Introduction

The temporomandibular joint (TMJ) is a bilaterally

linked joint in the jaw that functions as a single entity when

speaking, chewing, swallowing and yawning. More than 25% of the

world's population is affected by temporomandibular joint disorders

(TMDs) (1), leading to mandibular

dysfunction and pain. TMJ replacement is recommended for 2-5% of

TMDs linked to ankylosis, tumors and degenerative diseases

(1). The goal of TMJ replacement is

to reconstruct the anatomy and function of the mandible, enable the

patient to resume a sustainable diet, prevent further morbidity,

reduce pain and improve quality of life. In arthroplasty,

transplantation with either autologous or allogeneic bone has

substantial disadvantages when compared to artificial joint

transplantation. These include limited supplies, limited dimensions

and the risk of infection (bacterial or viral) (2,3).

Therefore, using an artificial TMJ for joint reconstruction is one

of the most effective methods for clinical replacement.

Joint substitute implant materials require unique

properties, including excellent biological properties, such as

compatibility and safety, strong mechanical properties and fatigue

resistance, a Young's modulus similar to that of human bone,

biological inertia and good bio-surface modification capability.

Orthopedic implant materials are typically composed of metals,

inorganic non-metals (or bioceramics), polymers, complexes and

biological derivatives. The most common orthopedic or dental

materials are metals, such as titanium and precious metals that

have excellent environmental resistance and good physical and

biological properties (4). However,

metallic materials may lead to various problems after implantation,

including the release of toxic metal ions, interference with

imaging diagnoses, bone resorption, osteolysis, allergic reactions

and implant shedding (5,6). In dentistry, the clinical use of

precious metals, such as titanium, has resolved certain issues

related to the use of metallic materials; however, the inherently

high elastic modulus of metallic materials frequently leads to

stress shielding due to mismatch with the human bone, resulting in

bone absorption (7). At present,

there are two types of mature TMJ prostheses worldwide, provided by

the companies TMJ Concepts and Biomet Microfixation, whose condylar

prostheses are predominantly made of metal. Therefore, there is

still a requirement to improve the clinical performance of the

prosthesis and reduce the incidence of post-operative complications

by using more suitable biomaterials and subject-specific

designs.

Polyetheretherketone (PEEK) is widely used in

medical fields, such as cranioplasty (8-10)

and spinal fusion (11,12) for its light weight, excellent

biocompatibility, biomechanical properties and stability.

Specifically, its modulus of elasticity is similar to that of

cortical bone, which improves load sharing between the implant and

the surrounding tissue (13).

However, reports on the use of PEEK in TMJ reconstruction are

limited (14), primarily those

evaluating the effect of carbon fiber reinforced-PEEK material in

the reconstruction of TMJ defects in rabbits, and there is no

relevant research on the biomechanical properties of PEEK

materials, to the best of our knowledge. The objective of the

present study was to evaluate the biomechanical behavior of custom

3D-printed PEEK condylar prostheses. For this purpose, a finite

element analysis (FEA) was established to explore the effect of the

clenching tasks on the prosthesis and surrounding bones. The

designed prostheses were prepared using fusion deposition modeling

(FDM) technology and their compression properties were tested using

uniaxial compression experiments.

Materials and methods

Modeling the mandible and custom

condylar prosthesis

In the present study, the skull of the patient was

scanned CT (slice thickness, 0.625 mm; slice interval, 0.5 mm) for

26 dental implants at the Radiology Department of the First

Affiliated Hospital of Xi'an Jiaotong University (Xi'an, China).

The patient presented with a normal occlusion and without TMJ

disease. The patient provided informed consent. The data were

stored and then imported into the Mimics medical imaging processing

software (version 20.0; Materialise, Inc.) for 3D reconstruction.

In this modeling process, the mandible included the cortical bone,

cancellous bone and complete dentition.

