Introduction

The repair of bone defects resulting from tumors,

congenital malformations and surgical resections remains a

challenge that is being addressed by advanced bone tissue

engineering approaches (1,2). A

combined approach for treating large bone defects including the use

of cell seeding techniques, growth factors and biomaterials further

enhances the success of cell therapy (3,4).

The interactions between various growth factors involved in bone

healing and remodeling has been extensively studied in recent

years. The role of transforming growth factor-β1 (TGF-β1) in normal

human fracture healing has been demonstrated in a previous study

(5). TGF-β1 is known to induce

the differentiation and proliferation of osteoblasts and bone

marrow-derived mesenchymal stem cells (BMSCs), and also to

stimulate the appearance of extracellular matrix (ECM) proteins

in vitro (6,7). TGF-β1 has been widely used to

promote the osteogenesis of BMSCs in a variety of in vitro

culture systems by continuously supplying it in the medium for

>4 weeks (8–10). Thus, the controlled administration

of TGF-β1 may represent an emerging tissue engineering technology

that modulates cellular responses to encourage bone regeneration at

the site of a skeletal defect (11,12).

BMSCs are multipotent progenitor cells that have the

ability to differentiate into mesenchymal lineages, including

osteoblasts, chondrocytes and adipocytes (13). The differentiation and function of

BMSCs is regulated by TGF-β1. For example, TGF-β1 stimulates the

proliferation of BMSCs and promotes their differentiation into

chondrocytes (14). TGF-β1

promotes chondrogenesis as well as the early phase of osteogenesis;

however, in the absence of bone morphogenetic proteins (BMPs),

TGF-β1 is unable to promote the differentiation of BMSCs into

osteoblasts (15). Thus, in the

present study, BMSCs were induced into osteoblast-like cells

together with osteogenic medium prior to transplantation.

Osteoblast-like cells derived from BMSCs share similar

characteristics with osteoblasts. The present study evaluated the

effects of BMSCs and of osteoblast-like cells differentiated from

BMSCs, on TGF-β1-silk fibroin-chitosan (TGF-β1-SF-CS) scaffolds and

silk fibroin-chitosan (SF-CS) scaffolds, as well as analyzing the

effects of TGF-β1 in SF-CS scaffolds and in vitro

biocompatibility for the first time, to the best of our

knowledge.

Both silk fibroin (SF) and chitosan (CS) are natural

biomaterials with good biocompatibility which are available in

abundance. It is, however, difficult to prepare a pure SF scaffold

with a porous structure, and SF has poor anticoagulant properties.

In addition, a pure CS scaffold degrades relatively quickly, and is

unstable in aqueous solution (16–18). In our previous study (19), we blended SF and CS into a

three-dimensional (3D) scaffold with unique chemical, structural

and mechanical properties, which has potential applications in bone

tissue engineering and regenerative medicine. Previously, it was

found that the the most appropriate proportion between CS and SF is

5:5 for bone tissue engineering (20). Our current study at our laboratory

is examining soluble growth factor supplementation schemes in order

to enhance the bioactivity of bone cells for bone tissue

engineering applications.

The optimal strategy for delivering growth factors

to cells for the purposes of bone tissue engineering and bone

repair remains an unmet challenge. For this purpose, we added

TGF-β1 into a SF-CS scaffold to construct a 3D scaffold for the

first time to the best of our knowledge. In previous studies,

growth factors were added to the medium, and then the growth

factors in the solution were incorporated into the resulting

polymer scaffolds and the sustained release of growth factors

facilitated bone regeneration in vitro and in vivo

(21–26). This approach was limited by the

fact that the dose and spatial distribution of growth factors in

these scaffold systems was uncontrolled. In another study, rapid

drug delivery occurred in the early stages as the drug that was

close to the surface was released or the drug easily diffused out

of the bulk of the material until supplies were exhausted resulting

in lower release rates (27). To

address this issue, we aimed to explore the novel strategy of

directly adding TGF-β1 onto an SF-CS scaffold during SF-CS scaffold

fabrication, rather than after scaffold fabrication. In the future,

this novel strategy may be applied to pattern and immobilize other

growth factors to the SF-CS 3D scaffolds developed herein. We

discussed the application and biocompatibility of TGF-β1-SF-CS

scaffolds which meet the requirements of bone tissue engineering.

One of the aims of our study was to ensure that the release of

TGF-β1 from the SF-CS scaffolds occurred at therapeutic levels and

enhanced matrix production by BMSCs. The effect of TGF-β1-SF-CS

scaffolds on the morphology, differentiation and function of BMSCs

has not yet been studied and no study of this type has been

performed previously on BMSCs, to the best of our knowledge. To

examine the in vivo biocompatibility and osteogenesis of the

TGF-β1-SF-CS scaffolds, both the TGF-β1-SF-CS scaffolds and the

SF-CS scaffolds were implanted in rabbit mandibles and studied

histologically and microradiographically. The effect of all the

materials on morphogenesis was analyzed from the in vivo

response in order to identify the clinical relevance of the SF-CS

scaffold. We examined the ability of SF-CS scaffold-immobilized

TGF-β1 to drive TGF-β1 bioactivity in the TGF-β1-SF-CS scaffolds.

The sustained delivery of TGF-β1 combined with the attractive

mechanical properties of a biodegradable SF-CS scaffold may prove

more advantageous for bone repair and regeneration. The present

study enabled us to evaluate this technique as a potential method

of constructing an ideal TGF-β1-SF-CS scaffold for bone tissue

engineering. To the best of our knowledge, this is the first study

to use TGF-β1-SF-CS composite scaffolds for mandibular repair.

Materials and methods

Animals and ethics statement

In the present study, we established an animal model

to examine the repair of mandible defects using tissue engineering

techniques. Eighteen healthy New Zealand white rabbits of either

gender (3 months old, weighing approximately 3.0 kg) were obtained

from the Center for Experimental Animals at China Medical

University (Shenyang, China) with a National Animal Use License

number of SCXK-LN2011-0009. Animal use was approved by the Animal

Use and Care Committee at China Medical University with a protocol

number of CMU62043006. All experiments and surgical procedures were

approved by the Animal Care and Use Committee at China Medical

University, and complied with the National Institutes of Health

Guide for the Care and Use of Laboratory Animals. All efforts were

made to minimize the number of animals used and their

suffering.

Materials

Raw silk was purchased from Nanchong Silk Co., Ltd.

(Nanchong, China). Chitosan was purchased from Nantong Xing Cheng

Biological Products Factory (Jiangsu, China). TGF-β1 (100

ng/bottle) was purchased from ProSpec-Tany TechnoGene, Ltd.

(Rehovot, Israel). Chemicals including NaHCO3,

CaCl2 and ethanol were purchased from Jiancheng

Biotechnology Institute (Nanjing, China). All other chemicals and

reagents were of analytical grade unless specified otherwise.

Preparation of TGF-β1-SF-CS and SF-CS

scaffolds

Bombyx mori silk fibers (Nanchong Silk Co.,

Ltd.) were treated with 0.5% (w/w) NaHCO3 solution twice

at 100°C for 30 min and then rinsed with 70°C distilled water for

30 min to remove sericin. Degummed silk was dissolved in a mixed

solvent system of

CaCl2/CH3CH2OH/H2O

(mole ratio of 1:2:8) at 70°C for 6 h and filtered to obtain a SF

solution. The solution was dialyzed in cellulose dialysis tubing

(MWCO=50,000) against distilled water for 3 days and the water was

replaced every 12 h to remove all impurities. CS solutions were

prepared by dissolving high molecular weight CS (82.7%

deacetylation; Tongxing Co.) at 3.66% (w/v) in 2% acetic acid. The

final concentration of CS used was 2%.

TGF-β1 solution was prepared by dissolving 100 ng

TGF-β1 in 1 ml deionised sterile water (100 ng/ml). The selected

concentrations were based on the mid-range concentrations used in

previous studies (28,29).

SF/CS blend solutions (100 ml) with a SF/CS weight

ratio 5:5 were prepared in the same solvent system at 10 wt%

(combined weight of CS and SF). Following dialysis in cellulose

dialysis tubing (MWCO=50,000) against distilled water for 3 days

with a water change every 12 h, CS and SF solutions were obtained.

TGF-β1 solution (1 ml) was then added and stirred with a magnetic

stirrer for 50 min. The CS, SF and TGF-β1 solution was poured into

a 24-well Teflon culture plate. The CS, SF and TGF-β1 solution was

lyophilized (VFD-2000; Boyikang Laboratory Instruments Co., Ltd.,

Beijing, China) for a total time of 48 h to obtain TGF-β1-SF-CS

scaffolds. We then prepared SF-CS scaffolds using the same

method.

To improve water stability, the dry TGF-β1-SF-CS and

SF-CS scaffolds were treated with methanol solution (concentration

<10%) for 2 h to crystallize the SF content and neutralize the

CS content. The TGF-β1-SF-CS and SF-CS scaffolds were lyophilized

to remove excess methanol.

The dry TGF-β1-SF-CS and SF-CS scaffolds were

fractured in liquid nitrogen using a razor blade. They were cut

into square pieces of 0.5×0.5 cm in size, placed on aluminum stubs

with conductive adhesive tape composed of carbon, coated with gold

using a JFC-110E Ion Sputter (Jeol USA, Inc., Peabody, MA, USA) for

60 sec at 20 mA prior to observation under a scanning electron

microscope (JSM-TM3000; Hitachi, Tokyo, Japan). Scanning electron

microscopy (SEM) images and pore size were analyzed using ImageJ

software. For each type of scaffold, a minimum of 30 pores were

examined.

Determination of scaffold porosity and

water absorption capacity

The porosity of the TGF-β1-SF-CS and SF-CS scaffolds

was evaluated using hexane displacement (30). The scaffolds were immersed in a

known volume (V1) of hexane. The total volume of

hexane and hexane-impregnated scaffold was recorded as

V2. The volume difference (V2 −

V1) was the volume of the polymer scaffold.

Hexane-impregnated scaffold was removed, and the residual hexane

volume was recorded as V3. The porosity of the

SF-CS scaffold was calculated as [(V1 −

V3)/(V2 −

V3)] ×100.

The water absorption capacity of the TGF-β1-SF-CS

and SF-CS scaffolds was determined by immersion in phosphate

buffered saline (PBS; pH 7.4) at 37°C for 24 h. At predetermined

time intervals, three scaffold samples of each scaffold were

carefully blotted to remove excess water and weighed. Wet weight

(W1, swollen weight) and dry weight

(W2, dried at 37°C overnight) were measured. The

water absorption capacity of the scaffold was calculated using the

following formula: [(W1 −

W2)/W2] ×100.

The swelling ability of SF-CS scaffolds, using three

samples/scaffold, was determined by immersion in PBS (pH 7.4) at

37°C for 24 h. Wet volume (S1, swollen volume)

and dry volume (S2, dried at 37°C overnight) were

measured. The swelling index of the scaffold was calculated using

the following formula: [(S1 −

S2)/S2] ×100.

Isolation, culture and differentiation of

BMSCs

Prior to the surgical procedures, the rabbits were

anesthetized with 10% chloral hydrate (0.35 ml/100 g)

intraperitoneally. Bone marrow (3–5 ml) was extracted from rabbit

femurs using a heparinized syringe, and then centrifuged and washed

with PBS. The cell suspension was centrifuged with Percoll

lymphocyte separation medium, and the ivory white layer in the

middle was collected, washed with PBS and cultured in complete

low-glucose Dulbecco's modified Eagle's medium (DMEM). The cells

were seeded in culture flasks at a density of 1.0×104

cells/cm2 and incubated at 37°C in a humidified

atmosphere with 5% CO2. Half of the culture medium was

replaced after 24 h, and completely replaced after 48 h, followed

by medium changes every 2–3 days. The unattached cells were

discarded by refreshing the medium. The cells at 85% confluency

were trypsinized, centrifuged and passaged at a 1:2 ratio.

Third-passage cells were induced to differentiate with osteogenesis

induction liquid (0.1 µmol/l dexamethasone, 50

µmol/ml vitamin C, 10 mmol/l β-glycerophosphate and 10%

fetal bovine serum in glucose DMEM), followed by medium changes

every 2–3 days. BMSC morphology at different time points was

examined under a light-inverted microscope (CKX41; Olympus, Tokyo,

Japan).

Alkaline phosphatase (ALP) staining and

the von Kossa assay

ALP activity was evaluated in BMSCs 14 days after

osteogenesis induction and in those without osteogenesis induction

(control group). The cells were fixed for 10 min at 4°C and

incubated with 2% cobalt nitrate and 1% ammonium sulfide (ALP kit;

Hongqiao, Shanghai, China). Areas stained tan were designated as

positive.

BMSCs plated in 6-well plates were fixed in 70%

ethanol 18 days after osteogenesis induction and those without

osteogenesis induction (control group). The cells were stained with

von Kossa silver (Jiancheng Biotechnology Institute) and placed

under ultraviolet (UV) light for 10 min. The cells were then

treated with 5% NaS2O3 for 2 min, and washed

with distilled water. Calcium nodules with a diameter >1 mm were

visualized under a light-inverted microscope.

