weighing

Prior to implantation, the AZ31 pins were weighed on

an electronic balance (accuracy, ±0.001 g). At 1, 4, 12, 24, 36 or

48 weeks, pins were removed from the femoral condyle and dry

machined with clean tools. After machining, the pins were cleaned

with pure ethanol in an ultrasonic bath and dried in warm air

(23). The pins were weighed again

and the difference between the pre- and post- implantation weights

was calculated. To explore the difference between weight and

Micro-CT methods, the pin weight fraction was calculated using the

following formula: Weight loss of implanted pins/weight before

implantation. Subsequently the pin weight fraction was compared

with the pin volume fraction.

Micro-CT

Micro-CT is an emerging technology that permits

non-invasive, tissue-preserving imaging and quantitative

morphometry of bone structure in three dimensions (55–56).

Scans were performed with an RS-9 micro-CT (GE Healthcare, Chicago,

IL, USA) to assess the condyle before it was placed in 25% formic

acid solution for decalcification. The micro-CT system was operated

at 80 kV tube voltage and 450 µA tube electric current, with a scan

resolution of 45 µm and exposure time of 400 msec. Images were

reconstructed and the pin volume, bone volume, BMD, tissue mineral

density (TMD), BMC, BVF, BV/TV, BS/BV, Tb.Th, Tb.N, and Tb.Sp were

analyzed using the built-in software (Version MicroView Advanced

Bone Analysis Application 2.2; GE Healthcare) of the micro-CT

equipment at each time point. A cylinder of the same size was

selected from the corresponding region around the pins of the

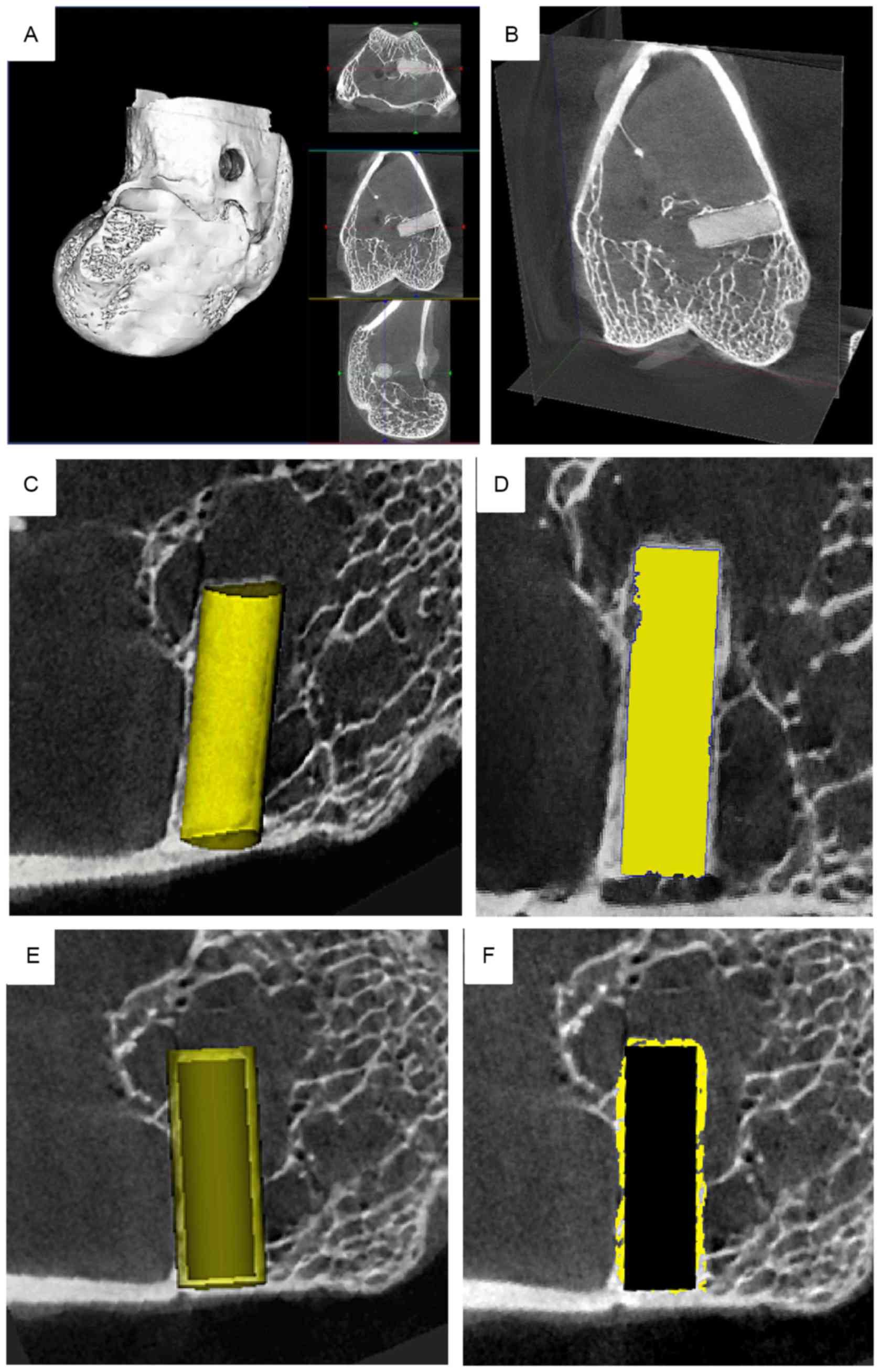

femoral condyle (Fig. 1A-F). A

cylindrical ROI was set at each time point, matching the size of

the magnesium alloy pins, 2.0 mm in diameter and 6.0 mm in length,

ensuring that the ROI and pin fully overlapped (Fig. 1C). The threshold was set to 850 and

the ROI was highlighted using the built-in software (Fig. 1D). The magnesium alloy was considered

as bone tissue to assess degradation of the implant. Similar to the

bone volume fraction, the Mg volume fraction was applied as:

Degraded alloy pin volume/pin volume before implantation. The BMD

and TMD reflected the Mg cylinder mineral and CT image densities,

respectively. However, unlike natural bone, the pins had no

trabecular, and thus the trabecular meant the thickness of the pin

was calculated from the radius of its cross-section. To investigate

new bone formation, the previous ROI was replaced with a larger ROI

(diameter 2.5 mm, length 6.5 mm) in the same shape and position

(Fig. 1E), from which new bone

formation and the stimulatory effects on the growth of new tissue

were observed. The threshold was then set at 1,000 and the ROI was

highlighted with the built-in software (Fig. 1F). The maximum inner diameter of the

new bone loop in the cross-section of the magnesium pin was

selected, and the diameter of the pin was measured with the

built-in software at the same position. Magnesium degradation and

bone ingrowth were subsequently investigated.

Histological processing

The femoral condyles were excised and fixed in a 10%

buffered neutral formalin solution for 1 week at room temperature

at weeks 4, 24 and 48. Following decalcification, the samples were

cut in half longitudinally and embedded in paraffin wax. Central

sections (5 µm thick) were cut from the femoral condyle with a

Leitz 1512 microtome (Leica Microsystems GmbH, Wetzlar, Germany)

and stained at room temperature for 10 min with hematoxylin and

eosin (H&E) for histological examination. Microscopic images

were captured using a light microscope (dotSlide Virtual Slide

System; Olympus Corporation, Tokyo, Japan) at ×40, ×100 and ×200

magnification.

Statistical analysis

Statistical analyses were performed using SPSS

software (version 22.0; IBM Corp., Armonk, NY USA). Experimental

values were expressed as the mean ± standard deviation and were

analyzed using an unpaired Student's t-test to determine

differences between the pre-implantation value and the

post-implantation values at each time point. P<0.05 was

considered to indicate a statistically significant difference.

