Introduction

Monoclonal antibodies (mAbs) have revolutionised the

treatment of oncological and autoimmune diseases over the past 10

years. Moreover, they are also successfully used in the management

of asthma, hypersensitivity reactions, osteoporosis,

skeletal-related events in patients with bone metastases from solid

tumours, neovascular (wet) age-related macular degeneration,

hyperlipidaemia, and many others. According to data from the U.S.

National Institutes of Health and other publications, various

ongoing clinical studies look promising for indications like

Alzheimer's disease, infections, and type-1 diabetes (1,2).

According to our local drug registration database

(EU-Slovenia), there are currently 64 medical products that contain

40 active mAbs (data retrieved in November 2017). Among these, 39

are intended for intravenous administration, 22 for subcutaneous,

and one each for intramuscular and intravitreal administration. For

their pharmaceutical forms, 50 are solutions or concentrates for

solution, 13 are in the form of powder for solutions, and one is a

kit for radiopharmaceutical preparations for infusion. The data

from the Agency for Medicines and Medical Devices of the Republic

of Slovenia show a wide spectrum of the designs, forms and routes

of administration of pharmaceutical drugs. In the earlier years of

clinical use, these preparations were compounded by healthcare

professionals in controlled environments, and administered in

healthcare facilities. However, with the introduction of TNF-α

inhibitors in pre-filled syringes in the last 10 years, medicinal

products have left such controlled environments, and can now be

stored and administered by the patients themselves (3). Therefore, in many cases the

responsibility for the appropriate storage conditions has shifted

from the healthcare professional to the patients.

The correct handling of biologicals at all times is

extremely important, from their production to their being released

to the market. As protein molecules retain their biological

activities and pharmacokinetics and pharmacodynamics profiles only

when the higher-order protein structure is maintained, various

factors that can lead to immune reactions should be avoided. Risks

to protein stability can arise from not only a low percentage of

‘foreignness’ of the protein, but also from minimal product

impurities and the formation of aggregates during handling. These

can result in unwanted immunogenicity and anti-drug Ab responses in

the patient, with subsequent effects on their treatment outcome.

The desired clinical outcome can be lost through immune reactions,

creating the potential need to switch to another drug with a

different mechanism of action; e.g., a switch from a TNF-α

inhibitor to an interleukin-6 inhibitor in patients with rheumatoid

arthritis. Such loss of efficacy of a treatment and the subsequent

lower interest in a medication can be attributed to human as well

as clinical outcomes. Also, considering the high value of the these

medicinal products, there are economic consequences that should not

be ignored regarding the waste from discarded medicines, potential

unwanted side-effects, and the costs of new medicines and hospital

staff and facilities.

Potential instabilities of medicinal

products and pharmaceutical preparations containing monoclonal

antibodies

Compared to a broad range of known proteins, the

molecular structure of Abs provides them with one of the most

stable and resistant forms against changes to their environment.

However, due to their therapeutic use, even small deviations from

the native structure of these proteins can severely affect one or

more of the pharmaceutical standards of quality, efficacy and

safety of the therapeutic product.

The protein structure of therapeutic mAbs is highly

similar to the structure of Abs produced daily by lymphocyte B

cells in response to any invasion of microorganisms in our body.

The majority of the biotechnological pipelines provide Abs of the

IgG1k type (~150 kDa), although other derivatives are also

produced, such as certolizumab pegol (48 kDa pegylated Fab'

fragment) and radio-nuclide Ab drugs. The most important parts of

the IgG molecule that contribute to binding specificity with the

antigen are the CDR loops-the complementarity determining

regions-of the variable regions (Fig.

1). Small variations in the amino-acid side chains in CDR loops

can result in diversity of the molecular surface, and the

subsequent loss of recognition and specificity for binding to the

antigen.

Chemical instability

Oxidation

Although not all proteins are uniformly susceptible

to oxidative damage, oxidation remains one of the most important

mechanisms of covalent protein modification. This can lead to

altered or diminished biological functions because of

fragmentation, dimerisation, aggregation or denaturation of the

protein. The native conformation of proteins in a medicinal product

is usually protected by the addition of stabilisers. Oxidation

reactions are catalysed by free radicals, light, and trace amounts

of metal ions (4–8). Many studies have confirmed that

oxidation of cysteine or methionine in the Fc region can alter the

effector functions of mAbs, and decrease their binding to Fc

receptors on immune cells (9,10). The

amino-acids histidine, tyrosine and tryptophan are potential sites

of oxidation, and at the same time, they are also highly

concentrated in antigen-binding sites of Ab molecules (11). The effects of the oxidation of these

amino-acids in the binding regions have not been clearly defined to

date, although important alterations to Ab specificity and

proinflammatory activities have been reported in in-vitro studies

(12,13).

Deamidation

Deamidation is one of the most common modifications

to mAb structure, which introduces a high level of charge

heterogeneity into both their light and heavy chains. Removal of

the functional amide group from asparagine residues is generally

favoured, and to some extent also from glutamine. These reactions

are highly selective for individual Ab (14), and they have a detrimental effect on

potency if a negative charge is introduced into the antigen-binding

region (15).

