Introduction

3-Methylindole (3MI) is a substance with an

unpleasant odor (1–4) that is produced by the tryptophan

removal process in the caecum and colon of intact male pigs

(5,6). It has been reported that consumers

are able to detect the negative odor when the level of 3MI is

>0.21 mg/kg (7).

In numerous countries, the castration of male

piglets is common practice to remove the odor. However, intact male

pigs have demonstrated a superior performance compared with

barrows, due to better carcass traits, lean meat percentage and

feed efficiency. Furthermore, the surgical castration of male

piglets not only diminishes the benefits of intact male pigs, but

also increases concerns about animal welfare (1). Surgical castration is not performed

in Australia, the United Kingdom and Ireland. In Norway, a total

ban on castration was initiated in January 2009 (8). However, if intact male pigs are to be

used for pork production, the 3MI level must be substantially

reduced. At present, a number of microbial methods have been used

to investigate the problem in vitro. Compared with physical

and chemical methods, biological techniques are preferable due to

the economical advantages and low possibility of byproduct

generation. Various bacterial strains have been applied to reduce

the levels of harmful substances for a number of years.

Ochrobactrum intermedium DN2 has been used to degrade

nicotine in tobacco waste extracts and the average degradation rate

of nicotine in a 30 l fed-batch culture was 140.5 mg/l/h (9). In addition, Shinella

zoogloeoides BC026 has been identified to reduce pyridine

levels, resulting in a degradation rate of 1,806 mg/l pyridine in

45.5 h (10). Moreover,

Bacillus odysseyi SUK3, Morganella morganii SUK5 and

Proteus species SUK7 have been shown to decolorize Reactive

Blue 59 (50 mg/l) completely within 60, 30 and 24 h, respectively

(11). With regard to 3MI

degradation, Kohda et al (12) identified that 0.05% (w/v) 3MI may

be degraded by a type of Clostridium from the feces of pigs

in under 4 weeks with a removal rate of up to 32.18%. Yin et

al (13) demonstrated that 2.5

mmol/l 3MI may be reduced by Pseudomonas aeruginosa

(extracted from the sediment of lapacho wood) in 3 days and the

time was extended as the 3MI concentration increased from 2.5 to

3.5 mmol/l. Additionally, Gu and Berry (14) indicated that 1–1.5 μmol/l

3MI was reduced in 36 days by a bacterial colony that produced

methane. Furthermore, Gu et al (15) reported that 3MI may be completely

degraded by sulfate-reducing bacteria.

The objectives of the present study were to

investigate the growth of lactic acid bacteria [Lactobacillus

brevis 1.12 (L. brevis 1.12), L. plantarum 102,

L. casei 6103 and L. plantarum ATCC8014] in culture

medium with varied concentrations of 3MI, and to explore the

correlation between the levels of 3MI and the 3MI removal ability

of the lactic acid bacteria during the fermentation process in

vitro.

Materials and methods

Strains and medium

L. brevis 1.12, L. casei 6103 and

L. plantarum ATCC8014 were purchased from China Center of

Industrial Culture Collection (Beijing, China). L. plantarum

102 was obtained from American Type Culture Collection (Manassas,

VA, USA). MRS broth (Oxoid Ltd., Basingstoke, UK) was used as the

culture medium for the lactic acid bacteria.

Chemicals and reagents

3MI, acetonitrile and methanol of high-performance

liquid chromatography (HPLC) grade were purchased from

Sigma-Aldrich (St. Louis, MO, USA). Phosphate-buffered saline (PBS;

Sigma-Aldrich) was of analytical grade. All remaining chemicals

were of biological and analytical reagent grades, and were obtained

from Kelong Chemical Reagent Factory (Chengdu, China).

Effects of 3MI on the growth of lactic

acid bacteria

The 3MI standard solutions contained 0.0, 0.2, 0.4,

0.6, 0.8 and 1.0 g 3MI standard substance dissolved in 10 ml

absolute ethyl alcohol (w/v; 0.00, 0.02, 0.04, 0.06, 0.08 and 0.10

g/ml, respectively). The bacterial colonies of L. brevis

1.12, L. plantarum 102, L. casei 6103 and L.

plantarum ATCC8014 were suspended in 10 ml 0.75% (w/v)

physiological saline. Subsequently, 2.5% (v/v) suspension liquid

and 1 ml 3MI solution were mixed with 100 ml MRS medium for 72 h at

37°C. The optical density (OD) value at 600 nm was detected every 2

h by a spectrophotometer (722-spectrophotometer; Tairui Instrument

Co., Ltd., Chongqing, China) (16,17).