Results

Changes in the weight of implant

material

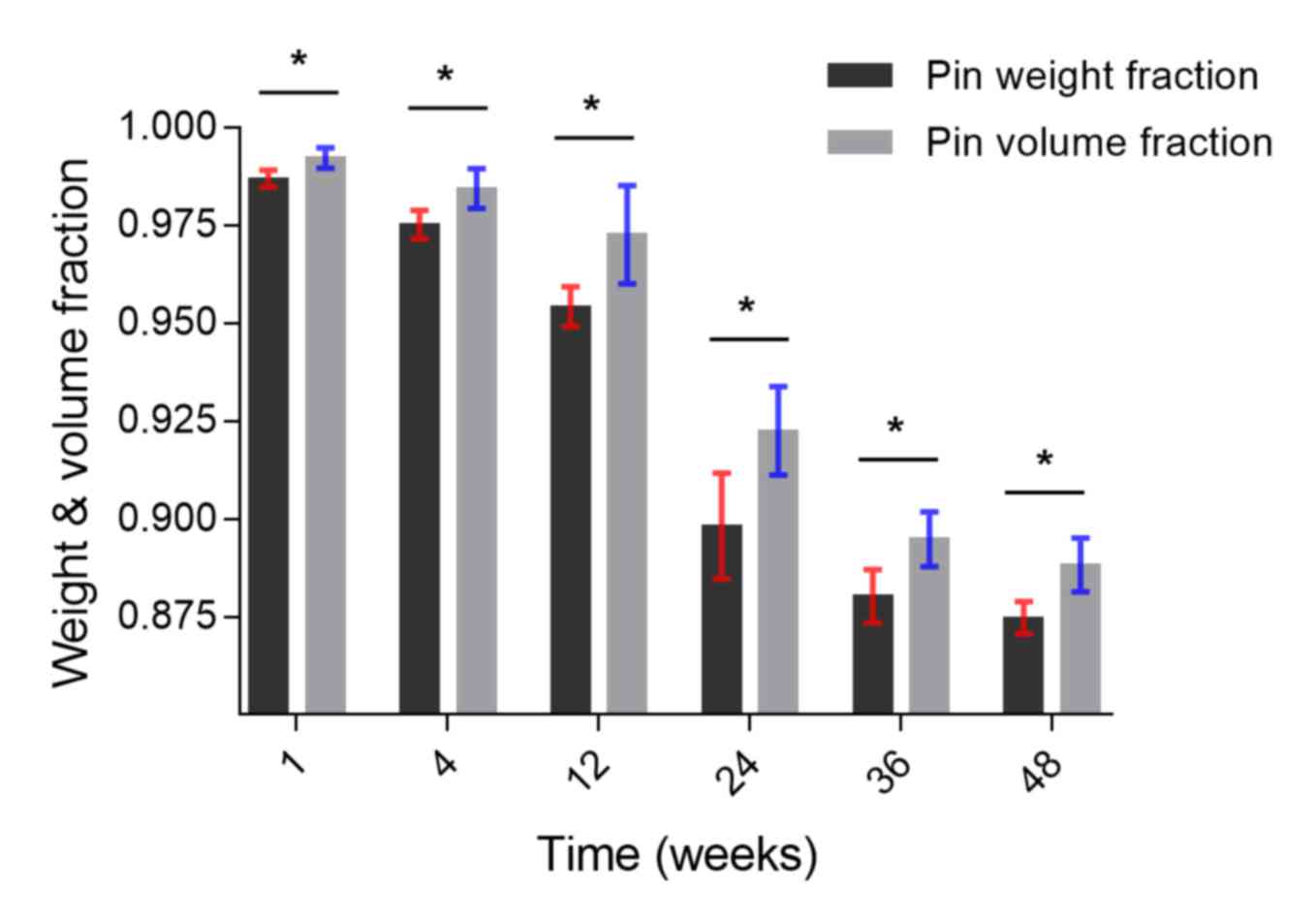

According to the weight change of pins at each time

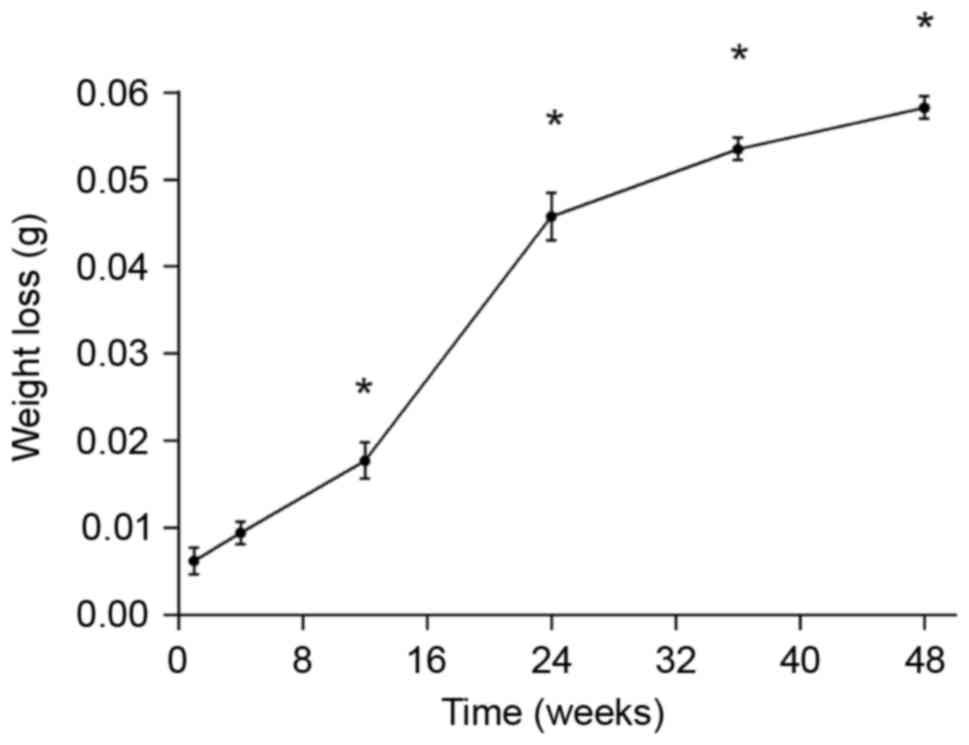

point (Fig. 2), there was almost no

weight loss of the implants within the first week (−0.007 g).

However, by week 12, significant weight loss of the pins was

observed compared with their pre-implantation weights (−0.017 g;

P<0.05; Fig. 2). During weeks

12–24, the rate of weight loss was markedly increased when compared

with weeks 1–4 and 4–12. After week 24, the rate of weight loss

gradually decreased. This may be due to the production of new bone

during corrosion of the micro arc-oxidized surface at the later

time points.