Hydrolysis

Hydrolysis is a chemical process that affects the

primary structure of a protein, and it can result in loss of

protein conformation and mAb function. An example from the

literature shows that even when stored at 5°C, muromonab-CD3

(withdrawn in 2010) undergoes hydrolysis in the hinge region

between the cysteine in the variable region and the proline in the

Fc region (2). Today, such

hydrolysis of mAbs would not be expected under the conditions that

these medicinal products are exposed to during normal formulation

and storage (5), due to the use of

excipients.

Physical instability

During processing and handling of proteins, changes

in their molecule structure can result in many structural variants

of their conformation as they adapt to the changes in their

environment. Non-physiological conditions, shear stress, agitation

and stirring represent stress factors that are routinely

encountered during synthesis, purification, shipping and

preparation of such medicinal products. These structural changes

alter the physical properties of mAbs and can introduce physical

instability into the protein molecule. This can include adsorption

onto surfaces (e.g., containers, syringes, needles), unfolding and

formation of soluble aggregates, or formation of insoluble

precipitates. This instability will result in loss of efficacy of

the therapeutic protein, and also potential immunogenicity in

vivo.

In a complex, structure-function related protein, as

in the case of immunoglobulin, the different regions/domains

denature independently: The Fab region is more sensitive to heat

treatment, and the Fc region is more sensitive to lower pH

(16). Aggregates can form due to

changes to pH, ionic strength or surface tension, or to the

presence of organic solvents, although these are often reversible.

However, elevated temperature usually leads to irreversible

aggregation and loss of protein function. Aggregates are

organoleptically recognized as turbidity of a solution, although,

there can also be a period of transparency at the very beginning of

the nucleation process. Aggregation poses greater problems for the

use of pharmaceutical forms for subcutaneous and intramuscular

administration, where the protein concentrations in the solution

can reach 125 mg/ml, while the concentrates used for solutions for

infusion are usually lower, from 1 to 25 mg/ml. For

self-administration, a low solution volume is preferred due to

lower levels of site reactions and greater tolerability for the

patient (14).

Elevated temperatures

The stability of mAbs in pharmaceutical preparations

greatly depends on the temperatures they are exposed to. Longer

exposure to less-elevated temperatures mainly accelerates their

chemical instability. Studies have shown than a mAb exposed to 40°C

for 6 months mainly showed deamidation and hydrolysis (17). When mAbs are exposed to temperatures

near their unfolding temperature (defined as the temperature at

which 50% of the protein molecules are unfolded), the prevailing

instability mechanism is aggregation (4,5).

The stability of pharmaceutical preparations with

mAbs also depends on the pharmaceutical form (and consequently, the

use of excipients) and the properties of the protein itself. Ye

(18) exposed abciximab

(Reopro®) and trastuzumab (Herceptin®) to

temperatures up to 70°C for 15 min, and to room temperature for up

to 42 days. Under these conditions, 95% of abciximab was degraded

or aggregated with the 70°C treatment, while it remained stable at

room temperature; trastuzumab did not undergo any physical or

chemical changes under either condition. During the development of

equine venom Abs that are suitable for storage at room temperature

in climate zone IV, Segura et al (19) managed to achieve stability at 37°C

for 1 year using sorbitol and phenol as excipients.

Freeze-thaw cycles

The main mechanisms of protein instability during

their freezing and thawing result from their aggregation. This can

be due to their exposure to elevated concentrations of excipients

in the non-water phase [that do not freeze; (20)] and to pH changes (21), to their adsorption onto ice-liquid

interfaces or the walls of the vessels (5,22), as

well as gas-liquid interfaces caused by accelerated cooling

(23). The effects of freeze-thaw

cycles are also cumulative, where faster cooling can denaturate

proteins at rates up to 11-fold greater than seen for slower

cooling (24).

Protein stabilisation in pharmaceutical

forms

Diverse instability mechanisms are prevalent under

conditions that cause changes to pH or temperature. To achieve

greater stability and longer shelf-life of mAbs, these parameters

need to be adjusted accordingly during the development phase. The

U.S. Food and Drug administration criteria on stability of

pharmaceutical forms state that no more than 10% of the active

ingredient should deteriorate over 2 years (25).

Excipients

Various excipients are used in all mAb preparations

to assure their appropriate pharmacokinetics properties and

stability, to enable the formulation of the pharmaceutical product,

and to enhance the tolerability of the patient. Medicinal products

that contain mAbs are generally either powders for solutions or

concentrates for solutions for parenteral administration (Table I). Here, excipients are used to

maintain the pH (e.g., Tris, acetate, histidine, citrate buffers),

to enhance the protein stability and prevent oxidation (e.g.,

sugars, polyols), to achieve an appropriate viscosity, or to bind

metal ions and free radicals (e.g., chelators, antioxidants). Their

addition can therefore stabilise solutions or lyophilisates (see

section 3.2) over long periods of time (6).

| Table I.Roles of excipients used in powder

for concentrate for the solution for infusion with belimumab

(Benlysta®). |

Table I.

