Introduction

Knee arthroplasty is a valuable surgical

intervention that markedly enhances the quality of life of patients

suffering from knee joint degeneration. This procedure is

considered for patients with varying degrees of disease severity,

aiming to alleviate pain and restore joint function (1). However, in some cases, patients present

with pre-existing bone loss in the tibia area, leading to more

complex surgical challenges (2,3).

The successful correction of bone loss in the tibia

region depends on the type and extent of the bone defect. The

primary objective of correcting a bone defect is to establish a

stable foundation capable of adequately supporting the knee joint

components, ensuring the weight-bearing capacity of the femoral and

tibial components without compromise (4,5). This,

in turn, enables patients to regain mobility and engage in

weight-bearing activities more efficiently post-surgery. Several

methods are employed to address bone defects, including the use of

bone cement (6), bone grafting

(7), metal and rods (8) and combinations thereof (9).

For the treatment of uncontained or segmental

defects, which entail the loss of bone extending from the internal

bone tissue to the outer edge, the combination of screws and bone

cement has emerged as the preferred approach (10). The screws play a crucial role in

reinforcing bone cement by providing an anchor for it to adhere to,

thereby increasing the overall stability (11). This approach is particularly suitable

for cases where the bone defect comprises <50% of the tibial

plateau on each side and the defect is <1 cm in depth. Studies

with long-term follow-ups have reported positive outcomes using

this method (12-14).

Despite the effectiveness of the screw-cement

combination, there is currently a wide array of screw types

available. The choice of which to use remains largely dependent on

individual surgeon preference and familiarity. Notably, there

exists a limitation in comparative studies evaluating the clinical

efficacy and mechanical impact of various screw insertion factors,

such as the screws themselves or the methods by which they are

anchored to the bone. Consequently, there is a need to investigate

these factors, which, when utilized in total knee arthroplasty

(TKA) for treating limited marginal tibial bone loss, may yield

distinct effects.

The present study aimed to address this gap by

employing finite element analysis, an advanced computer technique

for structural stress analysis developed in engineering mechanics.

The aim was to evaluate the mechanical effects of using a different

number of screws, screw locations, screw lengths and angles of

screw insertion. The findings presented herein may provide valuable

insight for surgeons when selecting the most appropriate screw

conditions for their surgical interventions.

Materials and methods

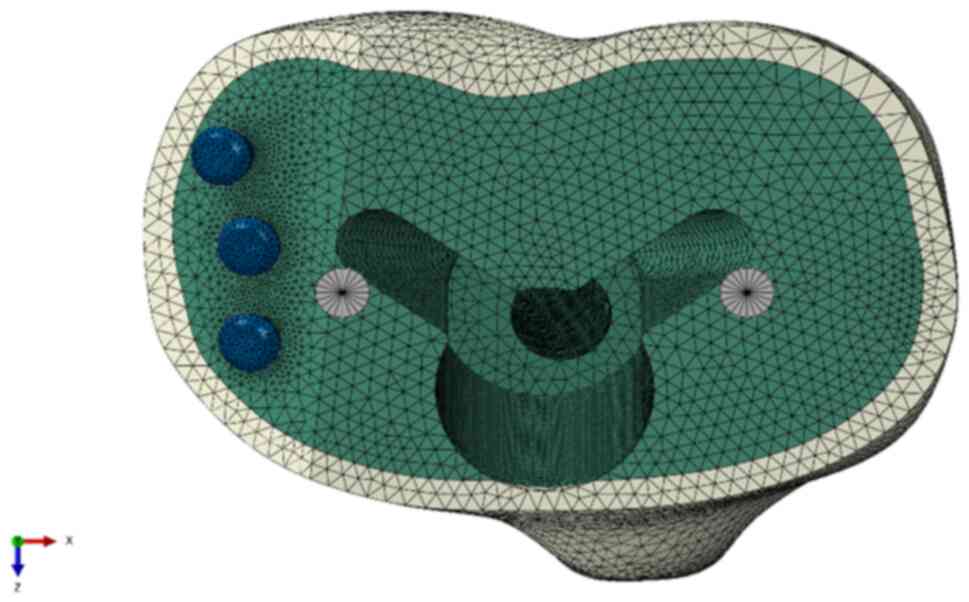

The present study commenced with the construction of

a knee prosthesis model featuring an uncontained bone defect,

specifically constituting 50% of the medial tibial plateau. The

dimensions of the defect are precise, measuring 1 cm in depth and

an incline at 30 degrees. Various parameters were systematically

adjusted in the computer model and evaluated by finite element

analysis to assess their impact on the model. This involved testing

different quantities of screws (1, 2 or 3 screws), various screw

lengths (10, 18, 30 or 40 mm), and exploring different screw

positions with lateral shifts of 2, 4 or 6 mm from the original

sites. Additionally, rotational adjustments were examined,

introducing angles of 5, 10 and 15 degrees away from the original

sites in an abduction direction.

Finite element model of knee

arthroplasty with an uncontained tibial bone defect model

construction

An artificial left tibia (Sawbones® #3401

4th gen., Composite, 17 PCF Solid Foam Core, Medium, Pacific

Research Laboratories, Inc.) with a tibial tray (Zimmer®

NexGen® Complete Knee Solution, Size 5, Zimmer Biomet

Holdings, Inc.), along with relevant components including

polymethylmethacrylate (PMMA) bone cement and Ø3.5 mm screws, was

meticulously assembled to replicate the conditions of knee

arthroplasty with an uncontained tibial bone defect. This construct

was transformed into a three-dimensional (3D) model by utilizing a

series of 256 computed tomography (CT) images, each boasting a

resolution of 512x512 pixels and a slice thickness of 1.0 mm. The

processes involved in creating the 3D model of knee arthroplasty

with an uncontained tibial bone defect encompassed the segmentation

of artificial bone and implant regions, followed by voxel

generation for constructing the 3D model. These steps were executed

using Mimics Research software (version 20.0, Materialise NV).