BMSC seeding onto scaffolds and

morphological analysis

The scaffolds were sterilized with 75% alcohol under

UV light overnight and then rinsed extensively three times with

sterile PBS. Prior to cell culturing, the scaffolds were pre-wetted

by immersion in DMEM for 12 h in an incubator at 37°C.

The BMSCs were cultured onto TGF-β1-SF-CS scaffolds,

SF-CS scaffolds and 24-well tissue culture plate wells (control

group; n=3; diameter 15 mm; height 13 mm) for 3 and 6 days after

osteogenesis induction at 37°C under an atmosphere of 5%

CO2 and 95% air, with the original cell culture density

of 4,000 cells/well.

BMSC morphology following osteogenesis induction on

the TGF-β1-SF-CS scaffold and the SF-CS scaffold was observed on

days 1, 3 and 7 by SEM. The samples were washed with PBS and fixed

with 3.0% glutaraldehyde at 4°C for 4 h. Subsequently, they were

dehydrated through a graded ethanol series (30, 50, 70, 80, 90, 95

and 100%), air-dried overnight, and sputtered with gold for SEM

observation. Adherent cell morphology, patterns of cellular

adherence with respect to structural features of the TGF-β1-SF-CS

scaffold and the SF-CS scaffold, cell-cell interactions, and

adherent cell density were assessed.

Adhesion of BMSCs to scaffolds

Following osteogenesis induction on the TGF-β1-SF-CS

scaffold, the SF-CS scaffold and the control group, the BMSCs were

harvested and the concentration was adjusted to

1×104/ml. The cells were placed in cell culture plates

pre-coated with TGF-β1-SF-CS scaffold and SF-CS scaffold at 1

ml/well. The cells cultured in culture plates with no scaffold

served as the controls. Three parallel wells were used for each

group. The cells were cultured in an incubator at 37°C with 5%

CO2. The number of non-adherent cells was quantified at

1, 3 and 6 h. The cell adhesion rate (%) was calculated as (number

of seeded cells − non-adherent cells)/(number of seeded cells)

×100.

Cell Counting Kit-8 (CCK-8) assay and ALP

activity

To examine grafted cell survival, cell viability and

proliferation was determined using a CCK-8 assay. After the samples

were cultured for 1, 3, 5 and 7 days, the culture medium was

replaced with a serum-free culture medium containing CCK-8 (0.5

mg/ml). After 4 h of culturing, the samples were transferred to a

96-well plate. Absorbance was measured at 450 nm using an ELISA

reader (Bio-Rad Model 550; Bio-Rad, Berkeley, CA, USA). Optical

density (OD) at 450 nm was proportional to the number of cells.

Intracellular ALP activity in the scaffolds and the

control group was measured using an ALP assay kit (Nanjing

Jiancheng Bioengineering Institute, Nanjing, China). The samples

were cultured for 1, 4, 7, and 10 days, and then washed with PBS

three times. The samples and the control group with cells were

immersed overnight in 500 ml cell lysis solution containing 0.1%

Triton X-100 and 5 mM MgCl2. The solution was

transferred to a tube and centrifuged at 28,340 × g for 10 min at

4°C. ALP activity was measured by mixing 50 µl supernatant

with 50 ml p-nitrophenyl phosphate (5 mM) in 150 mM

2-amino-2-methyl-1-propanol buffer solution at room temperature for

30 min in the dark. Following the incubation period, the reaction

was stopped by adding 50 µl 0.2 N NaOH to denature ALP and

the OD was measured at 520 nm using an ELISA reader (Bio-Rad Model

550; Bio-Rad).

Surgical procedure and implantation

The bone-forming ability of the TGF-β1-SF-CS

scaffolds and the SF-CS scaffolds was assessed in the rabbit model

of a submaxillary defect. The rabbits were randomly divided into

the following 3 groups: i) the TGF-β1-SF-CS scaffolds group (n=6);

ii) the pure SF-CS scaffolds group (n=6); iii) the non-scaffold as

a control group (n=6). The surgical procedures were performed under

aseptic conditions. The rabbits were anesthetized with 10% chloral

hydrate (0.35 ml/100 g) intraperitoneally, and the jaw was exposed

and disinfected. Bilateral 3-cm parallel incisions were made on the

jaw of the rabbit. The periosteum was retracted and the submaxilla

was exposed. A critical round full-thickness bone defect, 8×8

mm2, was made in a buccal-lingual direction using a

slow-speed dental drill on one side of the mandible that was cooled

continuously. To avoid tissue damage due to overheating, 0.9%

saline was dripped onto the contact point between the bur and bone.

A 8×8-mm2 sized pure SF-CS scaffold or TGF-β1-SF-CS

scaffold construct was inserted into the defect. To ensure that the

bony defects were critically sized, rabbits in the control group

had nothing inserted into the defect. The region of the defect was

washed with normal saline, and the incision was sutured layer by

layer. Penicillin (400,000 units) was intramuscularly injected over

3 days to prevent infection.

General observations, dual energy X-ray

absorptiometry (DXA) analysis, and radiographic analysis

Following surgery, all rabbits were housed and fed

routinely, and monitored for changes in their appearance,

submaxilla movements, and healing of the surgical wounds.

Additionally, the local bone mineral densities (BMDs) were measured

on a Discovery DXA system (Hologic Inc., Bedford, MA, USA). 3D

images of the mandibles were captured with a multi-slice spiral

computed tomography (CT) scanner (GE Lightspeed Ultra 16; GE

Healthcare, Milwaukee, WI, USA) at 12 weeks after implantation.

Biomechanical evaluation

Flexural modulus and peak flexural strength were

measured. The specimens were tested to flexural failure in a

three-point bending configuration with a 10-mm spacing between the

loading supports and a 20-mm spacing between the base supports. The

specimens were loaded in buccal-lingual orientation at a constant

strain rate of 0.5 mm/min on an Insight 5 uniaxial test frame (MTS

Systems Corp., Eden Prairie, MN, USA).

Histomorphometric analysis of bone

regeneration

Rabbits from each group were sacrificed at 4, 8 and

12 weeks after implantation by acute blood loss under anesthesia.

To quantitatively determine the amount of newly formed bone, we

statistically analyzed histological sections from different

implantation periods. At every implantation time (4, 8 and 12

weeks), three histological sections were randomly chosen from the

pure SF-CS scaffold, the TGF-β1-SF-CS scaffold and the control

groups. These specimens were fixed in 4% paraformaldehyde, embedded

in paraffin and serial buccal and lingual sagittal cross sections

were made, which was followed by staining with hematoxylin and

eosin (H&E; Jiancheng Biotechnology Institute). Each section

was then observed under a light microscope (CKX41; Olympus) at ×100

magnification, and at least 5 images were randomly obtained from

one section. Using image analysis software Image-Pro Plus (Media

Cybernetics, Inc., Rockville, MD, USA), new bone volume (NBV) was

expressed as the percentage of newly formed bone area in the

available pore space (bone area/pore area ×100).

Statistical analysis

All quantitative data are expressed as the means ±

standard deviation. Statistical analyses were performed using the

statistic program SPSS 17.0. The results were analyzed by one-way

analysis of variance (ANOVA) with a Student's t-test. A P-value

<0.05 was considered to indicate a statistically significant

difference. Before the results were analyzed by one-way ANOVA, all

quantitative data obeyed the normality distribution.

Results

Evaluation of porosity and water

absorption capacity of scaffolds

With the addition of TGF-β1, the pore size and

porosity of SF-CS scaffolds increased, although the difference was

not significant (P>0.05). The hexane displacement experiment

demonstrated that the porosity of the TGF-β1-SF-CS scaffolds

(90.2±4.6%), as well as the pore size (236±73 µm) (Table I), may facilitate nutrient and

waste transport into and out of the scaffolds.

| Table IPorosity, swelling and water

absorption of TGF-β1-SF-CS and SF-CS scaffolds. |

Table I

Porosity, swelling and water

absorption of TGF-β1-SF-CS and SF-CS scaffolds.

| Porosity (%) | Pore size

(µm) | Water absorption

(%) | Swelling index

(%) |

|---|

| TGF-β1-SF-CS | 90.2±4.6 | 236±73 | 271±12 | 25.6±0.4 |

| SF-CS | 89.5±7.9 | 220±91 | 282±4 | 24.5±0.5 |

Water absorption capacity, swelling ability and

retain ability are other important factors in determining the

usefulness of the biomaterials. The absorption capacity of the

TGF-β1-SF-CS and SF-CS scaffolds was measured in terms of the

degree of swelling at equilibrium. It was found that the degree of

swelling of the scaffolds was in range of 24–26% of their dry

weight and the difference was not significant (P>0.05) following

the addition of TGF-β1 (Table I).

The TGF-β1-SF-CS and SF-CS scaffolds, which exhibited a high degree

of swelling and water absorption, also retained their structure

after immersion in PBS (pH 7.4) for 24 h.

Cell morphology and osteogenic

differentiation of BMSCs

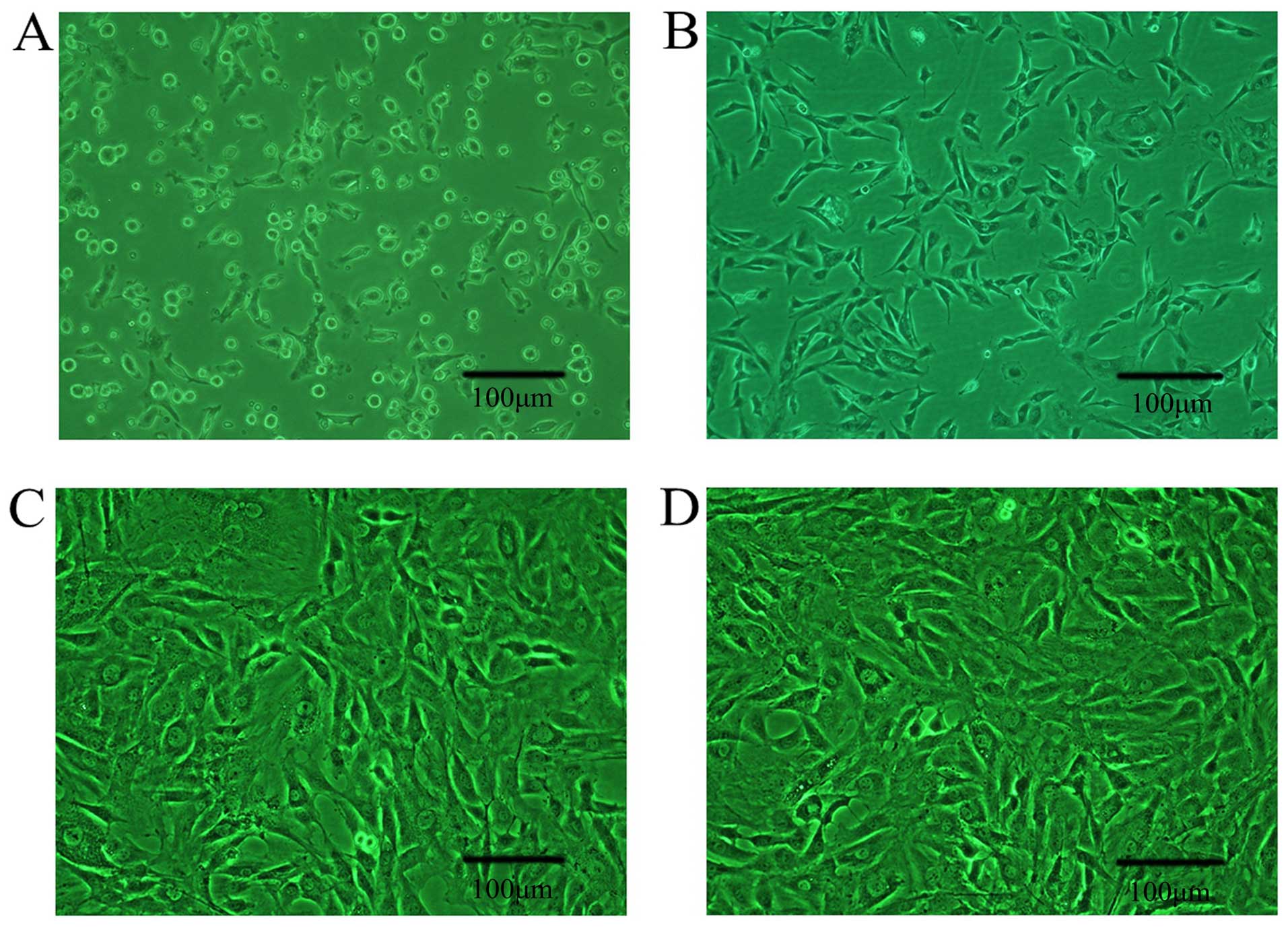

Cell morphology was studied using a light-inverted

microscope (Fig. 1). The BMSCs

demonstrated good survival and rapid proliferation.

