Introduction

A total of 375,000 hip and knee endoprostheses

implants are performed in Germany each year (1). In 1.5% of cases, implant-associated

infections (IAI) occur following total joint arthroplasty (2). Despite the relatively low prevalence

of IAI, it may have severe consequences for patients, physicians

and the health care system (3). In

the majority of cases, infections are initiated by

Staphylococcus aureus, a biofilm-forming coagulase-negative

Staphylococcus epidermidis (S. epidermidis), or

gram-negative species (4). Early

infections occur within weeks following surgery and are usually

acquired intraoperatively. In addition, IAI may manifest as a late

infection, occurring between 3 and 24 months following surgery,

resulting from hematogenous spreading of the bacteria from other

foci (5,6). IAI requires local and systemic

antimicrobial therapy, which necessitates the removal of the

contaminated endoprosthetic implant and insertion of a temporary

cement implant (spacer) loaded with antibiotics (7–9).

There is currently a requirement for novel

endoprosthetic materials with optimal surface and mechanical

characteristics that prevent bacterial biofilm formation avoid

bacterial resistance mechanisms and mediate biocompatibility and

osseointegration (10). In recent

years, magnesium has emerged as a promising implant material

solution. Magnesium has various favourable properties, as it is a

freely accessible metal and an essential cation serves an important

role in the metabolism of human cells (11,12).

The biocompatibility of magnesium as a coating is influenced by the

corrosion rate, corrosion products and the varying pH-value of the

solution (13). A previous in

vitro study revealed that rapidly corroding magnesium in a thin

layer on titanium (Ti6Al4V) was a suitable candidate for implant

coatings with antimicrobial and biocompatible properties (14). Monocultures of S.

epidermidis and human osteoblasts (hOB) revealed that magnesium

coatings may prevent initial bacterial adhesion while remaining

biocompatible according to the cytotoxicity test standards of the

International Organisation for Standardisation (15). In contrast to monocultures,

co-cultures provide a more comprehensive model of the development

of the infection, as demonstrated in a previous study (16).

The aim of the present study was to investigate the

antibacterial potential and cytotoxic effects of a thin, rapidly

corroding magnesium coating on titanium samples in a co-culture

model of S. epidermidis and hOBs.

Materials and methods

Titanium samples coated with pure

magnesium

The present study used Ti6Al4V discs (DOT GmbH,

Rostock, Germany) coated with pure magnesium for the experiments.

Uncoated Ti6Al4V discs (a common implant material) served as a

control. The discs were 11 mm in diameter and 2.5 mm in thickness.

Magnesium-sputtering targets (diameter, 20 cm; 3.5 mm thickness;

purity, 3N5) were produced by Fhr Anlagenbau GmbH

(Ottendorf-Okrilla, Germany). The magnetron sputtering process was

conducted with a Von Ardenne CS730 cluster machine (Von Ardenne

GmbH, Dresden, Germany) with a 200 W sputtering power and 2.3×103

mbar pressure. The samples were coated with layers of magnesium

(5-µm thick) by breaking the vacuum and turning the samples. The

temperature of the substrate holder did not surpass 76°C, and all

process parameters were performed in accordance with those

described by Schlüter et al (17). The roughness (Rz) of the

surfaces was measured via 3D laser scanning microscopy (VK-X260,

Keyence Corporation, Osaka, Japan). The Ti6Al4V disc roughness was

between 8 and 12.7 µm for the magnesium-coated discs as determined

in our previous study (14). The

samples were Υ-sterilized at 25 kGy following the sputtering

process.

Magnesium ion release and pH of the

supernatants

The magnesium-coated Ti6Al4V samples were

pre-incubated for 24 h in Modified Eagle's osteogenic cell culture

medium (MEM; EMD Millipore, Billerica, MA, USA) without calcium or

antibiotics, containing 10% foetal calf serum (EMD Millipore), 1%

HEPES buffer (Gibco; Thermo Fisher Scientific, Inc., Waltham, MA,

USA) and the following osteogenic additives: 100 nM dexamethasone,

50 µg/ml L-ascorbic acid and 10 mM β-glycerophosphate, which were

all obtained from Sigma-Aldrich; Merck Millipore (Darmstadt,

Germany). Following 24 h pre-incubation and at 2, 4 and 7 days

following infection, supernatants were transferred to 1.5-ml

Eppendorf reaction tubes (Eppendorf, Hamburg, Germany). Digestion

was achieved using 65% concentrated nitric acid (1.0% v/v;