Micro-CT evaluation of implant

degradation

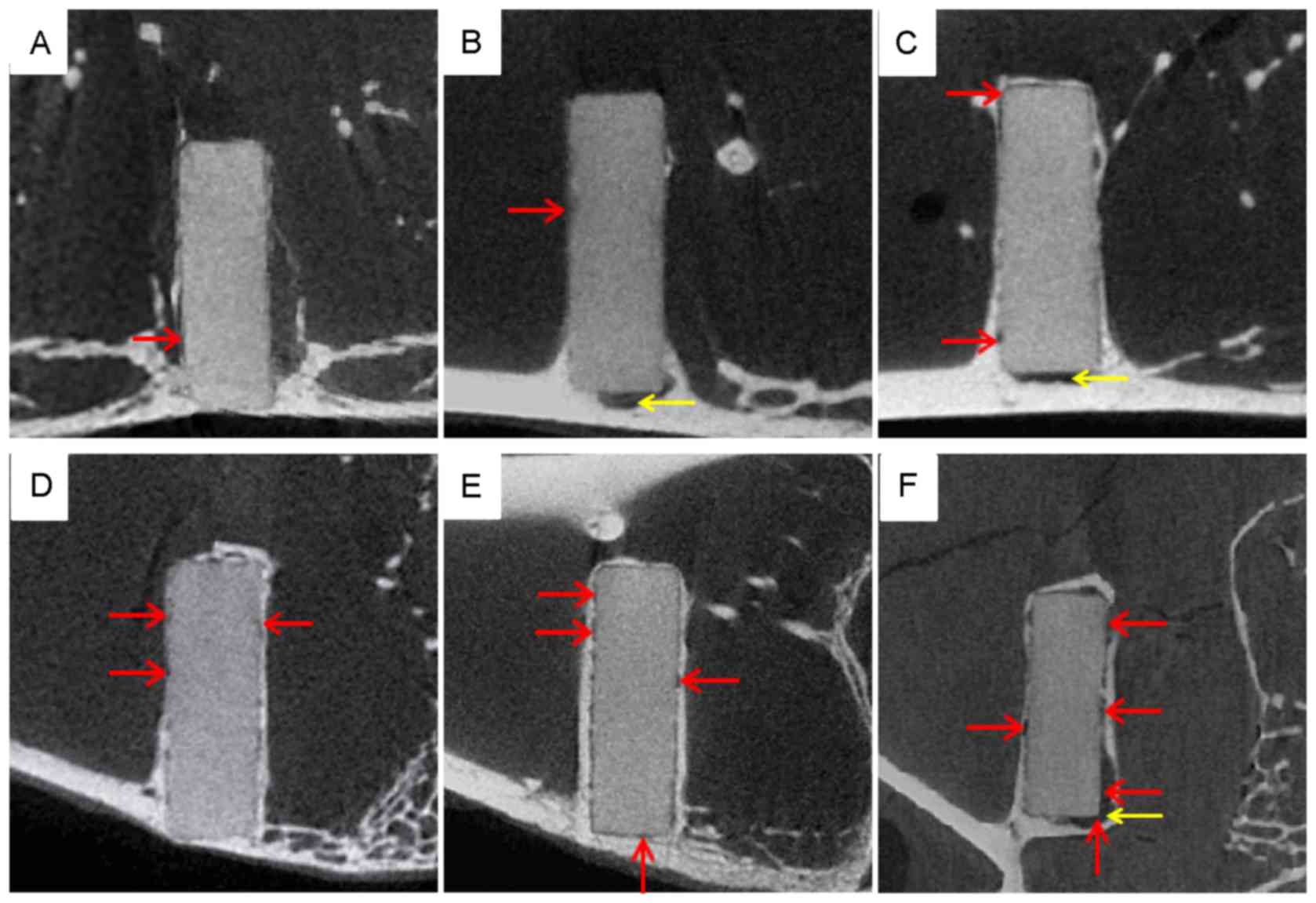

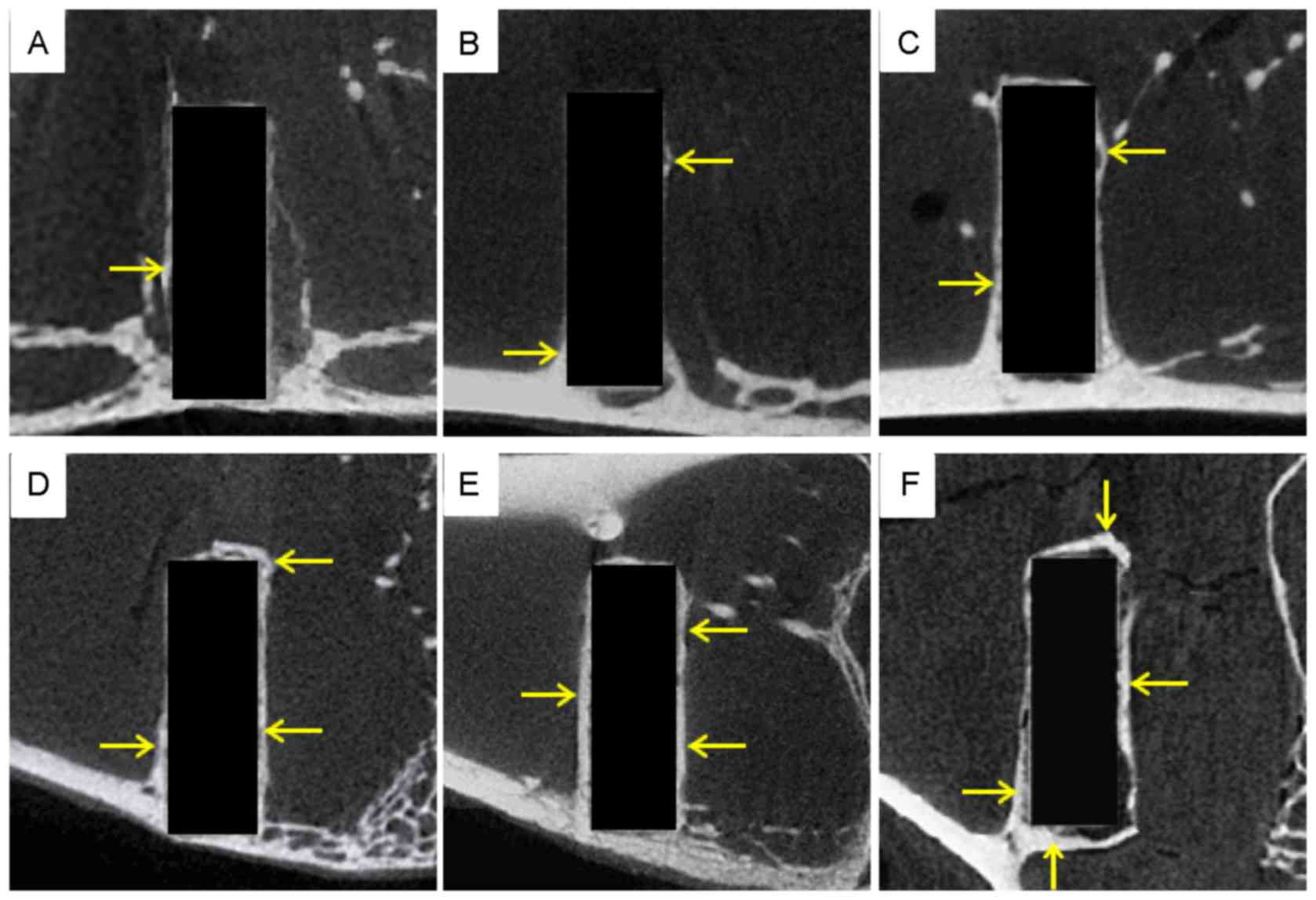

The micro-CT images in Fig. 3 provide examples of the degradation

process of an AZ31 implant at each time point. In the first week of

the first month, little corrosion was observed, and the boundary of

the pin was continuous and smooth (Fig.

3A). By week 4, the surface of the pin appeared blurred

(Fig. 3B), indicating that the rate

of degradation had increased compared with week 1. Corrosion

pitting became evident at week 12 (Fig.

3C), and during weeks 12–24 the surfaces of the pins were

surrounded by new bone tissue (Fig. 3C

and D). These results suggest that degradation of the implants

accelerated between weeks 4–24 and was markedly faster than that in

the first 4 weeks. From week 36, corrosion pitting became more

obvious, the boundary of the pin was inconclusive and the corners

of the pins became indistinct (Fig. 3E

and F). The images at this point suggested that degradation was

still proceeding and the area of corrosion pitting was expanding.

The acceleration of the degradation rate was observed at the

preexisting corrosion points, and there did not appear to be

corrosion at new positions on the surface of the pins. As indicated

in Fig. 3F, corrosion pitting was

evident on all surfaces and degradation was clear by week 48.

However, the micro-CT images also identified a small amount of

hydrogen gas around the pins at weeks 4, 12 and 48 only (Fig. 3B, C and F), however, no apparent

trend was observed.

Similar to the micro-CT images, the data exported

from the built-in software of the micro-CT equipment provided

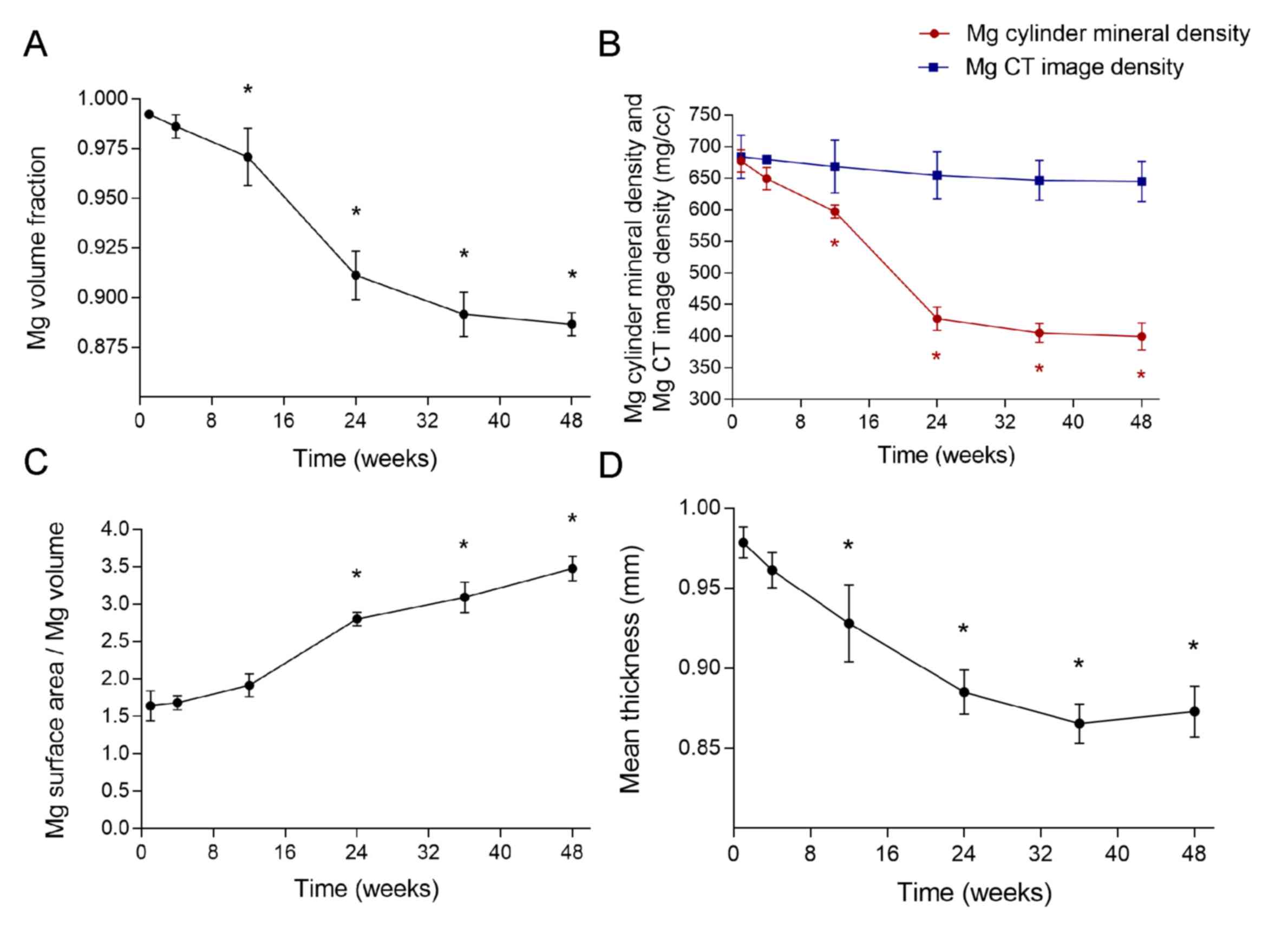

precise results (Fig. 4). The pin

volume fraction was ≥99.0% during the first month of the study,

indicating that degradation was slow and minor, and remained above

96.5% until week 12, after which the volume fractions were

significantly lower when compared with the pre-implantation value

(P<0.05; Fig. 4A). From week 12

to 24, the pin volume fraction decreased markedly faster than in

the first 3 months, and reached 91.2% by week 24. During this

period, the micro arc-oxidized surface was being degraded and new

bone tissue had not yet been sufficiently produced (Fig. 3A-D). After week 24, the rate of

decrease slowed, and during the final 24 weeks, pin volume fraction

only decreased by 2.25% (Fig. 4A).

This may have been due to enclosure of the residual pin by new bone

tissue, thus reducing contact between the metal and tissue

fluid.

The AZ31 magnesium alloy pin was regarded as bone to

analyze the BMD and TMD, which reflected the Mg cylinder mineral

and CT image densities, respectively. The Mg cylinder mineral

density continuously decreased throughout the study period,

degrading most rapidly between weeks 12 and 24. From week 12, the

Mg cylinder material densities were significantly decreased

compared with the pre-implantation value (P<0.05; Fig. 4B), and by week 48 it had reached

403.1424 mg/cc. By contrast, no significant change was observed in

the pin CT image density, which started at 683.6439 (week 1) and

ended at 644.9468 mg/cc (week 48; Fig.

4B). These results indicate that Mg content decreased as the

implant degraded, while the density of the material underwent

little change.

During degradation, the volume of the pin decreased,

most notably during weeks 12–24 (Fig.

4A). Furthermore, with corrosion pitting, the surface of the

pins became rough (Fig. 3C-F), which

may increase the superficial area. Thus, the ratio between the

surface area and volume of the pins increased throughout the study

period, and were significantly higher compared with the

pre-implantation value from week 24 (P<0.05; Fig. 4C). However, the surface area of the

pins was preserved during the first 4 weeks (Fig. 4C). Unlike natural bone, the pins had

no trabecular, and thus the trabecular mean thickness of the pin

was calculated from the radius of its cross-section, and

theoretically should be 1.0 mm. The computer creates a theoretical

line that automatically runs through the longitudinal axis of the

AZ31 pin, and the radius of its cross-section represents the pin's

mean thickness. During the period investigated, degradation of the

pins and increased corrosion pitting on the surface resulted in a

decrease in the pin radius. The thickness of the pre-implantation

pin was 1.0 mm and remained above 0.925 mm up to week 12, from

which point it was significantly decreased compared with the

pre-implantation value (P<0.05; Fig.