Subsequently, the 3D model, with a particular focus

on the tibial cortical and cancellous bones, underwent enhancement

using 3-matic research software (version 12.0, Materialise NV).

This enhancement process included the removal of extraneous

components, rectification of defects and the refinement of surfaces

to attain a precise representation of the intended construct.

To finalize the 3D model of knee arthroplasty with

an uncontained tibial bone defect, the enhanced 3D models of the

construct were imported into NX software (version 12.0, Siemens

Product Lifecycle Management Software, Inc.) for further

modifications, employing a range of functions available within the

software. The unnecessary distal portion of the artificial tibia

was removed to economize the analysis, and the uncontained bone

defect of 50% on the medial tibial plateau was refined. Due to the

metal-related artifacts evident in the CT images, it was imperative

to accurately reproduce the tibial tray and the screws. The

geometry of the tibial tray was simplified, while the geometry of

screw was enhanced to adhere to the ISO standard for metallic bone

screws. A layer of PMMA bone cement was modeled to correspond with

the surrounding tibial tray and tibial bone. The aim was to ensure

adhesion between the tibial tray and tibial bone, as well as to

fill the existing defect. However, the original positions of all 3D

components were maintained in alignment with the CT images.

The completed 3D model of the construct was then

imported into Abaqus/CAE software (version 2020, Dassault Systèmes

Simulia Corp.) to commence the creation of a finite element model.

At this stage, the tibial cancellous bone was interconnected with

the tibial cortical bone, and cavities were simulated to mimic the

fixing hole of the screw and the installation hole for the stem of

the tibial tray in relation to the PMMA bone cement and the tibial

bone (Fig. 1).

Material properties

The material properties of all components in the

present study were assumed to be homogenous, isotropic and linearly

elastic. The Young's moduli of the synthetic cortical and

cancellous bones, as provided by the manufacturer, were 16.7 GPa

and 155 MPa respectively, with Poisson's ratios of 0.30 for both.

The tibial tray and all screw types were assumed to be composed of

a titanium alloy, possessing Young's modulus and Poisson's ratios

of 110 GPa and 0.3, respectively (15). The corresponding values for the PMMA

bone cement were 2.28 GPa for the Young's modulus and 0.3 for the

Poisson's ratio (16).

Interactions, loads and boundary

conditions

In the present study, the PMMA bone cement served as

the adhesive that secured all components, including the tibial

bone, bone screw and tibial tray. These interrelated properties

were established as fully constrained to simulate the adhesive

force of the PMMA bone cement. However, the distal part of the bone

screw extended beyond the boundary of the PMMA bone cement and

penetrated into the tibial bone. Defining the bone-screw interface

property was also imperative. The contact properties between the

tibial bone, encompassing both cortical and cancellous sections,

and the bone screws were categorized into two types. The interface

of the bone screw was assigned a coefficient of friction of

0.3.

The distal end of the tibial shaft was entirely

immobilized. A compressive force of 2,100 N, equating to 2-3-fold

the normal body weight, was exerted on the tibial tray through two

loading points; one loading point was positioned approximately at

the midpoint of the medial tibial plateau, while the other was

situated near the midpoint of the lateral tibial plateau.

Furthermore, the loading conditions were bifurcated, 55 and 45% of

the total load were applied to the medial and lateral tibial

plateaus, respectively, emulating normal varus-valgus

alignment.

A mesh convergence study and sensitivity analysis

were conducted on models representing the tibial bone, as well as

bone screws. These analyses were performed to enhance the accuracy

and reliability of the simulation results.