Roles of excipients used in powder

for concentrate for the solution for infusion with belimumab

(Benlysta®).

| Excipient | Role of the

excipient |

|---|

| Citric acid

monohydrate | Buffer

component-weak acid (pH regulation) |

| Sodium citrate | Buffer

component-strong base (pH regulation) |

| Sucrose | Cryoprotectant,

bulking agent |

| Polysorbate 80 | Surfactant |

Lyophilisation

Hydrophilic solutions provide a favourable milieu

for physico-chemical changes to proteins. Aqueous media allow the

transfer of the electrons needed for oxidation and deamidation

reactions, and have an important role in protein aggregation. The

exclusion of water from pharmaceutical forms can therefore provide

important enhancement to the stability of proteins (14). The most commonly used method for this

water exclusion is the three-phase process of freeze-drying,

lyophilisation, and addition of cryoprotectants.

Unwanted immunogenicity of biologicals that

contain monoclonal antibodies

In general, the immunogenicity of drugs refers to

the formation of Abs against a certain drug (i.e., anti-drug Abs;

ADAs). All such biologicals can potentially induce unwanted immune

responses that can activate the mechanisms of innate and acquired

immunity. It has been recognized that mAb drugs or their novel mAb

derivatives (e.g., Fab fragments, scFv, nanobodies, fusion

proteins) can induce both humoral and cellular immune responses.

ADAs can alter the pharmacokinetics, pharmacodynamics and

bioavailability of mAbs, thus affecting the safety and efficacy of

these drugs.

There are two main mechanisms of immunogenicity: i)

activation of classical immune reactions that are triggered by

foreign proteins, which results in synthesis of ADAs and induction

of memory cells, and leads to enhanced reactions upon rechallenge

(26); and ii) breach of B-cell and

T-cell immune tolerance. The clinical consequences of these can

vary widely among individuals, and they are mostly unpredictable.

The major safety concerns related to immunogenicity are induction

of anaphylaxis, cytokine storms (the rapid release of

proinflammatory cytokines), serum sickness disease, and delayed

hypersensitivity. These can be accompanied by various clinical

symptoms, including fever, rash, myalgia, haematuria, proteinuria

and haemolytic anaemia, and can even induce autoimmune

reactions.

Two types of ADA responses have been defined: i)

Neutralising or blocking Abs (NAbs) which block the effects of the

exogenous drug or destroy the drug itself. These can neutralise the

biological activity of the drug by either blocking the cell-surface

molecule needed for its activity, or interfering with the binding

of the drug to its receptor on the target cells; and ii) binding

Abs, which (BAbs) bind to the drug but do not sterically hinder its

biological actions (27).

However, many studies have confirmed the altered

pharmacokinetics of a drug due to the formation of the immune

complex between the drug and the binding Ab, and the resulting

enhanced clearance (27–29). The levels of neutralising/blocking or

binding Abs that are produced depend on the dose and the frequency

and mode of injection or application of a drug (i.e., skin >

intramuscular > intravenous > per os). There was a well-known

case in 1998 where an increase in the incidence of pure red-cell

aplasia (PRCA) was associated with the formation of

anti-erythropoietin Abs after subcutaneous use of epoetin alpha

(Eprex®) in patients under chronic dialysis (30). Also, in 2006, a phase I clinical

study was being conducted for a humanised CD28 superagonist Ab,

TGN1412, as a potential drug candidate for the treatment of B-cell

lymphoma and rheumatoid arthritis. Within 8 h of the first infusion

at a dose 500-fold more dilute than that shown to be safe in animal

studies, all six of the human volunteers faced multiorgan failure.

This was later recognized to have been the result of cytokine storm

(31).

The earliest mAbs used as drugs originated from

mice, and their degree of ‘foreignness’ was a pivotal force for

development of immunogenicity. Indeed, overall some 90% of these

treated patients produced human anti-mouse Abs (32), which greatly diminished the clinical

objectives. The second generation of mAbs were chimeric mAbs, which

were fusions between the murine epitope-specific variable region

and the human constant region, and were produced by genetic

engineering methods. These Abs were much more successful for

therapeutic purposes. This technological advance from murine origin

to humanised Abs greatly improved their in vivo

tolerability, although 50% of treated patients still produced human

anti-chimeric Abs (HACA) (32).