4D). During weeks 24–36, the thickness decreased more slowly

than in 1–24 weeks, and during weeks 36–48, a slight increase in

pin thickness was observed. This may have been due to the

stimulatory effects of magnesium on the growth of new bone tissue

at the metal corrosion loci.

To analyze pin degradation, the changes in pin

weight fraction and volume fraction over the 48 weeks was plotted

(Fig. 5). The results of two methods

used (weighing and Micro-CT) to calculate amount of remaining pin

were similar: both the weight and volume of the pins decreased over

the 48 weeks, and during weeks 12–24, the decrease of the weight

and volume of the pin was markedly fast. However, the data were not

wholly consistent: at each time point, the quantity of magnesium

corrosion by weight was significantly greater than by volume

(P<0.05; Fig. 5).

Micro-CT evaluation of bone

formation

A new, larger ROI was subsequently selected in the

same shape and position as the original ROI (Fig. 1E), from which new bone formation and

the stimulatory effects on bone tissue growth were observed. The

threshold was set at 1,000, and the new ROI was highlighted with

the built-in software (Fig. 1F).

Before week 12, the majority of new bone formation occurred

longitudinally on the surface of the metal, and the new bone

appeared fragmentary and small (Fig. 6A

and B). From week 4, a small amount of new bone began to grow

transversely, and at the junction of the longitudinal and

transverse profiles (Fig. 6B).

Furthermore, the majority of new bone growth started at the bottom

of the pin, which was in contact with the host cortical bone

(Fig. 6B and C). From week 12, more

new bone was formed, and by week 48, the pin was almost surrounded

(Fig. 6C-E). The new bone growth was

progressive and increased in all directions.

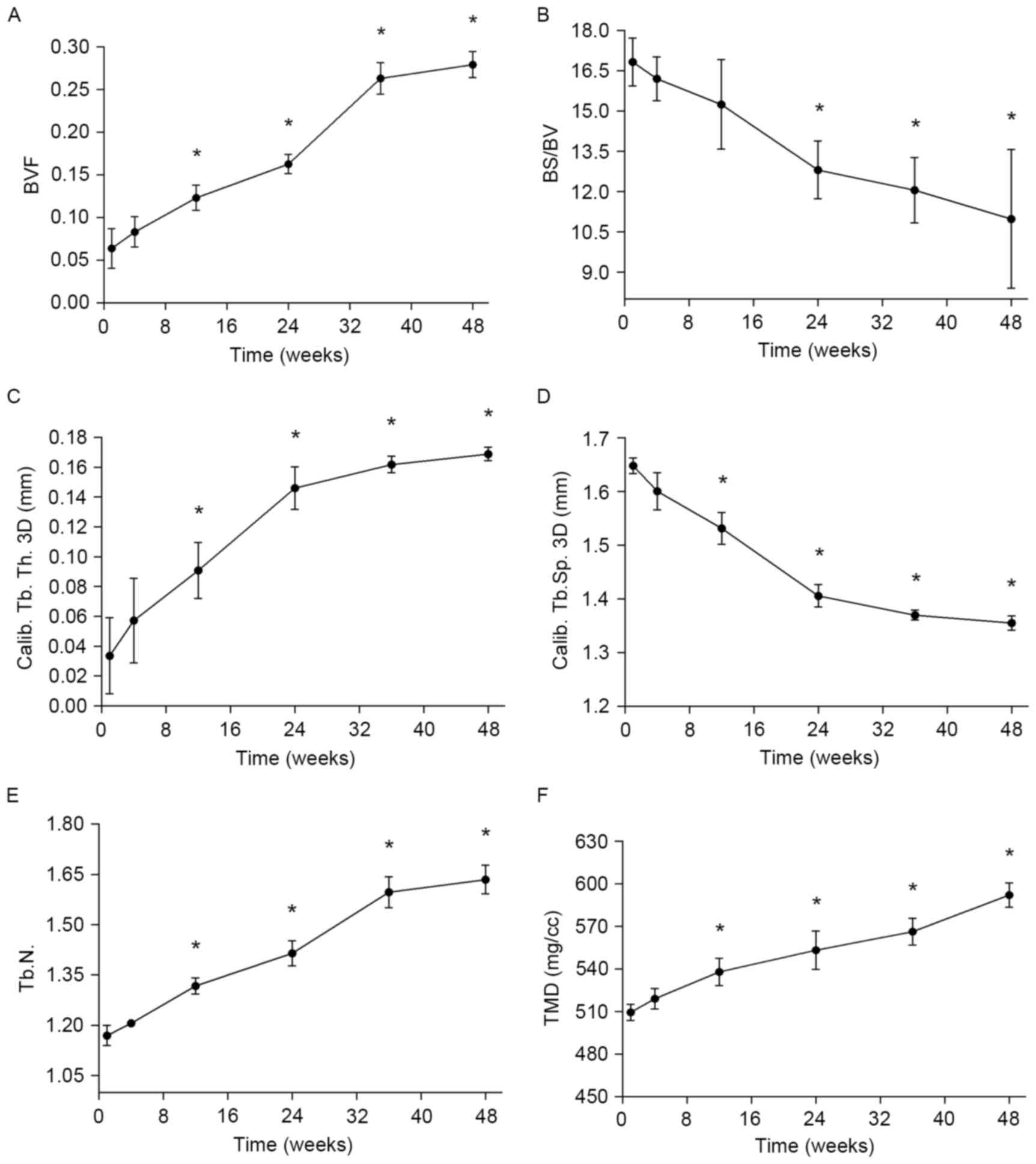

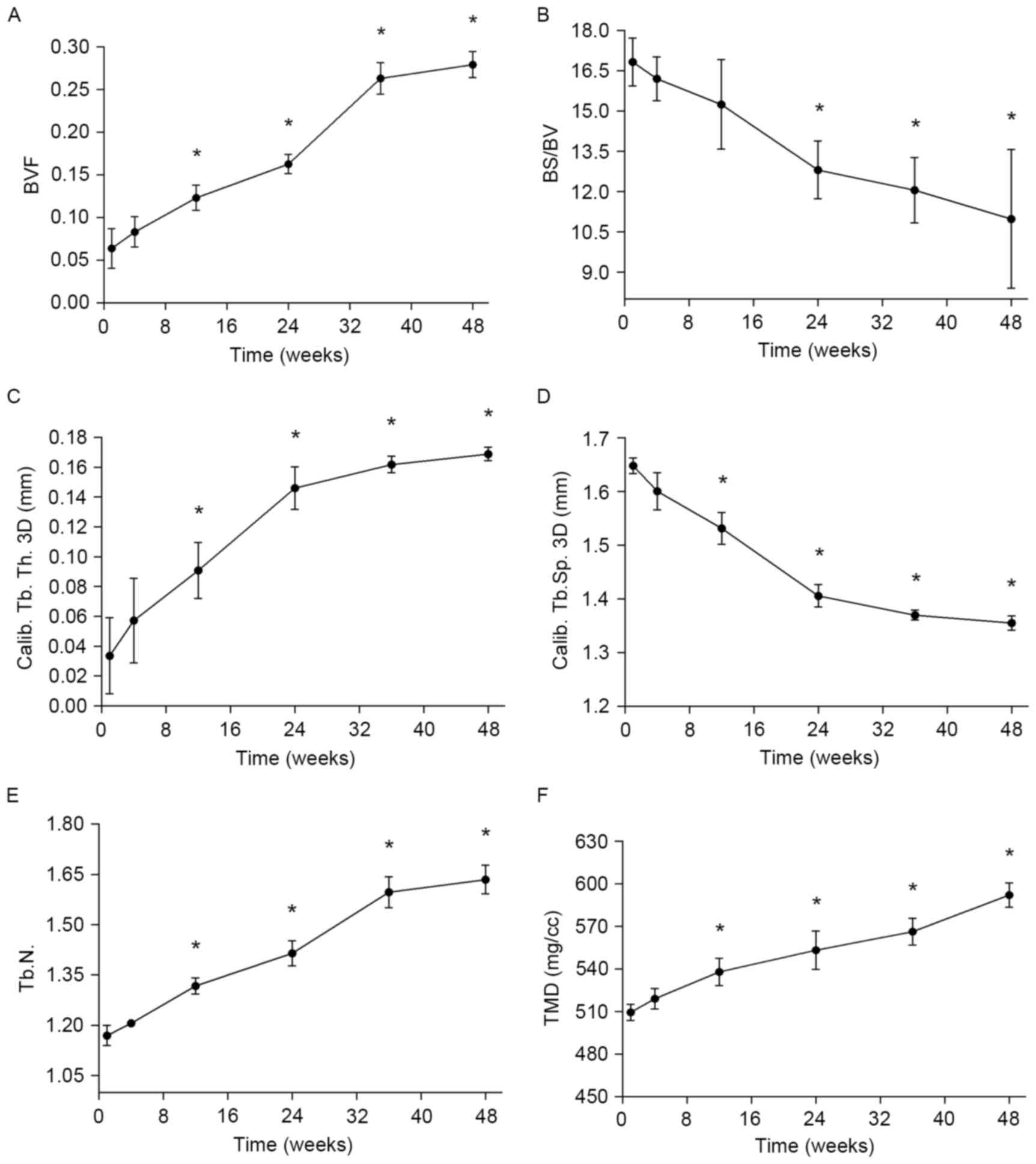

The data exported from the built-in software of the

micro-CT equipment provided further precise results (Fig. 7). As indicated in Fig. 7A, from week 12, BVF values were

significantly increased compared with the pre-implantation value

(P<0.05). In addition, it was observed that osteogenesis

increased slowly before week 24, while from week 24 to 36, the rate

of new bone formation markedly increased (Fig. 7A). This may have been due to a faster

corrosion rate and the stimulatory effects of released magnesium on

the growth of new bone tissue. From week 36 to 48, the increase in

BVF gradually slowed (Fig. 7A). This

may be explained, to some extent, by the new bone preventing the

magnesium alloy from degrading, to the disadvantage of further new

bone formation. As new bone was produced, the superficial area of

the ROI increased, and the ratio between the superficial area and

volume of new bone (BS/BV) decreased, with significantly lower

values of BS/BV observed from week 24 (P<0.05; Fig. 7B). This indicates that the new bone

was gradually transforming from cribrate to compact. Fig. 7C-E illustrates the thickness,

separation, and number of trabecular in the new bone over time. As

the pin degraded, trabecular thickness and number significantly

increased and separation significantly decreased from week 12

onwards (P<0.05; Fig. 7C-E).