Results

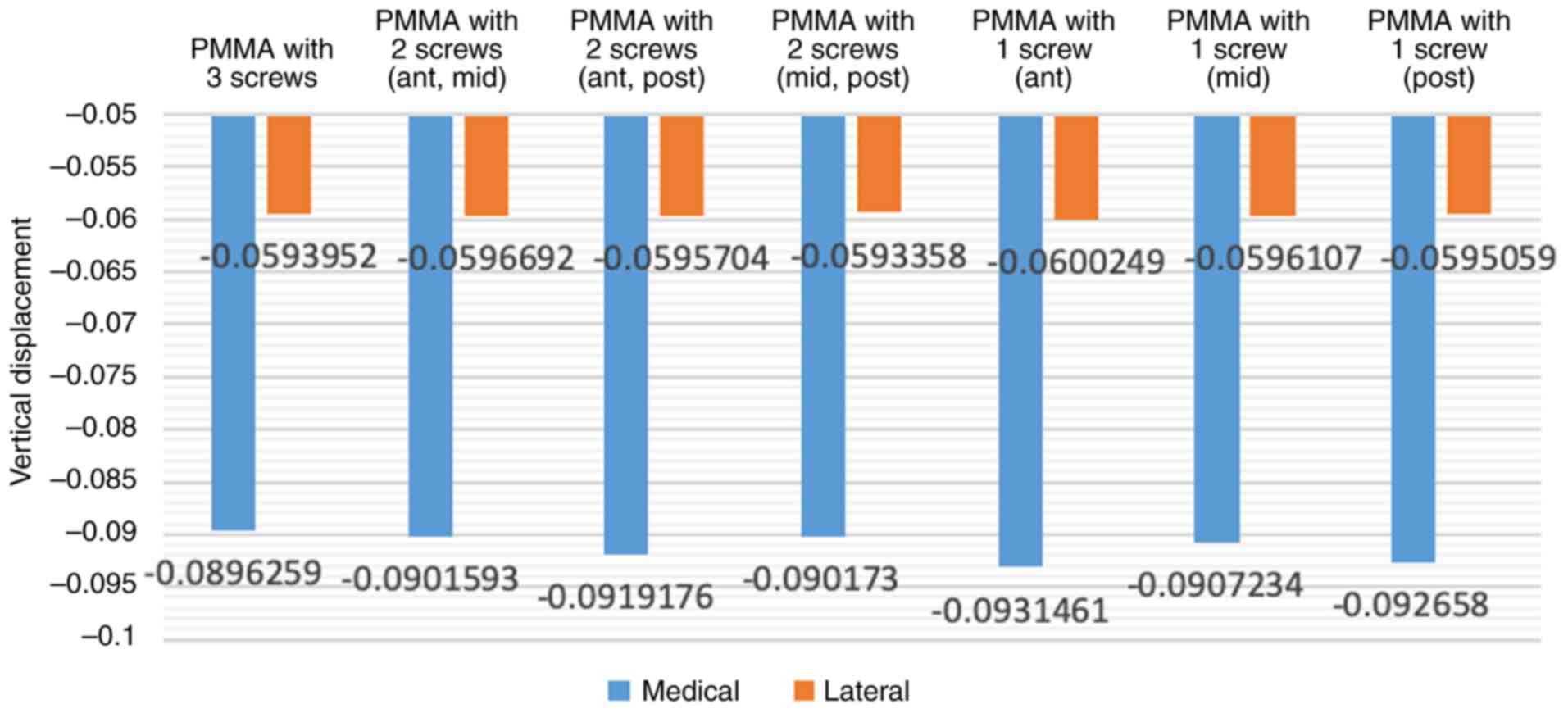

Finite element analysis of different

quantities of screws

(Fig. 2)

The comparison of the effects of the three-screw

reinforcement with those of one- or two-screw reinforcement in the

uncontained tibial bone defect filled with bone cement model

revealed that the vertical displacement values in the three-screw

reinforcement condition were lower (Fig.

3). However, in specific positions, a single screw exhibited

inferior load-bearing performance when compared to certain

scenarios involving the use of two screws. Notably, the utilization

of a single screw in the middle position exhibited superior

performance in preventing deformation in the form of abduction

angles compared to the use of two screws at anterior and posterior

positions without a middle screw. Placing a screw in the middle

position appears to play a crucial role in enhancing load-bearing

capacity.