Removal of 3MI from the MRS broth by

fermentation of lactic acid bacteria strains

3MI standard substance (0.0, 0.2, 0.4, 0.6, 0.8 and

1.0 g) was dissolved in 10 ml absolute ethyl alcohol to provide 3MI

standard solutions (0.00, 0.02, 0.04, 0.06, 0.08 and 0.10 g/ml,

respectively). Bacterial colonies of L. brevis 1.12, L.

plantarum 102, L. casei 6103 and L. plantarum

ATCC8014 were suspended in 10 ml 0.75% (w/v) physiological saline.

3MI solution (1 ml) and 2.5% (v/v) suspension liquid were mixed in

100 ml MRS medium for 120 h at 37°C. The sample treatment method

for HPLC was as follows: The fermentation broth was centrifuged at

9000 × g for 10 min; 1 ml of supernatant was mixed with 9 ml

acetonitrile:ultrapure water (75:25, v/v); and the intermixture was

filtered through an organic phase filter of 0.45 μm

(Frisenette ApS Co., Ebeltoft, Denmark) and loaded into a 1.5 ml

screw-thread bottle (16,17). In the present study, the removal

rate of 3MI (%) was the response value, which was calculated using

the following equation: Removal rate (%) = (A-B)/Ax100; where A is

the initial level of 3MI (ng/ml) and B represents the residual

level of 3MI (ng/ml).

Removal of 3MI by the supernatant fluid

of fermentation, cell pellets and extracts of lactic acid

bacteria

An activated culture of lactic acid bacteria (10 ml)

was centrifuged (9,000 × g, 5 min, 5°C). The supernatant fluid of

fermentation was collected, and the resultant cell pellets were

washed twice with 10 ml sterile PBS (0.01 M, pH 7.4) and suspended

in 10 ml sterile PBS. The cell pellet suspension (10 ml) was

disintegrated (400 W every 5 sec for 30 min) in an ice-water bath

by an ultrasonic cell disintegrator (Branson Sonifier 450; Branson

Ultrasonics Corp., Danbury, CT, USA). The disintegrated cell

suspension was centrifuged (9,000 × g, 5 min, 5°C) and the

supernatant (cell extract) was collected. 3MI was added to the

solutions of supernatant fluid of fermentation, suspensions of cell

pellets and cell extracts of lactic acid bacteria, to an initial

3MI concentration of 1.0 μg/ml. Sterile PBS containing 1.0

μg/ml 3MI was used as the control. The suspensions were

incubated at 37°C for 24 h, centrifuged (9,000 × g, 5 min, 5°C) and

the supernatant fluids were filtered through a 0.45-μm

filter and stored at 4°C prior to analysis (18,19).

Removal of 3MI from PBS by viable heat-,

acid- and alkali-treated cells and the supernatant fluid of lactic

acid bacteria

Activated culture of L. brevis 1.12 (10 ml)

was centrifuged (9,000 × g, 5 min, 5°C) and the cell pellets were

washed twice with 10 ml sterile PBS (0.01 M, pH 7.4). Cells of

L. brevis 1.12 were treated by the following methods:

heating (100°C for 30 min, incubated at 37°C for 24 h), acid

treatment (1 M HCl, incubated at 37°C for 24 h) and alkali

treatment (1 M NaOH, incubated at 37°C for 24 h). Following these

treatments, the suspensions were centrifuged (9,000 × g, 5 min,

5°C) and the supernatants were removed. The resultant cell pellets

were washed twice with 10 ml sterile PBS and then suspended in 10

ml sterile PBS. Sterile PBS containing 1.0 μg/ml 3MI was

used as the control. The removal of 3MI was tested as previously

described. The supernatant fluid of fermentation was cryodesiccated

and treated by the same method used for cells of L. brevis

1.12 (20,21).

Analysis of 3MI by HPLC

For HPLC, an LC-20A system (Shimadzu Co., Kyoto,

Japan) was used consisting of a SIL-10ADvp injector with a 100

μl loop and two LC-10 ADvp HPLC pumps. The detector used was

a RF-20A fluorometer and data were collected with an LC solution

integrator. The column was Hypersil (ODS-2, 5-μm particle

size; length, 200 mm; tubing I.D, 4.6 mm; Elite Analytical

Instrument Co., Ltd., Dalian, China) and operated at ambient

temperature. The mobile phase consisted of acetonitrile:ultrapure

water (60:40, v/v) and the flow rate was 1.0 ml/min. The detection

was carried out by measuring the fluorescence with the following

wavelengths: excitation at 281 nm and emission at 353 nm. The

volume of the injected sample was 10 μl (22).