Concurrently to these changes, the TMD of new bone surrounding the

pin significantly increased (Fig.

7F; P<0.05), indicating that the number of bones and new

bone density increased as magnesium degraded.

| Figure 7.In vivo bone formation around the

pins during the study period, assessed via micro-CT measurements.

(A) BVF, (B) BS/BV. (C) Calib. Tb.Th., (D) Calib. Tb.Sp., (E) Tb.N

and (F) TMD of new bone. *P<0.05 vs. prior to implantation. BVF,

bone volume fraction; BS/BV, bone surface/bone volume; Calib,

calibrated; Tb., trabecular; Th., thickness; Sp., separation; N.,

number; TMD, tissue mineral density. |

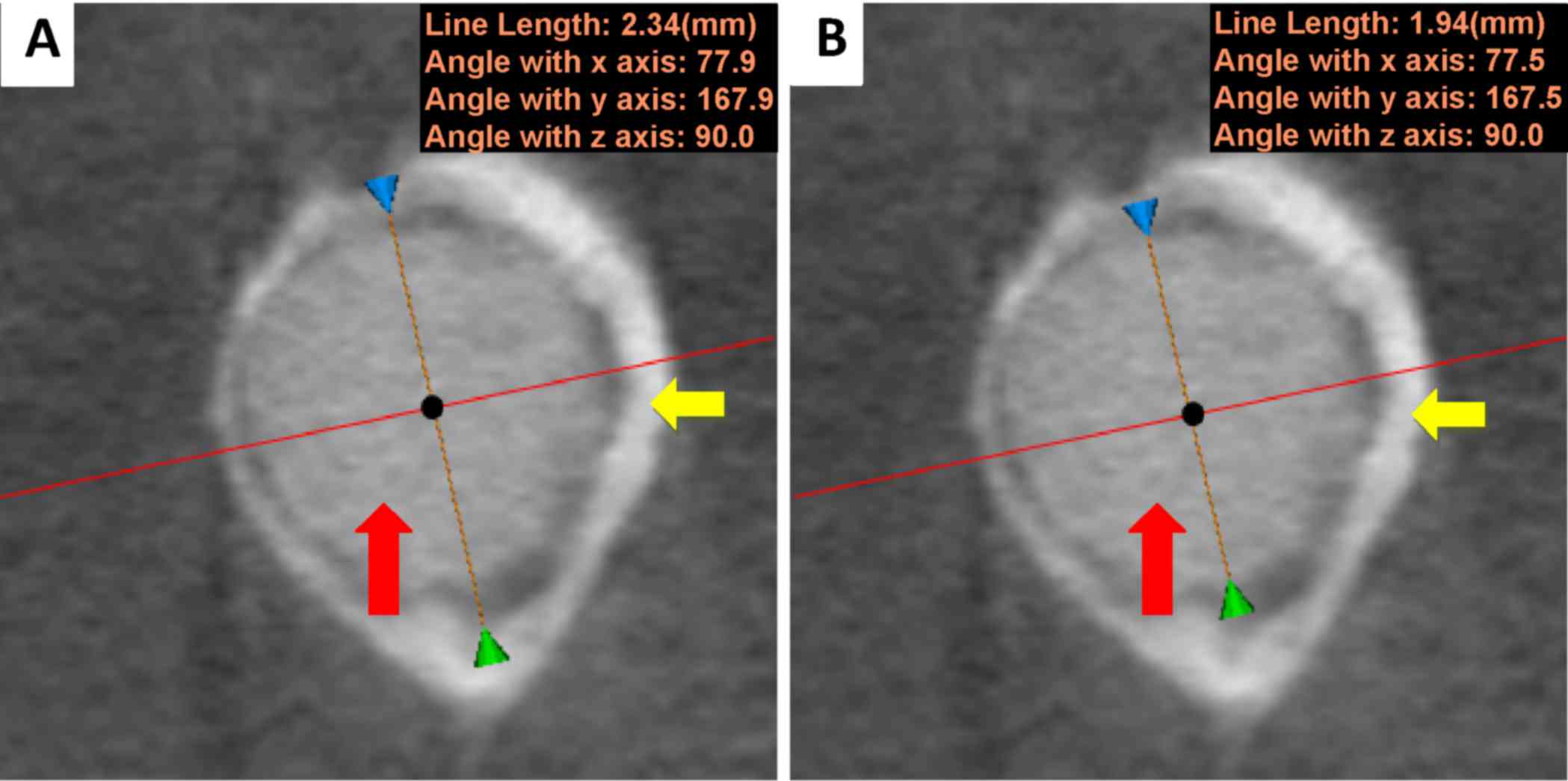

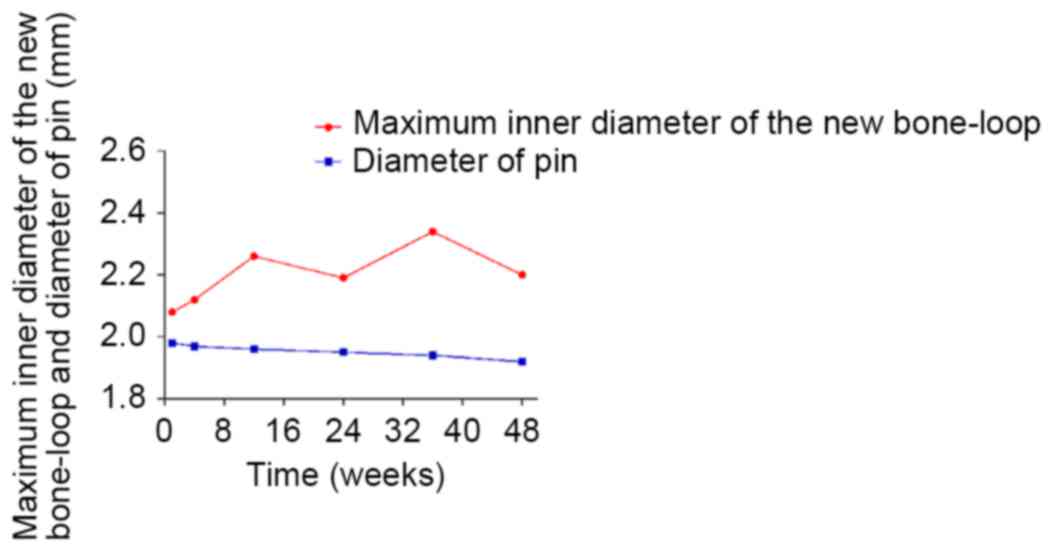

In the cross-section of the magnesium pin, the

maximum inner diameter of the new bone loop (Fig. 8A) and the diameter of the pin in the

same position (Fig. 8B) were

measured. During degradation, the diameter of the magnesium pin

decreased. Theoretically, a firm attachment between the pin and new

bone would cause the maximum inner diameter of the new bone loop to

diminish, possibly faster than the diameter of the pin. As depicted

in Fig. 9, the diameter of the

magnesium pin decreased with degradation, from 1.98 mm in week 1 to

1.92 mm in week 48; however, no trend was observed in the maximum

inner diameter of the new bone loop (max: 2.34 mm, week 36; min:

2.08 mm, week 1), instead of the expected downtrend. The two curves

indicated that bridges had not been not adequately created by bone

formation between the pin and surrounding tissues, although some

bone and tissue contacts had appeared. It is probable that the

biomaterials were not firmly attached to the surrounding tissues

due to inadequate holding forces. This suggests that the magnesium

alloy was not capable of creating sufficient bridges between the

bones and biomaterials when there were preexisting gaps.