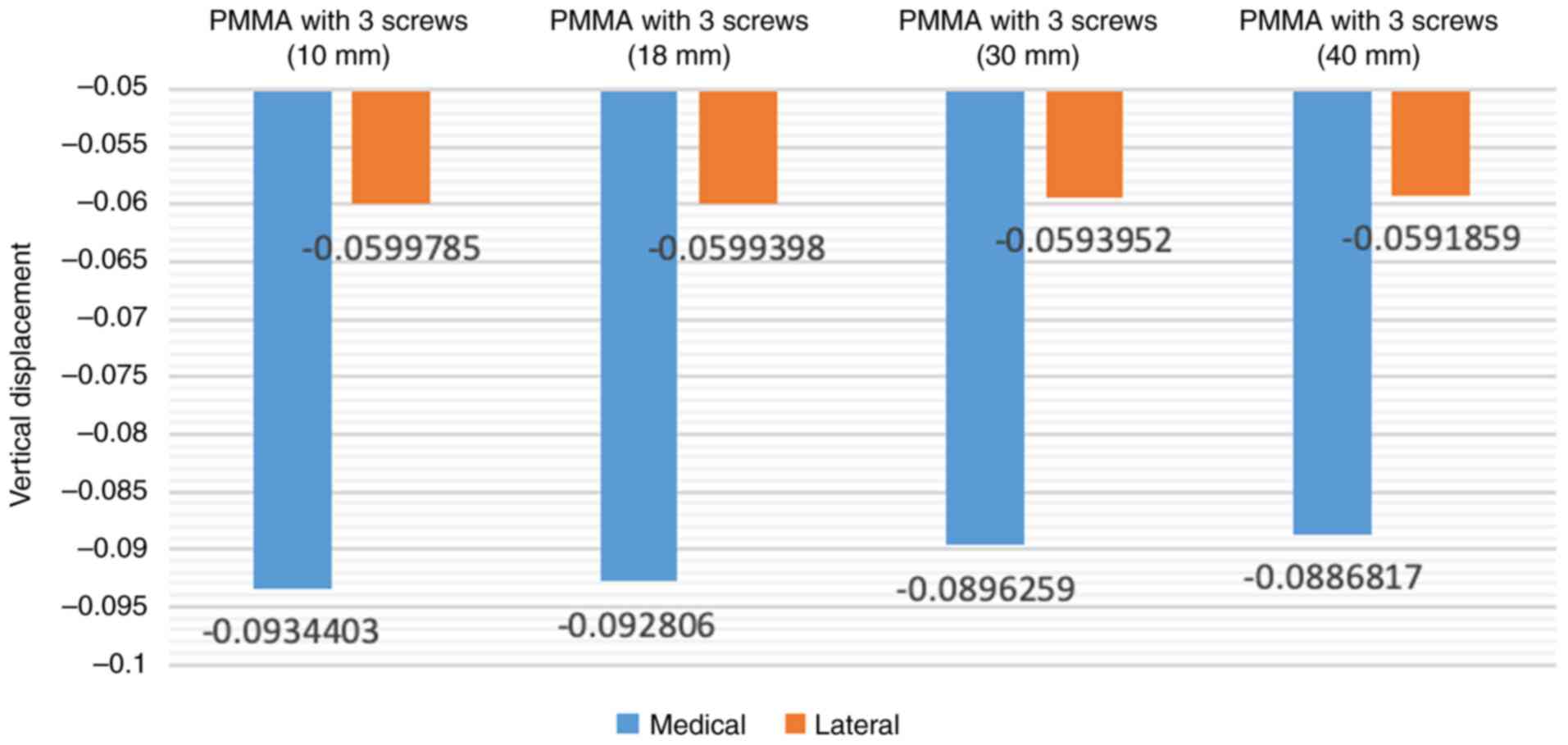

Finite element analysis of different

lengths of screws

In the initial model, the screw length employed in

the present study was 30 mm. Increasing the screw length to 40 mm

resulted in a reduction of vertical displacement values by up to

1%, and the abduction angle decreased by approximately 2.5%.

Conversely, the vertical displacement values measured at the

loading point on the tibial tray increased when the screw lengths

were decreased (10 and 18 mm screws), exhibiting an inverse

variation. The findings indicated that the length of screw

reinforcement had a direct association with the load-bearing

performance of tibial arthroplasty in the condition of an

uncontained tibial bone defect filled with bone cement (Fig. 4).