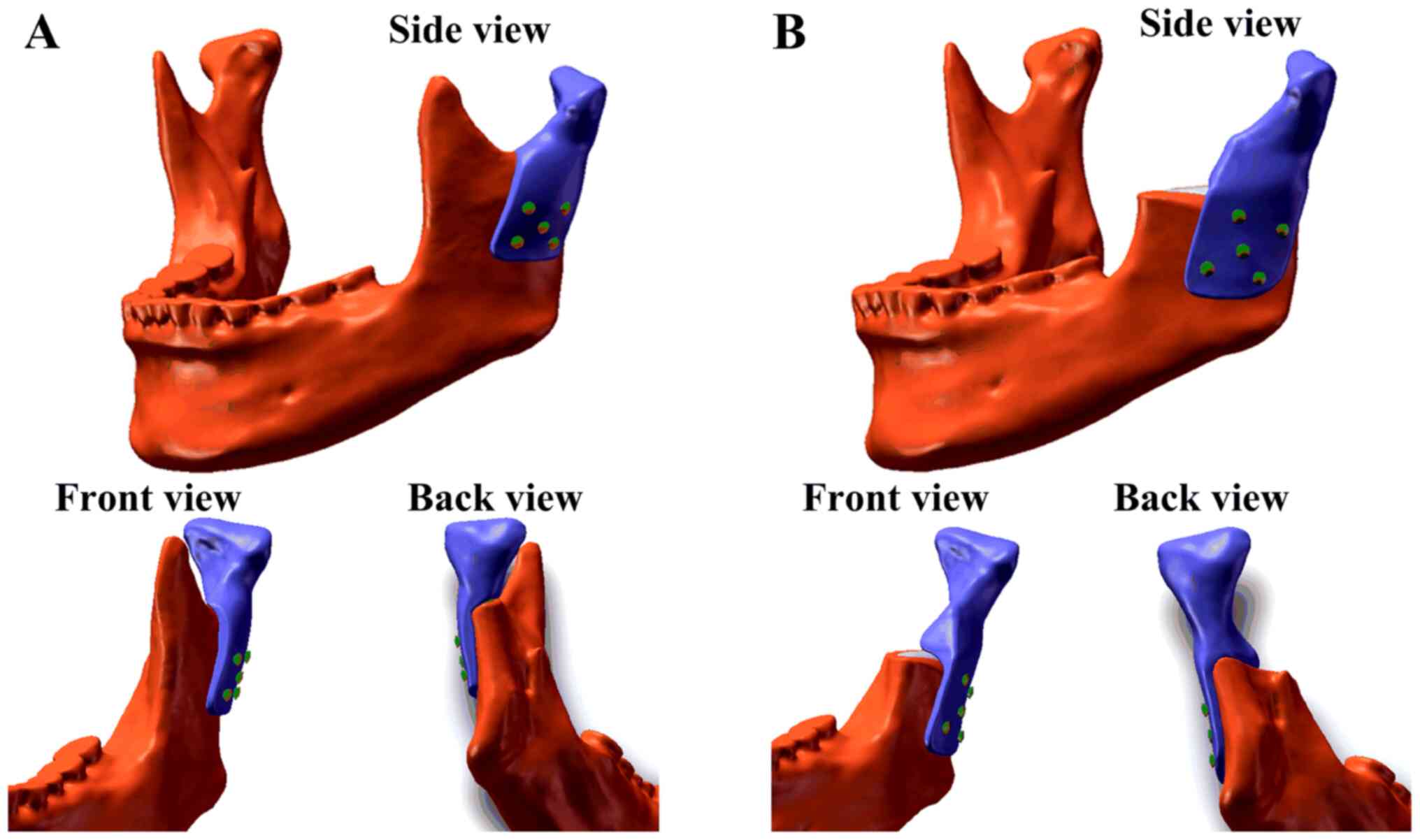

Due to the different extents of surgical osteotomy

in real clinical applications, two models were created. One model

(Model A) had a higher osteotomy position and retained the coracoid

process, whereas the other model (Model B) had a lower osteotomy

position and did not retain the coracoid process (Fig. 1). To design the corresponding

prostheses and create the two models, the 3D reconstruction model

of the mandible was imported into Geomagic Studio (version 2012; 3D

Systems, Inc.). The osteotomy of the mandibular lesion was

simulated according to the surgical requirements and partial bone

grinding (circular blunt) was performed on the buccal side of the

surgical stump to reduce the stress concentration on the

corresponding part of the prostheses. The corresponding data of the

contralateral mandible were symmetrically mapped to the defect area

according to the natural symmetry of the mandibular side. Part of

the condylar prostheses data in the defect area was obtained and

the overall design of the prostheses was achieved (Fig. 1). The TMJ condylar prostheses were

designed on the left side of the mandible and fixed with five

screws (Fig. 1). Each screw was 8

cm in length, 2 mm in diameter and did not have any screw

teeth.

FEA of the PEEK condylar

prostheses

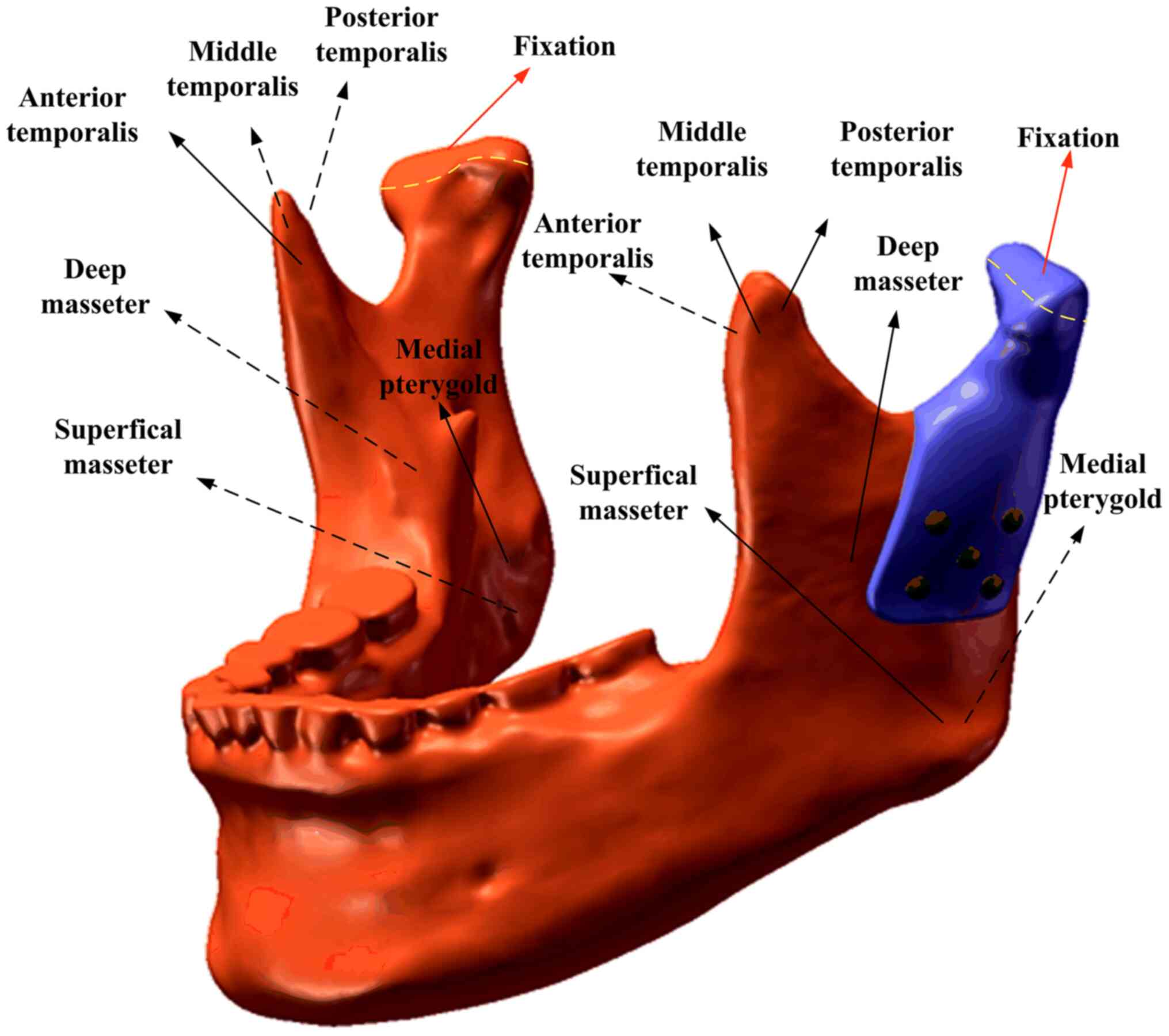

The FEM was used to investigate the biomechanical

properties of the condylar prostheses and mandible. In the present

study, FEA was performed using the ANSYS Workbench finite element

package (version 14.5; ANSYS, Inc.). The parameters of the

materials used in the FEA are presented in Table I (15,16).