In primary cells, BMSCs exhibited a round

morphology. After 12 h, the BMSCs were attached to the culture

flasks sparsely and displayed a fibroblast-like, spindle-shaped

morphology (Fig. 1A). After 3–4

days of incubation, cell numbers increased, the cells continued to

grow well and actively proliferate and the cells gradually grew

into small colonies, and they assumed a more spindle-shaped,

fibroblastic morphology (Fig.

1B). After 10–12 days, the majority of the cells were attached

and had acquired a large, flattened or multilayer growth morphology

(Fig. 1C) which remained

unchanged throughout subsequent passages (Fig. 1D).

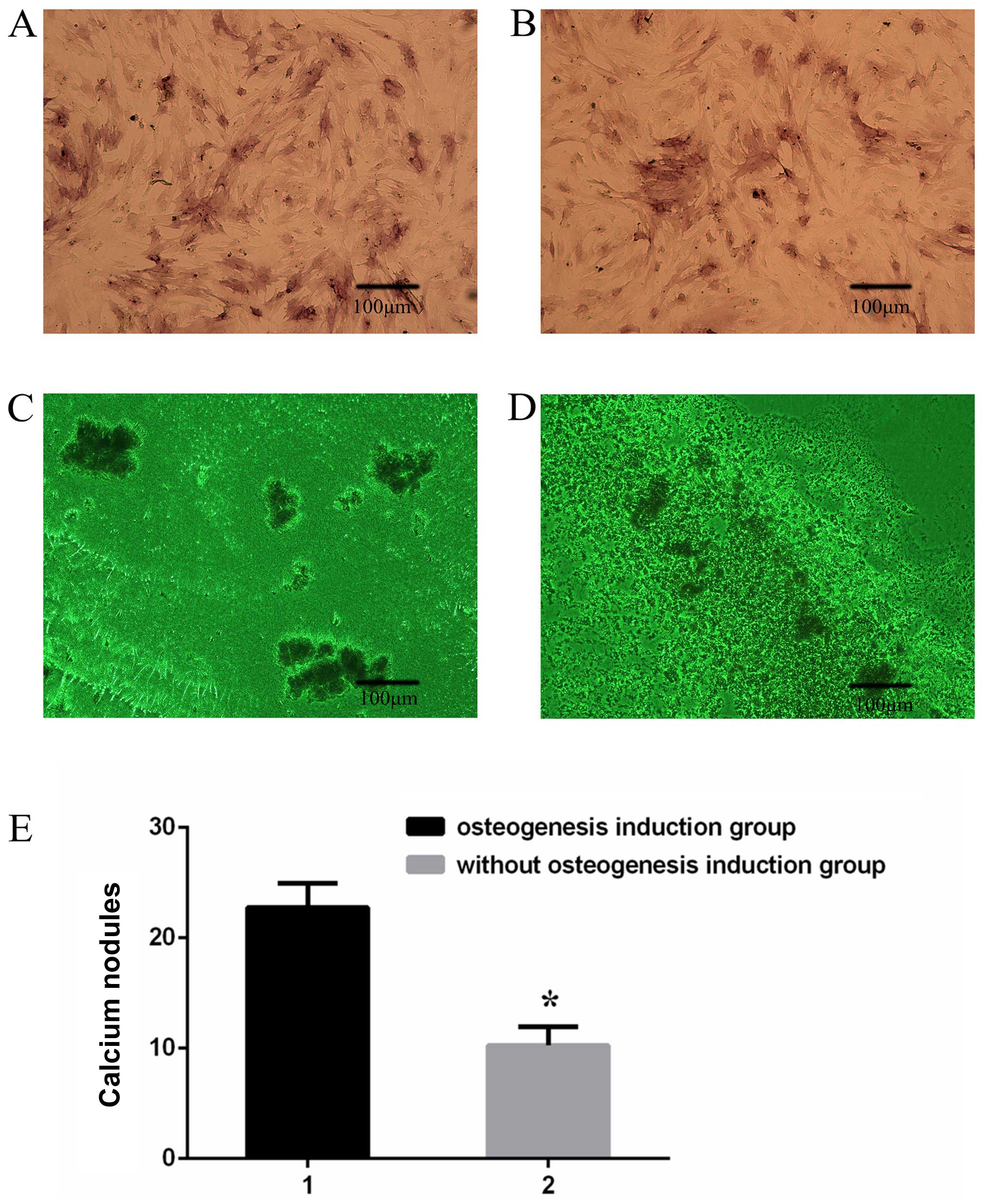

Two weeks later, ALP staining was greater in the

BMSCs after osteogenesis induction (Fig. 2A) than in those without

osteogenesis induction (Fig. 2B).

In addition, Von Kossa staining 2 weeks after osteogenesis

induction (Fig. 2C) revealed a

significant increase in calcium nodules compared with that in the

BMSCs without osteogenesis induction (Fig. 2D).

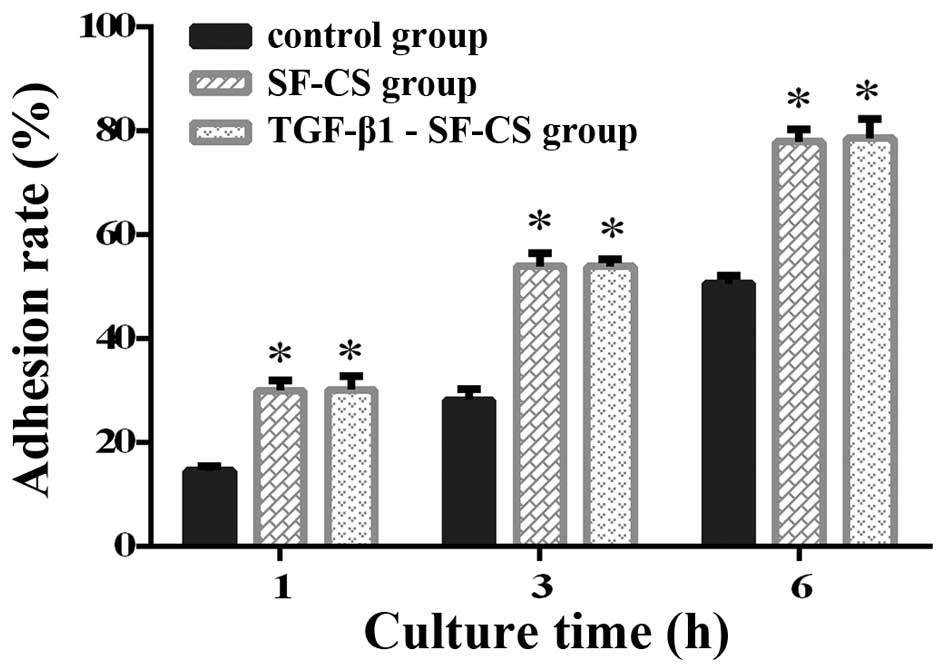

Adhesion rate of BMSCs

After 1, 3 and 6 h, the cell adhesion rate increased

in all three groups, in a time-dependent manner (Fig. 3). The adhesion rates in the

TGF-β1-SF-CS group and the SF-CS group were higher than those in

the control group (P<0.01). At 1 h, the adhesion rate in the

SF-CS scaffold group was nearly the same as that in the

TGF-β1-SF-CS scaffold group; there were no significant differences

between the scaffold groups (P>0.05). After 3 h, there was a

significant increase in the adhesion rate compared with the groups

at 1 h. The adhesion rate in the TGF-β1-SF-CS group and the SF-CS

group was significantly higher than that in the control group

(P<0.05); however, there was still no significant difference

between the scaffold groups (P>0.05). These results have–proved

that the SF-CS scaffolds increased BMSC adhesion–and that TGF-β1

was unable to promote BMSC adhesion in the SF-CS scaffolds.

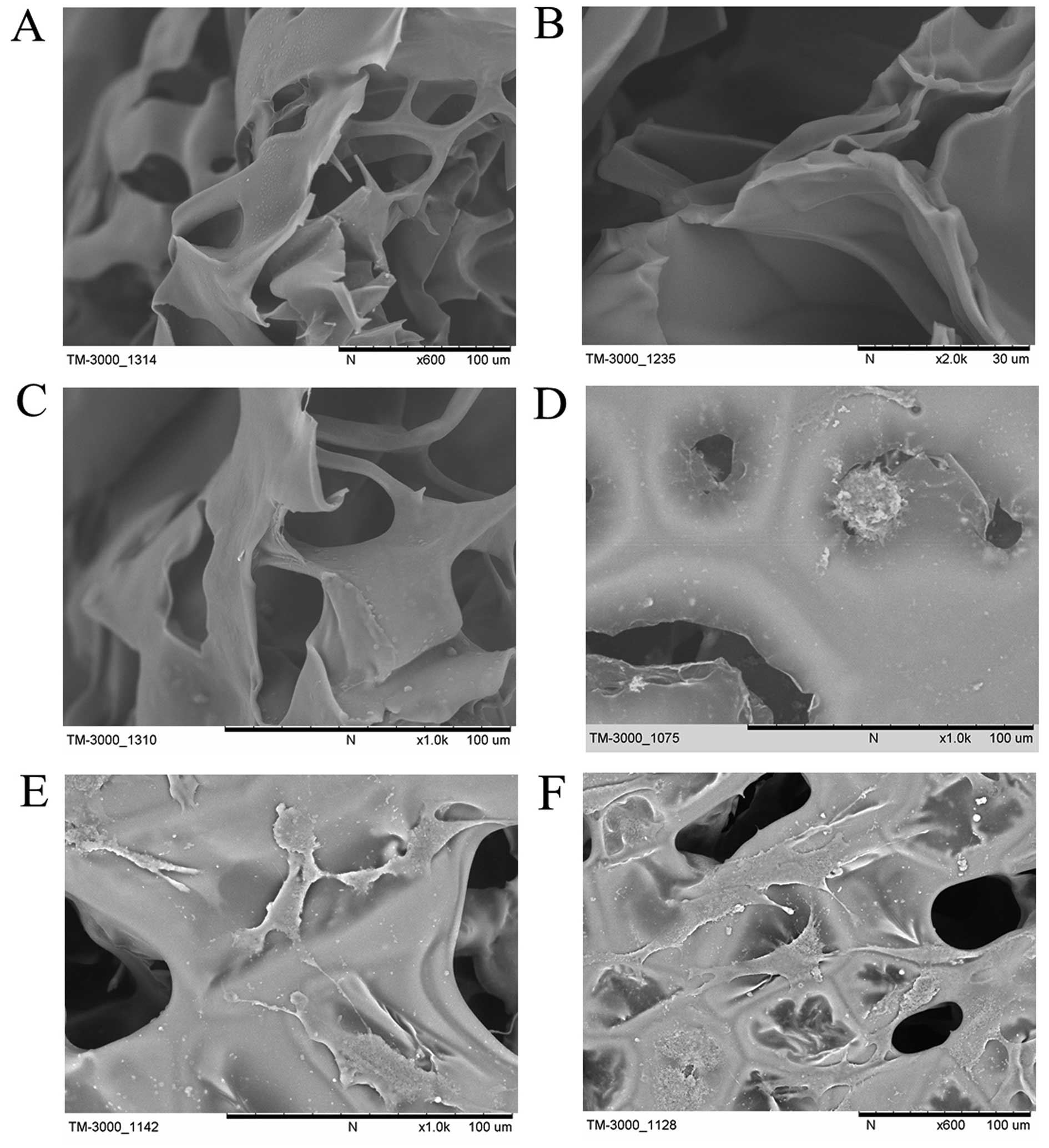

SEM images of TGF-β1-SF-CS scaffolds and

BMSCs cultured with the TGF-β1-SF-CS scaffolds

Following the addition of TGF-β1, the morphology of

the scaffolds did not change markedly. SEM revealed that all of the

TGF-β1-SF-CS scaffolds and the SF-CS scaffolds exhibit porous

structures (Fig. 4). The

composite of TGF-β1-SF-CS scaffolds was mixed well by a homogeneous

method. A smooth surface is observable in the SEM images. The

TGF-β1-SF-CS scaffolds exhibit well-oriented, porous structures

from the surface to the inside which may be beneficial for cell

seeding and distribution (Fig.

4A). The TGF-β1-SF-CS scaffold with fully porous structures may

facilitate uniform cell seeding and nutrient delivery, which are

important for cell growth in a 3D porous scaffold. To measure the

pores in the TGF-β1-SF-CS scaffolds, the scaffold was cut

transversely to expose the internal porous structures. The

TGF-β1-SF-CS scaffolds exhibited a homogeneous pore structure. The

inner pore size of the TGF-β1-SF-CS scaffolds was approximately

10–300 μm. Fig. 4B shows

that the pore wall of the TGF-β1-SF-CS scaffold has a smooth

surface morphology and the width of the pore wall is approximately

1–2 µm. The homogeneous pore wall section morphology shows

that TGF-β1, SF and CS are compatible, even at nanoscale. Fig. 4C shows that the SF-CS scaffold has

a similar morphology to the TGF-β1-SF-CS scaffold. This result

suggests that TGF-β1, SF and CS may be combined to generate a

composite scaffold, possessing the advantages of the growth factor

and two naturally-derived biomaterials.

