Introduction

At present, tissue engineered bones can be prepared,

according to the specific requirements of the host, through the

implantation of tissues and materials with the desirable

physiological functions required to fix and repair bone defects

(1). This technique has attracted

significant focus, as it is a minimally invasive, easily performed

procedure that maintains the blood supply to the defective area.

Currently, there are two main types of scaffolds, natural

bio-derived materials (e.g. collagen, coral and bio-derived bones),

and synthetic materials (e.g. bioceramics and polymer materials).

As only one type of material is incapable of meeting the

requirements of bone tissue repair, composite scaffold materials

are preferred (2). However,

histocompatibility remains problematic (3,4).

Therefore, a novel injectable chitosan-β-tricalcium phosphate

composite was used in the present study to act as a carrier for

mesenchymal stem cells (MSCs). The compatibility of the MSCs with

the composite scaffold and the subsequent effects on cellular

proliferation were analyzed. The results of this study may provide

valuable evidence for the preparation of analogous injectable

tissue engineered bones.

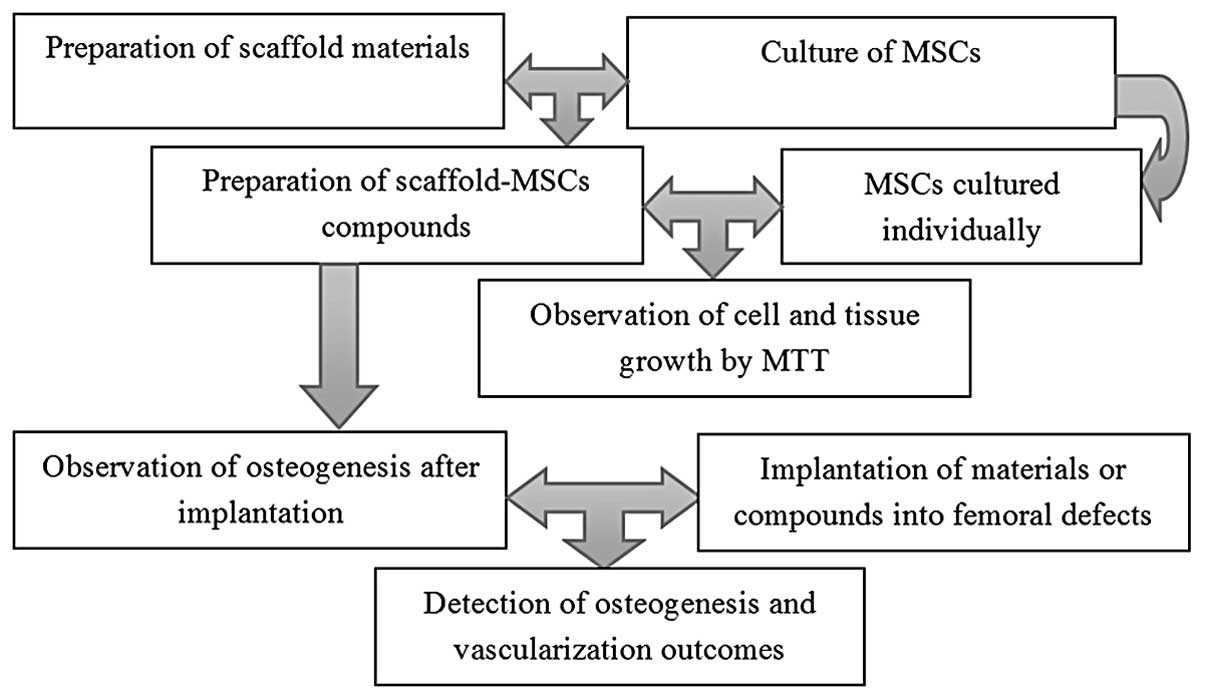

Materials and methods

General information

MSCs (China Infrastructure of Cell Line Resources,

Beijing, China) were divided into two groups: An experimental study

group that was cultured with injectable chitosan-β-tricalcium

phosphate composite and a control group that was cultured with

β-tricalcium phosphate composite only. The growth of the cells and

tissues was verified by MTT assay to determine the effects of the

composite. In addition, 10 12-month-old beagles were implanted with

composite scaffolds and subsequently observed for the effects on

osteogenesis and vascularization. The dogs were subsequently

divided into Groups A and B (n=5/group). Group A was subjected to

15-mm defects on the femur and was then was implanted with

scaffolds carrying MSCs. Group B was implanted with the composite

scaffold materials alone, without MSCs. The two groups were

observed on the 2nd, 4th, 8th and 12th weeks post-implantation

(Fig. 1).