Sigma-Aldrich, Merck Millipore). The concentration of magnesium

ions released from magnesium coatings was quantified using atomic

absorption spectrometry ZEEnit 650P in combination with a graphite

tube atomizer (all from Analytik Jena AG, Jena, Germany). The

analysis process started with evaporation steps at 80, 90 and

110°C. This was followed by a pyrolysis phase at 900°C in the

platform tube, heated to 2,000°C to evaporate and transform compact

fragments into atoms. This step involved elemental analysis using a

resonating cathode lamp and a magnesium cathode at a wavelength of

202.6 nm. Following 0, 2 and 7 days, the pH value of the

supernatants was determined using an InoLab® pH 720 pH

meter (WTW GmbH, Weilheim, Germany).

Isolation and cultivation of hOBs

The isolation of hOBs was conducted according to the

protocol previously described by Jonitz et al (18). The osteoblasts were obtained from

the cancellous femoral head of 6 patients that underwent total hip

replacement surgery (3 male donors, mean age, 72±8.6 years; 3

female donors, mean age, 78±3.8 years) at the Department of

Orthopaedics University Medicine Rostock (Rostock, Germany). The

present study was approved by The Local Ethics Committee of Rostock

(Rostock, Germany; registration number, A2010-10) and written

informed consent was obtained from each patient.

Co-culture of hOBs and S.

epidermidis

The procedures used to co-culture hOBs and S.

epidermidis were the same as those described by Zaatreh et

al (16). hOBs (25,000

cells/ml) at passage three were transferred to a 24-well-plate

(Sarstedt, Nümbrecht, Germany) and cultured on the Ti6Al4V sample

discs in MEM with adjunctions for 24 h. Similarly, hOBs and S.

epidermidis were cultured on Ti6Al4V sample discs coated with

magnesium for 24 h. A prepared overnight culture of S.

epidermidis (RP62A; ref. no. 35984; American Type Culture

Collection, Manassas, VA, USA) was subsequently used for

mono-species infections with a multiplicity of infection of 0.04

(25,000 osteoblasts/ml, 1,000 colony forming units/ml). Co-cultures

were incubated for a period of 7 days under standard aerobic

conditions (37°C and 5% CO2). At 2 and 4 days following

infection the medium was replenished.

Determination of hOB viability

hOBs that adhered to the discs were washed with 1X

phosphate-buffered saline (PBS; EMD Millipore), followed by the

addition of 200 µl trypsin/EDTA (1X; Gibco; Thermo Fisher

Scientific, Inc.) for 3 min under aerobic conditions (37°C and 5%

CO2). The hOBs were then mechanically relocated from the

discs with a pipette tip (Eppendorf). The solution with the

osteoblasts was transferred to a 1.5 ml Eppendorf reaction tube

(Eppendorf) centrifuged at 169 × g for 4 min at 4°C, and washed

with 1X PBS. Quantification of the number of viable primary

osteoblasts on the test samples was determined by trypan blue

staining (Sigma-Aldrich; Merck Millipore). Trypan blue enters the

damaged membranes of dead cells, leaving viable cells unstained.

The viable cells were counted using a Thoma cell counting chamber,

obtained from Paul Marienfeld GmbH & Co. KG (Lauda-Königshofen,

Germany) according to manufacturer's protocol (19) and using an Olympus CKX41SF optical

light microscope, (Olympus Soft Imaging Solutions GmbH, Hamburg,

Germany). Measurements were performed at 2 and 7 days of

co-culture.

Quantification of biofilm-bound S.

epidermidis

The test samples were transferred to glass test

tubes (Greiner Bio-One International GmbH, Kremsmünster, Austria)

containing 1 ml PBS (1X). S. epidermidis were removed by

ultrasonic treatment with device settings at 100% for 4 min

(BANDELIN BactoSonic, GmbH & Co. KG, Berlin, Germany) at days 2

and 7 of co-culture. The solution in the glass test tube was

diluted in 1X PBS and plated onto tryptic soy broth (TSB)-agar

plates (Thermo Fisher Scientific, Inc.). Following 24 h incubation

at 37°C and 5% CO2, the number of colony forming units

were quantified.