The growth of osteogenically-induced BMSCs on

scaffolds, cellular attachment and interactions within the

TGF-β1-SF-CS scaffold were evaluated by electron microscopy. The

SEM images reveal that BMSCs are present on the surfaces and the

pores of the scaffolds. The SEM images also show that on the

TGF-β1-SF-CS scaffold, there are a number of BMSCs present that

extend towards other cells in the culture.

On day 1, BMSCs seeded onto the scaffold had a

distinct, round morphology and a large number of particles were

observed on the cell surface, characterized by numerous plasma

membrane microstructural extensions. Adherent BMSCs were observed

preferentially localized to the fold regions of the TGF-β1-SF-CS

sheets, with BMSCs noted among fibrils projecting outwards from the

scaffold edges (Fig. 4D).

After 3 days of culture, a large number of cells are

adhered to the scaffold. The cell aggregates are enlarged and have

actively proliferated. The SEM images reveal that the BMSCs have

spread to the scaffold surface and the pores, and they exhibit a

flat and elongated morphology. Granular and filiform substances are

observable around the cells, with microvilli and larger

lamellipodia extensions extending from the BMSCs localized to the

scaffold. The cells initially exhibit a stereo spindle and

dendritic morphology at day 3 (Fig.

4E).

At day 7, the BMSCs have spread wider and deeper

into the scaffold, an increased number of cells are adhered to the

surface and the pores of the scaffold compared with that at day 3,

and the cells have grown and proliferated well. They exhibit

typical osteoblast cell morphology and adhere tightly to the

surface of the scaffold or inside, by forming lamellipodia and

filopodia. Cell-cell interactions are also observable on the

surface of the TGF-β1-SF-CS scaffold as evidenced by connection of

the fibrous extensions between two BMSCs. Similar cellular

spreading and cell-cell interactions are apparent in more cells

spread throughout the scaffold, which is crucial for the viability

and function of BMSCs in vitro (Fig. 4F).

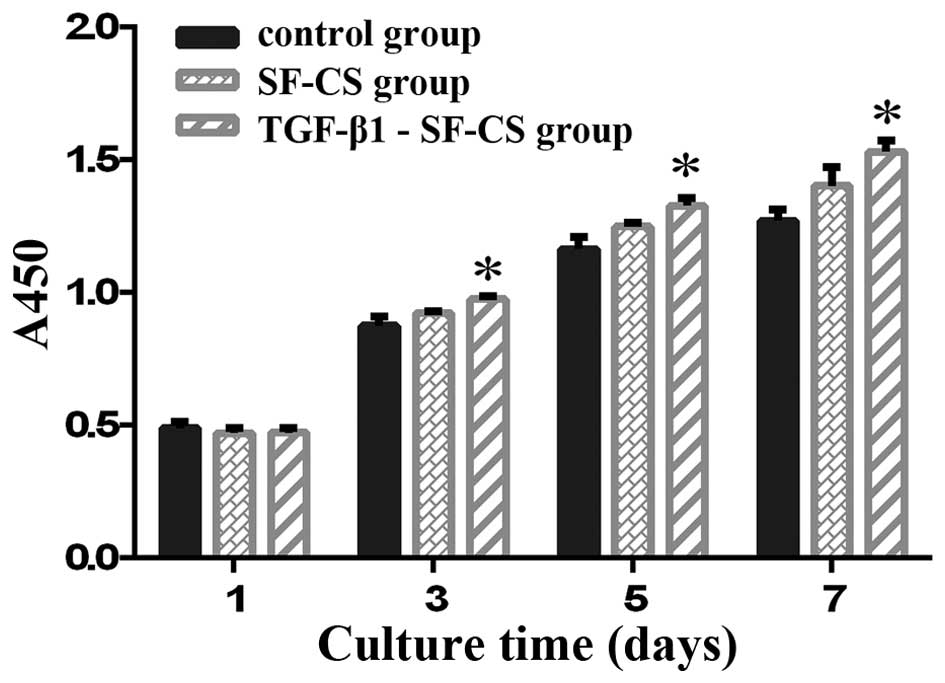

CCK-8 assay and ALP activity

The proliferation of BMSCs on the TGF-β1-SF-CS

scaffolds, the SF-CS scaffolds and in the control group cultured

for 1, 3, 5 and 7 days were compared using a CCK-8 assay (Fig. 5). The absorbance index of the

three groups increased with the increase in culture time, which

indicated that significant cell growth had occurred within both

scaffolds. The data regarding BMSCs cultured without scaffolds is

also present. The BMSCs proliferated well in the TGF-β1-SF-CS

scaffolds and the SF-CS scaffolds, and there were no significant

differences with the cells cultured in the control group at day 1

(P>0.05). However, after 3 days, more proliferation was observed

in the BMSCs cultured on the TGF-β1-SF-CS scaffolds than in the

cells cultured on the SF-CS scaffolds, and the proliferation of

BMSCs cultured on both scaffolds was markedly increased compared

with those cultured without scaffolds (P<0.05). These results

indicate that the TGF-β1-SF-CS scaffolds significantly enhanced the

attachment and proliferation of BMSCs under these conditions

compared with the SF-CS scaffolds.

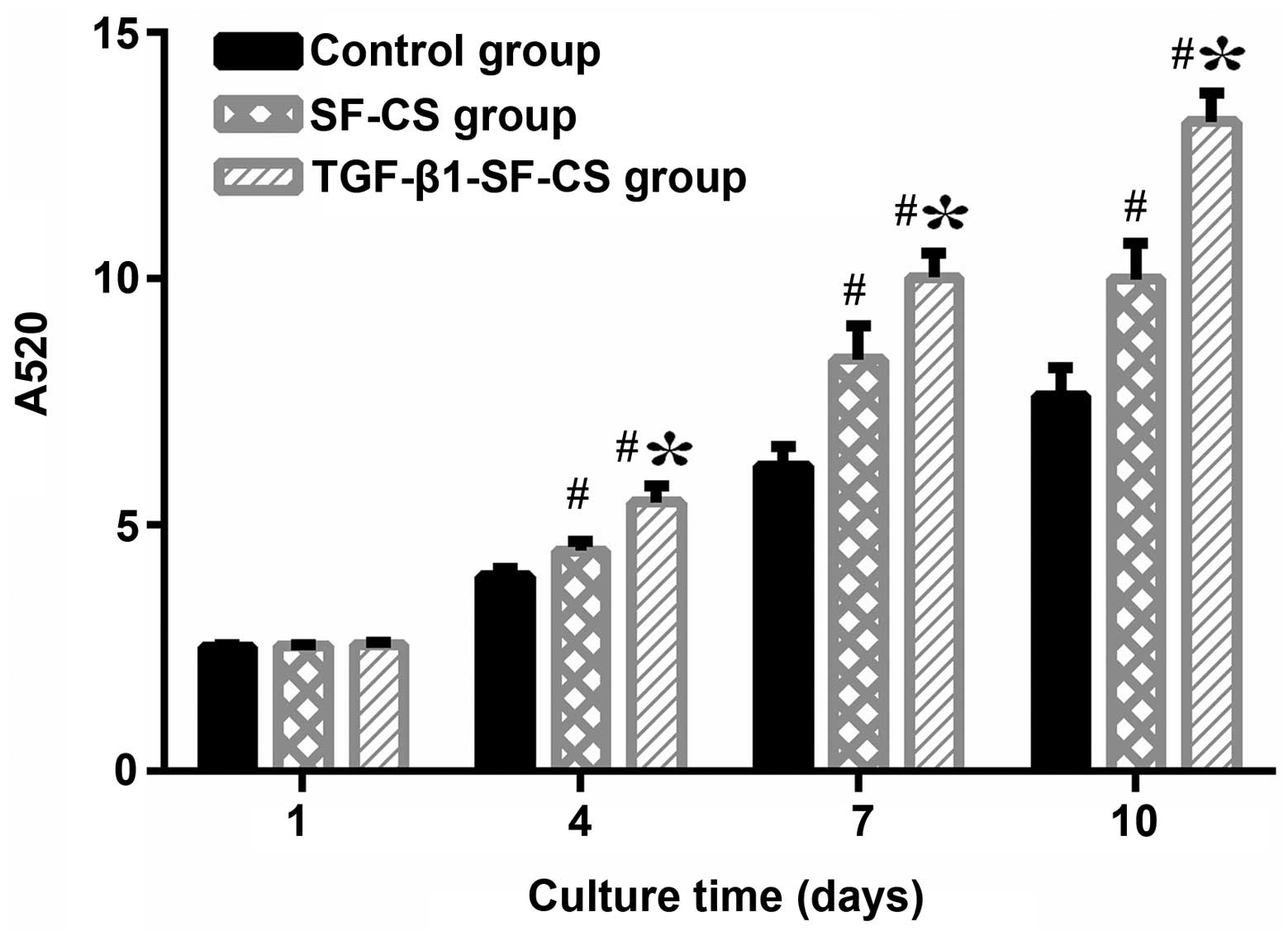

To evaluate the osteoblastic differentiation of the

mesenchymal stem cells on the TGF-β1-SF-CS scaffolds and the SF-CS

scaffolds, we measured ALP activity using spectrophotometry. The

ALP activity of the BMSCs cultured on the TGF-β1-SF-CS scaffolds,

the SF-CS scaffolds and the control group is shown in Fig. 6. For total ALP activity

measurement on day 1, there was no significant difference in OD

values between the TGF-β1-SF-CS, SF-CS and control groups

(P>0.05). On days 4 to 10, a significant difference in OD values

was found between the scaffolds groups and the control group

(P<0.01). The OD values in the TGF-β1-SF-CS group were the

highest. This suggests that TGF-β1 exerts an effect on the activity

of BMSCs. As the culture time increased from days 4 to 10, the

growth trend of the OD values in the three groups increased

rapidly. The OD values reached a peak at day 10. This suggests that

the TGF-β1-SF-CS scaffolds are a stable, prolonged culture system

and stabilized TGF-β1 greatly enhanced ALP activity.

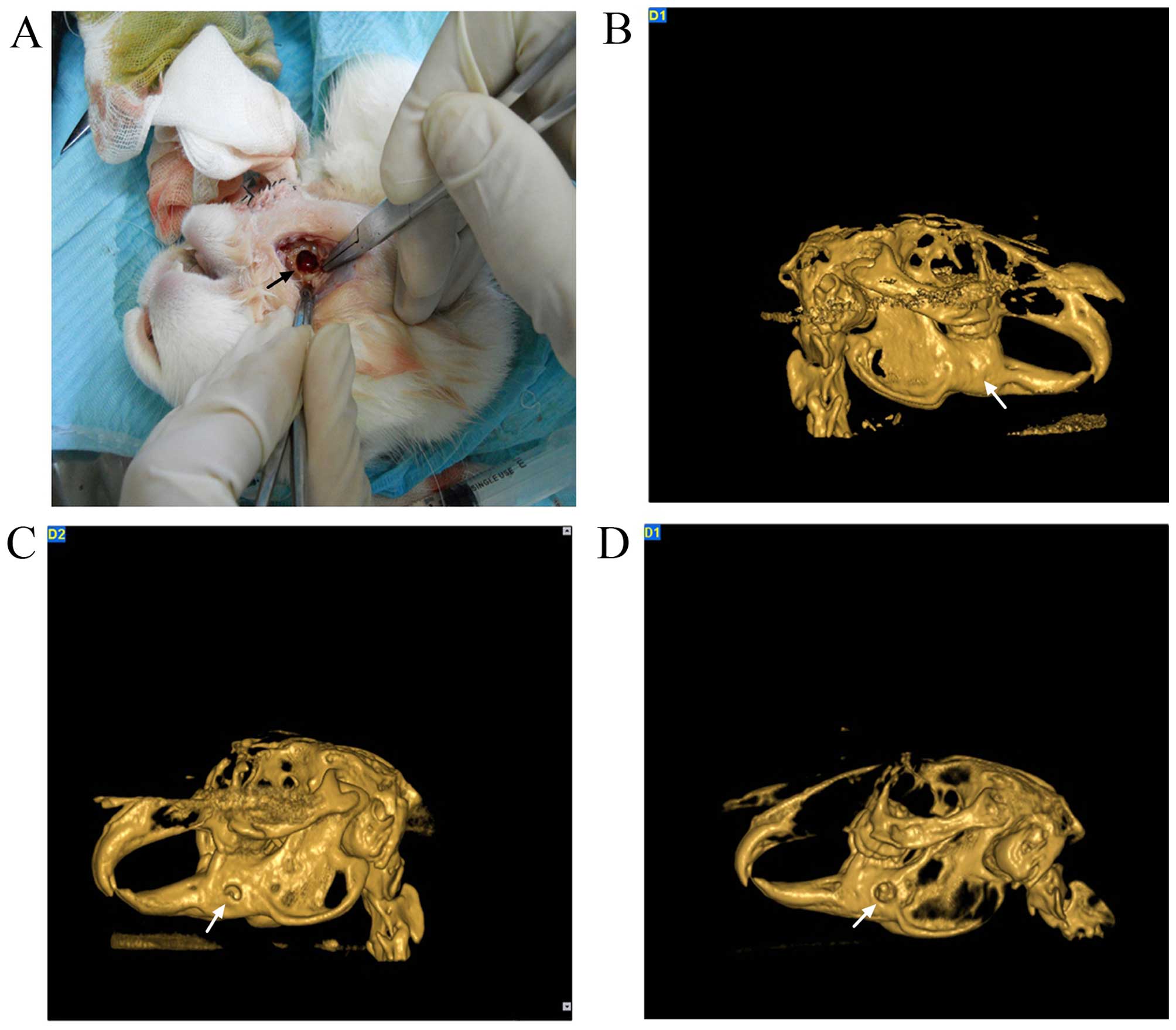

Animals and clinical observations

A total of eighteen rabbits underwent the successful

creation of a mandibular defect (Fig.