Statistical analysis

All data are expressed as the mean ± standard

deviation of triplicate assays. Simple linear regressions for 3MI

standard solutions with different gradient concentrations and the

growth of lactic acid bacteria in the MRS medium with 3MI were

calculated using Microsoft Excel 2007. Statistical analyses for the

removal rate of 3MI (%) were carried out using PASW statistics

(formerly SPSS), version 18.0 (IBM SPSS, Inc., Chicago, IL,

USA).

Results

Effects of 3MI on the growth of lactic

acid bacteria

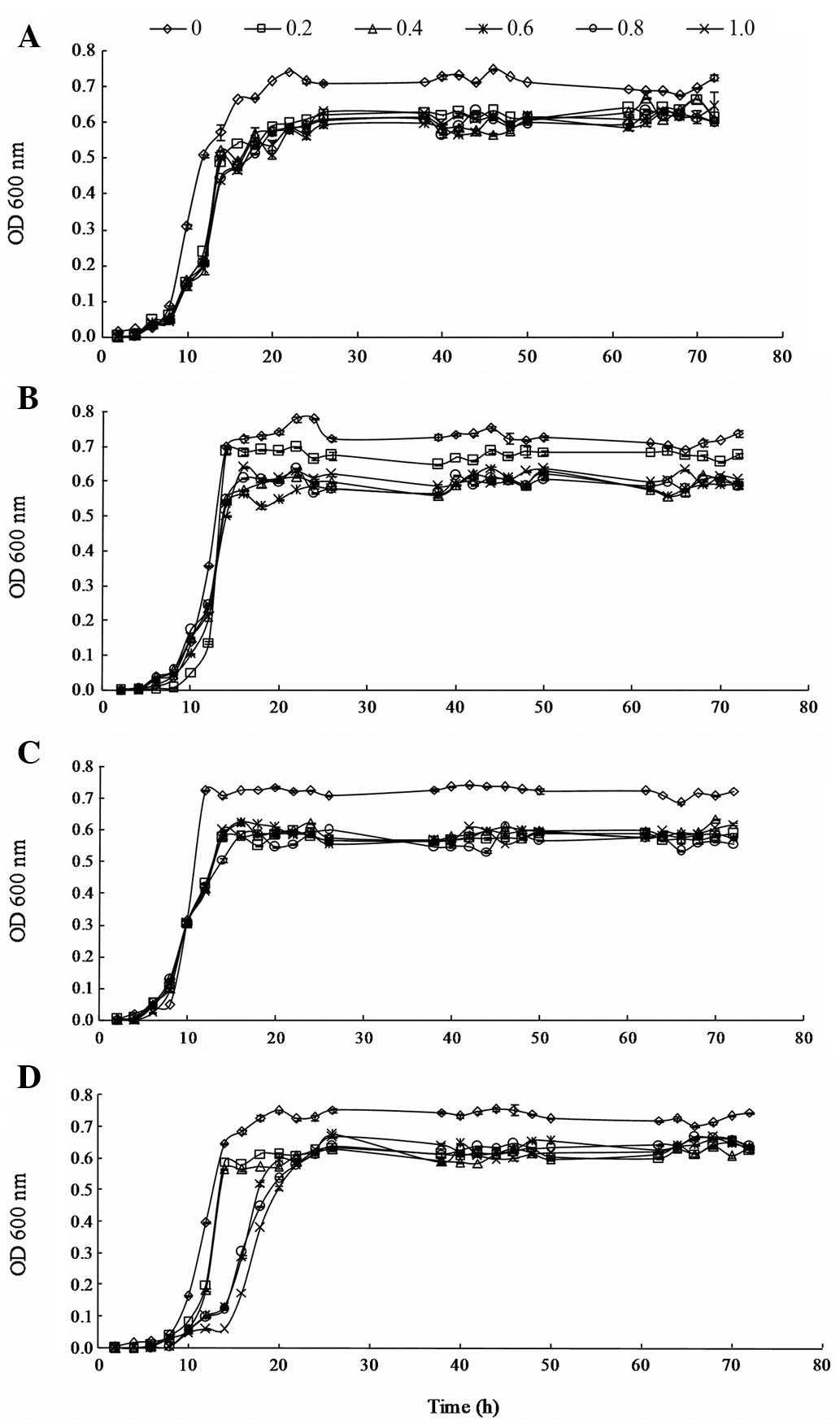

The growth responses of lactic acid bacteria (L.

brevis 1.12, L. plantarum 102, L. casei 6103 and

L. plantarum ATCC8014) to different concentrations of 3MI

(from 0.2 to 1.0 μg/ml) are shown in Fig. 1.