To reduce the influence of manufacturing methods and process

parameters, the material properties of the PEEK condylar prostheses

were defined based on the results of tensile, compression and

flexure tests, which were conducted using an electrohydraulic servo

mechanical testing machine (SANS CMT4304; MTS Corp.) according to

ISO 527-1:2012, ISO 604 and ISO 178, respectively. All materials

were assumed to be homogeneous, linearly elastic and isotropic.

| Table IMechanical parameters of the materials

used in the modeling. |

Table I

Mechanical parameters of the materials

used in the modeling.

| Parameter | Cortical bone | Cancellous bone | Titanium alloy | PEEK |

|---|

| Elastic

modulus/GPa | 13 | 1.6 | 110 | 2.8 |

| Poisson's ratio | 0.3 | 0.3 | 0.3 | 0.3 |

Mesh Model A contained 1,157,007 nodes (778,460

elements) and mesh Model B contained 1,115,658 nodes (751,727

elements). The contact interface between the prosthesis and

mandible was considered bonded. The loading conditions pertained to

six principal muscles (Fig. 2). A

total of four static clenching tasks were simulated in this study:

The intercuspal position (ICP), incisal clench (INC), left

unilateral molar clench (LMOL) and right unilateral molar clench

(RMOL). The models were constrained in all directions at the top

condyle in all clenching tasks. In addition, the models were

constrained in the incisor regions (INC constraint), the canine and

premolar regions (ICP constraint), the right molars (RMOL

constraint) and the left molars (LMOL constraint). The magnitude

and directions of the six muscular forces were obtained from a

previous study (17). The maximum

stress of the prostheses and screws and the stress and strain of

the cortical bone and cancellous bones during ICP, INC, LMOL and

RMOL were recorded and analyzed.

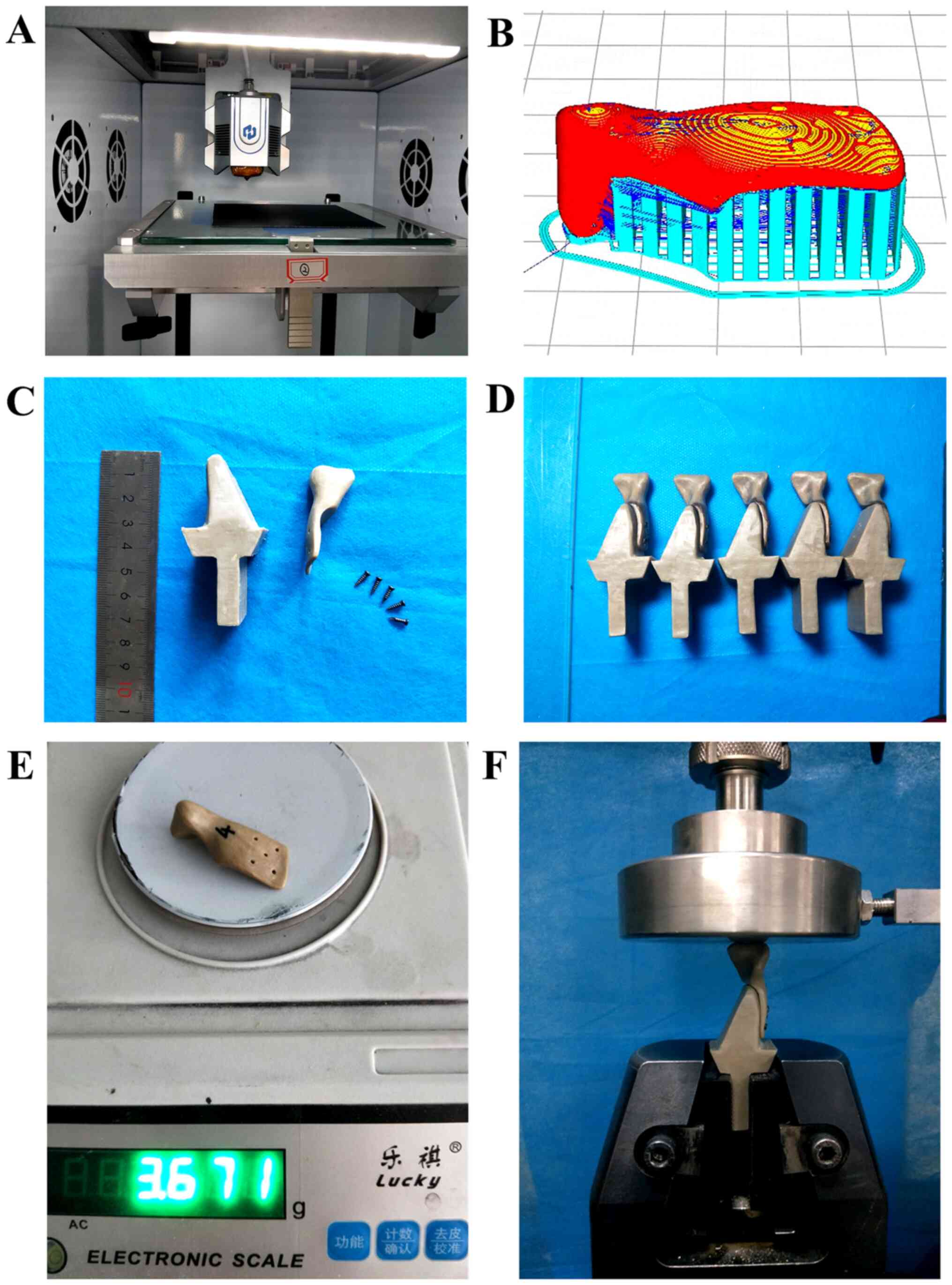

Preparation and mechanical testing of

the condylar prostheses

The condylar prostheses were prepared using a

self-developed 3D printer (Fig. 3A)

