Introduction

Advanced bone surgical therapies are currently based

on reconstruction surgery and tissue transplantation. However,

several therapeutic and methodological limitations, such as the

incomplete restoration of biological tissue functionality or the

progressive deterioration of implants have been observed (1). As an alternative clinical approach,

tissue engineering (2) has been

suggested and is currently used to restore tissue damage, promoting

the proliferation and differentiation of bone cells within

synthetic scaffolds. In particular, cell-induced bone regeneration

therapy is based on the transplantation of mesenchymal stem cells

(MSCs) combined with biomaterials favouring an efficient diffusion

of nutrients, a good gas exchange and 3D structure simulating in

vivo local environment. The low grafting rate of engineered

bone substitutes has been demonstrated to be greatly dependent on

the porosity grade and geometry of the scaffold (1). As previously demonstrated by Langer

and Vacanti (3), porous

biomaterials enhance the therapeutic efficacy of cellular

transplants, preserving cells from excretion and death. Synthetic

and natural materials, such as polymers, ceramics, metals or their

composites, have been largely investigated and their use has been

explored for bone repair applications using in vitro and

in vivo settings (2).

Polymers, including collagen, hydroxyapatite (HA), polylactic acid

(PLA), polyglycolic acid (PGA) and poly-ɛ-caprolactone (PCL) have

been used to obtain biodegradable and mechanically resistant

matrices using solution casting techniques (4), solvent casting particulate leaching

(5), gel casting (6), gas saturation (7) and phase separation (8,9).

The success of biomaterials to sustain a complete

bone repair is dependent on their ability to mimic the natural

extracellular matrix (ECM), thereby minimizing foreign body or

fibrotic responses. The mature bone matrix is composed of 65%

minerals predominantly including HA and 35% protein (10) as collagen I (Coll I) fibers and

proteoglycans (11). Bone ECM

components act as primary chemical effectors in cell signaling and

functionality. When HA (12,13) and/or Coll I (14,15) are combined with synthetic

scaffolds such as PCL, matrices become highly osteoconductive

(16) and acquire tensile and

bending force, but no compressive strength. PCL is a

semicrystalline, aliphatic polyester with a degradation grade rate

lower than collagen and strong mechanical strength (17). A composite matrix containing ECM

and PCL has been previously investigated by Phipps et al

(18) to obtain a useful scaffold

with defined mechanical properties and a high level of

biocompatibility. A tri-component electrospun scaffold composed of

PCL, Coll I and nanoparticulate HA was shown to blend the

advantageous mechanical resistance of PCL with the favourable

biochemical cues provided by native bone molecules, such as Coll I

and HA, guaranteeing the better adhesion, spreading and

proliferation of human MSCs (18).

In our previous study (9), experimental conditions were defined

to obtain porous PCL scaffolds using the phase separation technique

and alginate threads as porogen agents (PCL-AT). Although it was

demonstrated to sustain osteoblastic adhesion, growth and

differentiation, the mechanical properties of PCL-AT proved that it

was not sufficient for bone repair. Therefore, in this study, HA or

bone extracellular matrix powder (BP) was used to optimize the

mechanical properties of PCL-AT matrices, and the effects were

examined by a micro-CT analysis, while the improvement of the

osteogenic activity by rabbit bone marrow MSCs was evaluated by

gene expression analysis, MTS proliferation assay and an Alizarin

Red functionality test.

Materials and methods

Preparation of PCL scaffolds by the phase

separation technique

As previously reported (9), porous scaffolds were prepared using

PCL (molecular weight ~65 kDa; density, 1.145 g/cm3)

(Sigma Chemical Co., St. Louis, MO, USA) and Ca2+

alginate threads at 200/100 weight ratio (Ca2+

alginate/PCL). To increase mechanical resistance and osteogenic

properties, mineral components, such as HA or BP were added

(PCL-AT-HA, PCL-AT-BP). In parallel, PCL without porogen (PCL-WP)

was used as the control.

Hydroxyapatite

HA was prepared using calcium acetate aqueous

solution [Ca(Ac)2] (1 M) and ammonium phosphate aqueous

solution [(NH4) H2PO4] (1 M) as

follows: 5 Ca (Ac)2 + 3 (NH4) H2

PO4 + 7 (NH4) (OH) → Ca5

(PO4)3 (OH) + 6 H2O + 10

(NH4) (Ac). The final solution pH was corrected to 10

with 33% ammonium hydroxide solution. The mixture was stirred for

24 h and then heated at 70°C for 20 h under agitation. The

resulting precipitate was filtered, washed and dried overnight.

Bone extracellular matrix powder

BP was obtained using the femurs of Sprague Dawley

rats under animal care committee authorization. Following the

removal of residual covering tissues, the samples were frozen in

liquid nitrogen and pulverized using a mill. The resulting powder

was treated with 0.5 M HCl solution (25 mEq/g) for 2 h at 4°C and

then centrifuged at 4°C for 4 min at 4,000 rpm. To remove cellular

contaminants from BP, 4 repeated cycles of detergent-enzymatic

treatment were performed, as previously described by Meezan et

al (19), each one consisting

of the 3 following steps: i) distilled water for 72 h at 4°C; ii)

4% sodium deoxycholate solution for 4 h; and iii) 2,000 KU DNase I

in 1 M NaCl for 2 h.

Preparation of composite scaffolds

HA and BP were added to the PCL gel using 25/100

(PCL-AT-HA) and 13.3/100 (PCL-AT-BP) weight ratios, respectively.