Sampling site and criteria

The experiments were performed in the Experimental

Center of Hukou County Hospital of Traditional Chinese Medicine

(Hukou, China). Healthy 12-month-old beagles weighing 8–10 kg were

purchased from the Experimental Animal Center of Shandong

University (Jinan, China). The dogs were free of infections or

genetic diseases, and without history of limb bone fracture. The

present study was approved by the Ethics Committee of The

Saint-Petersburg State I.P. Pavlov Medical University (St.

Petersburg, Russia).

Cell culture

MSCs were cultured under sterile conditions, in

Dulbecco’s modified Eagle’s medium containing high-glucose levels

as a carbon source and serum in 10–20% CO2. MSCs were

extracted from the animals by puncture under anesthesia. Bone

marrow (10 ml) was collected using a 16-gauge bone needle, and then

filtered and cultured at 37°C in 10–20% CO2. The culture

medium was refreshed every three days until the end of the primary

culture. Pancreatin enzyme was subsequently added to the culture

medium in order to separate adhesive cells that were selectively

cultured in α-minimal essential medium supplemented with 10% fetal

bovine serum, with alendronate sodium used as an inhibitor

(Gibco-BRL, Gaithersburg, MD, USA). This new culture medium was

also changed every three days (5–7).

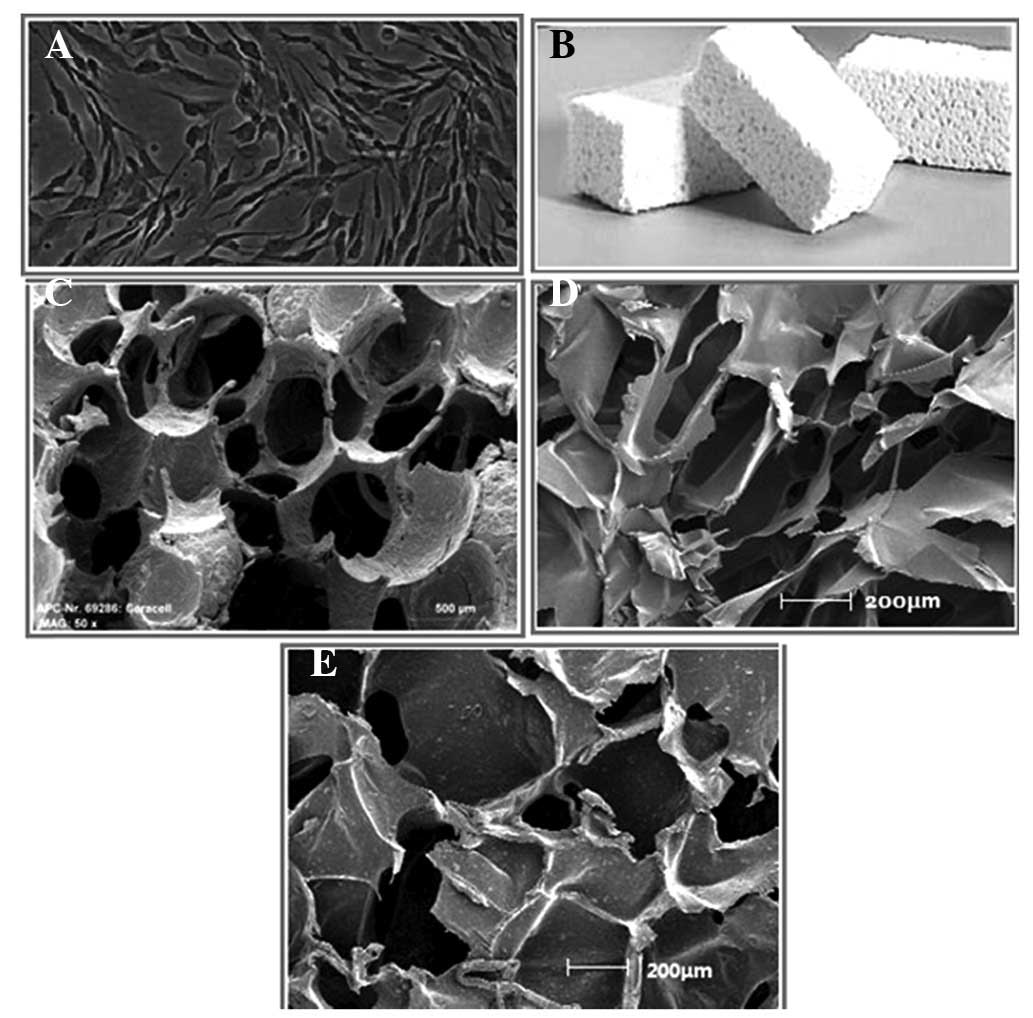

After three weeks of culture, the osteogenic differentiation of

MSCs (third generation) was determined by positive alkaline

phosphatase staining (Fig. 2).