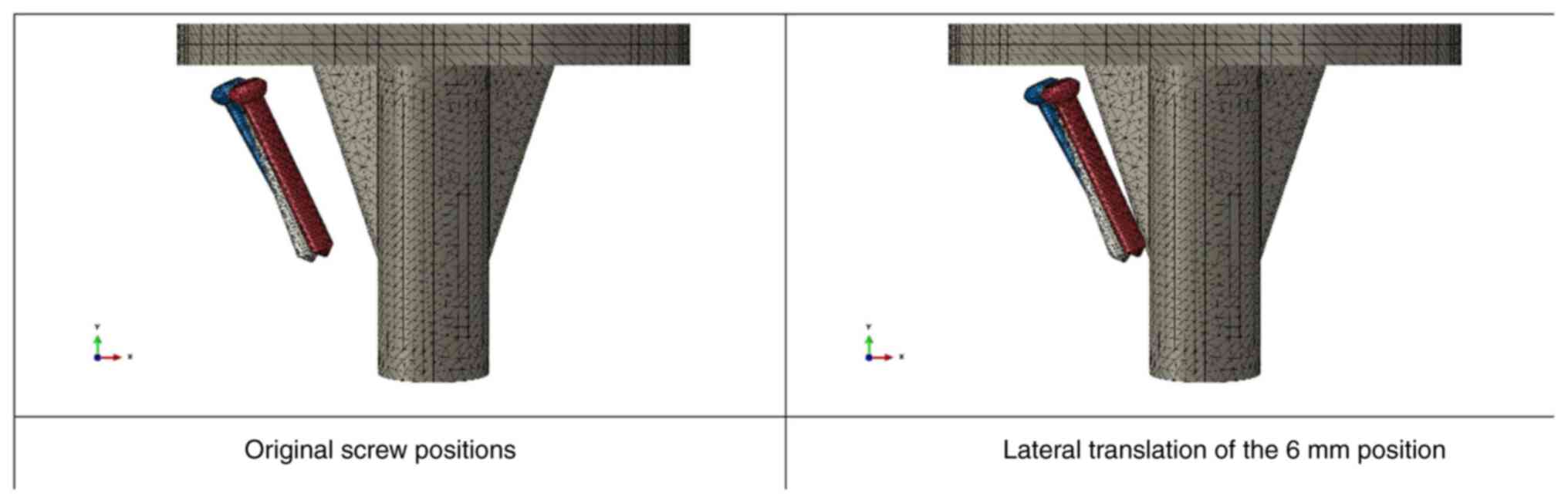

Finite element analysis of screw

placement locations

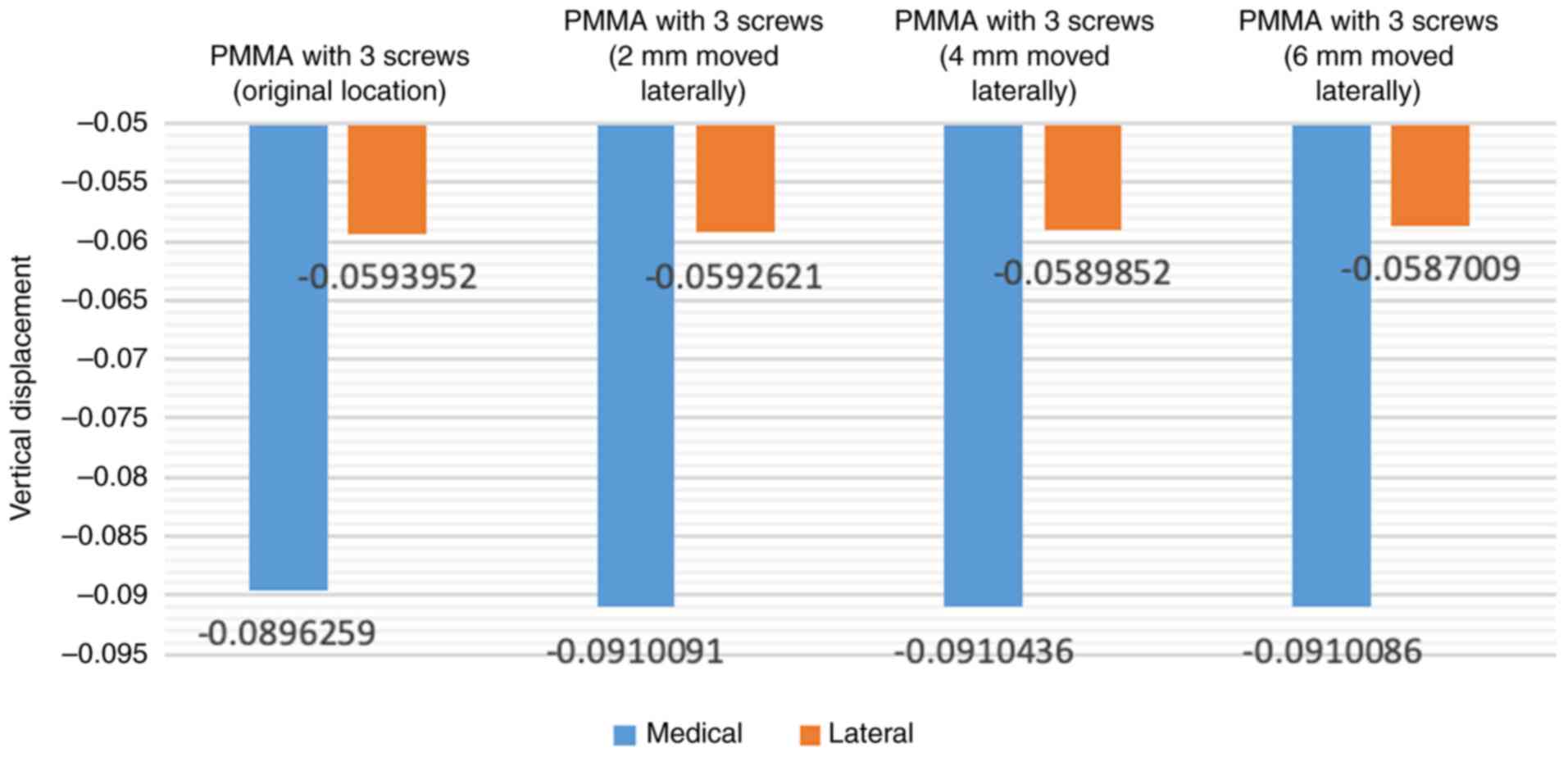

When adjusting the position of the screw laterally

to gradually approach the center of the tibial tray (2, 4 and 6 mm

laterally), there was an increase in vertical displacement values

(Fig. 5). Shifting the screws

laterally to increase the distance from the original location of

the screw to 6 mm resulted in an increase of ~1.5% in vertical

displacement values and around 6.9% in the abduction angle

(Fig. 6).