with a nozzle diameter of 0.4 mm, a printing speed of 40 mm/sec, a

wall thickness of 0.8 mm (printing line width of 0.4 mm), a layer

thickness of 0.2 mm, a nozzle temperature of 420˚C, an infill

percentage of 100% and printing trajectories of tiled scan, buccal

up and lingual down (Fig. 3B).

To evaluate the compression performance of the

printed samples, a compression test was conducted for the

3D-printed condylar prostheses using a universal testing machine.

The fixture was designed and fixed with titanium nails to simulate

an actual clinical prosthesis (Fig.

3C). The fixed end of the fixture was clamped and the speed was

tested at 1 mm/min (Fig. 3F). A

total of five physical models were used for the compression tests

(Fig. 3D). Finally, the results of

the FEA and experimental tests were compared to comprehensively

assess the mechanical properties of the condylar prostheses.

Results

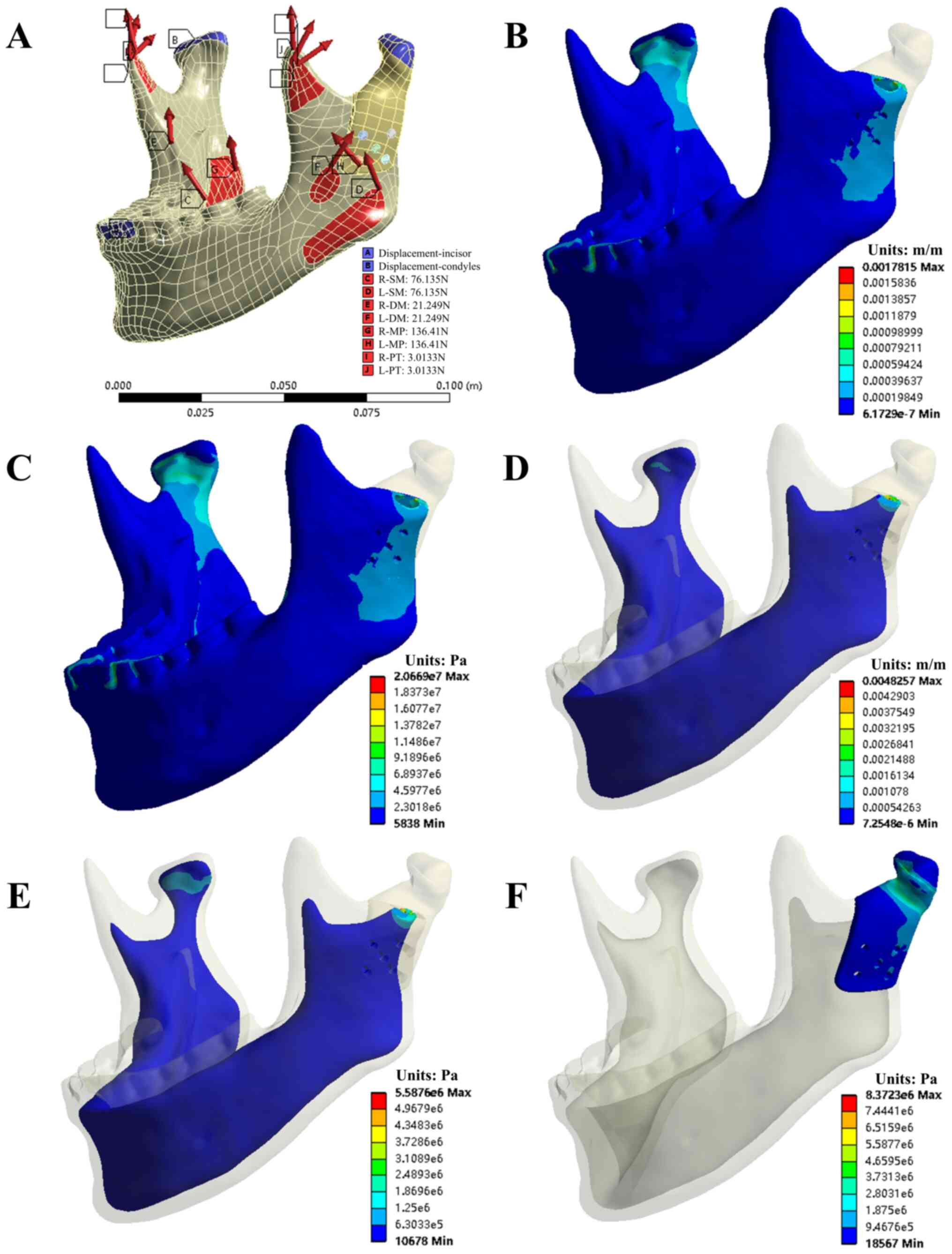

General

In the present study, the following parameters were

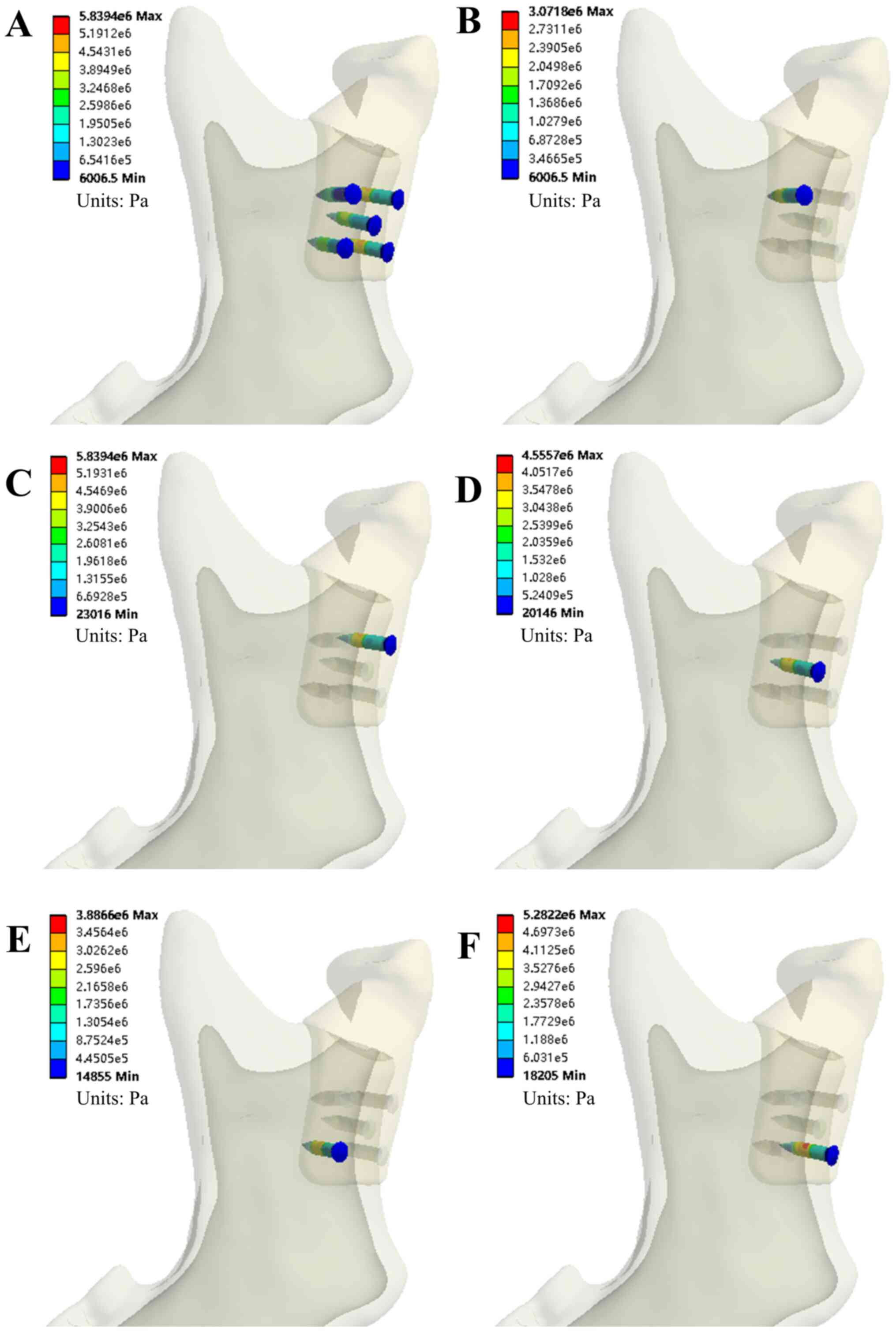

evaluated: The von Mises stress of the condylar prosthesis and five

bone screws along with the von Mises stress and von Mises strain of

the cortical bone and cancellous bone in four grasping tasks.

Figs. 4 and 5 provide the simulation results of the INC

task for model A. Tables II and

III present the evaluation

parameters for all four occlusion tasks for the two models.

| Table IISimulation results of the four

clenching tasks (Model A). |

Table II

Simulation results of the four

clenching tasks (Model A).

| | Maximum value |

|---|