The effects of 3MI on the growth of L. brevis

1.12 were not significant during the lag phase. However, the growth

of L. brevis 1.12 was inhibited by 3MI during the

logarithmic phase. During the stationary phase, the OD values of

L. brevis 1.12 in the MRS medium containing 3MI were lower

than such values of L. brevis 1.12 in MRS medium without

3MI. However, the growth of L. brevis 1.12 was steady as the

level of 3MI increased from 0.2 to 1.0 μg/ml in the

stationary phase.

The effects of 3MI on the growth of L.

plantarum 102 were not significant at the lag and logarithmic

phases. In addition, the results showed that the growth of L.

plantarum 102 was not inhibited by 3MI at the two phases.

During the stationary phase, the growth of L. plantarum 102

was restrained in the presence of increasing levels of 3MI (from

0.2 to 1.0 μg/ml) and significant differences between the

effects of the various levels of 3MI on the growth of L.

plantarum 102 were observed.

The effects of 3MI on the growth of L. casei

6103 were not significant at the lag and logarithmic phases;

however, growth was slower than that of the control group at 10–12

h in the logarithmic phase. At the stationary phase, the growth of

L. casei 6103 was restrained in the MRS medium with 0.2

μg/ml 3MI, but the OD value was steady as the level of 3MI

increased from 0.2 to 1.0 μg/ml. The results suggest that

the growth of L. casei 6103 was inhibited by 3MI at the

stationary phase; however, the difference in growth among the

varied levels of 3MI was not marked.

The effects of 3MI on the growth of L.

plantarum ATCC8014 were significant at the logarithmic phase,

with slower growth compared with that of the control. However,

during the stationary phase, the growth was steady with increasing

concentrations of 3MI from 0.2 to 1.0 μg/ml.

3MI removal during the fermentation of

lactic acid bacteria

The relationship between the concentration of 3MI

and the removal ability of the four strains during the fermentation

process was also studied. The results indicate that the levels of

3MI decreased during the fermentation process in all four strains

and the removal rate increased as the incubation time increased

from 24 to 120 h. Differences among the four strains were

significant, as shown in Table I.

L. brevis 1.12 indicated the strongest ability to remove 3MI

compared with the other strains. The removal rate increased as the

incubation time was extended from 24 to 120 h; however, the effects

of different 3MI levels on the ability of L. brevis 1.12 to

remove MI were not significant, as the removal rate was steady with

increasing levels of 3MI from 0.2 to 1.0 μg/ml; the highest

removal rate was 65.35±0.3% in the fermentation fluid of L.

brevis 1.12 with 1.0 μg/ml 3MI in 120 h. For L.

plantarum 102, L. casei 6103 and L. plantarum

ATCC8014, the effects of the different levels of 3MI on the removal

ability of the three strains were significant. The ability of the

three strains to remove 3MI decreased as the 3MI levels increased

from 0.2 to 1.0 μg/ml, and L. plantarum 102 and L.

plantarum ATCC8014 were more sensitive to 3MI when compared

with L. casei 6103. The removal ability of L.

plantarum 102 and L. plantarum ATCC8014 was sensitive to

0.4 and 0.8 μg/ml 3MI, respectively. The removal rates were

28.54±0.2 and 33.23±0.9% in the fermentation fluid of L.

plantarum 102 and L. plantarum ATCC8014 with 1.0

μg/ml 3MI, respectively, in 120 h.

| Table I.Effects of the level of 3MI on the

3MI removal ability of lactic acid bacteria. |

Table I.

Effects of the level of 3MI on the

3MI removal ability of lactic acid bacteria.

| Concentration of

3MI (μg/ml) | Incubation time

(h) | Removal rate (%)