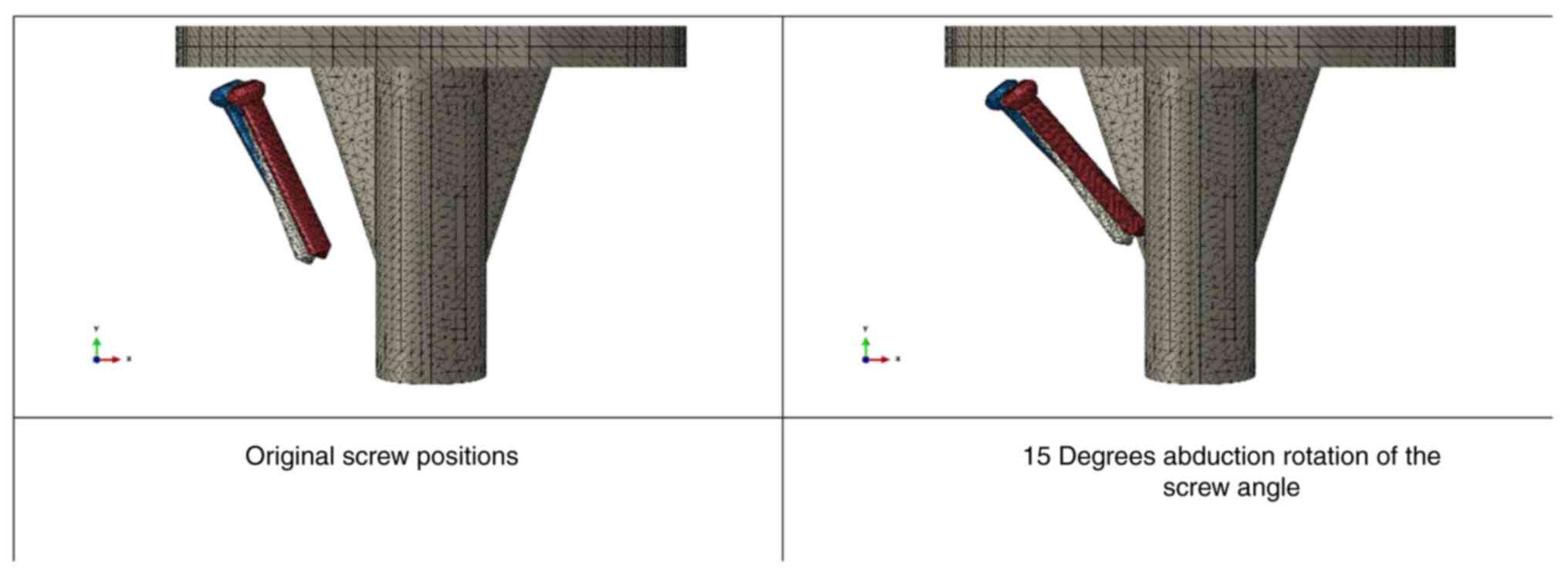

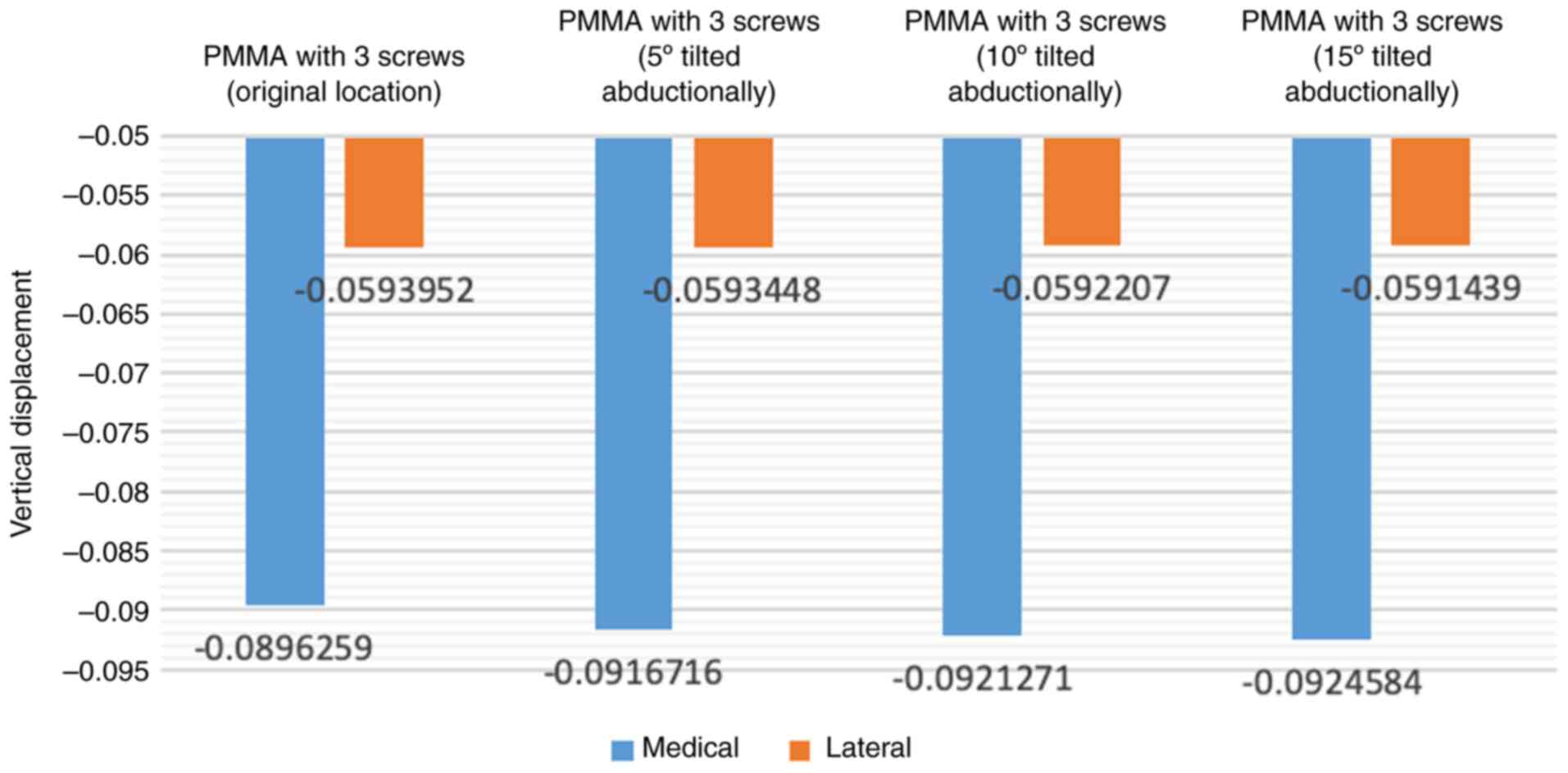

Similarly, when incrementally increasing the degree

of abduction rotation of the screw angle (5, 10 and 15 degrees),

the load-bearing performance gradually diminished (Fig. 7). Rotating the screws further in

abduction to increase the angle from the original location of the

screw to 15 degrees led to an increase of ~3.2% in vertical

displacement values and ~10.2% in the abduction angle (Fig. 8).

Discussion

Bone defects pose a significant challenge in TKA as

they affect prosthesis stability and may affect implant survival

(17,18). The combination of screws and bone

cement has been identified as an effective strategy to address this

issue, as evidenced by the successful long-term results reported by

Ritter and Harty (19). In their

study involving 125 TKA with metal-backed tibial components, screws

in cement were employed to manage medial defects caused by large

varus deformities. With an average follow-up of 7.9 years, only two

knees (1.6%) exhibited medial collapse, with no need for revision.