| Component/evaluation

parameter | INC | ICP | LMOL | RMOL |

|---|

| Condylar

prosthesis | | | | |

|

von Mises

stress (MPa) | 8.3723 | 10.733 | 4.8598 | 10.567 |

|

von Mises

strain (µ) | 3,263.7 | 4,261.5 | 1,889.3 | 4,027.2 |

| Cortical bone | | | | |

|

von Mises

stress (MPa) | 20.669 | 42.688 | 34.23 | 31.315 |

|

von Mises

strain (µ) | 1,781.5 | 4,897.2 | 3,388.1 | 2913.8 |

| Cancellous bone | | | | |

|

von Mises

stress (MPa) | 5.5876 | 10.826 | 3.7015 | 6.792 |

|

von Mises

strain (µ) | 4,825.7 | 7,772.4 | 2,920.5 | 5,857.4 |

| All screws | | | | |

|

von Mises

stress (MPa) | 5.8394 | 9.7075 | 5.3554 | 9.4276 |

|

von Mises

strain (µ) | 53.115 | 88.269 | 54.225 | 85.726 |

| Screw #1 | | | | |

|

von Mises

stress (MPa) | 3.0718 | 7.7425 | 4.7278 | 7.6845 |

|

von Mises

strain (µ) | 27.937 | 87.112 | 54.225 | 78.165 |

| Screw #2 | | | | |

|

von Mises

stress (MPa) | 5.8394 | 9.5725 | 5.3554 | 9.4276 |

|

von Mises

strain (µ) | 53.115 | 87.043 | 48.812 | 85.726 |

| Screw #3 | | | | |

|

von Mises

stress (MPa) | 4.5557 | 8.445 | 4.5214 | 7.6839 |

|

von Mises

strain (µ) | 41.441 | 76.817 | 41.128 | 69.894 |

| Screw #4 | | | | |

|

von Mises

stress (MPa) | 3.8866 | 7.7507 | 4.2435 | 6.7267 |

|

von Mises

strain (µ) | 35.34 | 70.501 | 38.600 | 61.188 |

| Screw #5 | | | | |

|

von Mises

stress (MPa) | 5.2822 | 9.7075 | 5.2122 | 9.2533 |

|

von Mises

strain (µ) | 48.042 | 88.269 | 47.394 | 84.139 |

| Table IIISimulation results of the four

clenching tasks (Model B). |

Table III

Simulation results of the four

clenching tasks (Model B).