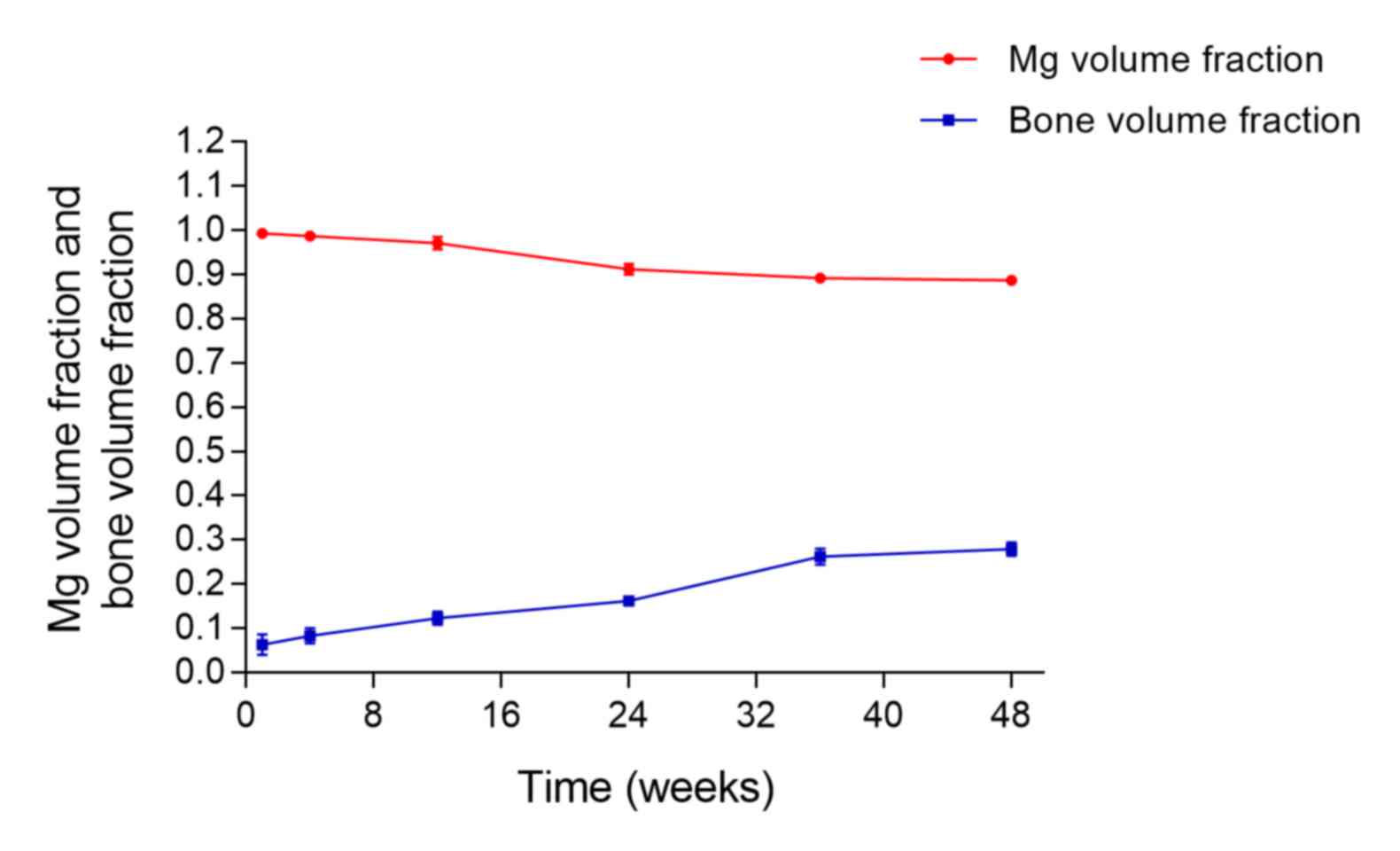

To investigate the association between material

degradation and novel bone formation, the changes in pin volume

fraction and bone volume fraction with time were plotted (Fig. 10). During the experiment, both rates

were slow, and from week 1 to week 48, the volume of the magnesium

alloy at each time point decreased by 10.58% (from 99.23 to

88.65%), whereas the volume of novel bone had increased by 21.54%

(from 6.39 to 27.93%). By the end of the study, there was no

intersection of the two curves (Fig.

10).

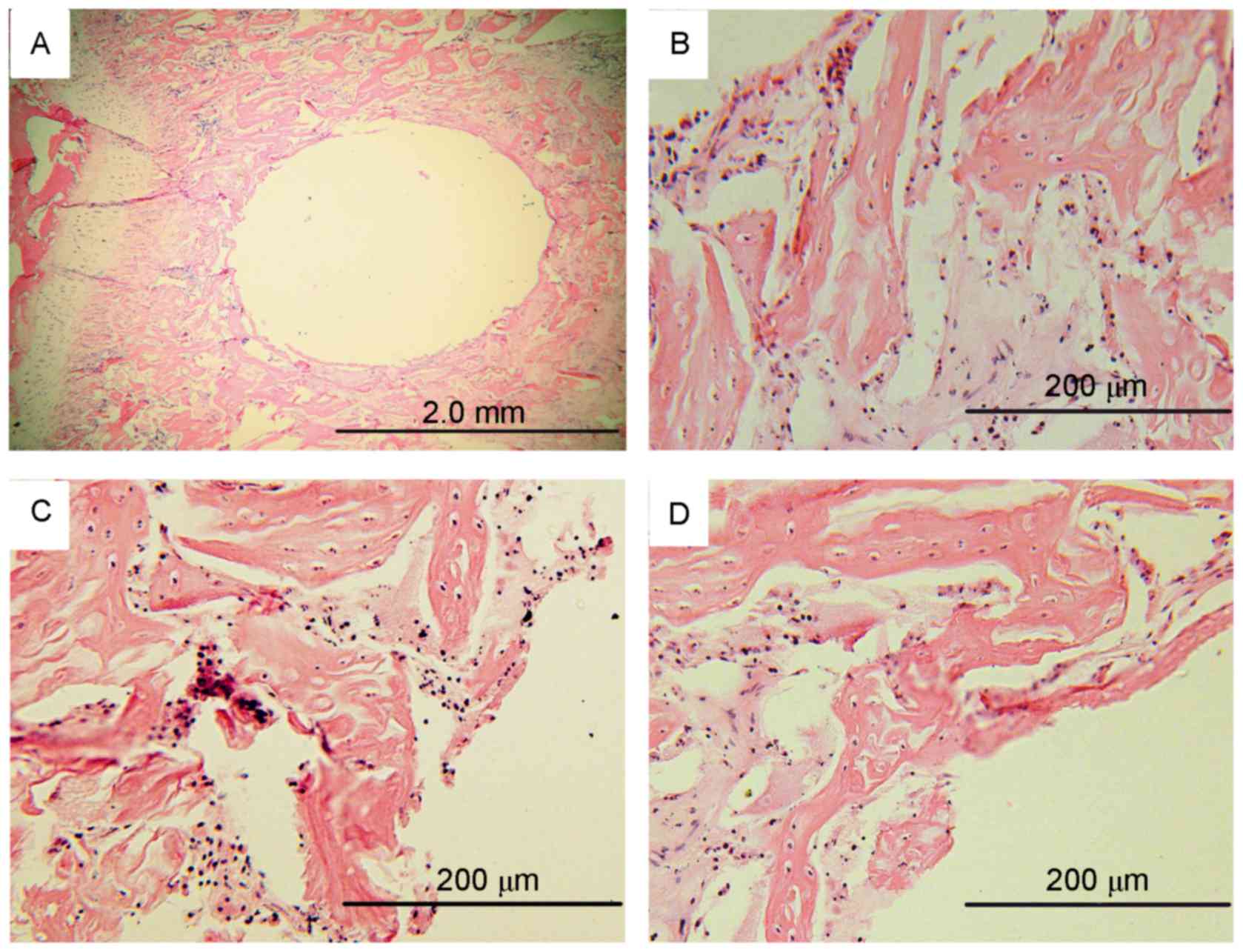

Histological evaluation

H&E staining was performed at weeks 4, 24 and

48. There were no apparent inflammatory cells surrounding the

implants; however, chondrocytes and osteocytes were observed. No

changes in the morphology of these cells between samples at 4, 24

and 48 weeks was observed (Fig.

11). Thus, there were no apparent inflammatory response around

the implants. These findings suggested that the AZ31 magnesium

alloys may be safe in human body.

Discussion

Metallic materials serve an essential role as

biomaterials for the repair or replacement of diseased bone.

Magnesium and its alloys have been investigated in recent years due

to their advantages over other materials, such as titanium alloys

and stainless steel (57,58). However, due to the electrochemical

activity of magnesium and its alloys in physiological solutions, it

is necessary to control the rate of corrosion for safe application

in the human body (59). Thus, the

development of suitable strategies to enhance the corrosion

resistance of magnesium alloys is important. A number of

preventative measures have been proposed and are being adopted to

overcome corrosion problems. While many previous studies have

focused on surface-modified magnesium alloys, protective coatings

must be nontoxic for orthopedic applications, and should ideally

improve the biocompatibility/bioactivity of the implant (1,3,59). In the present study, AZ31 magnesium

(alloyed with 3 wt.% Al, 1 wt.% Zn and 0.15 wt.% Mn) with a

micro-arc surface treatment was evaluated in vivo.

The degradation of the AZ31 magnesium alloy was

examined. It was demonstrated that, at 48 weeks, the total weight

loss of the magnesium was only 0.058 g, and the pin volume fraction

remained at 88.66%. This may have been due to the formation of new

bone around the pins, decreasing the rate of degradation at later

time points. In the first 4 weeks corrosion was slow, probably due

to protection by the micro arc-oxidized surface, whereas during

weeks 12 to 24, the surface of the magnesium alloy may have become

damaged, as indicated by an increase in corrosion. However, as the

alloy degraded, it is possible that high levels of released

magnesium stimulated the formation of new bone. After week 36, new

bone tissue around the pins formed an enclosed space, which may

have reduced contact between the pins and interstitial fluid and

again slowed degradation.

The weight fraction was calculated based on the

weight loss of the pins at each time point and compared with the

volume fraction. The two methods used to calculate the amount of

remaining pin were not wholly consistent; at each time point, the

quantity of magnesium corrosion by weight was greater than by

volume. Micro-CT is non-traumatic, which should improve the

accuracy of the results; however, the same precision cannot be

guaranteed with measurements based on weight loss. Prior to

weighing, pins were isolated from the femoral condyle, dry-machined

with cleaning tools, cleaned in ethanol in an ultrasonic bath and

dried in warm air (23). Each of

these steps may lead to a loss of material. Therefore, micro-CT was

selected as the gold standard in the present study. To investigate

the association between material degradation and new bone

formation, the changes in pin volume fraction and bone volume

fraction with time were plotted. During the experiment, both rates

were slow, and at the end of week 48, the volume of the magnesium

alloy had decreased by 10.58%, whereas the volume of new bone had

increased by 21.54%. However, by the end of the study, there was no

intersection of the two curves.

Magnesium exposed to a typical atmosphere will

develop a gray oxide film of magnesium hydroxide

[Mg(OH)2], which slows further corrosion (60,61).