Quantification of planktonic S.

epidermidis

The co-culture supernatants containing planktonic

S. epidermidis were collected in 15 ml centrifuge tubes

(Greiner Bio-One International AG, Kremsmünster, Austria) with 1 ml

PBS (1X), and centrifuged at 3,345 × g for 10 min at 4°C on day 2

and 7 of co-culture. The number of planktonic bacteria were

quantified by serial dilution in 1X PBS and then counting the

number of colony forming units on TSB-agar plates (Thermo Fisher

Scientific, Inc.) following 24 h incubation at 37°C and 5%

CO2.

Scanning electron microscopy

(SEM)

Test samples were fixed in a 2.5% glutaraldehyde

solution at 4°C for 24 h. Specimens were subsequently washed with

0.1 M sodium acetate buffer, and dried using a graded ethanol

series (5 min in 30% ethanol, 5 min in 50% ethanol, 10 min in 70%

ethanol, 15 min in 90% ethanol and twice for 10 min in 100%

ethanol). The samples were then dried by critical point drying with

CO2 (Critical Point Dryer, Emitech Ltd., Ashford, UK),

sputter-coated with gold, and examined with a scanning electron

microscope (Zeiss DSM 960A; Zeiss GmbH, Jena, Germany).

Statistical analysis

Data are expressed as the mean ± standard error for

three independent experiments. Statistical significance was

evaluated with an unpaired two-tailed t-test using SPSS software

(version, 20.0; IBM SPSS, Armonk, NY, USA). P<0.05 was

considered to indicate a statistically significant difference.

Results

Magnesium ion release of the test

samples and pH-values of the media

Ion release data were examined in order to

characterize the strength of the corrosion process as it progresses

over the 7 days. Fig. 1 shows the

release of magnesium ions in the medium following one day of

pre-incubation and at 2, 4 and 7 days following infection of the

co-culture and the test sample alone. The magnesium-coated titanium

alloy released 24 mM/day magnesium ions during pre-incubation and

11 mM/day over the first 2 days, decreasing to 3 mM/day during days

4–7. The magnesium-coated surface in the co-culture with

osteoblasts and bacteria released 24 mM/day during pre-incubation

and 8 mM/day over the first 2 days, which decreased to 2 mM/day

during days 4 to 7. Media were replenished following 1 day of

pre-incubation and after 2 and 4 days of co-culture. Magnesium ion

release levels in the magnesium-coated samples maintained in medium

without bacteria and cells were not significantly greater when

compared with the hOB and S. epidermis co-culture samples.

This indicates that hOB adhesion and S. epidermidis

infection did not significantly alter the release of magnesium.

Bacterial growth is influenced by pH, therefore the

pH-values of the media were monitored. Table I indicates the pH-values in the

co-culture at 0, 2, 4 and 7 days. The magnesium-coated Ti6Al4V

altered the pH-value to an alkaline environment whereas the

uncoated Ti6Al4V control demonstrated a slightly acidic pH

value.

| Table I.pH-values for Ti6Al4V and Mg-coated

Ti6A14V test samples in co-culture with hOB and S.

epidermidis for 0, 2, 4 and 7 days. |

Table I.

pH-values for Ti6Al4V and Mg-coated

Ti6A14V test samples in co-culture with hOB and S.

epidermidis for 0, 2, 4 and 7 days.