| | Maximum value |

|---|

|

Component/evaluation parameter | INC | ICP | LMOL | RMOL |

|---|

| Condylar

prosthesis | | | | |

|

von Mises

stress (MPa) | 5.9419 | 6.7679 | 1.9178 | 8.5229 |

|

von Mises

strain (µ) | 2,382.8 | 2,710.4 | 769.92 | 3,551.8 |

| Cortical bone | | | | |

|

von Mises

stress (MPa) | 13.93 | 34.535 | 43.038 | 24.148 |

|

von Mises

strain (µ) | 1,240.4 | 3,498.2 | 4,066.1 | 2,548.2 |

| Cancellous

bone | | | | |

|

von Mises

stress (MPa) | 2.5734 | 3.2374 | 2.4105 | 3.4237 |

|

von Mises

strain (µ) | 1,651.3 | 2,059.7 | 1,507.8 | 2,277.5 |

| All screws | | | | |

|

von Mises

stress (MPa) | 1.8837 | 1.9063 | 0.65778 | 2.7697 |

|

von Mises

strain (µ) | 17.267 | 17.441 | 6.041 | 25.332 |

| Screw #1 | | | | |

|

von Mises

stress (MPa) | 1.4413 | 1.3578 | 0.44294 | 1.6534 |

|

von Mises

strain (µ) | 13.455 | 12.69 | 4.1499 | 15.338 |

| Screw #2 | | | | |

|

von Mises

stress (MPa) | 1.8837 | 1.9063 | 0.65778 | 2.7697 |

|

von Mises

strain (µ) | 17.267 | 17.441 | 6.041 | 25.332 |

| Screw #3 | | | | |

|

von Mises

stress (MPa) | 1.3577 | 1.3148 | 0.44833 | 1.5328 |

|

von Mises

strain (µ) | 12.48 | 12.089 | 4.0937 | 14.087 |

| Screw #4 | | | | |

|

von Mises

stress (MPa) | 0.9578 | 0.86554 | 0.2715 | 0.90107 |

|

von Mises

strain (µ) | 8.8955 | 7.9824 | 2.5222 | 8.389 |

| Screw #5 | | | | |

|

von Mises

stress (MPa) | 1.3605 | 1.338 | 0.44003 | 1.7646 |

|

von Mises

strain (µ) | 12.528 | 12.311 | 4.2029 | 16.225 |

Evaluation of von Mises stress of the

TMJ condylar prosthesis and five bone screws

Mechanical analysis indicated that the stress values

of prosthesis Model A were <11 MPa in all four clenching tasks.

The von Mises stress on the five bone screws ranged from 3.07 MPa

(INC, screw #1) to 9.71 MPa (ICP, screw #5) for the same tasks.

Scre #5 was under the greatest von Mises stress during all tasks,

as shown in Table II. For Model B,

stress values of prosthesis were <9 MPa in all four occlusion

tasks. The von Mises stress on the five bone screws ranged from

0.27 MPa (LMOL, screw #4) to 2.77 MPa (RMOL, screw #2) and screw #2

was under the greatest stress during all tasks, as shown in

Table III.

Evaluation of the von Mises stress and

strain of the cortical and cancellous bones

The mechanical analysis of the entire mandible

cortical bone in Model A suggested that the maximum and minimum von

Mises stress occurred during the ICP (42.688 MPa) and INC (20.669

MPa) tests. The maximum and minimum von Mises strain also occurred

during the ICP (4,897.2 μ) and INC (1,781.5 μ) tests. However, in

the cancellous bone, the maximum and minimum von Mises stress and

strain occurred during the ICP (10.826 MPa and 7,772.4 μ,

respectively) and LMOL (3.7015 MPa and 2,920.5 μ, respectively)

tests, as shown in Table II.

Conversely, for the entire mandible cortical bone in Model B, the

maximum and minimum von Mises stress occurred during the LMOL

(43.038 MPa) and INC (13.93 MPa) tests, as did the maximum and

minimum von Mises strain (4,066.1 and 1,240.4 μ, respectively). In

the cancellous bone, the maximum and minimum von Mises stress and

strain occurred during the RMOL (3.4237 MPa and 2,277.5 μ,

respectively) and LMOL (2.4105 MPa and 1,507.8 μ, respectively)

tests, as shown in Table III.

Experimental results of the

prosthesis

The weights of the condyle prostheses printed by FDM

were 3.671 g (Model A) and 4.382 g (Model B). The compression test

results indicated that the maximum forces that the prostheses were

able to withstand were 3,814.7±442.6 N (Model A) and 4,245.7±348.3

N (Model B). The compressive force-displacement curves are

presented in Fig. 6.

Discussion

The present study introduced a novel TMJ prosthesis

that differs from the existing prostheses from Biomet and TMJ

Concepts. The custom condylar prostheses were designed using a

reverse engineering approach and were prepared by 3D printing using

PEEK as the printed material. PEEK is a high-strength

semi-crystalline thermoplastic that was first introduced to the

medical field in the early 1990s (18). PEEK has excellent biocompatibility

and its yield strength and Young's modulus are closer to cortical

bone than metal prostheses (13),

which facilitates the design of implants that reduce stress

shielding. Furthermore, high radiographic penetration may

effectively avoid artifacts during post-operative examination

(13). These advantages make PEEK a

better candidate for loadbearing orthopedic devices, particularly

in the spine. However, reports on the use of PEEK in TMJ

reconstruction are limited. In the present study, two PEEK condylar

prosthesis models were designed to reflect the different degrees of

surgical osteotomy. The FEM was used to analyze the biomechanical

behavior of the condylar prostheses, which was validated through

mechanical experiments.

To ensure the stability of the TMJ condylar

prostheses, the stress of each component of the prosthesis should

be less than the yield strength of the material. In the present

study, consistent with the study of Kashi et al (19) from 2010, the stress in the condylar

prostheses was predominantly concentrated in the anterior and

posterior areas of the condylar neck. The maximum stress in this

region was 10.733 MPa and 8.5229 in Models A and B, respectively,

which is far less than the yield strength of PEEK. Concerning the

five bone screws used to fix the PEEK condylar prostheses, the

maximum von Mises stresses in models A and B were 9.7075 MPa (screw

#5) and 2.7697 MPa (screw #2), far less than the yield strength of

titanium alloy. The peak stresses of the personalized PEEK condyle

prosthesis designed in this study and its retention screws are far

less than the yield strength of their respective materials.