7A). All animals developed some degree of postoperative

swelling at the incision site that resolved within one week of the

operation with no functional consequences. The animals were allowed

to heal for 4–12 weeks and then sacrificed for analysis. No rabbit

developed an abscess or was sacrificed and excluded from

analysis.

Analysis of 3D-CT images

To follow new bone formation and the development of

bone unions within the defects, 3D images were captured 3 months

postoperatively. Representative images from each group are shown in

Fig. 7.

Analysis of the 3D-CT images confirmed the findings

that the pure SF-CS scaffolds and the TGF-β1-SF-CS scaffold

substitutes are bioactive and biocompatible with the host bone. In

the TGF-β1-SF-CS scaffold group, the disappearance of the defect at

12 weeks after implantation indicated that the density of the newly

formed bone was as high as that of the host bone, and that complete

osteointegration of the defect area had been achieved (Fig. 7B). In comparison, in the pure

SF-CS scaffold group, the volume and radiopacity of the newly

formed bone are highly increased; however, the new bone formation

failed to cover the defect completely, and bone formation occurred

along the periphery of the defect area, which illustrated that the

new bone had increased in density and quantity and had grown into

the scaffold although incompletely (Fig. 7C). In the empty control group, the

untreated defect exhibited no evidence of healing by itself even at

12 weeks (Fig. 7D).

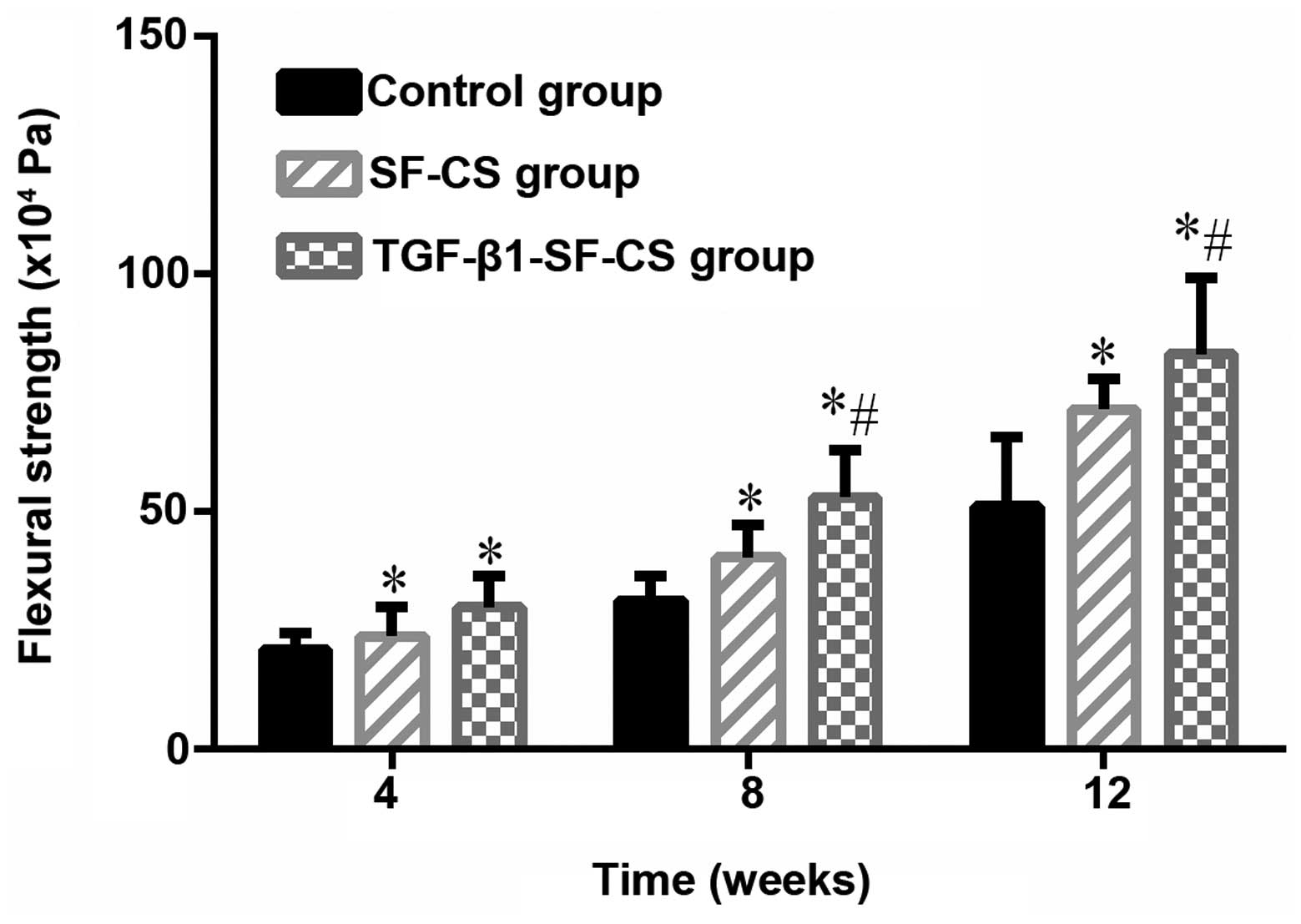

Biomechanical evaluation

As shown in Fig.

8, the flexural strength of the implanted scaffold groups and

the control group cultured for 4, 8 and 12 weeks were compared. The

flexural strength for the implanted scaffold groups gradually

increased, indicating the occurrence of significant bone growth

within both scaffolds. After 4 weeks, the flexural strength of the

implanted scaffold groups (23.9±6.223×104 Pa and

29.9±6.481×104 Pa) was significantly greater than the

flexural strength of the empty defects (20.9±3.610×104

Pa) (P<0.05). The increase in flexural strength was highest in

the TGF-β1-SF-CS group, and the flexural strength values reached a

peak at 12 weeks (87.2±11.766×104 Pa).

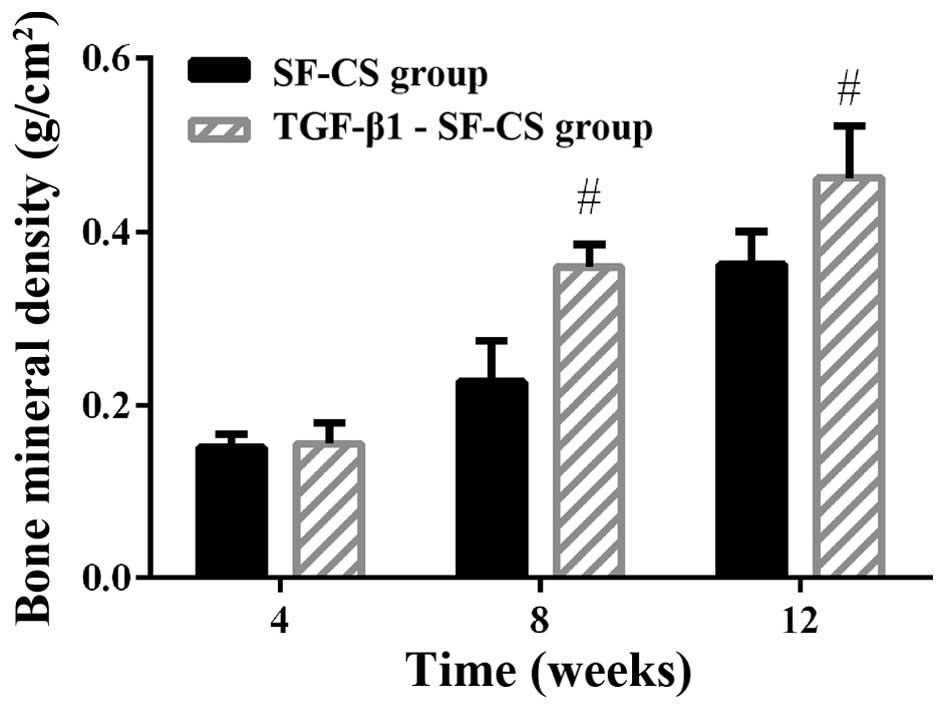

Evaluation of local BMD

To quantify the level of calcification in the

repaired mandibles, local BMD in all animals was measured on a DXA

system at 4, 8 and 12 weeks postoperatively (Fig. 9). The BMD for the implanted

scaffold groups gradually increased, indicating significant bone

growth within both scaffolds. The BMD of the TGF-β1-SF-CS scaffold

group was not significantly different from that in the SF-CS

scaffold group at 4 weeks (P>0.05). However, at 8 weeks, the

TGF-β1-SF-CS scaffold group showed a relatively higher BMD of

0.359±0.025 g/cm2. In the SF-CS scaffold group, the

local BMD was 0.227±0.047 g/cm2, which was significantly

lower than that in the TGF-β1-SF-CS scaffold group (P<0.05). At

12 weeks, the BMD of the TGF-β1-SF-CS scaffold group (0.462±0.060

g/cm2) was significantly higher than the BMD of the

SF-CS scaffold group (0.362±0.038 g/cm2) (P<0.05).

The control group with a defect the same size as those implanted

did not display any detectable BMD value in the DXA tests, thus,

the contribution to the total density was negligible (data not

shown).