Mg(OH)2 films are slightly soluble in water; however,

severe corrosion occurs in aqueous physiological environments where

chloride ions are present at levels (on the order of 150 mmol/l),

as Mg(OH)2 reacts with Cl− to form highly

soluble magnesium chloride and hydrogen gas (62). The following reactions summarize the

corrosion of magnesium (1,63):

Mg(s)+2H2O(aq) ↔

Mg(OH)2(s)+H2(g) (i)

Equations (ii)-(iv) show the partial reactions:

Mg(s) ↔

Mg2+(aq)+2e− (anodic reaction;

ii)

2H2O(aq)+2e− ↔

H2(g)+2 OH− (aq) (cathodic

reaction; iii)

Mg2+(aq)+2OH−(aq) ↔

Mg(OH)2(s) (product formation; iv)

This hydrogenation results in an alkaline

environment that raises the pH, which is harmful to cells and

decreases cell viability (64).

In the present study, implant degradation occurred

at a slower rate than expected. This potentially reduced the rate

of hydrogen gas production, and enabled the hydrogen to be absorbed

before it accumulated (65). The

micro-CT images identified a small amount of hydrogen gas around

the pins at weeks 4, 12 and 48 only, and no apparent trend was

observed.

The micro-CT results included both images and

numerical data. The images indicated the shape of the pins and the

corrosion pitting on the surface (black spots on the white surface

with high signals) at each time point, and new bone formation

around the pins. The numerical data indicated that the degradation

of magnesium pins had undergone a ‘slow-quick-slow’ process, and

that magnesium had stimulatory effects on the growth of new bone

tissue.

Micro-CT imaging and data analysis were used to

assess the consequences of degradation of micro-arc-oxidized AZ31

magnesium alloy used in bone implants. It also identified

increasing amounts of new bone around the alloy during the

experiment, and as the magnesium degraded, both the number of bones

and new bone density increased. The micro-CT data demonstrated

decreases in pin volume, mineral density, mean ‘pin thickness’,

BS/BV, Tb.Sp, and increases in pin surface area/pin volume, BVF,

Tb.Th, Tb.N and TMD, indicating a positive effect of magnesium on

osteogenesis. However, the data indicated that the magnesium alloy

was not capable of creating sufficient bridges between the bones

and biomaterials when there were preexisting gaps. In terms of the

biological safety, there were no apparent inflammatory responses

around the implants.

Overall, the results of the present study suggest

that the AZ31 magnesium had a long degradation period. Further

experiments should be performed to explore the degradation of AZ31

pins lacking prior surface treatment and the biomechanics of

magnesium alloys.

Acknowledgements

The present study was supported by the National

Science Foundation of China (grant nos. 81572148 and 51361130034),

the National Key Basic Research Development Program (973 Program;

grant no. 2012CB518106), the People's Liberation Army 12th

Five-Year Plan Period (grant no. BWS11J025), the People's

Liberation Army Key Scientific Research Program (grant no.

BWS13C029) and the Beijing Science and Technology Development

Foundation (grant no. Z141107004414044). The authors would like to

thank the Institutes for Food and Drug Control of China, the AVIC

Beijing Institute of Aeronautical Materials, Beijing Fule Science

& Technology Development Co., Ltd. and Beijing KEYU Animal

Experiment Center.

References

|

1

|

Staiger M, Pietak AM, Huadmai J and Dias

G: Magnesium and its alloys as orthopedic biomaterials: A review.

Biomaterials. 27:1728–1734. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Mantovani D and Witte F: The attraction of

a lightweight metal with mechanical properties suitable for many

applications brought a renewed focus on magnesium alloys in the

automotive and aerospace industries. Acta Biomater. 6:16792010.

View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Gordon LM and Joester D: Mapping residual

organics and carbonate at grain boundaries and the amorphous

interphase in mouse incisor enamel. Front Physiol. 6:572015.

View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Vladimirov BV, Krit BL, Lyudin VB,

Morozova NV, Rossiiskaya AD, Suminov IV and Epel'feld AV: Microarc

oxidation of magnesium alloys: A review. Surface Eng Applied

Electrochemistry. 50:195–232. 2014. View Article : Google Scholar

|

|

5

|

Windhagen H, Radtke K, Weizbauer A,

Diekmann J, Noll Y, Kreimeyer U, Schavan R, Stukenborg-Colsman C

and Waizy H: Biodegradable magnesium-based screw clinically

equivalent to titanium screw in hallux valgus surgery: Short term

results of the first prospective, randomized, controlled clinical

pilot study. Biomed Eng Online. 12:622013. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Yamako G, Chosa E, Totoribe K, Watanabe S

and Sakamoto T: Trade-off between stress shielding and initial

stability on an anatomical cementless stem shortening: In-vitro

biomechanical study. Med Eng Phys. 37:820–825. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Zielinski SM, Heetveld MJ, Bhandari M,

Patka P and Van Lieshout EM: FAITH Trial Investigators: Implant

removal after internal fixation of a femoral neck fracture: Effects

on physical functioning. J Orthop Trauma. 29:e285–e292. 2015.

View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Wong K, Yeung K, Lam J, Chu P, Luk K and

Cheung K: Reduction of corrosion behavior of magnesium alloy by PCL

surface treatment. Ors Ann Meeting. 2009;

|

|

9

|

Liu GY, Hu J, Ding ZK and Wang C:

Bioactive calcium phosphate coating formed on micro-arc oxidized

magnesium by chemical deposition. App Surface Sci. 257:2051–2057.

2011. View Article : Google Scholar

|

|

10

|

Kraus T, Fischerauer SF, Hänzi AC,

Uggowitzer PJ, Löffler JF and Weinberg AM: Magnesium alloys for

temporary implants in osteosynthesis: In vivo studies of their

degradation and interaction with bone. Acta Biomater. 8:1230–1238.

2012. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Zhang E: Phosphate treatment of magnesium

alloy implants forbiomedical applicationsSurface Modification of

Magnesium and its Alloys for Biomedical Applications. Narayanan

TSNS, Park IS and Lee MH: Woodhead Publishing; Waltham, MA: pp.

23–57. 2015, View Article : Google Scholar

|

|

12

|

Feng H, Wang G, Jin W, Zhang X, Huang Y,

Gao A, Wu H, Wu G and Chu PK: Systematic study of inherent

anti-bacterial properties of magnesium-based biomaterials. Acs App

Mater Interfaces. 8:9662–9673. 2016. View Article : Google Scholar

|

|

13

|

Warwick ME and Binions R: Advances in

thermochromic vanadium dioxide films. J Mat Chem A. 2:3275–3292.

2014. View Article : Google Scholar

|

|

14

|

Ko YM, Lee K and Kim BH: Effect of

functional groups on biodegradation and pre-osteoblastic cell

response on the plasma-polymerized magnesium surface. Jap J App

Phy. 52:20–21. 2013.

|

|

15

|

Sealy MP, Guo YB, Caslaru RC, Sharkins J

and Feldman D: Fatigue performance of biodegradable

magnesium-calcium alloy processed by laser shock peening for

orthopedic implants. Int J Fatigue. 82:428–436. 2016. View Article : Google Scholar

|

|

16

|

Sandip S, Asha K, Paulin G, Hiren S,

Gagandeep S and Amit V: A comparative study of serum uric acid,

calcium and magnesium in preeclampsia and normal pregnancy. J Adv

Res Biol Sci. 5:55–58. 2013.

|

|

17

|

Yoshizawa S, Brown A, Barchowsky A and

Sfeir C: Magnesium ion stimulation of bone marrow stromal cells

enhances osteogenic activity, simulating the effect of magnesium

alloy degradation. Acta Biomater. 10:2834–2842. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Yoshizawa S, Brown A, Barchowsky A and

Sfeir C: Role of magnesium ions on osteogenic response in bone

marrow stromal cells. Connect Tissue Res. 55 Suppl 1:S155–S159.

2014. View Article : Google Scholar

|

|

19

|

Castellani C, Lindtner RA, Hausbrandt P,

Tschegg E, Stanzl-Tschegg SE, Zanoni G, Beck S and Weinberg AM:

Bone-implant interface strength and osseointegration: Biodegradable

magnesium alloy versus standard titanium control. Acta Biomater.

7:432–440. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Johnson I, Akari K and Liu H:

Nanostructured hydroxyapatite/poly(lactic-co-glycolic acid)

composite coating for controlling magnesium degradation in

simulated body fluid. Nanotechnology. 24:3751032013. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Barfield WR, Colbath G, Desjardins JD, An

Yuehuei H, Hartsock and Langdon A: The potential of magnesium alloy

use in orthopaedic surgery. Curr Orthopaedic Practice. 23:146–150.

2012. View Article : Google Scholar

|

|

22

|

Seyedraoufi ZS and Sh M: Synthesis,

microstructure and mechanical properties of porous Mg-Zn scaffolds.

J Mech Behav Biomed Mater. 21:1–8. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Fischerauer SF, Kraus T, Wu X, Tangl S,

Sorantin E, Hänzi AC, Löffler JF, Uggowitzer PJ and Weinberg AM: In

vivo degradation performance of micro-arc-oxidized magnesium

implants: A micro-CT study in rats. Acta Biomater. 9:5411–5420.

2013. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Song G: Control of biodegradation of

biocompatable magnesium alloys. Corrosion Sci. 49:1696–1701. 2007.