Material preparation

Scaffold materials were prepared under sterile

conditions at 37°C in an atmosphere containing 5% CO2,

using chitosan and β-tricalcium phosphate as the liquid and solid

material components, respectively (8). The mixture transformed from a liquid

to solid state, and was then cut into 48-mm3 sections

using a sterile knife. The third-generation MSCs, culture medium

and incised scaffold materials were transferred to 24-well plates

(Fig. 3).

Construction of scaffolds

The composite material was cut into 12×15 mm pieces,

into which were injected third-generation MSCs. The compounds were

then cultured under sterile conditions in CO2 at 37°C

for 4–6 h, and were subsequently covered with culture medium.

MTT assay

Culture medium was discarded from the culture

plates, which were then washed with phosphate-buffered saline. The

cultures were subsequently stained with MTT and universal buffer,

and cultured in 5% CO2 at 37°C for 5 h. The MTT and

buffer were discarded and 0.1 ml acidified isopropanol was added to

the plates and mixed by agitation for 15 min. Finally, the

absorbance of the products was measured at 570 nm.

Scaffold implantation

The beagles were anesthetized by intravenous

administration of 0.03 ml/kg 1% sodium pentobarbital, and the

mucoperiosteum was separated following a skin incision 15 mm from

the posterior limb. Femoral defects, ~15 mm in length on one side

of the femur, were prepared by an ultrasonic bone knife, followed

by hemostasis. The tissue engineered bone scaffold materials were

implanted, followed by suturing of the soft tissues, embedding and

hemostasis. The wounds were rinsed with normal saline, sutured by

layered closure and bandaged. Following the surgical procedure, the

dogs were intramuscularly injected with 400,000 units penicillin

for three consecutive days (qd). Under normal conditions,

osteogenesis and vascularization would occur within 12 weeks.

Cluster of differentiation 31 (CD31)

immunohistochemical staining

Histological analysis was performed using Masson’s

trichrome staining (Sigma-Aldrich, St. Louis, MO, USA). Sections

were fixed at 60°C heat for 10 min and deparaffinized through

ethanol hydration. The sections were subsequently sterilized with

peroxidase and rinsed in buffer, prior to undergoing separation

using trypsin and blocking with bovine serum albumin. The sections

were then exposed to diluted anti-dog CD31 primary (1:100) and

anti-goat secondary antibodies (Santa Cruz Biotechnology, Inc.,

Dallas, TX, USA), in order to perform double-antibody sandwich

enzyme-linked immunosorbent assay. Upon clear color development,

the reaction was terminated using distilled water. The sections

were then double-stained with hematoxylin, prior to being

differentiated, recovered, dehydrated, resealed and visualized

under an inverted microscope. Areas of vascularization were

stained.

Vascular casting method

Dogs were anesthetized by intravenous administration

of 0.03 ml/kg 1% sodium pentobarbital. Skin incisions were then

made through the subcutaneous tissues to expose the femoral

arteries and veins for centrifugal intubation and fixation. Benzoyl

peroxide phthalocyanine (5 g), dimethylaniline (3 ml), dibutyl

phthalate (35 ml) and red oil paint (all Life Technologies,

Carlsbad, CA, USA) were then added to 300 ml pre-polymerized methyl

methacrylate. Following the initiation of polymerization, blood

vessels were infused until casting agents outflowed from the veins,

which were then ligated. The infusion was continued until the

peripheral skin was completely stained red (250 ml casting agent

was used on each side); at this point, the infusion was terminated

and the arteries were ligated. The infused methyl methacrylate

monomers underwent complete polymerization following cryogenic

storage of the blood vessels for 24–48 h while maintaining

intravascular pressure, and the samples were preserved and fixed in

10% formaldehyde solution for 2–3 weeks.