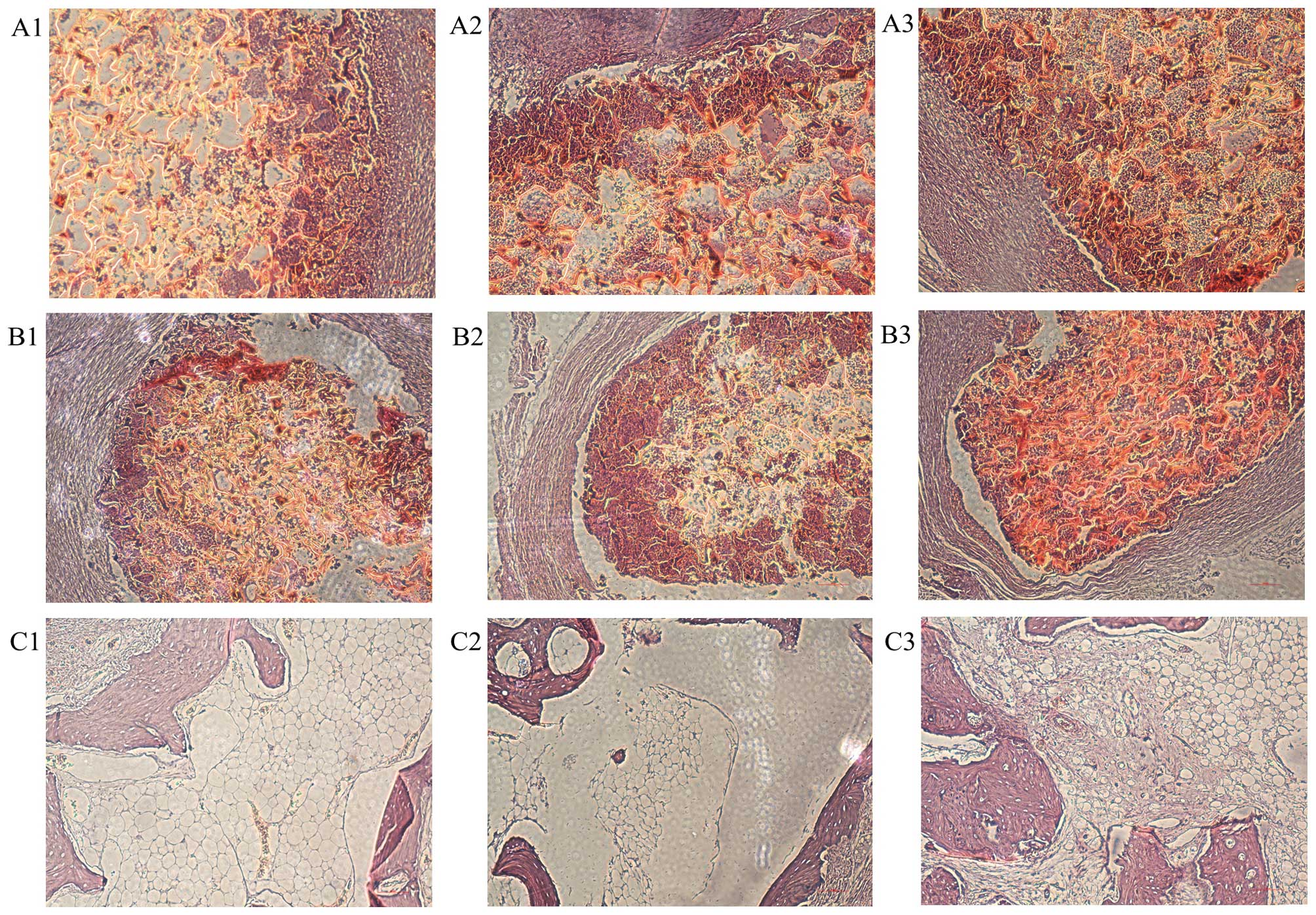

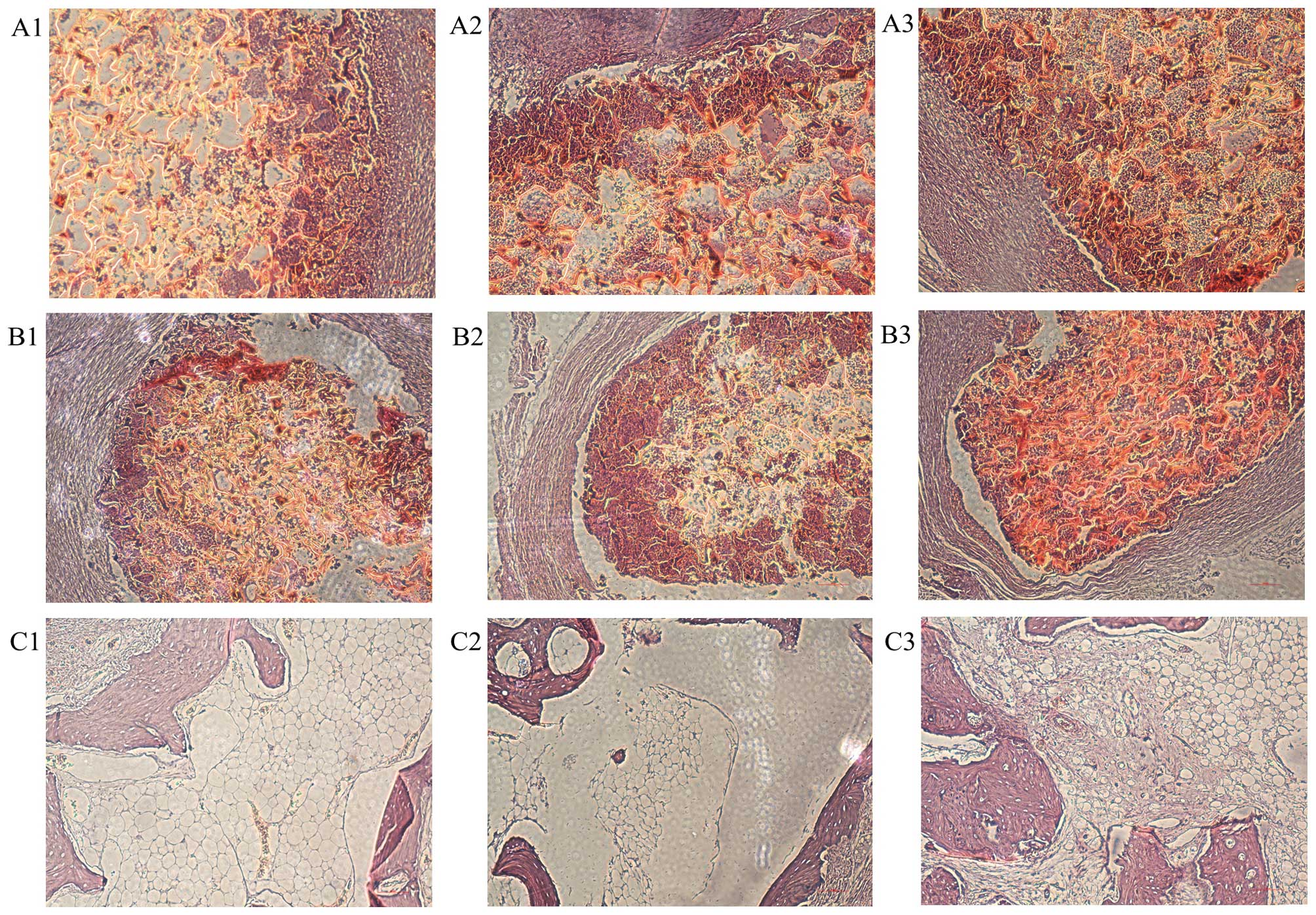

Histomorphometric analysis of bone

regeneration

Based on the in vivo histological study, all

of the light microscope images showed the architecture of the

scaffold clearly, which revealed that the scaffolds were not

markedly deformed. In the TGF-β1-SF-CS scaffold group and the SF-CS

scaffold group, all the scaffolds implanted after 4 weeks are

encapsulated by fibrous collagen, and some newly formed bone

tissues are deposited at the interface of material and bone with

the presence of active osteoblasts (Fig. 10A1 and B1). Moreover, a large

proportion of osteoblasts have penetrated into the porous cavities,

which accelerate the mineralization and regeneration of bone, and a

large number of inflammatory cells are observable, as well as some

newly generated tissues. Additionally, the interface between the

SF-CS scaffold and natural bone is clearly visible, whereas in the

TGF-β1-SF-CS scaffold group the boundary between the material and

host bone is unclear. In the control group, repaired tissues are

not observable, and the defects are filled with few fiber-like

tissues and adipocytes (Fig.

10C1).

| Figure 10Sample histology of healed defects

for the TGF-β1-silk fibroin-chitosan (TGF-β1-SF-CS) scaffolds, the

silk fibroin-chitosan (SF-CS) scaffolds and the control group

(light microscope, ×100 magnification). At 4 weeks: (A1 and B1) All

the scaffolds are encapsulated by fibrous collagen, some newly

formed bone tissues are deposited at the interface between material

and host bone with the presence of active osteoblasts. (C1) In the

control group, repaired tissues are not present, and the defects

are filled with few fiber-like tissues and adipocytes. At 8 weeks:

(A2) In the TGF-β1-SF-CS scaffold group, the boundary between

material and host bone is unclear, new bone has regenerated and

penetrated through the interconnective pores to the center of the

scaffolds, increasing the quantity and density of the defect area.

(B2) In the SF-CS scaffold group, the interface between scaffold

and natural bone remains clearly visible, some newly formed bone

tissues are deposited at the interface of material and bone with

the presence of active osteoblasts. (C2) In the control group, the

defects are filled with some fiber-like tissues and adipocytes. At

12 weeks: (A3) In the TGF-β1-SF-CS scaffold group, the interface

between material and host bone is hardly detectable and forms a

close union without any gap. There is an ordered cell arrangement

and an increased number of cells. (B3) In the SF-CS scaffold group,

new bone formation is observable with more residual scaffold at the

center of the defect compared with the TGF-β1-SF-CS scaffold group.

(C3) In the empty control group, the mandible defects exhibit no

signs of recovery and there is limited encapsulation by fibrous

tissues. Bony defects remain present in the center with new bone

only formed at the periphery. |

At 8 weeks post-implantation, in the TGF-β1-SF-CS

scaffold group the boundary between material and host bone is more

unclear due to the sufficient formation of mature bone tissues

which have grown into the pores of the artificial scaffold and

bonded tightly with the material. With the implantation prolonged,

new bone has regenerated and penetrated through the interconnective

pores to the center of the scaffolds, increasing the quantity and

density of the defect area, and decreasing the number of

inflammatory cells (Fig. 10A2).

In the SF-CS scaffold group, the interface between scaffold and

natural bone was still clearly visible, some newly formed bone

tissues have been deposited at the interface of material and bone

with the presence of active osteoblasts (Fig. 10B2). In the control group, the

defects are filled with some fiber-like tissues and adipocytes

(Fig. 10C2).

The histological results of the TGF-β1-SF-CS

scaffold group at 12 weeks show that the interface between material

and host bone has formed a close union. There is an ordered cell

arrangement and an increased number of cells. Additionally,

inflammatory cells, including lymphocytes, are not observable.

Despite some bone ingrowth from the interface region, there is

insufficient bone formation in the central area (Fig. 10A3). In the SF-CS scaffold group,

new bone formation is apparent with more residual scaffold at the

center of the defect compared with that in the TGF-β1-SF-CS

scaffold group. The SF-CS scaffolds still hold their pore structure

and are unfilled by sufficient newly formed bone (Fig. 10B3). By contrast, in the empty

control group, the mandible defects exhibited no signs of recovery

with minimal encapsulation by fibrous tissues. Bony defects are

still present in the center, the defects were filled with some

fiber-like tissues and adipocytes, and new bone was only formed at

the periphery. Despite some bone ingrowth from the interface

region, there is insufficient bone formation in the central area

(Fig. 10C3).

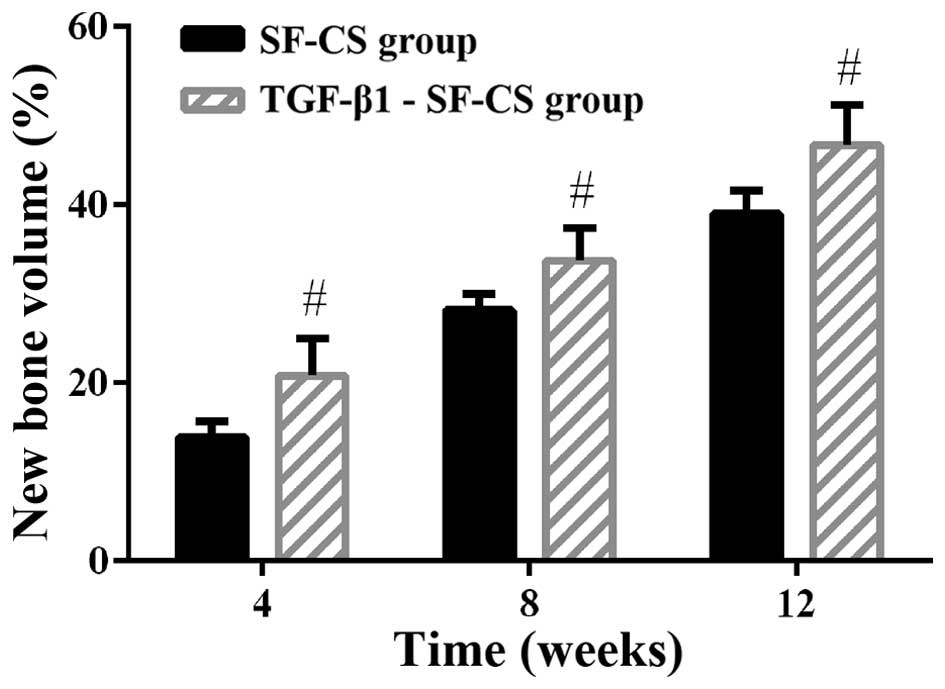

Quantitative determination of newly formed bone was

performed by statistical analysis of the histological sections.

Fig. 11 shows the NBV at each

implantation period. Clearly, after 4 weeks post-implantation, the

amount of newly formed bone in the TGF-β1-SF-CS scaffold group

increased markedly, much more than that in the pure SF-CS scaffold

group. However, after that period, bone formation in the pure SF-CS

scaffold slowed down, whereas in the TGF-β1-SF-CS scaffold group

the speed of new bone formation gradually increased. At 12 weeks,

NBV in the TGF-β1-SF-CS scaffold group was the highest. These

results confirmed that at the latter stage of implantation, the

TGF-β1-SF-CS scaffold achieved a higher efficiency of bone

formation than pure SF-CS scaffolds, and in the long-term, the

TGF-β1-SF-CS scaffolds showed far better biocompatibility and

osteogenesis. The TGF-β1-SF-CS scaffolds group showed a healing

percentage of 46.71±4.46%, which was higher than the SF-CS

scaffolds group (38.97±2.63%) (P<0.05). The control group did

not display marked bone formation in the NBV tests, so the

contribution to the total NBV was negligible (data not shown).

Discussion

Growth factors may be incorporated directly into a

polymeric scaffold to be used for tissue formation after scaffold

fabrication (21,22,31). Growth factor supplementation

strategies have shown significant functional value in the context

of bone tissue regeneration. Previous findings have 'immobilised'

or 'incorporated' growth factors such as TGF-β1 and fibroblast

growth factor into tissue scaffold systems with sustained release

properties (32). Active forms

were used and inevitably involved processing steps which may have

resulted in reduced bioactivity. In addition, the majority of

scaffold release systems are hydrogel based, and the release of

growth factors is by diffusion or degradation of the scaffold

matrix. This often results in a 'burst' release and a compromise in

the mechanical properties of the scaffold and in other properties

required for bone engineering (33). In the present study, a composite

scaffold design was constructed to increase the osteogenesis of

BMSCs through the incorporation of TGF-β1 during SF-CS scaffold

fabrication, rather than after scaffold fabrication. This method

was simple, convenient and had a high rate of success as well as

easily controlling the of growth factor content. It also improved

the loading content and loading efficiency of TGF-β1 on the SF-CS

scaffold. We analyzed the TGF-β1-SF-CS composite scaffolds for bone

tissue engineering applications. Such a scaffold may be

particularly suited for implantation into bone defects as it

promotes the proliferation, migration and differentiation of cells

as well as being osteoconductive. For this purpose, we added TGF-β1

into the SF-CS scaffold to construct a 3D scaffold for the first

time.