The samples were kept at 30°C until complete solidification. The

residual solvent and Ca2+ alginate threads were removed

by washing with a sodium phosphate solution (0.1 M, pH 7.0) and

then with distilled water.

Scaffold characterization

Morphological analysis

The size and distribution of pores were examined in

the PCL matrices by scanning electron microscopy (SEM). The

specimens were lyophilized, frozen in liquid nitrogen, fractured,

coated with gold and observed using a Stereoscan-205 S scanning

electron microscope (Cambridge Instruments, Cambridge, MA,

USA).

Porosity measurement

The total porosity of the PCL scaffolds was

determined by micro-CT analysis and density measurement, as

previously described (9).

Parallel sections were manually prepared and then scanned using a

Skyscan 1172 HR Micro-CT scanner (Skyscan, Aartselaar, Belgium)

using the following settings: voltage, 48 kV; current, 167 μA;

exposition time, 363 msec; field of view (FOV), 1280×1024 pixels;

and an 8-μm isotropic voxel size. Moreover, all samples were

submitted to 360° rotation, a 0.4° rotation step and 1 frame

averaging. The reconstruction of raw data was performed using

N-Recon software (Skyscan) and a back projection algorithm was

applied to the subsequent axial images acquired in bitmap format.

Micro-CT images were analyzed using Ct-An software (Skyscan) and

focusing the selected volume of interest (VOI; 3×1.59 mm) in the

centre of each scaffold to prevent artifacts from cutting. All

samples were binarized with the same instrument settings. Sample

porosity was calculated as follows: Φ = 1 − BV/TV, where Φ is total

porosity, BV the bone volume, TV the total volume and BV/TV the

percentage bone volume. Trabecular thickness (Tb.Th) (or pore wall)

and trabecular separation (Tb.Sp) (or pore diameter) were computed

by direct measurements. A 3D reconstruction was performed using CT

Vol software (Skyscan) and OsiriX open-source software.

Biological properties of PCL

scaffolds

The PCL scaffolds were sterilized in 95% ethanol for

2 h, incubated in PBS containing 2% penicillin/streptomycin

solution and then washed 3 times in αMEM (Invitrogen, Grand Island,

NY, USA). The scaffolds were then placed in 24-well plates, seeded

with MSCs (3×104 cells/cm2) and cultured in

proliferative medium containing αMEM, 15% fetal bovine serum (FBS)

(Invitrogen), 2 mM glutamax (Invitrogen) and 1% antibiotic solution

(Sigma). At different time points, the samples were submitted to an

analysis of cell viability study morphological analysis by SEM. To

determine the effects of PCL matrices on osteogenic

differentiation, the samples were cultured in differentiation and

proliferative medium and subsequently analyzed by RT-PCR and

functionality tests.