|

|---|

| L. brevis

1.12 | L. plantarum

102 | L. casei

6103 | L. plantarum

ATCC8014 |

|---|

| 0.2 | 24 |

15.71±0.20a |

11.47±0.40b |

9.20±0.10c |

11.55±0.20b |

| 48 |

30.62±0.10b |

39.77±0.10a |

21.39±0.40c |

30.50±0.10b |

| 72 |

57.36±0.60a |

53.33±0.30c |

54.23±1.50b |

50.27±0.30d |

| 96 |

62.64±0.10a |

57.28±0.10c |

60.30±0.20b |

52.09±0.10d |

| 120 |

67.63±0.20a |

60.79±0.10c |

61.53±1.20b |

56.75±0.10d |

| 0.4 | 24 |

15.36±0.10a |

9.46±0.30b |

6.28±0.60c |

9.50±0.20b |

| 48 |

29.81±0.10a |

25.38±0.10b |

20.72±0.50c |

17.90±0.20d |

| 72 |

57.20±0.10a |

46.21±0.50c |

53.55±0.40b |

26.64±0.90d |

| 96 |

62.12±0.10a |

53.51±0.50c |

57.14±0.20b |

27.32±0.20d |

| 120 |

67.87±0.20a |

55.02±0.70c |

59.16±0.10b |

35.41±0.30d |

| 0.6 | 24 |

15.13±0.60a |

2.65±0.40d |

6.21±0.50c |

7.70±0.80b |

| 48 |

30.93±0.20a |

19.38±0.30c |

20.16±0.50b |

17.93±0.10d |

| 72 |

57.52±0.20a |

40.23±0.60c |

46.89±0.60b |

23.96±0.10d |

| 96 |

61.76±0.40a |

46.72±0.10c |

50.32±0.60b |

26.73±0.70d |

| 120 |

67.61±0.30a |

47.51±0.20c |

59.14±0.20b |

35.20±0.20d |

| 0.8 | 24 |

16.09±0.10a |

1.05±0.10d |

4.21±0.50c |

8.12±0.30b |

| 48 |

31.23±0.20a |

12.44±0.50d |

17.21±0.80b |

15.53±0.40c |

| 72 |

57.66±0.20a |

33.35±0.30c |

46.40±0.40b |

22.35±0.10d |

| 96 |

61.63±0.10a |

35.64±0.20c |

52.18±0.60b |

23.27±0.60d |

| 120 |

67.12±0.10a |

35.68±0.30c |

52.76±0.10b |

35.71±0.10c |

| 1.0 | 24 |

17.43±0.20a |

0.88±0.10d |

3.48±0.26c |

5.50±0.40b |

| 48 |

31.68±0.20a |

10.62±0.20d |

16.43±0.20b |

19.05±0.90c |

| 72 |

56.72±0.60a |

29.60±0.20c |

39.32±0.30b |

25.42±0.50d |

| 96 |

61.55±0.60a |

29.63±0.10c |

51.78±0.20b |

26.16±0.50d |

| 120 |

65.35±0.30a |

28.54±0.20d |

52.15±0.30b |

33.23±0.90c |

Mode of removal

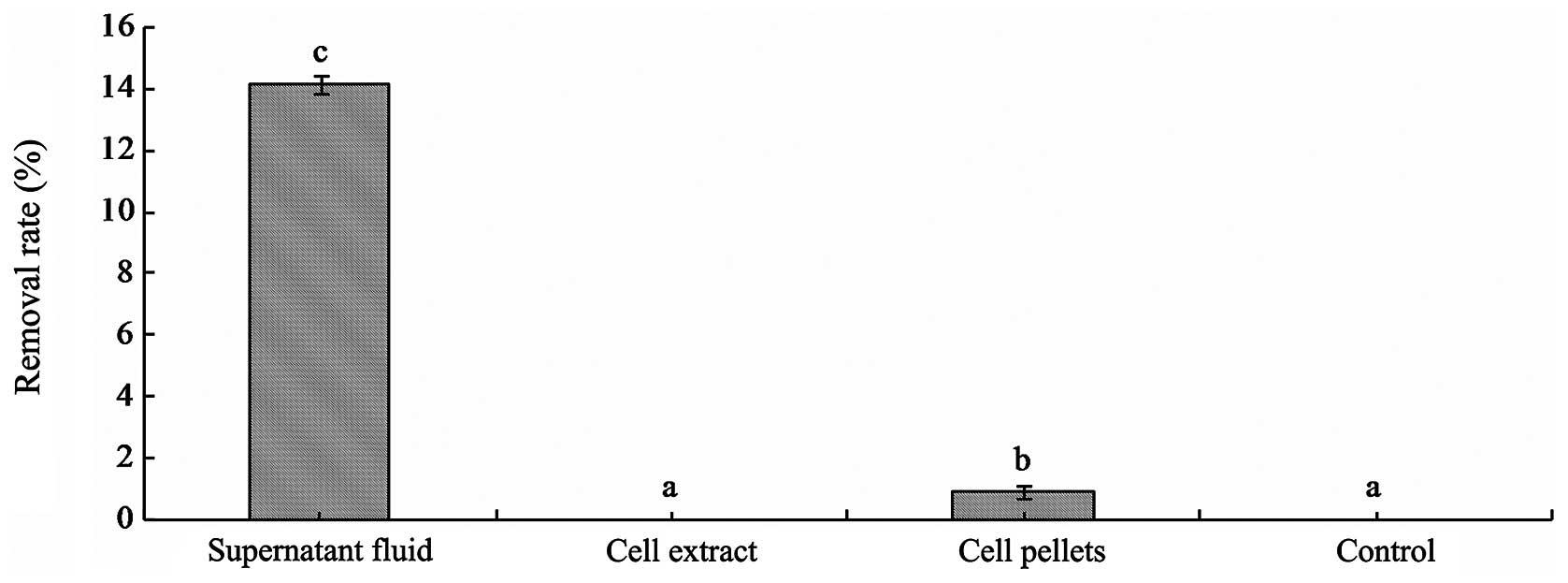

The concentrations of 3MI following incubation with

the supernatant fluid of fermentation, the suspension of cell

pellets and cell extracts of L. brevis 1.12 at 37°C for 24 h

were detected by HPLC. The results showed that the 3MI removal

ability of the supernatant fluid of fermentation broth was the

strongest. 3MI was removed by the supernatant fluid of fermentation

with a removal rate of 14.4±0.3% at 37°C for 24 h. 3MI was removed

by cell pellets of L. brevis 1.12 (0.88±0.2%) (Fig. 2), but 3MI was not detected in the

PBS eluent. The results suggest that the removal mode of 3MI was

not through the physical binding of cells by L. brevis 1.12.

Furthermore, the results showed that the removal rates of 3MI in

the suspensions following incubation with heat-, acid- and

alkali-treated cells decreased significantly, and the removal

ability of L. brevis 1.12 was inhibited under these methods

(Table II). The results also

confirmed that the removal mode for 3MI was not via physical

binding.

| Table II.Effects of supernatant and cell

pellets of L. brevis 1.12 on 3MI removal using different

treatment methods. |

Table II.

Effects of supernatant and cell

pellets of L. brevis 1.12 on 3MI removal using different

treatment methods.

| Substance | Removal rate (%)

|

|---|

| Heat-treated | Acid-treated | Alkali-treated | Non-treated | HCl control | NaOH control |

|---|

| Supernatant |

3.98±1.3a |

6.70±0.7c |

4.92±1.2b |

15.27±2.3d | − | − |

| Cell pellets | − | − | − | 0.95±1.5 | − | − |

Discussion

In the present study, the results suggest that the

four strains of lactic acid bacteria are more sensitive to 3MI than

previously investigated microorganisms from other studies regarding