| Co-culture of hOB

and S. epidermidis | Day 0 | Day 2 | Day 4 | Day 7 |

|---|

| MEM+10% FCS | 7.94±0.07 | 8.03±0.15 | 8.01±0.07 | 8.05±0.03 |

| Ti6Al4V | 7.88±0.06 | 7.83±0.08 | 7.81±0.03 | 7.64±0.04 |

| Mg-coating | 8.82±0.08 | 8.56±0.08 | 8.19±0.01 | 8.12±0.04 |

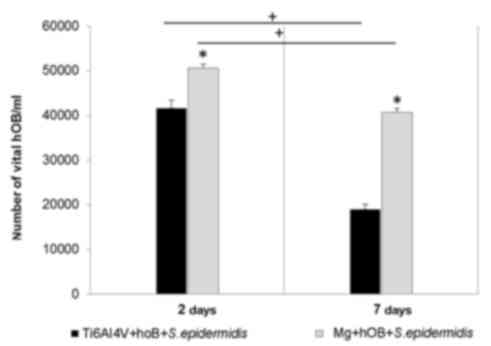

Determination of hOB viability in

co-culture with S. epidermidis

The number of viable hOBs was examined by trypan

blue staining (Fig. 2). A total of

25,000 cells were seeded on the two samples. The number of

osteoblasts on the magnesium-coated sample was 50,000 following 2

days (P=0.01) and 40,000 at 7 days (P=0.01). For the control, a

value of 40,000 cells at day 2 and 20,000 at day 7 were observed.

The number of viable osteoblasts was greater on the

magnesium-coated sample when compared with the control by ~10,000

at 2 days and ~20,000 at 7 days.

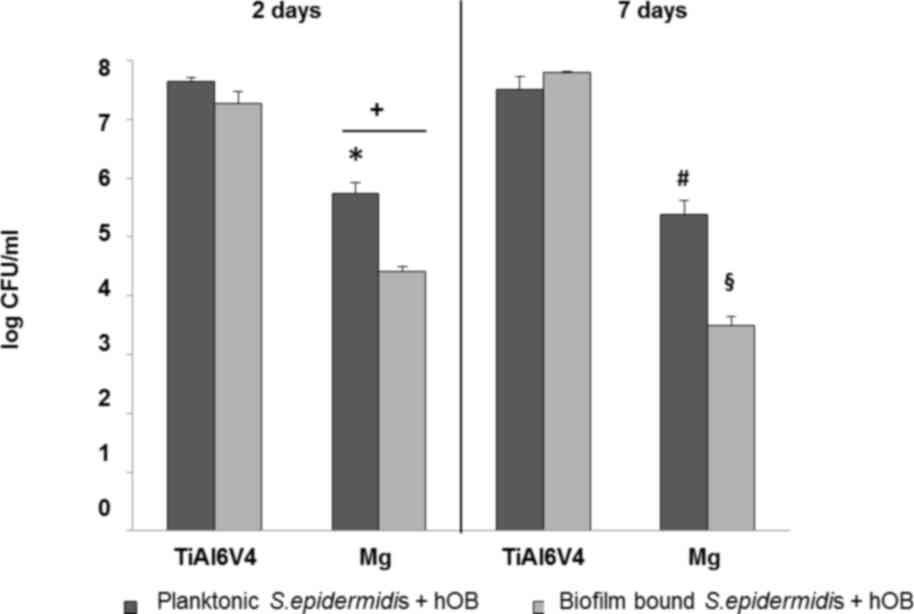

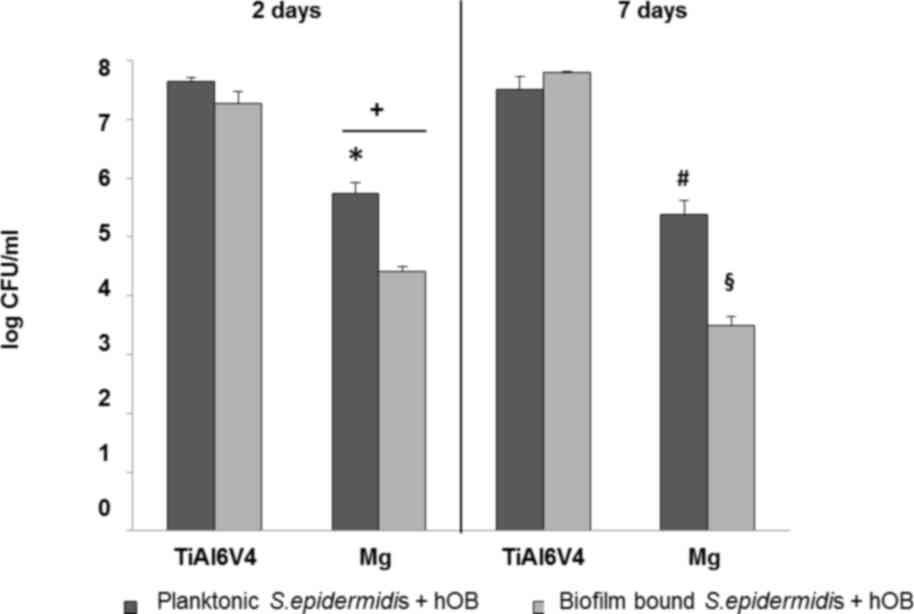

Evaluation of the viability of S.