Özcan et al (10) also

reported positive outcomes in high body mass index patients, where

no implant failure or revision was observed during the follow-up

period. However, the existing literature lacks consensus on optimal

screw insertion techniques. The aim of the present study was to

evaluate the mechanical effects of different screw parameters,

including the number of screws, screw positioning, length and

angulation, in uncontained medial tibial defects using finite

element analysis. The results suggest that three-screw

reinforcement is preferable for larger defects, the middle position

is crucial for enhancing load-bearing capacity, longer screws are

advantageous, a smaller abduction angle is favorable and medial

placement outperforms lateral placement.

In the present study, the three-screw reinforcement

condition demonstrated the lowest displacement values, aligning

with the findings of a prior study conducted by Zheng et al

(20). Zheng et al (20) assessed the impact of the number of

screws on stresses at the surface of uncontained tibial defects

using finite element analysis and reported that in models with a

12% defect area and a 12-mm depth, the use of two screws, as

opposed to a single screw, led to a reduction in stresses on the

defect surface. Furthermore, a separate finite element study by

Zhao et al (21) revealed

that in models with an 18% defect area and a 15 mm depth, higher

bone stresses were observed with the use of one screw compared to

two screws. Despite variations in the specific metrics measured

between studies, the collective evidence emphasizes the beneficial

effects of increasing the number of screws in reinforcing tibial

defects. This augmentation may contribute to an overall improvement

in stability within the context of tibial prostheses.

The present study identified a notable reduction in

vertical displacement of the tibial tray with the use of longer

screws. This observation contrasts with the findings of a prior

orthopedic study by Ma et al (22), employing finite element analysis to

evaluate the impact of screw length in tibial defects during TKA

with a cement-screw technique. In the study by Ma et al

(22), contact stresses on the

surface of cancellous bone screws remained consistent, exhibiting

no significant difference with varying screw lengths of the same

diameter. Additionally, stresses on the tibial surface did not

exhibit notable variations based on screw length. It is suggested

that the discrepancy in outcomes may be attributed to differences

in defect size. The study by Ma et al (22) focused on smaller defects, comprising

<12% of the total plateau and with a depth of <10 mm. By

contrast, the present study specifically addressed larger defects,

constituting ~25% of the total plateau. This substantial difference

in defect size may underlie the observed variations in the

influence of different screw lengths on vertical displacement in

the present study, highlighting the clinical relevance of defect

dimensions in TKA outcomes. However, the authors still believe that

in the clinical setting, choosing longer screws may provide a

benefit without incurring additional costs or risks for the

patient. Future comparative studies evaluating different screw

lengths in clinical settings would be beneficial to further guide

optimal screw selection for patient outcomes.

The present study observed a gradual diminishment in

load-bearing performance with decreasing vertical angles of the

screw. This trend concurs with the findings of a pertinent finite

element study conducted by Zheng et al (20). In their study conducted on models

with a 12% defect area and a 12-mm depth, the researchers reported

that utilizing one vertical screw for defect reconstruction

resulted in a lower focused stress within the cancellous bone

surrounding the screws (1.05 MPa) compared to the stress observed

with one oblique screw (1.23 MPa). Additionally, a complementary

finite element study by Zhao et al (21), examining models with a 9% defect area

and an 8 mm depth, demonstrated that the use of one vertical screw

yielded significantly lower focused stress (0.45 MPa) than one

oblique screw (1.72 MPa). These consistent findings underscore the

clinical importance of screw angles in influencing focused stress

within the cancellous bone, emphasizing its significance for

optimizing load-bearing performance, as reported in orthopedic

literature.

The present study has a number of limitations that

warrant consideration. Firstly, the finite element analysis relies

on simulation, offering controlled experimentation, but potentially

deviating from the intricate in vivo conditions. Secondly,

the study specifically targeted a defect size of 25% of the total

plateau, and caution should be exercised in applying the findings

to cases with different defect dimensions. Third, the assumption of

material homogeneity may not fully capture clinical variations and

did not account for potential individual variations in bone

quality, factors that could have implications. Finally, the

analysis, centered on mechanical aspects, necessitates further

validation through experimental and clinical studies for robust

clinical translation. Acknowledging these limitations is crucial

for a nuanced interpretation of the outcomes of the study and

offers directions for future research to systematically address

these constraints.

In conclusion, the finite element analysis performed

in the present study suggested that, for the treatment of medial

uncontained tibial defects, three-screw reinforcement is

advantageous for larger defects. Longer screws and a smaller

abduction angle are deemed favorable. Moreover, the results

underscore the superiority of medial screw placement over lateral

placement. It is imperative to note that further clinical

validation is essential to corroborate the biomechanical

implications observed herein.

Acknowledgements

Not applicable.

Funding

Funding: Some of finite element analysis expenses were funded by

the Horizon Europe Framework Programme (grant no. 101086348). The

present study was supported by the Faculty of Medicine, Prince of

Songkla University, Songkhla, Thailand through a funding support

for materials and laboratory expenses in this study.

Availability of data and materials

The datasets used and/or analyzed during the current

study are available from the corresponding author on reasonable

request.

Authors' contributions

AK, KI and VY were involved in the conception and

design of the study. AK, PS and VY were involved in the acquisition

of data or the finite element analysis. AK, PS, KI and VY were

involved in the analysis and interpretation of the data. AK and VY

confirm the authenticity of all the raw data. AK, PS, KI and VY

were involved in the writing of the manuscript. All authors have

read and approved the final manuscript.

Ethics approval and consent to

participate

The present study was approved by the Ethics

Committee and Institutional Review Board of the Faculty of

Medicine, Prince of Songkla University.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Kim SE, Ro DH, Lee MC and Cholewa JM:

Early- to mid-term review of a prospective, multi-center,

international, outcomes study of an anatomically designed implant

with posterior-stabilized bearing in total knee arthroplasty.