the effects of 3MI on microorganisms. The growth of all four

strains was inhibited by low levels of 3MI (0.2 μg/ml).

However, Dreizen and Spies (23)

identified that the growth of L. acidophilus was completely

restricted by 400 μg/ml 3MI, but growth occurred when the

3MI concentration was decreased from 400 to 100 μg/ml. In

addition, Tittlser et al (24) demonstrated that the growth of 25

species of Gram-negative bacteria extracted from the intestinal

tract was inhibited when the 3MI concentration was 330

μg/ml. Furthermore, Kohda et al (12) identified that the growth of

Clostridium was steady in 100–300 μg/ml 3MI solution;

however, the growth of certain clostridia was prevented in 50

μg/ml 3MI solution. In the present study, the growth of the

four strains was prevented in the incubation environment with 0.2

μg/ml 3MI and the tolerance levels for 3MI concentration

were lower than those identified in the previously mentioned

studies.

Furthermore, the ability of the four strains to

degrade 3MI was compared with results from previous studies. The

results showed that the 3MI removal ability of the four strains was

stronger than that of the microorganisms investigated in the

studies by Gu et al (15)

and Li et al (25). Gu

et al (15) identified that

3MI may be degraded by marine anaerobic microorganisms for 30 days.

Additionally, Li et al (22) indicated that 2.0 mmol/l 3MI may be

degraded by Pseudomonas putida LPC24 in <30 days. In the

present study, the degradation ability of L. brevis 1.12 was

the strongest among the bacteria tested, with a degradation rate

for 1.0 μg/ml 3MI of 65.35±0.3% in 5 days. However, the

degradation time was longer than that in the study by Yin et

al (13). The study suggested

that 2.5 mmol/l 3MI may be reduced by Pseudomonas aeruginosa

(extracted from the sediment of lapacho wood) in 3 days and the

time extended with increased 3MI concentration from 2.5 to 3.5

mmol/l (13). The different

results may be due to significant differences among the

microorganisms tested.

The results of the present study demonstrated that

3MI may be degraded by the supernatant fluid of fermentation and

suspension of cell pellets; however, 3MI was not detected in the

eluent of cell pellets. This suggests the key substance responsible

for the degradation of 3MI exists in the supernatant fluid of the

fermentation broth and that the mode of 3MI removal was not through

the physical binding of cells by L. brevis 1.12. However, in

the present study, the removal mechanism of 3MI during the

fermentation process of L. brevis 1.12 was not studied. The

removal mechanism of 3MI in certain microorganisms and the liver of

entire pigs have been demonstrated in previous studies. Gu et

al (15) identified that 3MI

may be degraded by marine anaerobic microorganisms, and the

mechanism included two steps of oxidation accomplished by

hydroxylation and then dehydrogenation at the 2- and 3-positions

sequentially prior to the cleavage of the pyrrole ring between the

2- and 3-positions. The 3MI degradation mechanism in pig liver is

usually conducted in two steps, phase I and II (26). Phase I consists of an oxidation of

the compound, usually catalyzed by cytochrome P450 (CYP450)

enzymes, while phase II is conducted by a more diverse group of

enzymes and consists of conjugation with a hydrophilic group, such

as by glucuronidation, sulfoconjugation or glucosidation. The

outcome of phase I and/or II metabolism is often the elimination of

the compound by excretion (26).