epidermidis in co-culture with hOBs

Measurements of bacterial colonization in the test

samples revealed that a greater number of S. epidermidis

colonies survived on the control TiAI6V4 surface when compared with

the magnesium-coated Ti6Al4V discs (Fig. 3). The magnesium-coated sample

demonstrated a significant antibacterial effect, as indicated by

the significant decrease in biofilm population by three orders of

magnitude following 2 days (P=0.02), and 4 orders of magnitude

following 7 days (P=0.03; Fig. 3).

The effect was approximately 1 order of magnitude lower for the

planktonic population. Complete results of the measurements for

S. epidermidis are presented in Fig. 3.

| Figure 3.Quantification of viable biofilm-bound

and planktonic S. epidermidis in co-culture with hOB cells

on the test samples following 2 and 7 days. The number of viable

biofilm-bound S. epidermidis on the Mg-coated specimen was

significantly decreased when compared with the titanium control

over a period of 7 days. Data are expressed as the mean ± standard

error of the mean (n=3). *P<0.05 Mg vs. titanium alloy control,

day 2, planktonic. +P<0.05 biofilm vs. planktonic,

day 2, on Mg. #P<0.05 Mg vs. titanium alloy control,

day 7, planktonic. §P<0.05 Mg vs. titanium alloy

control, day 7, biofilm. S. epidermidis, Staphylococcus

epidermidis; hOBs, human osteoblasts; Mg, magnesium; CFU,

colony forming units. |

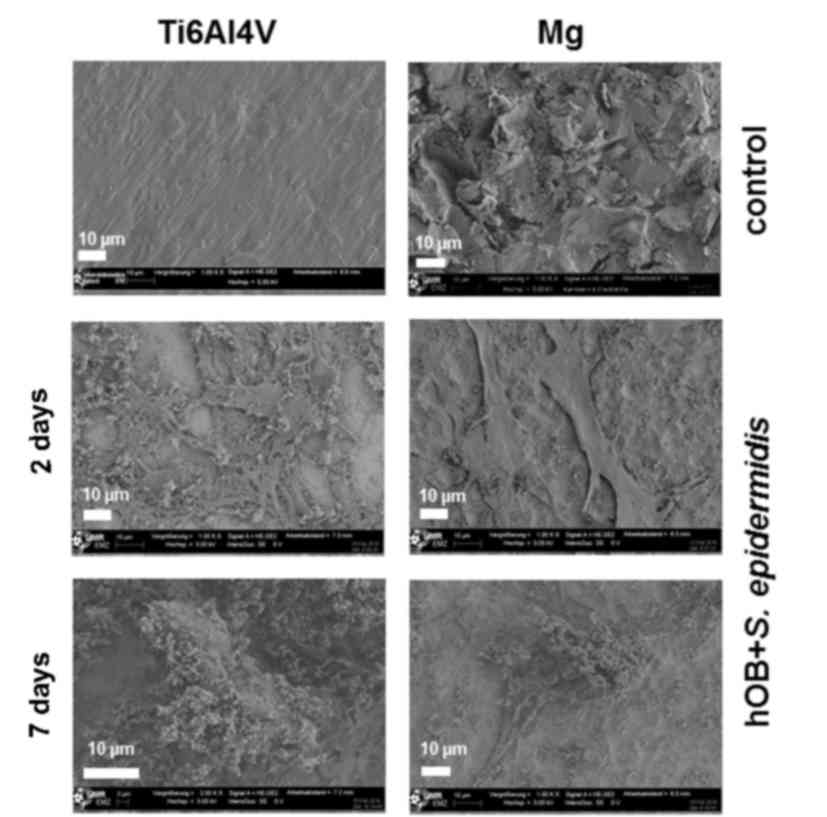

SEM imaging

SEM was performed to qualitatively assess the layer

structure and morphology of osteoblasts, as well as the growth

patterns and distribution of bacteria on the test specimen. The SEM

images shown in Fig. 4 confirm the

results of the quantitative measurements of the biofilm-bound

bacteria. S. epidermidis colonization was observed to be

lower on the magnesium-coated surface when compared with the

control on both days 2 and 7 (Fig.