The more recent production of fully human Abs

further decreased the unwanted immune response, although

anti-idiotypic response remain, which might influence the outcome

of immune responses. Anti-idiotypic Abs are raised against the

antigen-binding site because the individual T-cell receptors and

immunoglobulins are also immunogenic by virtue of the unique

sequence within their variable regions. Therefore, even with human

mAbs it is not reasonable to expect immunogenicity rates of zero,

as this can be affected by numerous patient-related and

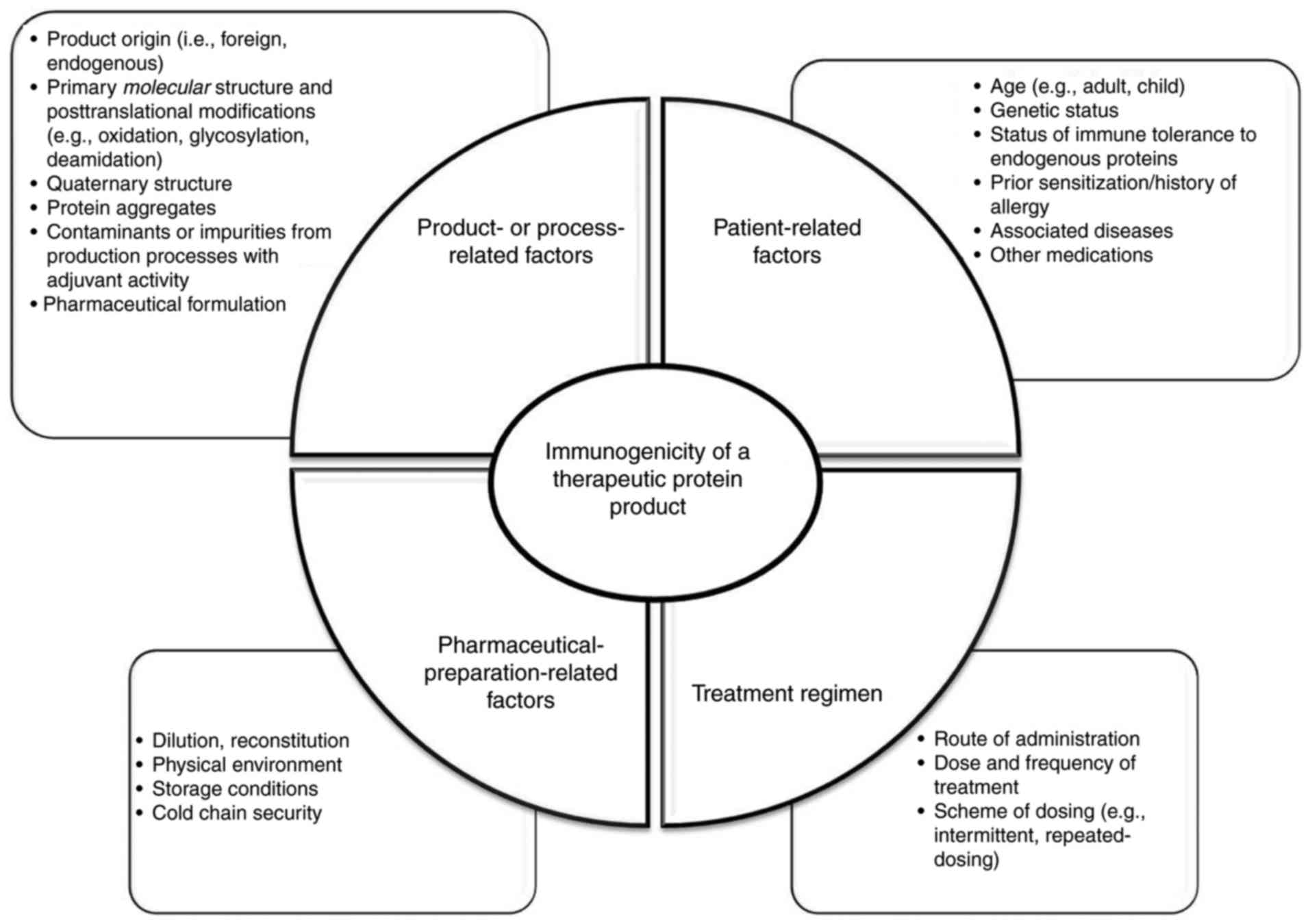

product-related factors (Fig. 2).

Aggregation, polymerization, denaturation or partial unfolding of

native proteins, expose neoepitopes, cryptic epitopes or repeated

epitopes. Subsequent immune response to the aggregates involves

previously mentioned mechanisms of the immunogenicity.

Protein aggregates in the size range of 0.1–10 µm

are believed to be the most immunogenic (33). Recently, new animal testing methods

have been developed that together with in-silico predication

models, can provide additional help to explain potential

immunogenicity (34,35). For mAbs intended for in-vivo

clinical use, the European Medicines Agency has issued regulatory

guidance about screening and confirmatory assays, as well as risk

assessment (EMA/CHMP/BMWP/86289/2010). Precise control of the

manufacturing processes with concomitant systematic evaluation of

immunogenicity would help to bridge this gap between product

quality and clinical immunogenicity and understanding of the

complex immune responses to mAbs. Due to the biological variability

and broad spectrum of biological agents that contain mAbs, their

different origins and different manufacturing processes, the ‘one

size-fits all’ strategy is no longer acceptable. Therapies should

be personalised and adapted to the individual patient, and

supported by therapeutic drug monitoring. Together with the assured

quality of mAb drugs, this will assure optimal treatment efficacy

with minimal toxicity.

Handling of biologicals

The main critical phases that can affect the

stability of mAb biologicals include the transportation and storing

of these medicinal products, and the reconstitution of

pharmaceutical preparations. Handling by the patient or a caregiver

can also prove critical, as the medicinal products are no longer

kept in a controlled environment.