Therefore, theoretically, the prostheses and screws would not

fracture. Moreover, the stress values of these screws are

significantly lower than the stress generated by a screw fixing

metal condyle prosthesis (17,20),

it showed that the PEEK condyle prostheses reduced the risk of the

retention screw fracture compared to the metal prostheses. In

addition, consistent with the study of Kashi et al (19) from 2010, the peak von Mises stresses

were observed in the upper and posterior regions of the mandible,

demonstrating the importance of the number and location of screws

when designing PEEK condyle prostheses.

The results of von Mises stress and strain generated

by the four clenching tasks in the entire mandible have the

following implications. First, the relationship between the von

Mises strain and variations in bone mass were divided into the

following ranges: disuse (bone loss): <10 µm/m (21), <50 µm/m (22) or <200 µm/m (23); normal load: 100-2,000 µm/m; mild

overload (bone gain): 2,000-4,000 µm/m (24); pathologic overload (irreversible

bone damage): >4,000 µm/m (24);

and bone fractures: 15,700-20,000 µm/m (24). With the exclusion of the right

condyle neck (near the fixed and restrained position) and the

lingual edge of the osteotomy surface (sharp edges after

osteotomy), the maximum strain on cortical bone and cancellous bone

was usually between 100 and 4,000 µm/m. Furthermore, regarding the

relationship between the von Mises stress and bone mass changes, a

study by Sugiura et al (25)

from 2000 indicated that the critical threshold for bone resorption

should be approximately -50 MPa. In the simulations of the present

study, the von Mises stress values in the bone were all <50 MPa.

In the present simulation of the four occlusal tasks, the stress

and strain of the mandible after adding a PEEK condyle prosthesis

were typically within the normal load range. Theoretically, no

disuse and overload absorption of the mandible was expected. In

addition, temporalis and part of the masseter muscles were resected

in Model B; therefore, the maximum stress of the condyle and the

stress and strain of the mandible were smaller than those in Model

A.

Personalized 3D-printed PEEK condylar prostheses are

able to meet individual requirements more effectively due to the

simple preparation method, one-time molding, convenient processing

and high material utilization. Furthermore, the intraoperative

adaptability is expected to surpass that of already available TMJ

prostheses. Furthermore, the experimental validation of the

biomechanical properties of the developed prostheses suggested that

the prostheses are able to withstand a maximum force of

3,814.7±442.6 N (Model A) and 4,245.7±348.3 N (Model B), which is

much larger than the combined maximum muscle force in the Z-axis

direction in the ICP. Therefore, the 3D-printed PEEK condyle

prosthesis developed in the present study is able to meet the

clinical requirements of TMJ reconstruction in terms of its

mechanical properties. This experiment revealed the following: FDM

printing is accomplished by the accumulation of materials layer by

layer and the molecular chains between the layers are less crossed

and entangled, resulting in a small interlayer force. When

designing the printing direction of the prosthesis, it is necessary

to consider the entire force environment and characteristics of the

prosthesis, so that frequent and larger forces act in the vertical

plane direction rather than the interlayer direction.

As with any theoretical simulation study, there are

certain limitations. First, a comparative study has yet to be

performed between the custom PEEK prostheses and a standard

prosthesis. In a future study, the stress and strain distribution

between the PEEK condylar prosthesis and the Biomet stock

prosthesis will be compared to further demonstrate the

biomechanical advantages of the proposed device. In addition, a

compression experiment will be conducted to evaluate the

biomechanics of the prosthesis. In subsequent studies, fatigue and

wear tests will be performed on the personalized PEEK condyle

prosthesis using mechanical testing equipment and validation in

animals.

Acknowledgements

Not applicable.

Funding

Funding: This work was supported by the National Natural Science

Foundation of China (grant no. 81801034), the High-level Introduced

Talent Fund Project of Xi'an Medical University (grant no.

2018RCYJ03), the Key R&D Program of the Department of Science

and Technology of Shaanxi Province (grant no. 2020SF-023) and the

Key R&D Program of Guangdong Province (grant no.

2018B090906001).

Availability of data and materials

The datasets used and/or analysed during the current

study are available from the corresponding author on reasonable

request.

Authors' contributions

MH and CL designed and supervised the project. FG,

SH, CY and DL performed the experiments. FG, SH and CY analyzed the

data. FG and SH confirmed the authenticity of the raw data. FG

wrote the manuscript. All authors read and approved the final

manuscript.

Ethics approval and consent to

participate

The patient provided informed consent.

Patient consent for publication

The patient has signed an informed consent for the

use of their CT data.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Rodrigues YL, Mathew MT, Mercuri LG, da

Silva JSP, Henriques B and Souza JCM: Biomechanical simulation of

temporomandibular joint replacement (TMJR) devices: A scoping

review of the finite element method. Int J Oral Maxillofac Surg.

47:1032–1042. 2018.PubMed/NCBI View Article : Google Scholar

|

|

2

|

Jones R: The use of virtual planning and

navigation in the treatment of temporomandibular joint ankylosis.

Aust Dent J. 58:358–367. 2013.PubMed/NCBI View Article : Google Scholar

|

|

3

|

Wolford LM, Dingwerth DJ, Talwar RM and

Pitta MC: Comparison of 2 temporomandibular joint total joint

prosthesis systems. J Oral Maxillofac Surg. 61:685–690; discussion

690. 2003.PubMed/NCBI View Article : Google Scholar

|

|

4

|

Zhao Y, Wong SM, Wong HM, Wu S, Hu T,

Yeung KW and Chu PK: Effects of carbon and nitrogen plasma

immersion ion implantation on in vitro and in vivo biocompatibility

of titanium alloy. ACS Appl Mater Interfaces. 5:1510–1516.