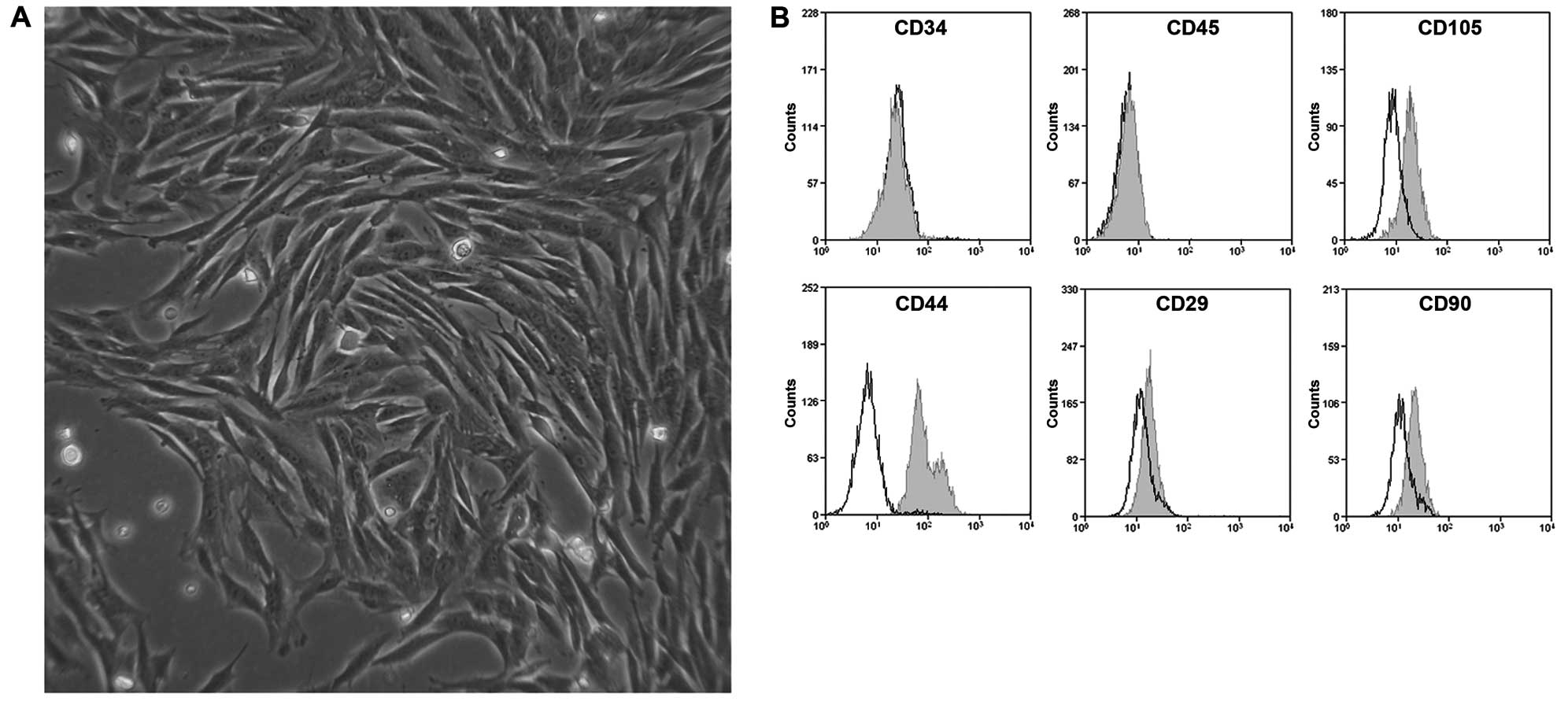

Mesenchymal stem cells

MSCs were isolated in sterile conditions from femurs

and tibia of rabbits (rMSCs) acquired from private animal breeding.

Following the removal of bone tips, bone marrow was harvested using

Dulbecco’s modified Eagle’s medium (DMEM) (Invitrogen) supplemented

with 0.2% penicillin-streptomycin (Invitrogen). The mononuclear

cell fraction was then isolated by centrifugation (2,000 rpm, 30

min) on Ficoll 1077 (Invitrogen) density gradient and subsequently

cultured in proliferative medium at 37°C, 95% humidity and 5%

CO2. The immunophenotypical profile of bone marrow MSCs

was verified on all primary cultures by detecting the expression of

CD105, CD44, CD29, CD90, CD34 and CD45 by flow cytometry (FACS).

The analysis was performed by indirect labeling using specific

anti-rabbit primary antibodies and FITC-conjugated secondary

antibodies (all from Santa Cruz Biotechnology, Inc., CA, USA).

Samples were loaded on a FACSCanto II cytometer (BD Biosciences,

San Jose, CA, USA) and the data were presented as a percentage of

positive cells relative to the labeling control.

SEM

SEM was performed to evaluate the morphology and

distribution of rabbit MSCs on the PCL scaffolds. At each time

point (24 h, 7 and 14 days), the samples were washed with PBS and

fixed with 3% glutaraldehyde in 0.1 M sodium cacodylate buffer (pH

7.4), for 24 h, at 4°C. The specimens were then rinsed 3 times with

sodium cacodylate buffer and dehydrated through a graded series of

ethanol and then air-dried. The scaffolds were coated with gold and

observed by SEM.

Analysis of cell viability

After seeding on PCL scaffolds, cell viability was

monitored at 24 h, 72 h, 7 and 14 days using the colorimetric

3-(4,5-dimethylthiazol-2-yl)-5-(3-carboxymethoxyphenyl)-2-(4-sulfophenyl)-2H-tetrazolium

(MTS) assay. Metabolically active cells react with tetrazolium salt

in MTS reagent to produce a soluble formazan dye detectable at 490

nm. At each time point, all constructs were rinsed with PBS and

then incubated for 3 h with 20% MTS reagent in culture medium.

Thereafter, the aliquots were pipetted into 96-well plates and the

absorbance of each sample was read at 490 nm using ELx 808 Ultra

Microplate reader (Bio-Tek Instruments, Winooski, VT, USA). The

data were expressed as the number of cells ×103. A

calibration curve (cell

number/cm2=3.8×105A490−1.1×104,

R2=0.98) was prepared.

Osteogenic differentiation of MSCs on

PCL matrices

At 48 h after seeding in proliferative medium, the

cells were stimulated from 7 to 21 days with αMEM, 10% FBS, 1%

antibiotic solution (APS), 0.1 μM dexamethasone, 10 nM

β-glycerophosphate and 0.05 mM ascorbate. Cultures of MSCs in

proliferative medium were used as the control. To verify the

maturation into osteoblastic-like cells, all samples were submitted

at different time points to the analysis of osteogenic markers by

RT-PCR (7 and 14 days), alkaline phosphatase (ALP) activity

analysis and the analysis of extracellular matrix calcium

deposition by Alizarin Red staining (24 h, 7 and 14 days) as

follows:

RT PCR. After 7 and 14 days, the constructs

were rinsed with PBS and then submitted to total RNA extraction

using TRIzol (Invitrogen). RNA was firstly quantified using a

NanoDrop 2000 spectrophotometer (Thermo Scientific, Waltham, MA,

USA) at 260 and 280 nm, and then reverse transcribed into cDNA by

M-MLV Reverse Transcriptase (Sigma Aldrich), according to the

manufacturer’s instructions. For PCR amplification, ReadyMix™ Taq

PCR Reaction Mix with MgCl2 (Sigma) and specific oligo

primers (Invitrogen) designed on GenBank sequences (Table I) were used. PCR products were

then analyzed on 2% agarose gels and visualized using a Gel Doc

imaging system (Bio-Rad, Hercules, CA, USA) after GelRed staining.