View Article : Google Scholar

|

|

25

|

Chaya A, Yoshizawa S, Verdelis K, Myers N,

Costello BJ, Chou DT, Pal S, Maiti S, Kumta PN and Sfeir C: In vivo

study of magnesium plate and screw degradation and bone fracture

healing. Acta Biomater. 18:262–269. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Li H, Pan H, Ning C, Tan G, Liao J and Ni

G: Magnesium with micro-arc oxidation coating and polymeric

membrane: An in vitro study on microenvironment. J Mater Sci Mater

Med. 26:1472015. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Huang YS and Liu HW: TEM Analysis on

Micro-Arc Oxide Coating on the Surface of Magnesium Alloy. J Mat

Eng Perf. 20:463–467. 2011. View Article : Google Scholar

|

|

28

|

Ma WH, Liu YJ, Wang W and Zhang YZ:

Improved biological performance of magnesium by micro-arc

oxidation. Braz J Med Biol Res. 48:214–225. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Pan YK, Chen CZ, Wang DG and Yu X:

Microstructure and biological properties of micro-arc oxidation

coatings on ZK60 magnesium alloy. J Biomed Mater Res B Appl

Biomater. 100:1574–1586. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Han P, Tan M, Zhang S, Ji W, Li J, Zhang

X, Zhao C, Zheng Y and Chai Y: Shape and Site dependent in vivo

degradation of Mg-Zn pins in rabbit femoral condyle. Int J Mol Sci.

15:2959–2970. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Marukawa E, Tamai M, Takahashi Y,

Hatakeyama I, Sato M, Higuchi Y, Kakidachi H, Taniguchi H, Sakamoto

T, Honda J, et al: Comparison of magnesium alloys and

poly-l-lactide screws as degradable implants in a canine fracture

model. J Biomed Mater Res B Appl Biomater. 104:1282–1289. 2016.

View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Victor SP and Muthu J: Bioactive,

mechanically favorable, and biodegradable copolymer nanocomposites

for orthopedic applications. Mater Sci Eng C Mater Biol Appl.

39:150–160. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Walker J, Shadanbaz S, Woodfield TB,

Staiger MP and Dias GJ: Magnesium biomaterials for orthopedic

application: A review from a biological perspective. J Biomed Mater

Res B Appl Biomater. 102:1316–1331. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Yeung KW and Wong KH: Biodegradable

metallic materials for orthopaedic implantations: A review. Technol

Health Care. Sep 6–2012.(Epub ahead of print). PubMed/NCBI

|

|

35

|

Niu Y, Dong W, Guo H, Deng Y, Guo L, An X,

He D, Wei J and Li M: Mesoporous magnesium silicate-incorporated

poly(ε-caprolactone)-poly(ethylene glycol)-poly(ε-caprolactone)

bioactive composite beneficial to osteoblast behaviors. Int J

Nanomedicine. 9:2665–2675. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Hofstetter J, Martinelli E, Weinberg AM,

Becker M, Mingler B, Peter J, Uggowitzera J and Löffler JF:

Assessing the degradation performance of ultrahigh-purity magnesium

in vitro, and in vivo. Corrosion Sci. 91:29–36. 2015. View Article : Google Scholar

|

|

37

|

Witkowski M, Hubert J and Mazur A: Methods

of assessment of magnesium status in humans: A systematic review.

Magnes Res. 24:1632011.PubMed/NCBI

|

|

38

|

Schambach SJ, Bag S, Schilling L, Groden C

and Brockmann MA: Application of micro-CT in small animal imaging.

Methods. 50:2–13. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

39

|

Vanderoost J and van Lenthe GH: From

histology to micro-CT: Measuring and modeling resorption cavities

and their relation to bone competence. World J Radiol. 6:643–656.

2014. View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Karl-Göran Thorngren: Proceedings of the

Swedish Orthopedic Society Helsingborg, June 1–2, 1987. Acta Orth.

59:77–100. 1988. View Article : Google Scholar

|

|

41

|

Wang ZL, Yu S, Sether LA and Haughton VM:

Incidence of unfused ossicles in the lumbar facet joints: CT, MR,

and cryomicrotomy study. J Comput Assist Tomogr. 13:594–597. 1989.

View Article : Google Scholar : PubMed/NCBI

|

|

42

|

Kapadia RD, Stroup GB, Badger AM, Koller

B, Levin JM, Coatney RW, Dodds RA, Liang X, Lark MW and Gowen M:

Applications of micro-CT and MR microscopy to study pre-clinical

models of osteoporosis and osteoarthritis. Technol Health Care.

6:361–372. 1998.PubMed/NCBI

|

|

43

|

Ding M, Odgaard A and Hvid I: Accuracy of

cancellous bone volume fraction measured by micro-CT scanning. J

Biomech. 32:323–326. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Salmon P: Micro-CT 3D Image Analysis

Techniques for Orthopedic Applications: Metal Implant-to-Bone

Contact Surface and Porosity of BiomaterialsA Practical Manual For

Musculoskeletal Research. World Scientific Publishing Co. Pte.

Ltd.; Hackensack, NJ: pp. 583–603. 2008, View Article : Google Scholar

|

|

45

|

Rhee Y, Hur JH, Won YY, Lim SK, Beak MH,

Cui WQ, Kim KG and Kim YE: Assessment of bone quality using finite

element analysis based upon micro-CT images. Clin Orthop Surg.

1:40–47. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

46

|

Agholme F, Li X, Isaksson H, Ke HZ and

Aspenberg P: Sclerostin antibody treatment enhances metaphyseal

bone healing in rats. J Bone Miner Res. 25:2412–2418. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

47

|

Wang J, Bi L, Bai JP, et al: Comparative

study of micro-CT and histological section in bone morphometry.

Orth J Chin. 381–384. 009.(In Chinese).

|

|

48

|

Park CH, Abramson ZR, Taba M Jr, Jin Q,

Chang J, Kreider JM, Goldstein SA and Giannobile WV:

Three-dimensional micro-computed tomographic imaging of alveolar

bone in experimental bone loss or repair. J Periodontol.

78:273–281. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

49

|

Buie HR, Campbell GM, Klinck RJ, MacNeil

JA and Boyd SK: Automatic segmentation of cortical and trabecular

compartments based on a dual threshold technique for in vivo

micro-CT bone analysis. Bone. 41:505–515. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

50

|

Clark DP and Badea CT: Micro-CT of

rodents: State-of-the-art and future perspectives. Phys Med.

30:619–634. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

51

|

Chang CY, Huang AJ and Palmer WE:

Radiographic evaluation of hip implants. Semin Musculoskeletal

Radiol. 19:12–20. 2015. View Article : Google Scholar

|

|

52

|

Ding W: Opportunities and challenges for

the biodegradable magnesium alloys as next-generation biomaterials.

Regen Biomater. 3:79–86. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

53

|

Liu YJ, Yang ZY, Tan LL, Li H and Zhang

YZ: An animal experimental study of porous magnesium scaffold

degradation andosteogenesis. Braz J Med Biol Res. 47:715–720. 2014.

View Article : Google Scholar : PubMed/NCBI

|

|

54

|

World Health Organization (WHO), .

Strategic Initiative for Developing Capacity in Ethical Review.

WHO; Geneva: 2005

|

|

55

|

Wong RW, Rabie B, Bendeus M and Hägg U:

The effects of Rhizoma Curculiginis and Rhizoma Drynariae, extracts

on bones. Chin Med. 2:132007. View Article : Google Scholar : PubMed/NCBI

|

|

56

|

Feldkamp LA, Goldstein SA, Parfitt AM,

Jesion G and Kleerekoper M: The direct examination of

three-dimensional bone architecture in vitro by computed

tomography. J Bone Miner Res. 4:3–11. 1989. View Article : Google Scholar : PubMed/NCBI

|

|

57

|

Wang J, Witte F, Xi T, Zheng Y, Yang K,

Yang Y, Zhao D, Meng J, Li Y and Li W: Recommendation for modifying

current cytotoxicity testing standards for biodegradable

magnesium-based materials. Acta Biomater. 21:237–249. 2015.

View Article : Google Scholar : PubMed/NCBI

|

|

58

|

Chen X, Geng Y and Pan F: Research

progress in magnesium alloys as functional materials. Rare Metal

Mat Eng. 45:2269–2274. 2016. View Article : Google Scholar

|

|

59

|

Chen Y, Xu Z, Smith C and Sankar J: Recent

advances on the development of magnesium alloys for biodegradable

implants. Acta Biomater. 10:4561–4573. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

60

|

Weizbauer A, Kieke M, Rahim MI, Angrisani

GL, Willbold E, Diekmann J, Flörkemeier T, Windhagen H, Müller PP,

Behrens P and Budde S: Magnesium-containing layered double

hydroxides as orthopaedic implant coating materials An in vitro and

in vivo study. J Biomed Mater Res B Appl Biomater. 104:525–531.

2016. View Article : Google Scholar : PubMed/NCBI

|

|

61

|

Janning C, Willbold E, Vogt C, Nellesen J,

Meyer-Lindenberg A, Windhagen H, Thorey F and Witte F: Magnesium

hydroxide temporarily enhancing osteoblast activity and decreasing

the osteoclast number in peri-implant bone remodeling. Acta

Biomater. 6:1861–1868. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

62

|

Salahshoor M and Guo Y: Biodegradable

orthopedic magnesium-calcium (MgCa) alloys, processing, and

corrosion performance. Materials (Basel). 5:135–155. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

63

|

Weng L and Webster TJ: Nanostructured

magnesium has fewer detrimental effects on osteoblast function. Int

J Nanomedicine. 8:1773–1781. 2013.PubMed/NCBI

|

|

64

|

Hampp C, Ullmann B, Reifenrath J, Nina A,

Dina D, Dirk B, Jan-Marten S and Andrea ML: Research on the

biocompatibility of the new magnesium alloy LANd442-An in vivo

study in the Rabbit Tibia over 26 weeks. Advanced Engineering

Materials. 14:B28–B37. 2012. View Article : Google Scholar

|

|

65

|

Kuhlmann J, Bartsch I, Willbold E,

Schuchardt S, Holz O, Hort N, Höche D, Heineman WR and Witte F:

Fast escape of hydrogen from gas cavities around corroding

magnesium implants. Acta Biomater. 9:8714–8721. 2013. View Article : Google Scholar : PubMed/NCBI

|