Statistical analysis

All data were analyzed by SPSS 10.0 (SPSS Inc.,

Chicago, IL, USA). Groups were compared by a two-sample t-test to

detect significant differences between the means of two samples and

their totals. P<0.05 was used to indicate a statistically

significant difference. An independent t-test was conducted using

the following formula:

Where S1 and S2 are two sample variances, and n1 and n2 are two

sample sizes.

Results

MTT assay

The absorbances at 570 nm were measured on the 2nd,

4th, 6th and 8th days. The absorbances were lower in the

experimental group than those in the control group (Table I). These results suggest that the

experimental group had a higher proliferative capacity than the

control group.

| Table IComparison between the MTT assay

results. |

Table I

Comparison between the MTT assay

results.

| Day | Absorbancea

| t-test | P-value |

|---|

| Group A | Group B |

|---|

| 2nd | 0.118±0.032 | 0.123±0.031 | 0.550 | 0.384 |

| 4th | 0.367±0.064 | 0.412±0.039 | 2.941 | 0.247 |

| 6th | 0.847±0.062 | 0.911±0.089 | 2.890 | 0.239 |

| 8th | 1.128±0.084 | 1.203±0.069 | 3.380 | 0.084 |

Osteogenesis outcomes following

implantation

The scaffold-implanted areas were sampled 2, 4, 8

and 12 weeks after surgical intervention and the sections were

subjected to Masson’s trichrome staining. In the first two weeks,

the degree of osteogenesis between the two groups was equivalent.

After four weeks, Group A had significantly larger areas of newborn

tissues as compared with Group B (Table II).

| Table IIComparison between bone areas. |

Table II

Comparison between bone areas.

| Week | Bone area

(mm2)

| t-test | P-value |

|---|

| Group A | Group B |

|---|

| 2nd |

3.5±0.8 |

3.2±0.4 | 1.64 | 0.213 |

| 4th | 17.6±1.6 |

6.8±1.2 | 26.45 | 0.004 |

| 8th | 50.4±6.3 | 18.4±4.1 | 20.85 | 0.007 |

| 12th | 80.7±8.2 | 51.2±6.1 | 14.14 | 0.009 |

Vascularization outcomes following

implantation

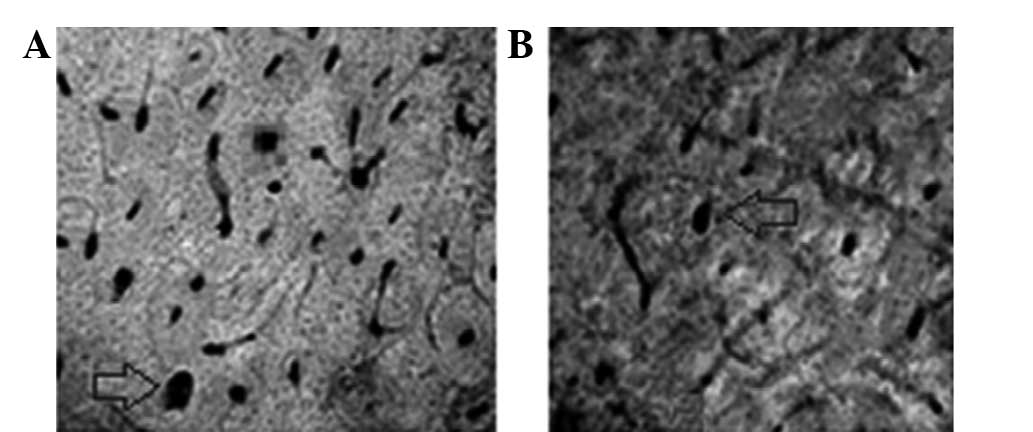

Sections were sampled at the sites of implantation

2, 4, 8 and 12 weeks after surgical intervention, and were

subjected to CD31 staining to observe the number of new blood

vessels. As shown in Figs. 4 and

5, Group A had a significantly

higher number of new blood vessels than Group B.