The expression of β-actin was used as an internal control.

| Table IPrimers used for RT-PCR. |

Table I

Primers used for RT-PCR.

| Gene | Forward primer

sequence (5′→3′) | Reverse primer

sequence (3′→5′) |

|---|

| β-actin |

AGATCTGGCACCACACCTTCTACA |

ACTCGTCATACTCCTGCTTGCTGA |

| Runx2 |

AGTTTGTTCTCTGACCGCCTCAGT |

ATGGTCGCCAGACAGATTCATCCA |

| Osteocalcin

(OC) |

CATGAGAGCCCTCACA |

AGAGCGACACCCTAGAC |

| Osteopontin

(OPN) |

CCGACCAAGGAACAAT |

CTCTGAAGCACCAGGATA |

| Collagene type I

(Coll I) |

GGCAAACATGGAAACCG |

TCAAGGAAGGGCAAACG |

Alkaline phosphatase assay. ALP activity was

analyzed using p-nitrophenyl phosphate (p-NPP) as the substrate.

Following cell lysis and centrifugation at 12,000 × g for 10 min,

the supernatants were incubated with p-NPP for 30 min at 37°C. The

reaction was terminated by the addition of 3 N NaOH and the

absorbance was measured at 405 nm. All results were expressed as

the mean values ± SD of 3 separate experiments consisting of

triplicates.

Alizarin Red staining. To detect the calcium

deposition of MSCs on the PCL scaffolds, an Osteogenesis assay kit

(Millipore, Billerica, MA, USA) was used. The samples were fixed

with 10% formalin solution for 15 min, washed twice with distilled

water and then incubated with Alizarin Red S for 20 min at room

temperature. After washing with distilled water and incubation for

30 min with 10% acetic acid under agitation, the cellular

monolayers were then transferred to microcentrifuge tubes, heated

to 85°C for 10 min, placed on ice for 5 min and then centrifuged at

20,000 rpm for 15 min. After the addition of ammonium hydroxide,

the amount of extracted Alizarin Red dye was measured at 562 nm and

quantified using an Alizarin Red S standard curve. All results were

expressed as the mean concentration (μM) ± SD of 3 separate

experiments performed in triplicate on stimulated and unstimulated

samples with osteogenic factors.

Statistical analysis

Data are expressed as the means value ± SD of at

least 3 different samples. Significant differences were estimated

by one-way analysis of variance (ANOVA) followed by a

Student-Newman-Keuls post hoc test. Values of p<0.05 were

considered to indicate statistically significant differences.

Results

PCL scaffolds

The absence of alginate threads in PCL-WP (Fig. 1A) determined a random formation of

fine and not interconnected micropores. Homogeneously distributed

pores largely characterized by a diameter of ~10 μm were observed

by SEM in PCL-AT (Fig. 1B) and

PCL-AT-BP (Fig. 1D) or ranging

from 10 to 100 μm in PCL-AT-HA (Fig.

1C). Differently sized and distributed large pores due to air

bubbles were detected in all samples.

Micro-CT analysis

The analysis revealed a significative increase in

total porosity (Table II),

trabecular spacing (Tb.Sp) (Fig.

2B) and trabecular thickness (Tb.Th) (Fig. 3B). In comparison to PCL-WP

(Fig. 2A) characterized by a pore

diameter ranging from ~15 to 300 μm, PCL-AT (Fig. 2B) showed a porous structure with

cavities homogeneously distributed and sized (diameter, ~15 to

1,400 μm). In PCL-AT-HA (Fig. 2C)

and PCL-AT-BP (Fig. 2D), the

maximum size of the pores detected was ~700 μm and unimodal

(Fig. 2C) or bimodal (Fig. 2D) distribution was respectively

observed. In parallel, Tb.Th values ranging from ~15 to 600 μm were

observed with a similar distribution in PCL-AT (Fig. 3B) and PCL-AT-BP (Fig. 3D) in comparison to the control

characterized by Tb.Th values from ~15 to 150 μm (Fig. 3A). The highest Tb.Th value (~900)

was observed in PCL-AT-HA (Fig.

3C). 3D scaffold reconstruction confirmed the presence of

interconnected pores in all scaffolds relative to the control

(Fig. 4), suggesting a trabecular

bone-like structure. As shown in Fig.

5, the addition of HA did not significantly alter the

mechanical properties of PCL-AT. An increase in the displacement

value (3,900±2.17) and the shift/deformation due to the load

(3,273±4.73) observed on PCL-AT-BP suggested that the addition of

BP led to a reduction in the elastic module of the PCL-AT matrix,

preserving the porous structure.

| Table IITotal porosity value of PCL matrices

detected by micro-CT analysis and density measurement. |

Table II

Total porosity value of PCL matrices

detected by micro-CT analysis and density measurement.

| Samples | Φ micro-CT (% value

± SD) | Φ density method (%

value ± SD) |

|---|

| PCL-WP | 21.59±7.06 | 70±3.75 |

| PCL-AT | 51.83±5.30 | 79.6±1.17 |

| PCL-AT-HA | 55.92±5.31 | 82.5±0.46 |

| PCL-AT-BP | 52.53±3.15 | 84±0.43 |

Biological properties of PCL

scaffolds

MSC cultures

A total of 7 days after seeding, typical colony

forming units with fibroblastic cell morphology (Fig. 6A) were observed. FACS analysis

revealed that the rMSCs were positive for MSC markers, such as

CD105, CD44, CD29 and CD90 and negative for hematopoietic markers,

such as CD34 and CD45 (Fig.

6B).

MTS assay

From 24 h to 14 days, porous PCL matrices showed a

significant increase in cell viability relative to the control

(Fig. 8). Larger cavities were

shown to promote optimal conditions for cell growth at 72 h, as

detected in PCL-AT. After 1 week, all porous PCL scaffolds

presented similar cell proliferation rates (p<0.05) in

comparison to PCL-WP (Fig. 8).