An optimum scaffold should meet certain criteria,

such as a suitable 3D structure for cell growth and nutrient

transport and optimal pore size to prevent cell loss from the

scaffolds. We found that the SF-CS scaffolds had random porous

microstructures, whether or not TGF-β1 was added. Porous structures

allow for the optimal interaction of the scaffold with the cells

(34). Pore size determines the

efficiency at which the cells seed into the scaffold (35). Small scaffold pores may result in

pore occlusion by the cells, preventing cellular penetration

whereas large pores prevent cell attachment due to a reduced area.

It is necessary for the scaffold to have an adequate porosity; this

includes the magnitude of the porosity, the pore size distribution

and its interconnectivity. A pore size >100 µm and

<400 µm is usually considered optimal for osteoconduction

(36). In the present study, the

TGF-β1-SF-CS scaffold had an open and interconnected pore network

and a high degree of porosity. The inner pore size of the scaffold

was approximately ten to three hundred microns, which led to

uniform cell distribution inside the scaffolds. It was an ideal

scaffold for interacting and integrating with the bone tissue. We

also found that despite adding TGF-β1 to the SF-CS scaffold, the

porosity and swelling index of the scaffold did not markedly alter

the shape and structure or morphology of the scaffolds.

CS is a polysaccharide found in the native ECM and

it is known to play a critical role in sequestering growth factors

within the matrix. Structural variations in the carbohydrate

backbone, allows CS to possess varying levels of negative charges

depending on the degree of sulfation (37,38), making it attractive option for the

development of growth factor-sequestering biomaterials. In addition

to the non-specific, electrostatic growth factor-CS interactions, a

similar study has also shown that TGF-β1 may be adsorbed onto

biomaterials such as SF composed of type I collagen (39). It is important to consider

strategies to immobilize and pattern proteins, such as growth

factors and other cytokines, to develop long-term tissue

engineering solutions (40–44). Factor immobilization may offer

numerous advantages, including improved protein stability and

reduced diffusion, as well as increased localization of the

therapeutic effects within the material. A previous study

demonstrated that TGF-β1 was immobilized in the SF-CS scaffold

through ionic interactions and covalent bonds (45). The effectiveness of adsorbing

TGF-β1 onto the SF-CS scaffold may be due to protection of the

molecule from proteolytic digestion, allowing a more sustained

release of TGF-β1 over time. This indicates that the growth factor

remains bioactive within the matrix for a long period of time

(46).

When constructing the TGF-β1-SF-CS scaffold for bone

tissue engineering, it is critical to maintain the bioactivity of

TGF-β1 as during this process TGF-β1 bioactivity is mostly like to

be destroyed by lyophilization and methanol crosslinking. During

the process of lyophilization, the use of a cryoprotectant may

reduce or even prevent the adverse effects of stress on protein

activity (47). Silk protein and

CS may be used as a cryoprotectant to maintain the activity of

TGF-β1 (48,49). Klibanov proved that the

conformation of protein treated with low concentrations of methanol

was basically unchanged and the covalent structure of protein

molecules was not destroyed (50). We implemented the following

measures in manufacturing the TGF-β1-SF-CS scaffold to prevent the

loss of TGF-β1 bioactivity: i) setting the lyophilization

temperature at −40°C and using SF and CS as cryoprotectants to

further maintain TGF-β1 activity; ii) selecting a methanol

concentration <10%; iii) designing the whole TGF-β1-SF-CS

manufacturing procedure as a physical process. The results of the

analysis of ALP activity and the CCK-8 assay revealed that there

was no clear degradation of TGF-β1 bioactivity. We immobilized

TGF-β1 such that the total amount immobilized on the SF-CS scaffold

was equivalent to the total soluble biomolecule content in the

TGF-β1 solution. This experiment revealed that, as expected, the

freely soluble TGF-β1 induced high bioactivity.

SEM analysis confirmed that subcellular microvillous

and lamellopodia extensions were employed by adherent cells to

establish anchorage fronts with the SF-CS substrate. Additionally,

a BMSC growth differentiation study was performed to further

evaluate the biocompatibility of these scaffolds. The seeding of

BMSCs onto TGF-β1-SF-CS scaffolds resulted in a completely flat and

elongated cell morphology, similar to what is typically observed in

standard cell culture flasks. These observations confirmed the

long-term cell viability and proliferation of BMSCs on TGF-β1-SF-CS

scaffolds, assuring its biocompatibility.

Nominal differences in cellular adhesion were

observed between BMSCs after osteogenesis induction. Additionally,

these results suggested that the SF-CS scaffolds were suitable for

the proposed in vitro studies as the initial attachment onto

the surface as well as the spreading and subsequent growth of BMSCs

was facilitated. The adhesion rate of BMSCs in the TGF-β1-SF-CS

group and in the SF-CS group significantly exceeded those in the

control groups (P<0.05). However, no statistically significant

differences (P>0.05) were observed between the SF-CS and the

TGF-β1-SF-CS scaffold groups. It proved that TGF-β1 was unable to

promote BMSC adhesion in the SF-CS scaffolds.

The number of viable cells at day 1 (after 24 h of

cell attachment) was taken as a reference point to compare the

growth and proliferation rate of BMSCs on the TGF-β1-SF-CS and

SF-CS scaffolds. It was observed that the absorbance index of the

tested groups increased in a time-dependent manner. However, there

was a TGF-β1-dependent effect of the scaffolds on cell

proliferation rate. At day 1, the viable cell number was not

significantly different among the three groups, indicating that

cell attachment to scaffolds was similar. With regard to cell

growth, from day 3, a significant difference (P<0.05) in cell

number was observed between the scaffolds groups and the control

group as well as between the TGF-β1-SF-CS and SF-CS scaffolds.

These results indicated that TGF-β1 significantly promoted the

growth and proliferation of BMSCs after osteogenesis induction

under these conditions. The in vitro experiments performed

in the present study also suggest that TGF-β1 may regulate bone

formation through a direct effect on BMSCs after osteogenesis

induction. Our results indicated a difference in the activity of

BMSCs in the different types of scaffold which may be due to: i)

the release of TGF-β1 from TGF-β1-SF-CS scaffolds in a sustained

manner thus, the released TGF-β1 was able to reach the cells more

quickly and homogeneously, and ii) TGF-β1 maintained its

bioactivity after being released from the TGF-β1-SF-CS scaffold.

Through the ALP and CCK-8 assay results, we basically determined

that in TGF-β1-SF-CS scaffolds, IGF-1 was evenly and continuously

released within a certain time period.

Due to the rapid immobilization of TGF-β1 in the

SF-CS scaffold and the sustained and effective local release of

growth factors after seeding BMSCs in the porous TGF-β1-SF-CS

scaffold, as expected, the level of proliferation and

differentiation of the BMSCs was controlled by the presence of

TGF-β1. The results obtained from the analysis of ALP activity and

the CCK-8 assay in vitro showed that the TGF-β1-SF-CS

scaffolds did not contain products toxic to cells and the

proliferation of BMSCs on the scaffolds increased regularly in a

time-dependent manner. The SEM images revealed the spindle-like

shape of the attached cells with filopodia-like extensions adhering

to the scaffold and connecting to adjacent BMSCs. Evidence of

cell-to-cell interactions and cell spreading may be considered as

signs of healthy BMSCs and indicative of a noncytotoxic response of

the cells on the supporting material (51,52). In the present study, TGF-β1

bioactivity was studied over the first 2 weeks of drug delivery. It

has been shown that TGF-β1 incorporated into the SF-CS scaffolds is

capable of maintaining bioactivity over at least 2 weeks,

suggesting that longer-term maintenance of bioactivity is

feasible.

To evaluate the mechanical recovery of bone grafts

in rabbit models of segmental radius defects, bending test

configurations have been reported (53–55). Our studies have shown that both

three-point bending resulted in similar outcomes when testing the

mechanical integrity of rabbit mandible (53). In agreement with this study, the

primary failure mode for bending was a short oblique fracture.

Additionally, the reported primary failure zone was constrained to

the location of the central contact in the three-point bending

whereas the four-point mode was reported to have a more uniform

stress distribution within the central loading span (56). Since the objective of this study

was to evaluate the interfacial integration of the scaffold to the

bone, three-point bending testing was selected, with the scaffold

lying completely within the loading span. Other confounding factors

such as loading to support span ratios, contact geometry and load

rates were matched to the suggestions in the literature (56).

In the present study, bony union was achieved as

early as 1 to 3 months after transplantation and an improved

mandibular shape was observed after sacrifice. We also found that

the BMD and NBV of the TGF-β1-SF-CS scaffold group was higher than

the SF-CS scaffold group at 4 weeks postoperatively. This indicated

that new bone formation and mineralization in the TGF-β1-SF-CS

scaffold group surpassed that occurring during the repair process

in the SF-CS scaffold group. Our data indicated that the SF-CS

scaffold was feasible and conferred that TGF-β1 possessses the

potential physiological benefit of accelerated reconstruction. The

results of CT scans, gross view and histological analyses

consistently showed that the TGF-β1-SF-CS scaffold group had the

strongest capacity for bone regeneration compared with the other

groups.

The capability of the TGF-β1-SF-CS scaffold to

enhance the viability and proliferation of BMSCs as a function of

time demonstrates its cytocompatibility and feasibility for bone

tissue engineering applications. TGF-β1 did not promote the

activity and proliferation of osteoblasts significantly at early

time-points; however, it had a marked effect when culturedfor

longer periods of time (3–10 days), demonstrating that the effect

of TGF-β1, which promotes the activity and proliferation of BMSCs,

is time-dependent. In the in vivo experiment, TGF-β1 did not

induce significantly more new bone formation at early time-points

(4 weeks) whereas it had a marked effect at later time-points

(after 8 weeks), demonstrating that the effect of TGF-β1 which

promotes the activity and proliferation of osteoblasts is

time-dependent. These results indicate that correct TGF-β1 delivery

strategies greatly affect osteogenic differentiation and are of

importance when designing a delivery system. The ideal duration of

TGF-β1 delivery is dependent on the drug delivery application. For

example, for slowly progressing bone healing, controlled-release

formulations leading to sustained improvements in patient symptoms

and/or disease conditions allow for more convenient dosage and

increased compliance with treatment.

Our data suggested that the anchorage of TGF-β1 onto

the SF-CS scaffold may achieve the intended natural configuration,

as TGF-β1 was protected and available for activation. The

TGF-β1-SF-CS scaffold exerts positive effects on matrix production

as well as the proliferation and differentiation of BMSCs. Our data

supports the potential use of SF-CS as a biocompatible scaffold.

Our findings demonstrated that TGF-β1-SF-CS scaffolds are suitable

substrates for bone tissue engineering and TGF-β1 confers the

potential physiological benefit of accelerated reconstruction. We

explored the immobilization of TGF-β1 within the SF-CS scaffold to

evaluate relative biomolecule bioactivity as a function of

presentation modality. Future bone tissue engineering studies are

warranted, focusing on how TGF-β1 combined with the scaffold, and

whether the sustained release of TGF-β1 is maintained and enhanced

in longer-term studies, or examining whether the culture of

different types of cells on the TGF-β1-SF-CS scaffolds yields

similar outcomes. Our future studies aim to examine the potential

repair reaction of the TGF-β1-SF-CS scaffolds in a bone defect

model in large animals. We also aim to explore additional soluble

factors and exploit immobilization techniques to identify

combinations of biomolecules capable of improving scaffolds. The

materials developed here are also likely to be useful as 3D

templates for bone tissue engineering.

In conclusion, we compared, for the first time to

the best of our knowledge, the physiochemistry and osteogenesis of

TGF-β1-SF-CS scaffolds and SF-CS scaffolds. Our results confirmed

that TGF-β1, a bioactive growth factor, has a significant capacity

to improve the bioactivity of SF-CS scaffolds. The results showed

that TGF-β1-SF-CS scaffolds exhibit good biocompatibility and

extensive osteoconductivity with the host bone. Moreover, the

introduction of TGF-β1 to the SF-CS scaffolds markedly enhanced the

efficiency of new bone formation, particularly 12 weeks after

implantation. The TGF-β1-SF-CS scaffolds possessed as good

biocompatibility and osteogenesis as the hybrid ones. All these

results indicated that the TGF-β1-SF-CS scaffolds fulfiled the

basic requirements of an ideal scaffold for use in bone tissue

engineering, and have the potential to be applied in orthopedic,

reconstructive and maxillofacial surgery.

Acknowledgments

The present study was supported by the Science and

Technology Plan Project of Liaoning Province (grant no.

2012-B-00002012225082).

References

|

1

|

Vacanti JP and Langer R: Tissue

engineering: the design and fabrication of living replacement

devices for surgical reconstruction and transplantation. Lancet.