4). The bacteria form biofilm-like structures on the human

primary osteoblasts on the two surfaces.

Discussion

The aim of the present study was to investigate the

antimicrobial properties of a rapidly corroding magnesium coating

on titanium against S. epidermidis, as well as its effects

on hOBs, in a co-culture model. Measurements of hOB and S.

epidermidis populations revealed that hOB growth was improved

and S. epidermidis growth was inhibited; these alterations

differed by several orders of magnitude when compared with the

uncoated titanium control.

In previously conducted monoculture experiments, the

number of hOBs that colonized the magnesium-coated surface

increased to ~80% when compared with the uncoated titanium control,

due to the slightly less favourable growth conditions on the

corroding surface (14). However,

in the present co-culture experiments, hOB growth on the

magnesium-coated samples increased to ~125% following 2 days and

200% following 7 days. The antibacterial surface significantly

reduced the negative influence of S. epidermidis on the hOB.

This result was achieved despite the presence of the magnesium

coating, which demonstrates a negative effect on the growth

potential of the hOBs. The negative influence of S.

epidermidis on hOB may be due to competition for nutrients and

pathogenicity (20). The

uninhibited negative effects was observed on the control sample,

where hOB numbers were markedly reduced following 7 days when

compared with 2 days (a decrease of 20,000 from 40,000).

The increased growth of the hOBs on magnesium-coated

samples, and the observed antibacterial effect, may be explained by

the following factors: Prevention of bacterial adherence due to the

corrosive dissolution process, osmotic stress in the strongest

phase of initial corrosion, the microstructure of the surface, an

unfavourable increase in pH-value for the bacteria or the

inhibitory effects of magnesium ions on the bacteria (21–28).

These effects are most prominent in the local environment close to

the surface. The effects of dissolution and osmotic pressure

decline over 2 days, however the pH shift may also have a negative

effect on S. epidermidis growth over the 7-day period. The

impact on the planktonic population may be less significant due to

reduced exposure to these factors (13,29).

The antibacterial effects observed in the

monoculture experiments were reproduced in the co-culture setup,

however, they were observed to be one order of magnitude less

prominent (14). These

observations are in agreement with a prior comparison of a

monoculture to co-culture experiment conducted by Zaatreh et

al (16). Putative reasons for

the diminished effect may include the favourable environment that

the hOBs present for S. epidermidis and the protection that

they may provide from antibacterial effects of the surface. The

planktonic population of S. epidermidis depends on the

biofilm population, as this is where most of the bacterial

reproduction occurs (30).

In previous studies, the authors demonstrated that

monocultures may capture only a limited number of interactions

among human cells, bacteria and the tested surface (14,16).

Unpredicted behaviour may arise from the complex interaction among

human cells, bacteria and implant surfaces. Therefore, the results

of co-culture experiments are regarded as more robust (31,32).

In the present study, the co-culture model captured the apparent

protective effects of the hOB cells, whereby this layer of cells

protects bacteria from the adverse effects of the surface. The

antibacterial effects were diminished in the co-culture system,

however a significant antibacterial effect persisted (three orders

of magnitude following 7 days).

The investigation of different experimental

parameters must be limited. Future work will aim to test different

growth media, a greater number of bacterial strains and species, as

well as different osteoblast cell lines. In addition, the length of

time for infection to occur, and the ratio of initial hOB and

bacterial numbers will be explored. The results of the present

study provide significant observations with promising implications

for implant material research.

In conclusion, novel implant materials are in high

demand due to the severity of IAI, which may be life-threatening

for patients with lengthy and demanding treatment procedures and

may result in a marked decrease in quality of life. It has been

previously demonstrated that titanium coated with a thin, rapidly

corroding layer of magnesium may be a suitable candidate material,

based on monoculture studies involving primary hOBs and S.

epidermidis. The present study applied a more rigorous test

system with hOBs and S. epidermidis in co-culture on the

magnesium-coated titanium surface. The favourable qualities of this

surface as an antibacterial and biocompatible material were

verified. These results provide evidence for progression towards

future animal model testing.