In pigs, the phase I metabolism of 3MI is mainly mediated by

hepatic CYP1A2, CYP2A and CYP2E1 (27). Diaz and Squires (28) indicated that 3MI is metabolized by

the CYP450 system in the lungs and liver of ruminants, rodents and

humans. Squires and Lundström (26) demonstrated that a similar system

may be involved in 3MI metabolism in pigs and a particular CYP2E1

was indicated as the major enzyme responsible for metabolic

breakdown of 3MI in the liver. Moreover, Chen et al

(8) identified that a dietary

supplement of raw potato starch reduced the levels of 3MI.

Furthermore, the addition of fructooligosaccharide to pig fecal

slurries significantly reduced 3MI levels but not indole synthesis

from tryptophan. In future studies, the supernatant fluid of the

fermentation broth with 3MI will be detected using HPLC to analyze

whether new metabolites are produced and to study the mechanism of

3MI degradation by L. brevis 1.12.

In conclusion, the present study used various in

vitro experimental methods to investigate the growth of lactic

acid bacteria in the presence of 3MI, the 3MI removal ability of

four strains of bacteria during the fermentation process and the

removal mode of 3MI by L. brevis 1.12. The results

demonstrated that the growth of all four strains was inhibited by

3MI and the 3MI removal ability of L. brevis 1.12 was the

strongest. The 3MI removal rate of L. brevis 1.12 was

65.35±0.3% from the incubation medium of 1 ml 1.0 μg/ml 3MI

in 120 h. Furthermore, this study demonstrated that the mode of 3MI

removal was not through the physical binding of cells by L.

brevis 1.12.

Acknowledgements

This study was funded by the National

Basic Research Program of China (973 program; grant no.

2009CB118806), the National Rabbit Industry Technology System

Program (grant no. CARS-44D-1) and the National Natural Science

Foundation of China (grant no. 31071566).

References

|

1.

|

Barton Gade PA: Meat and fat quality in

boars, castrates and gilts. Livest Prod Sci. 16:187–196. 1987.

|

|

2.

|

Bonneau M, Dufour R, Chouvet C, Roulet C,

Meadus W and Squires EJ: The effects of immunization against

luteinizing hormone-releasing hormone on performance, sexual

development, and levels of boar taint-related compounds in intact

male pigs. J Anim Sci. 72:14–20. 1994.

|

|

3.

|

Babol J, Squires EJ and Lundström K:

Relationship between metabolism of androstenone and skatole in

intact male pigs. J Anim Sci. 77:84–92. 1999.PubMed/NCBI

|

|

4.

|

Babol J, Squires EJ and Lundström K:

Hepatic metabolism of skatole in pigs by cytochrome P4502E1. J Anim

Sci. 76:822–828. 1998.PubMed/NCBI

|

|

5.

|

Jensen MT, Cox RP and Jensen BB:

3-Methylindole (skatole) and indole production by mixed populations

of pig fecal bacteria. Appl Environ Microbiol. 61:3180–3184.

1995.PubMed/NCBI

|

|

6.

|

Yokoyama MT and Carlson JR: Microbial

metabolites of tryptophan in the intestinal tract with special

reference to skatole. Am J Clin Nutr. 32:173–178. 1979.PubMed/NCBI

|

|

7.

|

Lunde K, Skuterud E, Hersleth M and

Egelandsdal B: Norwegian consumers’ acceptability of boar tainted

meat with different levels of androstenone or skatole as related to

their androstenone sensitivity. Meat Sci. 86:706–711. 2010.

|

|

8.

|

Chen G, Zamaratskaia G, Andersson HK and

Lundström K: Effects of raw potato starch and live weight on fat

and plasma skatole, indole and androstenone levels measured by

different methods in entire male pigs. Food Chem. 101:439–448.

2007. View Article : Google Scholar

|

|

9.

|

Yuan YJ, Lu ZX, Huang LJ, Li Y, Lu FX, Bie

XM, et al: Biodegradation of nicotine from tobacco waste extract by

Ochrobactrum intermedium DN2. J Ind Microbiol Biotechnol.