Although cell viability markedly decreased in all samples at 14

days, possibly due to an impaired flux of nutrients and gas under

static growth conditions, the cell number detected on PCL-BP

significantly (p<0.05) diverged from that of the control,

suggesting that the porosity grade and BP prolonged the cell

viability on the PCL scaffolds over time.

SEM

At 24 h after cell seeding, the surface of all the

porous PCL scaffolds was shown to be largely populated by MSCs

(Fig. 7). From 7 to 14 days, the

cells were still organized in a monolayer. By contrast, the rare

cells observed on PCL-WP at the early (24 h), intermediate (7 days)

and late growth phase (14 days) suggested that the scaffold

porosity grade was not functional to guarantee cell viability,

adhesion and proliferation.

RT-PCR

The expression of osteopontin (OPN) and Coll I was

shown to be independent of PCL substrates (Fig. 9). Although its expression was

detected at 14 days in the samples under both proliferative and

osteogenic conditions, Runx2 was expressed as early as 7 days on

PCL-BP, possibly due to the combined stimulatory effects of the

composite matrix and differentiation medium. Independent of the

porosity grade of the scaffolds, the differentiation induction by

soluble factors was shown to strictly control the mRNA expression

of osteocalcin (OC) in rMSCs (Fig.

9A–D).

| Figure 9(A) Expression of Runx2, osteopontin

(OPN), osteocalcin (OC) and collagen I (Coll I) mRNAs in MSCs

cultured for 7 (7d) and 14 days (14d) in (a–d) proliferative and

(A′–D′) osteogenic medium on (a, A′) PCL-WP, (b, B′) PCL-AT, (c,

C′) PCL-AT-HA and (d, D′) PCL-AT-BP scaffolds. In parallel, the

gene expression of the housekeeping, β-actin, was evaluated. All

RT-PCR products were electrophoresed on 2% agarose gels pre-stained

with GelRed. (B) Densitometry of agarose gel bands.

*p<0.05; **p<0.01. PCL,

poly-ɛ-caprolactone; WP, without porogen; AT, alginate threads;