Handling by pharmacy staff and

healthcare professionals

The transport to the healthcare provider is well

established, with the maintenance of the cold-chain conditions, and

this does not generally represent a risk to a medication. We

therefore describe here critical preparation steps and procedures

after the delivery of a biological to a healthcare facility. In

1976, the Breckenridge report stated that if possible, all

parenteral pharmaceutical preparations administered to a patient

should be compounded centrally in a hospital pharmacy, to ensure

patient safety and maintain the sterility of the final product

(36). The U.K. National Health

Service guidelines HC(76)9 from 2008, the American Society of

Clinical Oncology guidelines from 2012, and the South Australian

Health Service guidelines from 2015 all added pharmaceutical

preparations with mAbs used for oncological indications to their

list of medications that should be compounded in the hospital

pharmacy setting. In rare cases, where centralised preparation is

neither possible nor feasible, such preparations can be carried out

by a specially trained nurse (37).

Even though the establishing of a clean room is

associated with high costs, this investment returns through

rationalisation of the use of high-cost medicinal products that

contain mAbs. This is achieved by using large-volume vials and

being able to store the unused drug through the use of aseptic

conditions. The dosing of mAbs is usually based on patient weight

or body surface area. Due to limitations in the availability of

such powders or solutions of mAbs, during on-ward preparation, the

unused drug has to be discarded, according to the manufacturer

instructions.

The preparation of intravenous pharmaceutics should

be carried out by a pharmacy technician under the supervision of a

registered pharmacist, and more recently this can be guided by

specific compounding computer software. Two methods are commonly in

use. For volumetric preparation, every addition of a drug to the

base solution has to be confirmed by a pharmacist. As this requires

additional staff, more recently the gravimetric method is in

greater use as the workflow is guided by a predefined protocol

provided by the computer software (BD Cato™ medication

workflow solutions compounding), and the validity of every step

involving additions of the drug is confirmed by weighing. The use

of bar codes, defined drug solution densities, and predefined

tolerance levels, can exclude the human factor, and this ensures

the traceability and safety of every pharmaceutical preparation, as

well as providing better management of the unused drug.

Nevertheless, both methods require skilled staff who have undergone

training for working under aseptic conditions, as well as for

handling of medicinal products containing mAbs.

Especially in cases where prescriptions are not

verified in the pharmacy, it is crucial that medical doctors

consider incompatibility issues regarding medicinal products with

mAbs, such as the use of the correct dilution media and the

concentration ranges needed. In some cases, it is recommended that

the patients receive premedication prior to administration. Also,

administration of medicinal products with mAbs can be accompanied

by various adverse reactions. Again, it is crucial for physicians

to recognize and manage these. Based on local guidelines, medical

doctors are usually obligated to report these adverse reactions.

The European Medicines Agency pharmacovigilance legislation has

also placed mAbs under so-called ‘additional monitoring’, and these

medicines are labelled with an inverted black triangle to encourage

healthcare professionals, and especially medical doctors, to report

any suspected adverse effects (EMA/169546/2012).

Practical points for pharmacists and

healthcare professionals

i) Elevated temperature. All currently commercially

available pharmaceutical forms that contain mAbs have to be kept

between 2 and 8°C until the compounding of the pharmaceutical

preparation, or the administration of the drug itself (Agency of

the Republic of Slovenia for Medicines and Medical Devices). It is

highly unlikely that a product with mAbs would be exposed to

temperatures that would threaten their instability during storage

in a pharmacy, except in the case of refrigerator failure.

In rare cases, when such a product is accidentally

exposed to elevated temperatures, the manufacturer should be

consulted to obtain the necessary stability studies data, to

determine whether the drug is safe or should be discarded.

ii) Freeze-thaw cycles. Although medical products

with mAbs are not expected to be subjected to freeze-thaw cycles

after the formulation of the final drug product, the possibility of

accidental freezing cannot be fully ignored.

iii) Reconstitution of lyophilisates. The required

solvent should be added slowly to a lyophilisate that contains

mAbs, to minimise foaming and promote the formation of the native

conformation of the protein. During lyophilisation, the protein

molecules can form certain non-native conformations, due to

interactions with the molecules that substitute the water during

this process (14). Solvation can be

accelerated with rotation of the vial around its axis. Newer

medicines with lyophilised powders also provide the end-user with

parameters for use with mechanical reconstitution devices (European

Medicines Agency, Summary of product characteristics Benlysta). The

reconstitution of pharmaceutical preparations from lyophilisates is

technically challenging and time consuming.

iv) The effects of interfaces and adsorption.