2013.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Niki Y, Matsumoto H, Otani T, Suda Y and

Toyama Y: Metal ion concentrations in the joint fluid immediately

after total knee arthroplasty. Mod Rheumatol. 11:192–196.

2001.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Wang L, He S, Wu X, Liang S, Mu Z, Wei J,

Deng F, Deng Y and Wei S:

Polyetheretherketone/nano-fluorohydroxyapatite composite with

antimicrobial activity and osseointegration properties.

Biomaterials. 35:6758–6775. 2014.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Sarot JR, Contar CM, Cruz AC and de Souza

Magini R: Evaluation of the stress distribution in CFR-PEEK dental

implants by the three-dimensional finite element method. J Mater

Sci Mater Med. 21:2079–2085. 2010.PubMed/NCBI View Article : Google Scholar

|

|

8

|

Jonkergouw J, van de Vijfeijken SE, Nout

E, Theys T, Van de Casteele E, Folkersma H, Depauw PR and Becking

AG: Outcome in patient-specific PEEK cranioplasty: A two-center

cohort study of 40 implants. J Craniomaxillofac Surg. 44:1266–1272.

2016.PubMed/NCBI View Article : Google Scholar

|

|

9

|

Lethaus B, Safi Y, ter Laak-Poort M,

Kloss-Brandstätter A, Banki F, Robbenmenke C, Steinseifer U and

Kessler P: Cranioplasty with customized titanium and PEEK implants

in a mechanical stress model. J Neurotrauma. 29:1077–1083.

2012.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Zegers T, Ter Laak-Poort M, Koper D,

Lethaus B and Kessler P: The therapeutic effect of patient-specific

implants in cranioplasty. J Craniomaxillofac Surg. 45:82–86.

2017.PubMed/NCBI View Article : Google Scholar

|

|

11

|

Hu B, Yang X, Hu Y, Lyu Q, Liu L, Zhu C,

Zhou C and Song Y: The n-HA/PA66 cage versus the PEEK cage in

anterior cervical fusion with single-level discectomy during 7

years of follow-up. World Neurosurg. 123:e678–e684. 2019.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Zhang J, Pan A, Zhou L, Yu J and Zhang X:

Comparison of unilateral pedicle screw fixation and interbody

fusion with PEEK cage vs. standalone expandable fusion cage for the

treatment of unilateral lumbar disc herniation. Arch Med Sci.

14:1432–1438. 2018.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Kurtz SM and Devine JN: PEEK biomaterials

in trauma, orthopedic, and spinal implants. Biomaterials.

28:4845–4869. 2007.PubMed/NCBI View Article : Google Scholar

|

|

14

|

Han ML, Li MH, Ji X, Han RY, Zhang N, Cui

LH, Sun LF and Han CM: Establishment of TMJ defect models and

evaluation on repair effect of CFR-PEEK material artificial joint

in rabbits. J Jilin Univ Med Εd. 43:903–909. 2017.

|

|

15

|

Arabshahi Z, Kashani J, Rafiq M, Kadir A

and Azari A: Influence of the TMJ implant geometry on stress

distribution. Adv Mat Res. 488:991–995. 2012.

|

|

16

|

Hsu JT, Huang HL, Tu MG and Fuh LJ: Effect

of bone quality on the artificial temporomandibular joint condylar

prosthesis. Oral Surg Oral Med Oral Pathol Oral Radiol Endod.

109:e1–e5. 2010.PubMed/NCBI View Article : Google Scholar

|

|

17

|

Huang HL, Su KC, Fuh LJ, Chen MY, Wu J,

Tsai MT and Hsu JT: Biomechanical analysis of a temporomandibular

joint condylar prosthesis during various clenching tasks. J

Craniomaxillofac Surg. 43:1194–1201. 2015.PubMed/NCBI View Article : Google Scholar

|

|

18

|

Torstrick FB, Lin ASP, Potter D, Safranski

DL, Sulchek TA, Gall K and Guldberg RE: Porous PEEK improves the

bone-implant interface compared to plasma-sprayed titanium coating

on PEEK. Biomaterials. 185:106–116. 2018.PubMed/NCBI View Article : Google Scholar

|

|

19

|

Kashi A, Chowdhury AR and Saha S: Finite

element analysis of a TMJ implant. J Dent Res. 89:241–245.

2010.PubMed/NCBI View Article : Google Scholar

|

|

20

|

Chen X, Wang Y, Mao Y, Zhou Z, Zheng J,

Zhen J, Qiu Y, Zhang S, Qin H and Yang C: Biomechanical evaluation

of Chinese customized three-dimensionally printed total

temporomandibular joint prostheses: A finite element analysis. J

Craniomaxillofac Surg. 46:1561–1568. 2018.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Rubin CT and Lanyon LE: Regulation of bone

mass by mechanical strain magnitude. Calcif Tissue Int. 37:411–417.

1985.PubMed/NCBI View Article : Google Scholar

|

|

22

|

Jaworski ZF, Liskova-Kiar M and Uhthoff

HK: Effect of long-term immobilisation on the pattern of bone loss

in older dogs. J Bone Joint Surg Br. 62-B:104–110. 1980.PubMed/NCBI View Article : Google Scholar

|

|

23

|

Lovell NC: Structure function, and

adaptation of compact bone. By R. Bruce Martin and David B. Burr.

Am J Phys Anthropol. 82:116–117. 1990.

|

|

24

|

Mellal A, Wiskott HWA, Botsis J, Scherrer

SS and Belser UC: Stimulating effect of implant loading on

surrounding bone. Comparison of three numerical models and

validation by in vivo data. Clin Oral Implants Res. 15:239–248.

2004.PubMed/NCBI View Article : Google Scholar

|

|

25

|

Sugiura T, Horiuchi K, Sugimura M and

Tsutsumi S: Evaluation of threshold stress for bone resorption

around screws based on in vivo strain measurement of miniplate. J

Musculoskelet Neuronal Interact. 1:165–170. 2000.PubMed/NCBI

|