AT-HA, alginate threads and hydroxyapatite; AT-BP, alginate threads

and bone powder. |

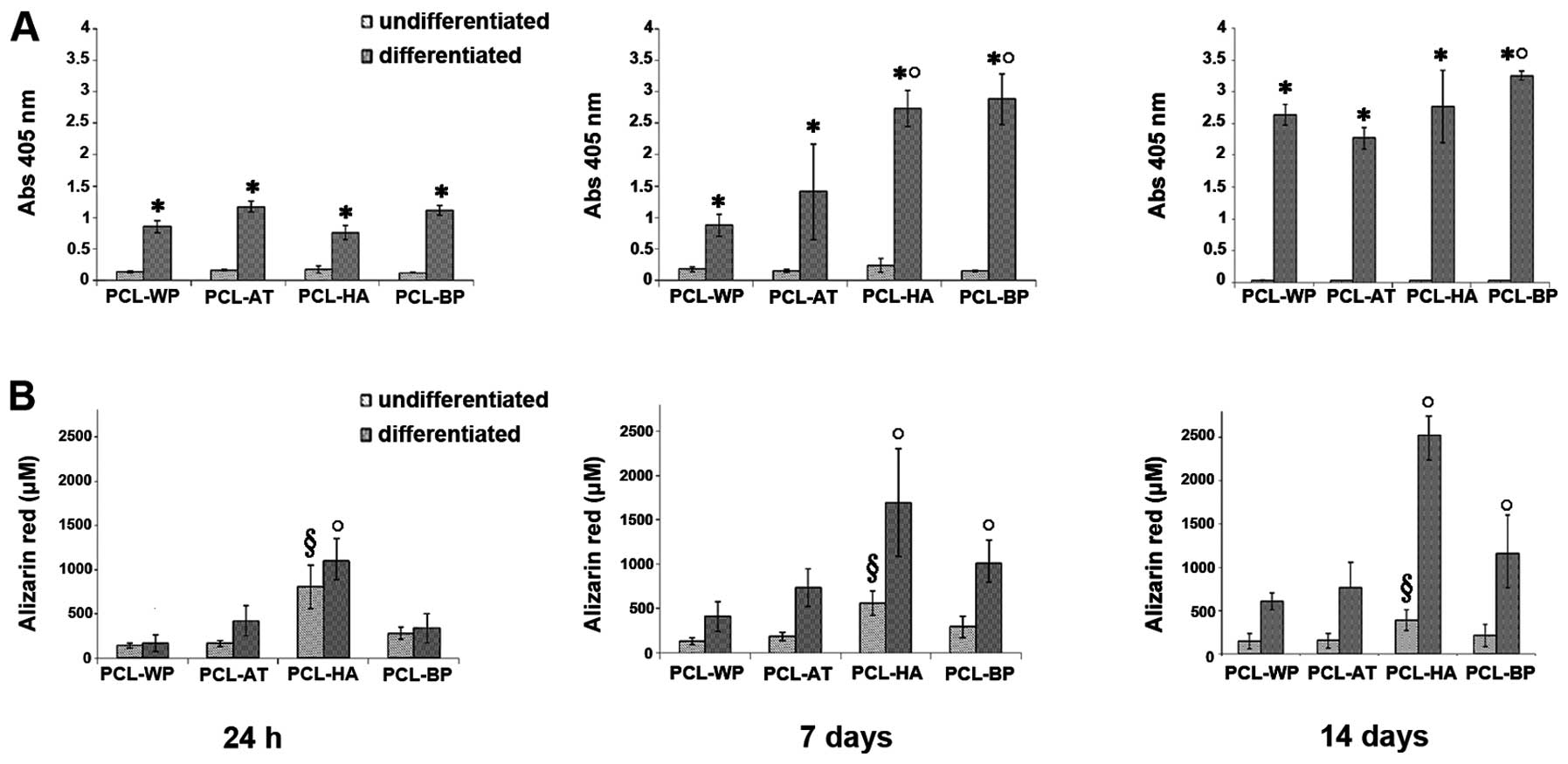

ALP assay and Alizarin Red

staining

From 24 h to 14 days, a low activity of the ALP

enzyme was detected in all porous PCL scaffolds and control samples

under proliferative conditions (Fig.

10A). When the MSCs were induced with osteogenic medium, the

ALP value significantly (p<0.05) increased. In particular, the

differentiated cells on PCL-HA (7 days) and PCL-BP (7, 14 days)

showed a significant (p<0.05) increase in ALP activity in

comparison to PCL-AT, suggesting that BP and HA enhanced the

osteogenic properties of the porous PCL scaffolds. As expected,

mineralized deposits (Fig. 10B)

were detected from 24 h to 14 days on PCL-HA under both

proliferative (p<0.05) and differentiation (p<0.05)

conditions. The BP extracts revealed to be effective (p<0.05) in

stimulatig ECM mineralization from 7 to 14 days only in samples

cultured in osteogenic medium.

Discussion

Following bone injury, the healing process develops

through the recruitment of immature cells that first originate from

osteoprogenitor cells (20) and

then differentiate into bone cells under local, biochemical and

biophysical stimuli. During bone implant incorporation, the

phenomenon of osteoinduction can be observed (20). It is dependent on scaffold

properties, such as porosity, which is defined as the percentage of

internal void space (21) and

pore size (22). Including

micropores (diameter size <10 μm) and macropores (diameter size

>50 μm), total porosity is a variable parameter among tissue

sites (~50–90% in trabecular bone and 3–12% in cortical tissue)

(23,24) and is crucial for the invasive

growth of cells, vascularization and the diffusion of nutrients and

gasses. Thus, for bone replacement, in order to achieve optimal

bone-tissue outcomes, the effects of pore size and morphology on

osteoinduction and scaffold mechanical properties have been

extensively investigated (25,26). As large pores favour direct

osteogenesis and small pores guarantee osteochondral ossification,

fabricating scaffolds with different grades of porosity and pore

size is appealing in terms of improving the bone regeneration

process.

Grandi et al (9) demonstrated that the biological

activities of PCL scaffolds obtained by the phase separation

technique were greatly enhanced when alginate threads were added as

the porogen (PCL-AT) and pore size was in the range of 15–1,400 nm.

As a bigger void volume implies a reduction in scaffold mechanical

strength, and the tensile strength of PCL-AT was not optimal for

in vivo bone applications, in the present study, mineral

components, such as HA or decellularized bone matrix powder (BP)

were used in order to prepare composite PCL-AT matrices with

increased mechanical strength. The obtained multi-scale porosity

and pore size in the range of ~15–800 nm in both PCL-AT-HA and

PCL-AT-BP was in agreement with structural properties previously

reported as functional to promote in vivo bone regeneration.

In particular, Hulbert et al (21) demonstrated that pore sizes in the

range of 100–150 and 150–200 μm resemble normal haversian systems

and stimulate in vivo substantial bone ingrowth. Macropores

with a diameter of 400–600 μm in porous HA implants have been shown

to promote the in vivo healing of rat femoral defects

(27), while pores ranging from

100 to 600 μm have been shown to sustain the in vitro

osteogenic differentiation of murine pluripotent C3H10T1/2 cells

(28).

As the in vivo bone environment is subjected

to mechanical compression, an elective scaffold for bone

regeneration must be designed to withstand this force, while

adequate porosity [Bignon et al (29)] is preserved. In the present study,

the porous PCL-AT scaffold demonstrated a significant increase in

structural resistance only when decellularized extracellular bone

matrix was added, suggesting that the reduction of total macropores

due to HA is not sufficient to modify the scaffold structural

strength. Despite being characterized by a high level of

osteoconductivity, HA is considered a bone graft extender or

carrier of growth factors rather than a ‘stand-alone’ bone graft

substitute. It is weak in tensile strength and toughness, and thus

when added to bone scaffolds, no significant change in mechanical

properties was detected while, as expected, a reduction in total

porosity, trabecular thickness and trabecular space was

observed.

As previously reported (9) and confirmed in this study, the

adhesion and proliferation of bone-forming cells in PCL-AT

scaffolds are enhanced by pores differentially organized into

‘blind’, ‘closed’ and ‘through’ pores (30). ‘Blind’ pores start from one

surface and terminate inside the material. They influence the

amount of fluids that can be stored within a matrix and contribute

to increasing the surface area of cell growth. ‘Closed’ pores are

void cavities not connected to the external surface and do not

contribute to the inflow of nutrients and gasses. ‘Through’ pores

are channels extending from one free scaffold surface to another

and are responsible for the flow of fluid through the material.