34:567–570. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

10.

|

Bai YH, Sun Q, Zhao C, Wen D and Tang X:

Aerobic degradation of pyridine by a new bacterial strain,

Shinella zoogloeoides BC026. J Ind Microbiol Biotechnol.

36:1391–1400. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

11.

|

Patil PS, Shedbalkar UU, Kalyani DC and

Jadhav JP: Biodegradation of Reactive Blue 59 by isolated bacterial

consortium PMB11. J Ind Microbiol Biotechnol. 35:1181–1190. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

12.

|

Kohda C, Ando T and Nakai Y: Isolation and

characterization of anaerobic indole- and skatole-degrading

bacteria from composting animal wastes. J Gen Appl Microbiol.

43:249–255. 1997. View Article : Google Scholar : PubMed/NCBI

|

|

13.

|

Yin B, Huang L and Gu JD: Biodegradation

of 1-methylindole and 3-methylindole by mangrove sediment

enrichment cultures and a pure culture of an isolated

Pseudomonas aeruginosa Gs. Water Air Soil Poll. 176:185–199.

2006. View Article : Google Scholar

|

|

14.

|

Gu JD and Berry DF: Metabolism of

3-methylindole by a methanogenic consortium. Appl Environ

Microbiol. 58:2667–2669. 1992.PubMed/NCBI

|

|

15.

|

Gu JD, Fan Y and Shi H: Relationship

between structures of substituted indolic compounds and their

removal by marine anaerobic microorganisms. Mar Pollut Bull.

45:379–384. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

16.

|

El-Nezami HS, Polychronaki N, Salminen S

and Mykkänen H: Binding rather than metabolism may explain the

interaction of two food-grade Lactobacillus strains with

zearalenone and its derivative ά-zearalenol. Appl Environ

Microbiol. 68:3545–3549. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

17.

|

Niderkorn V, Boudra H and Morgavi DP:

Binding of Fusarium mycotoxins by fermentative bacteria

in vitro. J Appl Microbiol. 101:849–856. 2006.

|

|

18.

|

Cheng B, Wan C, Yang S, Xu H, Wei H, Liu

J, et al: Detoxification of deoxynivalenol by Bacillus

strains. J Food Safety. 30:599–614. 2010.

|

|

19.

|

Lu Q, Liang X and Chen F: Detoxification

of zearalenone by viable and inactivated cells of Planococcus

sp. Food Control. 22:191–195. 2011. View Article : Google Scholar

|

|

20.

|

El-Nezami HS, Kankaanpaa PE, Salminen S

and Ahokas J: Ability of dairy strains of lactic acid bacteria to

bind a common food carcinogen, afatoxin B1. Food Chem Toxicol.

36:321–326. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

21.

|

Topcu A, Bulat T, Wishah R and Boyaci IH:

Detoxification of aflatoxin B1 and patulin by Enterococcus

faecium strains. Int J Food Microbiol. 139:202–205. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

22.

|

Tuomola M, Vahva M and Kallio H:

High-performance liquid chromatography determination of skatole and

indole levels in pig serum, subcutaneous fat, and submaxillary

salivary glands. J Agr Food Chem. 44:1265–1270. 1996. View Article : Google Scholar

|

|

23.

|

Dreizen S and Spies TD: Further studies on

the association between the products of protein putrefaction and

dental caries activity. J Dent Res. 27:305–315. 1948. View Article : Google Scholar : PubMed/NCBI

|

|

24.

|

Tittsler RP, Sandholzer LA and Callahan

ET: The bacteriostatic action of skatole on Gram-negative enteric

bacilli. J Infect Dis. 57:57–60. 1935. View Article : Google Scholar

|

|

25.

|

Li P, Tong L, Liu K and Wang YX:

Biodegradation of 3-methylindole by Pseudomonas putida LPC24

under oxygen limited conditions. Fresenius Environ Bull.

19:238–242. 2010.

|

|

26.

|

Squires EJ and Lundström K: Relationship

between cytochrome P4502E1 in liver and levels of skatole and its

metabolites in intact male pigs. J Anim Sci. 75:2506–2511.

1997.PubMed/NCBI

|

|

27.

|

Matal J, Matuskova Z, Tunkova A,

Anzenbacherova E and Anzenbacher P: Porcine CYP2A19, CYP2E1 and

CYP1A2 forms are responsible for skatole biotransformation in the

reconstituted system. Neuro Endocrinol Lett. 30:36–40.

2009.PubMed/NCBI

|

|

28.

|

Diaz GJ and Squires EJ: Metabolism of

3-methylindole by porcine liver microsomes: responsible cytochrome

P450 enzymes. Toxicol Sci. 55:284–292. 2000. View Article : Google Scholar : PubMed/NCBI

|