The sections showed clear microvessels and blood

vessels, which were reticulated along Haversian and Volkmann’s

canals. Nutrient vessels had extended into the endostea and

periostea. In addition, Haversian canals were observed in the

middle and internal and external lamellae, with blood vessels

reticulating along Haversian and Volkmann’s canals (Table III). Blood vessels were observed

to have extended and grown well, and the differences between Groups

A and B became more apparent with increased time.

| Table IIIComparison between the number of blood

vessels in the cross-sections. |

Table III

Comparison between the number of blood

vessels in the cross-sections.

| Week | Blood Vessels (n)

| t-test | P-value |

|---|

| Group A | Group B |

|---|

| 2nd | 83.2±6.4 | 26.4±4.6 | 35.31 | 0.004 |

| 4th | 254.8±8.4 | 84.1±6.5 | 78.73 | 0.002 |

| 8th | 342.3±24.7 | 126.1±16.4 | 35.72 | 0.004 |

| 12th | 512.4±36.6 | 156.4±24.6 | 39.55 | 0.004 |

Discussion

The injection of tissue engineered bones is a highly

efficient intervention with minimal associated trauma. In the

procedure, seed cells are carried in the liquid state, which then

solidifies at the sites of bone defect following injection

(9,10).

Previous studies have endeavored to improve the

histocompatibility of tissue engineering bones. Currently, only one

type of material fails to satisfy the requirements of bone tissue

repair, therefore composite scaffold materials are required

(11,12). Compared with previous studies, the

present study presents the vascularization of repaired limb bone

defects more clearly and directly. The findings suggest that

chitosan-β-tricalcium phosphate composite is a suitable injectable

tissue engineering bone material when stem cells are implanted

simultaneously.

The currently available biomaterials are gels. These

produce satisfactory osteogenesis but are low in stability and

highly brittle, and thus perform poorly in repairing weight-bearing

bones, such as femurs. At present, eligible tissue engineered bones

are generally made from both organic or inorganic compounds, using

citric acid as the crosslinking agent, thus fusing tissue cells

well due to high strength and low toxicity (13–15).

To maintain the survival of tissue engineered bones

in vivo, the vascularization and nerve generating capacities

of the seeded cells should also be enhanced to accelerate bone

recovery (16). The growth of

seeded cells following implantation is associated with blood

microcirculation. In cases of severe bone defect, the deep tissues

may succumb to ischemic necrosis. It is therefore essential to

reconstruct the microcirculation to elevate the survival rate of

seed cells. Periosteal tissue is abundant in nerves, of which a

number enters the bone marrow together with nourishing blood

vessels (17–20). The femur is supplied by the direct

branches of blood vessels surrounding bone tissues as well as the

periosteal vasoganglion. The vasoganglion forms with both skeletal

muscles with arteries adhering to the bones and the periosteal

branches adjoining to the arteries, and nutrients further penetrate

into the tissues through pores in the bone.

Nervous tissue, which is widely distributed

throughout bone tissue, controls the proliferation of osteoblasts

and facilitates healing at the sites of defect upon bone fracture.

Under normal conditions, nervous tissues regulate the metabolism of

bone cells and therefore the nerves are considered to dominate the

process of bone repair. Neurotransmitters secreted by nerve cells

can upregulate or downregulate microcirculation and stimulate cell

secretion. Peripheral nerves and the central nervous system

cooperate in regulating the repair of defects (21,22).

To date, liquid compounds have only been applicable

to filling, rather than repairing, defects. Despite normal growth

in liquid gels, it remains to be determined whether MSCs can grow

in solid compounds (23).

Reconstructing blood vessels and nervous tissues in defects not

only recovers the blood supply and self-regulation of bones, but is

also required for postoperative treatment and effective recovery.

This study has therefore initiated a novel approach for the

surgical repair of bone defects.

References

|

1

|

Dimitriou R, Jones E, McGonagle D and

Giannoudis PV: Bone regeneration: current concepts and future

directions. BMC Med. 9:662011. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Bose S, Roy M and Bandyopadhyay A: Recent

advances in bone tissue engineering scaffolds. Trends Biotechnol.

30:546–554. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Muschler GF, Nakamoto C and Griffith LG:

Engineering principles of clinical cell-based tissue engineering. J

Bone Joint Surg Am. 86-A:1541–1558. 2004.PubMed/NCBI

|

|

4

|

Muschler GF, Raut VP, Patterson TE, Wenke

JC and Hollinger JO: The design and use of animal models for

translational research in bone tissue engineering and regenerative

medicine. Tissue Eng Part B Rev. 16:123–145. 2010. View Article : Google Scholar

|

|

5

|

Tasso R, Fais F, Reverberi D, Tortelli F

and Cancedda R: The recruitment of two consecutive and different

waves of host stem/progenitor cells during the development of

tissue-engineered bone in a murine model. Biomaterials.