Although the role of porosity in bone substitution to promote the

migration and proliferation of osteoblasts and mesenchymal cells,

as well as vascularization (31)

has been demonstrated, the optimal porosity percentage and pore

size have been not yet been identified. In this study, we

demonstrated that the increased porosity of scaffolds due to AT was

associated with a major degree of cell adhesion and proliferation.

Moreover, the heterogeneity of scaffold pores in PCL-AT-HA and

PCL-AT-BP was shown to favour the growth and differentiation of

MSCs isolated from rabbit bone marrow.

The proliferation of osteoblasts and mesenchymal

cells has been largely demonstrated to be dependent on both

macropores, assuring a major interconnected network of void

cavities and an improved oxygen and nutrients inflow (31–33), as well as micropores, stimulating

high levels of bone-inducing protein adsorption, ion exchange and

bone-like apatite formation (34). Although the greater porosity in

PCL-AT guaranteed better conditions for the proliferation of MSCs

at the early phase, the presence of BP was shown to be crucial to

prolong the viability of cells at the late phase.

It is known that the microenviroment and soluble

factors interact to drive the proliferation and differentiation of

cells. When rMSCs were cultured for 14 days on porous PCL

scaffolds, the mRNA expression of Coll I and OPN was observed at

the early and late phase suggesting their expression is not

controlled by the microenviroment. The mRNA expression of Runx2 (at

7 days) and osteocalcin (at 14 days) was observed only following

stimulation with osteogenic factors, demonstrating that soluble

factors cooperate with the microenviroment to promote the

progression of the differentiation process. The transcription

factor, Runx2, is a key regulator of osteoblast differentiation

(35), controlling both

intramembranous and endochondral bone formation (36) and promoting chondrocyte maturation

(37). As the expression of Runx2

progressively increased during osteogenic differentiation, and the

activity of ALP and the levels of osteocalcin in the

culture-expanded MSCs significantly increased in response to Runx2,

it can be hypothesized that all porous PCL scaffolds sustain the

expression of certain osteogenic markers, but only in combination

with specific inducers (HA or BP) and that they are functional to

promote the activity of ALP and the mineralization of ECM,

suggesting a marked influence of HA and BP on osteogenic maturation

in bone substitutes.

In conclusion, the data presented in this study

indicate that PCL scaffolds prepared with AT as the porogen and HA

or BP acquire similar osteoinductive properties, but differ in

mechanical strength. Due to the more appropriate porosity grade,

structural resistance and biological properties, PCL-AT-BP was

shown to have greater potential for use in bone repair

applications.

Acknowledgements

We would like to thank San Luca Hospital, ULSS 18,

Trecenta (Rovigo), Italy and the University of Padua for providing

the laboratory facilities. We would also like to express our

gratitude to Thomas Bertalot for providing technical support.

References

|

1

|

Tabata Y: Biomaterial technology for

tissue engineering applications. J R Soc Interface. 6(Suppl 3):

311–324. 2009. View Article : Google Scholar

|

|

2

|

Porter JR, Ruckh TT and Popat KC: Bone

tissue engineering: a review in bone biomimetics and drug delivery

strategies. Biotechnol Prog. 25:1539–1560. 2009.PubMed/NCBI

|

|

3

|

Langer R and Vacanti JP: Tissue

engineering. Science. 260:920–926. 1993. View Article : Google Scholar

|

|

4

|

Schmitz JP and Hollinger JO: A preliminary

study of the osteogenic potential of a biodegradable

alloplastic-osteoinductive alloimplant. Clin Orthop Relat Res.

237:245–255. 1988.PubMed/NCBI

|

|

5

|

Mikos AG, Sarakinos G, Leite SM, Vacanti

JP and Langer R: Laminated threedimensional biodegradable foams for

use in tissue engineering. Biomaterials. 14:323–330. 1993.

View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Agrawal CM and Kennedy MB: The effects of

ultrasound irradiation on a biodegradable delivery system.

Transactions of the Society for Biomaterials. 19:2921993.

|

|

7

|

Mooney DJ, Baldwin DF, Suh NP, Vacanti JP

and Langer R: Novel approach to fabricate porous sponges of poly

(D,L-lactic-co-glycolic acid) without the use of organic solvents.

Biomaterials. 17:1417–1422. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Schugens C, Maquet V, Grandfils C, Jerome

R and Teyssie P: Polylactide macroporous biodegradable implants for

cell transplantation. II Preparation of polylactide foams by

liquid-liquid phase separation. J Biomed Mat Res. 30:449–461. 1996.

View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Grandi C, Di Liddo R, Paganin P, Lora S,

Dalzoppo D, Feltrin G, Giraudo C, et al: Porous

alginate/poly(ɛ-caprolactone) scaffolds: preparation,

characterization and in vitro biological activity. Int J Mol

Med. 27:455–467. 2011.

|

|

10

|

Costa-Pinto AR, Reis RL and Neves NM:

Scaffolds based bone tissue engineering: the role of chitosan.

Tissue Eng Part B Rev. 17:331–347. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Karsenty G: The genetic transformation of

bone biology. Genes Dev. 13:3037–3051. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Ito Y, Hasuda H, Kamitakahara M, Ohtsuki

C, Tanihara M, Kang IK and Kwon OH: A composite of hydroxyapatite

with electrospun biodegradable nanofibers as a tissue engineering

material. J Biosci Bioeng. 100:43–49. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Thomas V, Jagani S, Johnson K, Jose MV,

Dean DR, Vohra YK and Nyairo E: Electrospun bioactive nanocomposite

scaffolds of polycaprolactone and nanohydroxyapatite for bone

tissue engineering. J Nanosci Nanotechnol. 6:487–493. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Teng SH, Lee EJ, Wang P and Kim HE:

Collagen/hydroxyapatite composite nanofibers by electrospinning.