Manufacturers often state that the shaking of vials with

concentrates for infusions and with the pharmaceutical preparations

themselves should be avoided. Solutions of mAbs can be exposed to

an air-liquid interface while shaking, and also during removal from

the vial and addition into the dilution medium. The transfer from a

syringe should be as slow as feasible, with the needle always

submerged in the dilution medium to avoid unnecessary contact of

the solution with the air. It has become common practice to use

polymer spikes with separate channels for fluid transfers and

air-pressure equalisation. These are usually equipped with 0.22 or

0.45-µm hydrophobic air filters (38). Before removal of an Ab solution from

the vial or after its reconstitution, the solution has to be

visually checked for turbidity or the presence of floating

non-transparent particles that indicate protein aggregation. Newer

products that are prepared for longer periods of use (e.g., up to

96 h) can include a separate stabilising solution that is added to

the infusion bag immediately before preparation of the

pharmaceutical (European Medicines Agency, Summary of product

characteristics Blincyto).

v) Protection from light. Until the compounding of

the pharmaceutical preparation, the medicinal products containing

mAbs are kept in secondary packaging to protect the solution from

light. Should the duration of administration to the patient last

several hours, the pharmaceutical preparation should be further

protected from light. The same applies to any remaining solutions

kept in preparation areas.

vi) Long-term stability of pharmaceutical

preparations with mAbs. There are several situations when a

solution that contains a mAbs cannot be administered immediately

after its preparation. The manufacturers define the time limits in

which prepared infusions or injections should be used if they were

not prepared under aseptic conditions. Pharmaceutical preparations

with mAbs do not contain preservatives. If preparations have been

compounded under validated aseptic conditions, these periods can be

longer. It appears that even for aseptic preparations, storage

times for diluted solutions are based on microbiological integrity,

rather than physico-chemical stability. For example, for diluted

rituximab solutions, the manufacturer states that these are

physically and chemically stable for up to 24 h at temperatures

between 2 and 8°C, and then for an additional 12 h at room

temperature (European Medicines Agency, Summary of product

characteristics MabThera). On the other hand, Paul et al

(39) reported that 1% rituximab

solutions in 0.9% NaCl stored at 4°C for 6 months did not show any

physical or chemical instability. The direct cytotoxic effects of

rituximab were also fully retained. The availability of

ready-to-use solutions with mAbs that are prepared in a controlled

environment by the manufacturers themselves would cut the

healthcare staff preparation costs and lessen their burden.

Handling by patients

The use of medicinal products containing mAbs for

self-administration has steadily been rising worldwide. As more

prescriptions for medications with mAbs are filled, the number of

patients or caregivers that handle them also rises. All of these

people should be properly informed about the concept of the cold

chain, and they should know to follow the recommendations of the

manufacturers and healthcare professionals.

The number of prescriptions dispensed and the total

cost of medicines in Slovenia are given in Table II. The rise of prescriptions filled

in 2012 and 2013 without a corresponding rise in costs can be

attributed to the use of denosumab in the prevention of

osteoporosis. The unusual increase in the number of prescriptions

filled in 2015 can be attributed to changes in dispensing

regulations, where most medicinal products that contain mAbs can

now only be dispensed for 1 month at a time, instead of the

previous 3 months limit (Health Insurance Institute of

Slovenia).

| Table II.Details of prescriptions filled for

medicinal products containing mAbs for self-administration in

Slovenia EU (estimated population, ~2 million) from 2004 to

2016.a |

Table II.

Details of prescriptions filled for

medicinal products containing mAbs for self-administration in

Slovenia EU (estimated population, ~2 million) from 2004 to

2016.a

| Year | Number of

prescriptions | Total value

(€) |

|---|

| 2004 |

278 |

150,697 |

| 2005 |

827 |

1,154,331 |

| 2006 |

1,308 |

2,370,870 |

| 2007 |

1,966 |

4,491,672 |

| 2008 |

2,495 |

7,432,900 |

| 2009 |

3,367 | 10,854,609 |

| 2010 |

4,185 | 13,284,280 |

| 2011 |

7,490 | 17,141,873 |

| 2012 | 14,133 | 21,542,757 |

| 2013 | 20,115 | 24,701,471 |

| 2014 | 27,330 | 26,892,197 |

| 2015 | 39,507 | 30,276,936 |

| 2016 | 50,233 | 31,996,181 |

The first time a patient receives a medicinal

product that contains mAbs, they are usually given a package that

is prepared by the manufacturer. This contains information about

the safety of the drug and several practical aspects of its

handling. The roles of all of the healthcare professionals involved

in the care of a patient include the education of patients about

the correct transport and storage of their drug. The risks include

both the low and high temperatures that medicines can be exposed

to.

The conditions when a medicinal product containing

mAbs might be exposed to higher temperatures, and especially those

above the protein unfolding temperature, are frequent in the warmer

months of the year. The temperatures inside vehicles exposed to

direct sunlight can reach 90°C in summer and 60°C in spring and

autumn (40). Although these maximum

temperatures were measured on sunny days, on cloudy summer days the

temperatures are only 10°C lower (40). The colour of a vehicle is not a major

contributing factor. The patient has to be informed that the

transport time from the pharmacy should be as short as possible,

and that the medicine should not be left in a vehicle for long

periods under any conditions. Even greater risk is posed by

refrigerators used for storing medicines at the home of the

patient. As it would be unrealistic to expect that patients have a

medical-grade refrigerator for the sole purpose of storing their

medicinal products, these are mostly kept in domestic

refrigerators. Domestic refrigerators use heat exchange via the

walls, where the chilling liquid runs through. The temperature near

the walls where the heat exchangers are placed can reach −5°C

(41), while for the doors or in the

corners of the refrigerator, this can rise to 15°C (42). Domestic refrigerators also work in

cycles that can pose additional risks to medicines, and especially

those kept near the wall. As temperature can vary from below to

above freezing point, a medicine might be subjected to freeze-thaw

cycles. Patients are advised to keep medicines in the central part

of the refrigerator, where the temperature is closest to the

pre-set temperature (42), and to

frequently monitor the temperature conditions using a

thermometer.