Medicina (Kaunas). 59(2105)2023.PubMed/NCBI View Article : Google Scholar

|

|

2

|

Alasaad H and Ibrahim J: Primary total

knee arthroplasty in patients with a significant bone defect in the

medial tibial plateau: Case series and literature review. Int J

Surg Case Rep. 110(108779)2023.PubMed/NCBI View Article : Google Scholar

|

|

3

|

Lei PF, Hu RY and Hu YH: Bone defects in

revision total knee arthroplasty and management. Orthop Surg.

11:15–24. 2019.PubMed/NCBI View

Article : Google Scholar

|

|

4

|

Tang Q, Guo S, Deng W and Zhou Y: Using

novel porous metal pillars for tibial bone defects in primary total

knee arthroplasty. BMC Musculoskelet Disord. 24(829)2023.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Brooks PJ, Walker PS and Scott RD: Tibial

component fixation in deficient tibial bone stock. Clin Orthop

Relat Res. 302–308. 1984.PubMed/NCBI

|

|

6

|

Engh GA and Ammeen DJ: Bone loss with

revision total knee arthroplasty: Defect classification and

alternatives for reconstruction. Instr Course Lect. 48:167–175.

1999.PubMed/NCBI

|

|

7

|

Cuckler JM: Bone loss in total knee

arthroplasty: Graft augment and options. J Arthroplasty. 19 (4

Suppl 1):S56–S58. 2004.PubMed/NCBI View Article : Google Scholar

|

|

8

|

Rand JA: Bone deficiency in total knee

arthroplasty. Use of metal wedge augmentation. Clin Orthop Relat

Res. 63–71. 1991.PubMed/NCBI

|

|

9

|

Whittaker JP, Dharmarajan R and Toms AD:

The management of bone loss in revision total knee replacement. J

Bone Joint Surg Br. 90:981–987. 2008.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Özcan Ö, Yeşil M, Yüzügüldü U and Kaya F:

Bone cement with screw augmentation technique for the management of

moderate tibial bone defects in primary knee arthroplasty patients

with high body mass index. Jt Dis Relat Surg. 32:28–34.

2021.PubMed/NCBI View Article : Google Scholar

|

|

11

|

Ritter MA: Screw and cement fixation of

large defects in total knee arthroplasty. J Arthroplasty.

1:125–129. 1986.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Ritter MA, Keating EM and Faris PM: Screw

and cement fixation of large defects in total knee arthroplasty. A

sequel. J Arthroplasty. 8:63–65. 1993.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Berend ME, Ritter MA, Keating EM, Jackson

MD and Davis KE: Use of screws and cement in primary TKA with up to

20 years follow-up. J Arthroplasty. 29:1207–1210. 2014.PubMed/NCBI View Article : Google Scholar

|

|

14

|

Cinotti G, Perfetti F, Petitti P and

Giannicola G: Primary complex total knee arthroplasty with severe

varus deformity and large bone defects: Mid-term results of a

consecutive series treated with primary implants. Eur J Orthop Surg

Traumatol. 32:1045–1053. 2022.PubMed/NCBI View Article : Google Scholar

|

|

15

|

Completo A, Rego A, Fonseca F, Ramos A,

Relvas C and Simões JA: Biomechanical evaluation of proximal tibia

behaviour with the use of femoral stems in revision TKA: An in

vitro and finite element analysis. Clin Biomech (Bristol, Avon).

25:159–165. 2010.PubMed/NCBI View Article : Google Scholar

|

|

16

|

Zhao Y, Robson Brown KA, Jin ZM and Wilcox

RK: Trabecular level analysis of bone cement augmentation: A

comparative experimental and finite element study. Ann Biomed Eng.

40:2168–2176. 2012.PubMed/NCBI View Article : Google Scholar

|

|

17

|

Qiu YY, Yan CH, Chiu KY and Ng FY: Review

article: Treatments for bone loss in revision total knee

arthroplasty. J Orthop Surg (Hong Kong). 20:78–86. 2012.PubMed/NCBI View Article : Google Scholar

|

|

18

|

Mancuso F, Beltrame A, Colombo E, Miani E

and Bassini F: Management of metaphyseal bone loss in revision knee

arthroplasty. Acta Biomed. 88:98–111. 2017.PubMed/NCBI View Article : Google Scholar

|

|

19

|

Ritter MA and Harty LD: Medial screws and

cement: A possible mechanical augmentation in total knee

arthroplasty. J Arthroplasty. 19:587–589. 2004.PubMed/NCBI View Article : Google Scholar

|

|

20

|

Zheng C, Ma HY, Du YQ, Sun JY, Luo JW, Qu

DB and Zhou YG: Finite element assessment of the screw and cement

technique in total knee arthroplasty. Biomed Res Int.

2020(3718705)2020.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Zhao G, Yao S, Ma J and Wang J: The

optimal angle of screw for using cement-screw technique to repair

tibial defect in total knee arthroplasty: A finite element

analysis. J Orthop Surg Res. 17(363)2022.PubMed/NCBI View Article : Google Scholar

|

|

22

|

Ma J, Xu C, Zhao G, Xiao L and Wang J: The

optimal size of screw for using cement-screw technique to repair

tibial defect in total knee arthroplasty: A finite element

analysis. Heliyon. 9(e14182)2023.PubMed/NCBI View Article : Google Scholar

|