Acknowledgements

The authors would like to thank Professor Andreas

Podbielski (Institute of Medical Microbiology, Virology and

Hygiene, University Medicine Rostock) for his help in performing

the tests. In addition, the authors would like to thank Dr Marcus

Frank, Mr. Wolfgang Labs, Mr. Gerhard Fulda (Electron Microscopy

Centre, University Medicine Rostock) Mr. Philipp Pisowocki

(Department of Orthopaedics, University Medicine Rostock) and Mrs.

Regina Lange (Institute for Electronic Appliances and Circuits,

University Medicine Rostock) for their help with SEM. Furthermore,

a special thanks to Professor Regine Willumeit-Römer (Institute of

Materials Research, Division of Metallic Biomaterials,

Helmholtz-Zentrum Geesthacht) for her support and expertise in the

field of magnesium as a biomaterial. This study was financially

supported by the Helmholtz Virtual Institute MetBioMat (grant no.

VH-VI-523) titled ‘In vivo studies of biodegradable

magnesium-based implant materials’.

References

|

1

|

Fallpauschalenbezogene

Krankenhausstatistik (DRG-Statistik): Operationen und Prozeduren

der vollstationären Patientinnen und Patienten der Krankenhäuser

(4-Steller). Statistisches Bundesamt (Destatis), Wiesbaden.

2015.

|

|

2

|

Darouiche RO: Treatment of infections

associated with surgical implants. N Engl J Med. 350:1422–1429.

2004. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Walter RP and Blake SM: Re: Two-stage

exchange for infected resurfacing arthroplasty use of a novel

cement spacer technique. J Arthroplasty. 26:9792011. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Harris LG and Richards RG: Staphylococci

and implant surfaces: A review. Injury. 37 Suppl 2:S3–S14. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Casey AL, Lambert PA and Elliott TSJ:

Staphylococci. Int J Antimicrob Agents. 29 Suppl 3:S23–S32. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Arciola CR, Campoccia D, Speziale P,

Montanaro L and Costerton JW: Biofilm formation in Staphylococcus

implant infections. A review of molecular mechanisms and

implications for biofilm-resistant materials. Biomaterials.

33:5967–5982. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Wilde AH and Ruth JT: Two-stage

reimplantation in infected total knee arthroplasty. Clin Orthop.

23–35. 1988.PubMed/NCBI

|

|

8

|

Vorndran E, Spohn N, Nies B, Rössler S,

Storch S and Gbureck U: Mechanical properties and drug release

behavior of bioactivated PMMA cements. J Biomater Appl. 26:581–594.

2012. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Uchiyama K, Takahira N, Fukushima K,

Moriya M, Yamamoto T, Minegishi Y, Sakai R, Itoman M and Takaso M:

Two-stage revision total hip arthroplasty for periprosthetic

infections using antibiotic-impregnated cement spacers of various

types and materials. ScientificWorldJournal. 2013:1472482013.

View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Connaughton A, Childs A, Dylewski S and

Sabesan VJ: Biofilm disrupting technology for orthopedic implants:

What's on the Horizon? Front Med (Lausanne). 1:222014.PubMed/NCBI

|

|

11

|

Staiger MP, Pietak AM, Huadmai J and Dias

G: Magnesium and its alloys as orthopedic biomaterials: A review.

Biomaterials. 27:1728–1734. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Luthringer BJ, Feyerabend F and

Willumeit-Römer R: Magnesium-based implants: A mini-review. Magnes

Res. 27:142–154. 2014.PubMed/NCBI

|

|

13

|

Robinson DA, Griffith RW, Shechtman D,

Evans RB and Conzemius MG: In vitro antibacterial properties of

magnesium metal against Escherichia coliPseudomonas aeruginosa and

Staphylococcus aureus. Acta Biomater. 6:1869–1877. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Zaatreh S, Haffner D, Pasold J,

Kreikemeyer B, Mittelmeier W, Podbielski A, Quandt E and Bader R:

Track A. Biomaterials and biocompatibility 1. Biomed Tech (Berl).