Conclusions

Various factors have to be taken into consideration

to assure the maximum safety of medicinal products containing mAbs.

Current guidelines recommend compounding of pharmaceutical

preparations with mAbs under the controlled aseptic conditions of

the hospital pharmacy, with this performed by trained and

experienced pharmacy staff. As well as chemical and physical

reactions, a panel of patient characteristics and degrees of

‘foreignness’ of a protein are important for individual treatments.

The main goal is to determine the bioavailability and to use data

on unwanted immunogenicity to optimise the therapeutic dose for

each individual while reducing possible immune reactions and

preventing incorrect therapy choice. Due to the high economic cost

of these biologicals and to safety concerns because of potential

protein instability, healthcare professionals (i.e., medical

doctors, nurses, pharmacists) have to be properly and continuously

educated in terms of the prescribing and preparation of biological

medicinal products. Furthermore, their knowledge should also be

transferred to the patient, to ensure the correct handling of these

medicinal products at home. Where adverse reactions do occur, it is

highly recommended that they are reported, according to local

legislation. Only with strict and regular supervision all the way

from production to final use will a medicinal products that

contains mAbs provide the desired clinical, humanistic and economic

effects designed for the therapy.

Acknowledgements

The authors acknowledge Dr. Chris Berrie for editing

of the manuscript.

References

|

1

|

Das G and Rees A: Use of monoclonal

antibodies for proprotein convertase subtilisin kexin type 9

inhibition: Issues with efficacy, tolerability and safety. Curr

Opin Lipidol. 25:96–98. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Elvin JG, Couston RG and van der Walle CF:

Therapeutic antibodies: Market considerations, disease targets and

bioprocessing. Int J Pharm. 440:83–98. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Shukla D, Schneider CP and Trout BL:

Molecular level insight into intra-solvent interaction effects on

protein stability and aggregation. Adv Drug Deliv Rev.

63:1074–1085. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Wang W: Instability, stabilization, and

formulation of liquid protein pharmaceuticals. Int J Pharm.

185:129–188. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Berrill A, Biddlecombe J and Bracewell D:

Product quality during manufacture and supplyPeptide and protein

delivery. Chris Van Der W: Academic Press; Boston, MA: pp. 313–339.

2011, View Article : Google Scholar

|

|

6

|

Kamerzell TJ, Esfandiary R, Joshi SB,

Middaugh CR and Volkin DB: Protein-excipient interactions:

Mechanisms and biophysical characterization applied to protein

formulation development. Adv Drug Deliv Rev. 63:1118–1159. 2011.

View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Bee JS, Nelson SA, Freund E, Carpenter JF

and Randolph TW: Precipitation of a monoclonal antibody by soluble

tungsten. J Pharm Sci. 98:3290–3301. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Davies MJ: The oxidative environment and

protein damage. Biochim Biophys Acta. 1703:93–109. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Margiloff L, Chaplia L, Chow A, Singhal PC

and Mattana J: Metal-catalyzed oxidation of immunoglobulin G

impairs Fc receptor-mediated binding to macrophages. Free Radic

Biol Med. 25:780–785. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Liu D, Ren D, Huang H, Dankberg J,

Rosenfeld R, Cocco MJ, Li L, Brems DN and Remmele RL Jr: Structure

and stability changes of human IgG1 Fc as a consequence of

methionine oxidation. Biochemistry. 47:5088–5100. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Mian IS, Bradwell AR and Olson AJ:

Structure, function and properties of antibody binding sites. J Mol

Biol. 217:133–151. 1991. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Dimitrov JD, Ivanovska ND,

Lacroix-Desmazes S, Doltchinkova VR, Kaveri SV and Vassilev TL:

Ferrous ions and reactive oxygen species increase antigen-binding

and anti-inflammatory activities of immunoglobulin G. J Biol Chem.

281:439–446. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Omersel J, Jurgec I, Cucnik S, Kveder T,

Rozman B, Sodin-Semrl S and Bozic B: Autoimmune and proinflammatory

activity of oxidized immunoglobulins. Autoimmun Rev. 7:523–529.