Mater Lett. 62:3055–3058. 2008. View Article : Google Scholar

|

|

15

|

Ngiam M, Liao S, Patil AJ, Cheng Z, Chan

CK and Ramakrishna S: The fabrication of nano-hydroxyapatite on

PLGA and PLGA/collagen nanofibrous composite scaffolds and their

effects in osteoblastic behavior for bone tissue engineering. Bone.

45:4–16. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Venugopal J, Low S, Choon AT, Sampath

Kumar TS and Ramakrishna S: Mineralization of osteoblasts with

electrospun collagen/hydroxyapatite nanofibers. J Mater Sci Mater

Med. 19:2039–2046. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Woodward SC, Brewer PS, Moatamed F,

Schindler A and Pitt CG: The intracellular degradation of poly

(epsilon-caprolactone). J Biomed Mater Res. 19:437–444. 1985.

View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Phipps MC, Clem WC, Catledge SA, et al:

Mesenchymal stem cell responses to bone-mimetic electrospun

matrices composed of polycaprolactone, collagen I and

nanoparticulate hydroxyapatite. PLoS One. 6:e168132011. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Meezan E, Hjelle JT, Brendel K and Carlson

EC: A simple, versatile, nondisruptive method for the isolation of

morphologically and chemically pure basement membranes from several

tissues. Life Sci. 17:1721–1732. 1975. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Albrektsson T and Johansson C:

Osteoinduction, osteoconduction andosseointegration. Eur Spine J.

10(Suppl 2): 96–101. 2001. View Article : Google Scholar

|

|

21

|

Hulbert SF, Young FA, Mathews RS,

Klawitter JJ, Talbert CD and Stelling FH: Potential of ceramic

materials as permanently implantable skeletal prostheses. J Biomed

Mater Res. 4:433–456. 1970. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Karageorgiou V and Kaplan D: Porosity of

3D biomaterial scaffolds and osteogenesis. Biomaterials.

26:5474–5491. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Kaplan FS, Hayes WC, Keaveny TM, Boskey A,

Einhorn TA and Iannotti JP: Form and function of bone. Orthopaedic

Basic Science. Simon SR: American Academy of Orthopaedic Surgeons;

Rosemont, IL: pp. 127–185. 1994

|

|

24

|

Cooper DM, Matyas JR, Katzenberg MA and

Hallgrimsson B: Comparison of microcomputed tomographic and

microradiographic measurements of cortical bone porosity. Calcif

Tissue Int. 74:437–447. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Bauer TW and Muschler GF: Bone graft

materials. An overview of the basic science. Clin Orthop Relat Res.

10–27. 2000. View Article : Google Scholar

|

|

26

|

Keating JF and McQueen MM: Substitutes for

autologous bone graft in orthopaedic trauma. J Bone Joint Surg.

83:3–8. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Damien E, Hing K, Saeed S and Revell PA: A

preliminary study on the enhancement of the osteointegration of a

novel synthetic hydroxyapatite scaffold in vivo. J Biomed Mater Res

A. 66:241–246. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Kim HD and Valentini RF: Retention and

activity of BMP-2 in hyaluronic acid-based scaffolds in vitro. J

Biomed Mater Res. 59:573–584. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Bignon A, Chouteau J, Chevalier J,

Fantozzi G, Carret JP, Chavassieux P, Boivin G, Melin M and

Hartmann D: Effect of micro- and macroporosity of bone substitutes

on their mechanical properties and cellular response. J Mater Sci

Mater Med. 14:1089–1097. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Ahuja G and Pathak K: Porous carriers for

controlled/modulated drug delivery. Indian J Pharm Sci. 71:599–607.

2009. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Kuboki Y, Takita H, Kobayashi D, et al:

BMP-induced osteogenesis on the surface of hydroxyapatite with

geometrically feasible and nonfeasible structures: topology of

osteogenesis. J Biomed Mater Res. 39:190–199. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Tsuruga E, Takita H, Itoh H, Wakisaka Y

and Kuboki Y: Pore size of porous hydroxyapatite as the

cell-substratum controls BMP-induced osteogenesis. J Biochem.

1:317–324. 1997. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Gotz HE, Muller M, Emmel A, Holzwarth U,

Erben RG and Stangl R: Effect of surface finish on the

osseointegration of laser-treated titanium alloy implants.

Biomaterials. 25:4057–4064. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Yuan H, Kurashina K, de Bruijn JD, Li Y,

de Groot K and Zhang X: A preliminary study on osteoinduction of

two kinds of calcium phosphate ceramics. Biomaterials.

20:1799–1806. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

35

|

Dong SW, Ying DJ, Duan XJ, et al: Bone

regeneration using an acellular extracellular matrix and bone

marrow mesenchymal stem cells expressing Cbfa1. Biosci Biotechnol

Biochem. 73:2226–2233. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Komori T, Yagi H, Nomura S, et al:

Targeted disruption of Cbfa1 results in a complete lack of bone

formation owing to maturational arrest of osteoblasts. Cell.

89:755–764. 1997. View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Inada M, Yasui T, Nomura S, et al:

Maturational disturbance of chondrocytes in Cbfa1-deficient mice.

Dev Dyn. 214:279–290. 1999. View Article : Google Scholar : PubMed/NCBI

|