354(Suppl 1): SI32–SI34. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Scheller EL, Krebsbach PH and Kohn DH:

Tissue engineering: state of the art in oral rehabilitation. J Oral

Rehabil. 36:368–389. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Hankenson KD, Dishowitz M, Gray C and

Schenker M: Angiogenesis in bone regeneration. Injury. 42:556–561.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Marsell R and Einhorn TA: The biology of

fracture healing. Injury. 42:551–555. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Andrew JG, Hoyland J, Andrew SM, Freemont

AJ and Marsh D: Demonstration of TGF-beta 1 mRNA by in situ

hybridization in normal human fracture healing. Calcif Tissue Int.

52:74–78. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Baylink DJ, Finkelman RD and Mohan S:

Growth factors to stimulate bone formation. J Bone Miner Res.

8(Suppl 2): S565–S572. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Bonewald LF and Mundy GR: Role of

transforming growth factor-beta in bone remodeling. Clin Orthop

Relat Res. 250:261–276. 1990.PubMed/NCBI

|

|

8

|

Connelly JT, Wilson CG and Levenston ME:

Characterization of proteoglycan production and processing by

chondrocytes and BMSCs in tissue engineered constructs.

Osteoarthritis Cartilage. 16:1092–1100. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Mouw JK, Connelly JT, Wilson CG, Michael

KE and Levenston ME: Dynamic compression regulates the expression

and synthesis of chondrocyte-specific matrix molecules in bone

marrow stromal cells. Stem Cells. 25:655–663. 2007. View Article : Google Scholar

|

|

10

|

Johnstone B, Hering TM, Caplan AI,

Goldberg VM and Yoo JU: In vitro chondrogenesis of bone

marrow-derived mesenchymal progenitor cells. Exp Cell Res.

238:265–272. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Murphy CM, O'Brien FJ, Little DG and

Schindeler A: Cell-scaffold interactions in the bone tissue

engineering triad. Eur Cell Mater. 26:120–132. 2013.PubMed/NCBI

|

|

12

|

Roberts AB and Sporn MB: Physiological

actions and clinical applications of transforming growth

factor-beta (TGF-beta). Growth Factors. 8:1–9. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Pittenger MF, Mackay AM, Beck SC, Jaiswal

RK, Douglas R, Mosca JD, Moorman MA, Simonetti DW, Craig S and

Marshak DR: Multilineage potential of adult human mesenchymal stem

cells. Science. 284:143–147. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Cashman JD, Eaves AC, Raines EW, Ross R

and Eaves CJ: Mechanisms that regulate the cell cycle status of

very primitive hematopoietic cells in long-term human marrow

cultures. I. Stimulatory role of a variety of mesenchymal cell

activators and inhibitory role of TGF-beta. Blood. 75:96–101.

1990.PubMed/NCBI

|

|

15

|

Spinella-Jaegle S, Roman-Roman S, Faucheu

C, Dunn FW, Kawai S, Galléa S, Stiot V, Blanchet AM, Courtois B,

Baron R and Rawadi G: Opposite effects of bone morphogenetic

protein-2 and transforming growth factor-beta1 on osteoblast

differentiation. Bone. 29:323–330. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Park SJ, Lee KY, Ha WS and Park SY:

Structural changes and their effect on mechanical properties of

silk fibroin/chitosan blends. J Appl Polym Sci. 74:2571–2575. 1999.

View Article : Google Scholar

|

|

17

|

El Sayed K, Marzahn U, John T, Hoyer M,

Zreiqat H, Witthuhn A, Kohl B, Haisch A and Schulze-Tanzil G:

PGA-associated heterotopic chondrocyte cocultures: implications of

nasoseptal and auricular chondrocytes in articular cartilage

repair. J Tissue Eng Regen Med. 7:61–72. 2013. View Article : Google Scholar

|

|

18

|

De Santis R, Gloria A, Russo T, D'Amora U,

Zeppetelli S, Dionigi C, Sytcheva A, Herrmannsdörfer T, Dediu V and

Ambrosio L: A basic approach toward the development of

nanocomposite magnetic scaffolds for advanced bone tissue

engineering. J Appl Polym Sci. 122:3599–3605. 2011. View Article : Google Scholar

|

|

19

|

Tong S, Xu DP, Liu ZM and Wang XK:

Construction and in vitro characterization of three-dimensional

silk fibroinchitosan scaffolds. Dent Mater J. 34:475–484. 2015.

View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Gobin AS, Froude VE and Mathur AB:

Structural and mechanical characteristics of silk fibroin and

chitosan blend scaffolds for tissue regeneration. J Biomed Mater

Res A. 74:465–473. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Whang K, Tsai DC, Nam EK, Aitken M,

Sprague SM, Patel PK and Healy KE: Ectopic bone formation via

rhBMP-2 delivery from porous bioabsorbable polymer scaffolds. J

Biomed Mater Res. 42:491–499. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Uebersax L, Merkle HP and Meinel L:

Insulin-like growth factor I releasing silk fibroin scaffolds

induce chondrogenic differentiation of human mesenchymal stem

cells. J Control Release. 127:12–21. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Li C, Vepari C, Jin HJ, Kim HJ and Kaplan

DL: Electrospun silk-BMP-2 scaffolds for bone tissue engineering.

Biomaterials. 27:3115–3124. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Hosseinkhani H, Hosseinkhani M,

Khademhosseini A and Kobayashi H: Bone regeneration through

controlled release of bone morphogenetic protein-2 from 3-D tissue

engineered nano-scaffold. J Control Release. 117:380–386. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Luginbuehl V, Wenk E, Koch A, Gander B,

Merkle HP and Meinel L: Insulin-like growth factor I-releasing

alginate-tricalciumphosphate composites for bone regeneration.

Pharm Res. 22:940–950. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Chung YI, Ahn KM, Jeon SH, Lee SY, Lee JH

and Tae G: Enhanced bone regeneration with BMP-2 loaded functional

nanoparticle-hydrogel complex. J Control Release. 121:91–99. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Li B, Brown KV, Wenke JC and Guelcher SA:

Sustained release of vancomycin from polyurethane scaffolds

inhibits infection of bone wounds in a rat femoral segmental defect

model. J Control Release. 145:221–230. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Long JL and Tranquillo RT: Elastic fiber

production in cardiovascular tissue-equivalents. Matrix Biol.

22:339–350. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Shi J, Wang A, Sen S, Wang Y, Kim HJ,

Mitts TF and Hinek A: Insulin induces production of new elastin in

cultures of human aortic smooth muscle cells. Am J Pathol.

180:715–726. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Kim UJ, Park J, Kim HJ, Wada M and Kaplan

DL: Three-dimensional aqueous-derived biomaterial scaffolds from

silk fibroin. Biomaterials. 26:2775–2785. 2005. View Article : Google Scholar

|

|

31

|

Li C, Vepari C, Jin HJ, Kim HJ and Kaplan

DL: Electrospun silk-BMP-2 scaffolds for bone tissue engineering.

Biomaterials. 27:3115–3124. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Chou CH, Cheng WT, Lin CC, Chang CH, Tsai

CC and Lin FH: TGF-beta1 immobilized tri-co-polymer for articular

cartilage tissue engineering. J Biomed Mater Res B Appl Biomater.

77:338–348. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Sohier J, Moroni L, van Blitterswijk C, de

Groot K and Bezemer JM: Critical factors in the design of growth

factor releasing scaffolds for cartilage tissue engineering. Expert

Opin Drug Deliv. 5:543–566. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Lyons F, Partap S and O'Brien FJ: Part 1:

scaffolds and surfaces. Technol Health Care. 16:305–317.

2008.PubMed/NCBI

|

|

35

|

Mooney DJ, Baldwin DF, Suh NP, Vacanti JP

and Langer R: Novel approach to fabricate porous sponges of poly

(D,L-lactic-co-glycolic acid) without the use of organic solvents.

Biomaterials. 17:1417–1422. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Chung HJ and Park TG: Surface engineered

and drug releasing pre-fabricated scaffolds for tissue engineering.

Adv Drug Deliv Rev. 59:249–262. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Raman R, Sasisekharan V and Sasisekharan

R: Structural insights into biological roles of

protein-glycosaminoglycan interactions. Chem Biol. 12:267–277.

2005. View Article : Google Scholar : PubMed/NCBI

|

|

38

|

Gama CI, Tully SE, Sotogaku N, Clark PM,

Rawat M, Vaidehi N, Goddard WA III, Nishi A and Hsieh-Wilson LC:

Sulfation patterns of glycosaminoglycans encode molecular

recognition and activity. Nat Chem Biol. 2:467–473. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

39

|

Hempel U, Hintze V, Möller S,

Schnabelrauch M, Scharnweber D and Dieter P: Artificial

extracellular matrices composed of collagen I and sulfated

hyaluronan with adsorbed transforming growth factor β1 promote

collagen synthesis of human mesenchymal stromal cells. Acta

Biomater. 8:659–666. 2012. View Article : Google Scholar

|

|

40

|

Ker EDF, Chu B, Phillippi JA, Gharaibeh B,

Huard J, Weiss LE and Campbell PG: Engineering spatial control of

multiple differentiation fates within a stem cell population.

Biomaterials. 32:3413–3422. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

41

|

Shen YH, Shoichet MS and Radisic M:

Vascular endothelial growth factor immobilized in collagen scaffold

promotes penetration and proliferation of endothelial cells. Acta

Biomater. 4:477–489. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

42

|

Oh SH, Kim TH and Lee JH: Creating growth

factor gradients in three dimensional porous matrix by

centrifugation and surface immobilization. Biomaterials.

32:8254–8260. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

43

|

Anderson SM, Chen TT, Iruela-Arispe ML and

Segura T: The phosphorylation of vascular endothelial growth factor

receptor-2 (VEGFR-2) by engineered surfaces with electrostatically

or covalently immobilized VEGF. Biomaterials. 30:4618–4628. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Martin TA, Caliari SR, Williford PD,

Harley BA and Bailey RC: The generation of biomolecular patterns in

highly porous collagen-GAG scaffolds using direct photolithography.

Biomaterials. 32:3949–3957. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

45

|

Weadock K, Olson RM and Silver FH:

Evaluation of collagen crosslinking techniques. Biomater Med

Devices Artif Organs. 11:293–318. 1983–1984. View Article : Google Scholar

|

|

46

|

Hortensius RA and Harley BA: The use of

bioinspired alterations in the glycosaminoglycan content of

collagen-GAG scaffolds to regulate cell activity. Biomaterials.

34:7645–7652. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

47

|

Haines AH: Non-equivalence of D- and

L-trehalose in stabilising alkaline phosphatase against

freeze-drying and thermal stress. Is chiral recognition involved?

Org Biomol Chem. 4:702–706. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

48

|

Kreilgaard L, Jones LS, Randolph TW,

Frokjaer S, Flink JM, Manning MC and Carpenter JF: Effect of Tween

20 on freeze-thawing- and agitation-induced aggregation of

recombinant human factor XIII. J Pharm Sci. 87:1597–1603. 1998.

View Article : Google Scholar

|

|

49

|

Pikal-Cleland KA and Carpenter JF:

Lyophilization-induced protein denaturation in phosphate buffer

systems: monomeric and tetrameric beta-galactosidase. J Pharm Sci.

90:1255–1268. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

50

|

Klibanov AM: Enzymatic catalysis in

anhydrous organic solvents. Trends Biochem Sci. 14:141–144. 1989.

View Article : Google Scholar : PubMed/NCBI

|

|

51

|

Nwe N, Furuike T and Tamura H: The

mechanical and biological properties of chitosan scaffolds for

tissue regeneration templates are significantly enhanced by

chitosan from Gongronella butleri. Materials (Basel). 2. pp.

374–398. 2009, View Article : Google Scholar

|

|

52

|

Neamnark A, Sanchavanakit N, Pavasant P,

Bunaprasert T, Supaphol P and Rujiravanit R: In vitro

biocompatibility evaluations of hexanoyl chitosan film. Carbohydr

Polym. 68:166–172. 2007. View Article : Google Scholar

|

|

53

|

Kim J, Yang HJ, Cho TH, Lee SE, Park YD,

Kim HM, Kim IS, Seo YK, Hwang SJ and Kim SJ: Enhanced regeneration

of rabbit mandibular defects through a combined treatment of

electrical stimulation and rhBMP-2 application. Med Biol Eng

Comput. 51:1339–1348. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

54

|

Cui X, Zhang B, Wang Y and Gao Y: Effects

of chitosan-coated pressed calcium sulfate pellet combined with

recombinant human bone morphogenetic protein 2 on restoration of

segmental bone defect. J Craniofac Surg. 19:459–465. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

55

|

Shafiei Z, Bigham AS, Dehghani SN and

Nezhad ST: Fresh cortical autograft versus fresh cortical allograft

effects on experimental bone healing in rabbits: radiological,

histopathological and biomechanical evaluation. Cell Tissue Bank.

10:19–26. 2009. View Article : Google Scholar

|

|

56

|

Draper ER and Goodship AE: A novel

technique for four-point bending of small bone samples with

semi-automatic analysis. J Biomech. 36:1497–1502. 2003. View Article : Google Scholar : PubMed/NCBI

|