60 Suppl 1:S1–S30. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Cytotoxicity test according to ISO

10993-5. CYTOX. 1999.

|

|

16

|

Zaatreh S, Wegner K, Strauß M, Pasold J,

Mittelmeier W, Podbielski A, Kreikemeyer B and Bader R: Co-culture

of S. epidermidis and human osteoblasts on implant surfaces: An

advanced in vitro model for implant-associated infections. PloS

One. 11:e01515342016. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Schlüter K, Zamponi C, Piorra A and Quandt

E: Comparison of the corrosion behaviour of bulk and thin film

magnesium alloys. Corros Sci. 52:3973–3977. 2010. View Article : Google Scholar

|

|

18

|

Jonitz A, Lochner K, Lindner T, Hansmann

D, Marrot A and Bader R: Oxygen consumption, acidification and

migration capacity of human primary osteoblasts within a

three-dimensional tantalum scaffold. J Mater Sci Mater Med.

22:2089–2095. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Anleitungen-Marienfeld-Superior.

[Internet]. [cited 3 Nov 2016]. http://www.marienfeld-superior.com/index.php/anleitungen.html

|

|

20

|

Von Eiff C, Peters G and Heilmann C:

Pathogenesis of infections due to coagulasenegative staphylococci.

Lancet Infect Dis. 2:677–685. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Wang HX, Guan SK, Wang X, Ren CX and Wang

LG: In vitro degradation and mechanical integrity of Mg-Zn-Ca alloy

coated with Ca-deficient hydroxyapatite by the pulse

electrodeposition process. Acta Biomater. 6:1743–1748. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Kirkland NT, Lespagnol J, Birbilis N and

Staiger MP: A survey of bio-corrosion rates of magnesium alloys.

Corros Sci. 52:287–291. 2010. View Article : Google Scholar

|

|

23

|

Fischer J, Prosenc MH, Wolff M, Hort N,

Willumeit R and Feyerabend F: Interference of magnesium corrosion

with tetrazolium-based cytotoxicity assays. Acta Biomater.

6:1813–1823. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Fischer J, Pröfrock D, Hort N, Willumeit R

and Feyerabend F: Reprint of: Improved cytotoxicity testing of

magnesium materials. Mater Sci Eng B. 176:1773–1777. 2011.

View Article : Google Scholar

|

|

25

|

Schlüter K, Zamponi C, Hapke J, Hort N,

Kainer KU and Quandt E: Mechanical properties and corrosion

behaviour of freestanding, precipitate-free magnesium WE43 thin

films. Int J Mater Res. 104:286–292. 2013. View Article : Google Scholar

|

|

26

|

Schlüter K, Shi Z, Zamponi C, Cao F,

Quandt E and Atrens A: Corrosion performance and mechanical

properties of sputter-deposited MgY and MgGd alloys. Corros Sci.

78:43–54. 2014. View Article : Google Scholar

|

|

27

|

Sanchez AH Martinez, Luthringer BJC,

Feyerabend F and Willumeit R: Mg and Mg alloys: How comparable are

in vitro and in vivo corrosion rates? A review. Acta Biomater.

13:16–31. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Willumeit R, Feyerabend F and Huber N:

Magnesium degradation as determined by artificial neural networks.

Acta Biomater. 9:8722–8729. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Charyeva O, Neilands J, Svensäter G and

Wennerberg A: Bacterial biofilm formation on resorbing magnesium

implants. Open J Med Microbiol. 5:1–11. 2015. View Article : Google Scholar

|

|

30

|

Gasol JM and Del Giorgio PA: Using flow

cytometry for counting natural planktonic bacteria and

understanding the structure of planktonic bacterial communities.

Sci Mar. 64:197–224. 2000. View Article : Google Scholar

|

|

31

|

Lee JH, Wang H, Kaplan JB and Lee WY:

Microfluidic approach to create three-dimensional tissue models for

biofilm-related infection of orthopaedic implants. Tissue Eng Part

C Methods. 17:39–48. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Kaji H, Camci-Unal G, Langer R and

Khademhosseini A: Engineering systems for the generation of

patterned co-cultures for controlling cell-cell interactions.

Biochim Biophys Acta. 1810:239–250. 2011. View Article : Google Scholar : PubMed/NCBI

|