31:2121–2129. 2010. View Article : Google Scholar

|

|

6

|

Yeatts AB and Fisher JP: Bone tissue

engineering bioreactors: dynamic culture and the influence of shear

stress. Bone. 48:171–181. 2011. View Article : Google Scholar

|

|

7

|

Yilgor P, Tuzlakoglu K, Reis RL, Hasirci N

and Hasirci V: Incorporation of a sequential BMP-2/BMP-7 delivery

system into chitosan-based scaffolds for bone tissue engineering.

Biomaterials. 30:3551–3559. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Mouriño V and Boccaccini AR: Bone tissue

engineering therapeutics: controlled drug delivery in

three-dimensional scaffolds. J R Soc Interface. 7:209–227. 2010.

View Article : Google Scholar :

|

|

9

|

Holzwarth JM and Ma PX: Biomimetic

nanofibrous scaffolds for bone tissue engineering. Biomaterials.

32:9622–9629. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Yamada Y, Nakamura S, Ito K, et al:

Injectable bone tissue engineering using expanded mesenchymal stem

cells. Stem Cells. 31:572–580. 2013. View Article : Google Scholar

|

|

11

|

Bi ZG, Han XG, Fu CJ, Cao Y and Yang CL:

Reconstruction of large limb bone defects with a double-barrel free

vascularized fibular graft. Chin Med J (Engl). 121:2424–2428.

2008.

|

|

12

|

Noaman HH: Management of upper limb bone

defects using free vascularized osteoseptocutaneous fibular bone

graft. Ann Plast Surg. 71:503–509. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Jiang Q, Reddy N and Yang Y:

Cytocompatible cross-linking of electrospun zein fibers for the

development of water-stable tissue engineering scaffolds. Acta

Biomater. 6:4042–4051. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Gyawali D, Nair P, Zhang Y, et al: Citric

acid-derived in situ crosslinkable biodegradable polymers for cell

delivery. Biomaterials. 31:9092–9105. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Kuo YC and Yeh CF: Effect of

surface-modified collagen on the adhesion, biocompatibility and

differentiation of bone marrow stromal cells in

poly(lactide-co-glycolide)/chitosan scaffolds. Colloids Surf B

Biointerfaces. 82:624–631. 2011. View Article : Google Scholar

|

|

16

|

Amini AR, Laurencin CT and Nukavarapu SP:

Differential analysis of peripheral blood- and bone marrow-derived

endo-thelial progenitor cells for enhanced vascularization in bone

tissue engineering. J Orthop Res. 30:1507–1515. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Sun X, Su J, Bao J, et al: Cytokine

combination therapy prediction for bone remodeling in tissue

engineering based on the intracellular signaling pathway.

Biomaterials. 33:8265–8276. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Zhao J, Luo C, Han W, Tu M, Zeng R, Cha Z

and Zhou C: Fabrication and properties of

poly(L-lactide)/hydroxyapatite/chitosan fiber ternary composite

scaffolds for bone tissue engineering. J Polymer Eng. 32:283–289.

2012. View Article : Google Scholar

|

|

19

|

Pan L, Pei X, He R, Wan Q and Wang J:

Multiwall carbon nanotubes/polycaprolactone composites for bone

tissue engineering application. Colloids Surf B Biointerfaces.

93:226–234. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Higuita-Castro N, Gallego-Perez D,

Pelaez-Vargas A, et al: Reinforced Portland cement porous scaffolds

for load-bearing bone tissue engineering applications. J Biomed

Mater Res B Appl Biomater. 100B:501–507. 2012. View Article : Google Scholar

|

|

21

|

Ji Y, Xu GP, Zhang ZP, Xia JJ, Yan JL and

Pan SH: BMP-2/PLGA delayed-release microspheres composite graft,

selection of bone participate diameters, and prevention of aseptic

inflammation for bone tissue engineering. Ann Biomed Eng.

38:632–639. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Clarke SA, Walsh P, Maggs CA and Buchanan

F: Designs from the deep: marine organisms for bone tissue

engineering. Biotechnol Adv. 29:610–617. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Alge DL, Bennett J, Treasure T,

Voytik-Harbin S, Goebel WS and Chu TM: Poly(propylene fumarate)

reinforced dicalcium phosphate dihydrate cement composites for bone

tissue engineering. J Biomed Mater Res A. 100:1792–1802. 2012.

View Article : Google Scholar : PubMed/NCBI

|