2008. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Daugherty AL and Mrsny RJ: Formulation and

delivery issues for monoclonal antibody therapeutics. Adv Drug

Deliv Rev. 58:686–706. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Huang L, Lu J, Wroblewski VJ, Beals JM and

Riggin RM: In vivo deamidation characterization of monoclonal

antibody by LC/MS/MS. Anal Chem. 77:1432–1439. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Vermeer AW and Norde W: The thermal

stability of immunoglobulin: Unfolding and aggregation of a

multi-domain protein. Biophys J. 78:394–404. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Liu H, Gaza-Bulseco G and Sun J:

Characterization of the stability of a fully human monoclonal IgG

after prolonged incubation at elevated temperature. J Chromatogr B

Analyt Technol Biomed Life Sci. 837:35–43. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Ye H: Simultaneous determination of

protein aggregation, degradation, and absolute molecular weight by

size exclusion chromatography-multiangle laser light scattering.

Anal Biochem. 356:76–85. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Segura A, Herrera M, González E, Vargas M,

Solano G, Gutiérrez JM and León G: Stability of equine IgG

antivenoms obtained by caprylic acid precipitation: Towards a

liquid formulation stable at tropical room temperature. Toxicon.

53:609–615. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Arakawa T, Prestrelski SJ, Kenney WC and

Carpenter JF: Factors affecting short-term and long-term

stabilities of proteins. Adv Drug Deliv Rev. 46:307–326. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Wang W, Nema S and Teagarden D: Protein

aggregation-pathways and influencing factors. Int J Pharm.

390:89–99. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Hawe A, Kasper JC, Friess W and Jiskoot W:

Structural properties of monoclonal antibody aggregates induced by

freeze-thawing and thermal stress. Eur J Pharm Sci. 38:79–87. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Wang W: Lyophilization and development of

solid protein pharmaceuticals. Int J Pharm. 203:1–60. 2000.

View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Chang BS, Kendrick BS and Carpenter JF:

Surface-induced denaturation of proteins during freezing and its

inhibition by surfactants. J Pharm Sci. 85:1325–1330. 1996.

View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Cleland JL and Langer R: Formulation and

Delivery of Proteins and Peptides: Design and Development

Strategies. (ACS Symposium Series 567). American Chemical Society;

Washington, DC: 1994, View Article : Google Scholar

|

|

26

|

Hermeling S, Crommelin DJ, Schellekens H

and Jiskoot W: Structure-immunogenicity relationships of

therapeutic proteins. Pharm Res. 21:897–903. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Rosenberg AS: Effects of protein

aggregates: An immunologic perspective. AAPS J. 8:E501–E507. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

28

|

De Groot AS and Scott DW: Immunogenicity

of protein therapeutics. Trends Immunol. 28:482–490. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Keiserman M, Codreanu C, Handa R,

Xibillé-Friedmann D, Mysler E, Briceño F and Akar S: The effect of

antidrug antibodies on the sustainable efficacy of biologic

therapies in rheumatoid arthritis: Practical consequences. Expert

Rev Clin Immunol. 10:1049–1057. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Schellekens H and Jiskoot W:

Eprex-associated pure red cell aplasia and leachates. Nat

Biotechnol. 24:613–614. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Suntharalingam G, Perry MR, Ward S, Brett

SJ, Castello-Cortes A, Brunner MD and Panoskaltsis N: Cytokine

storm in a phase 1 trial of the anti-CD28 monoclonal antibody

TGN1412. N Engl J Med. 355:1018–1028. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Hwang WY and Foote J: Immunogenicity of

engineered antibodies. Methods. 36:3–10. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Joubert MK, Hokom M, Eakin C, Zhou L,

Deshpande M, Baker MP, Goletz TJ, Kerwin BA, Chirmule N, Narhi LO

and Jawa V: Highly aggregated antibody therapeutics can enhance the

in vitro innate and late-stage T-cell immune responses. J Biol

Chem. 287:25266–25279. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Brinks V, Jiskoot W and Schellekens H:

Immunogenicity of therapeutic proteins: The use of animal models.

Pharm Res. 28:2379–2385. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

35

|

Swanson SJ and Bussiere J: Immunogenicity

assessment in non-clinical studies. Curr Opin Microbiol.

15:337–347. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Breckenridge A: Report of the working

party on the addition of drugs to intravenous infusion fluids

(HC(76)9). Department of Health and Social Security; London:

1976

|

|

37

|

Langford S, Fradgley S, Evans M and Blanks

C: Assessing the risk of handling monoclonal antibodies. Hospital

Pharm. 15:60–64. 2008.

|

|

38

|

Odou P: Medical devices for safe handling

of cytotoxic drugs. Eur J Oncol Pharm. 4:17–19. 2010.

|

|

39

|

Paul M, Vieillard V, Jaccoulet E and

Astier A: Long-term stability of diluted solutions of the

monoclonal antibody rituximab. Int J Pharm. 436:282–290. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Grundstein A, Meentemeyer V and Dowd J:

Maximum vehicle cabin temperatures under different meteorological

conditions. Int J Biometeorol. 53:255–261. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

41

|

Laguerre O and Flick D: Temperature

prediction in domestic refrigerators: Deterministic and stochastic

approaches. Int J Refrigeration. 33:41–51. 2010. View Article : Google Scholar

|

|

42

|

James SJ, Evans J and James C: A review of

the performance of domestic refrigerators. J Food Eng. 87:2–10.

2008. View Article : Google Scholar

|