Introduction

Polymers may be naturally-occurring, including

collagen and polysaccharides, or synthesized, including polylactide

(PLA), polyethylene and poly lactic-co-glycolic acid (PLGA)

(1–7). Polymers have been extensively studied

and used for biomedical and pharmaceutical applications (1,8). As

polymer synthesis may be conducted under controlled conditions, and

the properties of polymers, including hydrophilicity, degradability

and biocompatibility, may be tailored for specific applications,

numerous studies have focused on the development of novel synthetic

polymers for tissue-engineering (polymers as scaffolds for tissue

regeneration) and controlled drug release (polymers as drug

carriers) (3,4,9).

Additionally, synthetic polymers are frequently less expensive as

they may be synthesized in large quantities and exhibit long shelf

lives (4).

Aliphatic polyesters, including PLA, polyglycolide

(PGA) and PLGA, are among the most commonly used synthetic polymers

in medicine, due to their excellent biocompatibility and

biodegradability (10). PLA is

used for manufacturing sutures and bone screws; PLA, PGA and

particularly PLGA are being investigated for drug delivery

applications (7,11,12).

Polypropylene carbonate (PPC), a relatively new aliphatic

polyester, is synthesized via the copolymerization of

CO2 and propylene oxide (13,14).

It is known that PPC possesses limited mechanical strength, and is

therefore not suited to serve as a scaffold to support tissue

regeneration (10), although it

may be suitable for drug delivery; however, this requires further

investigation.

Electrospinning has been used for the fabrication of

polymer fibers (15–17). Electrospinning uses an electric

field, wherein a polymer solution is charged and driven by the

electric potential. When the charged jet of polymer solution

travels across an air gap, the solvent evaporates while the polymer

fibers, with diameters ranging between nanometers and micrometres,

are generated. In the present study, the applicability of the PPC

polymer as a drug carrier for sirolimus, also known as rapamycin,

was investigated. Sirolimus is a cell growth-inhibiting agent used

to treat vascular restenosis. Electrospinning was employed to

synthesize PPC polymer containing sirolimus. The properties of the

drug-containing PPC polymer were investigated, drug loading and

entrapment efficiency were determined, and in vitro

sirolimus release was assessed. In addition, the effect of the

PPC-sirolimus polymer on cell growth was studied in

vitro.

Materials and methods

Materials

PPC (MW 100,000; purity >99%) was purchased from

Inner Mongolia Mengxi High Tech Group Co., Ltd. (Ordos, China).

Sirolimus (rapamycin) was obtained from Fujian Kerui Pharmaceutical

Co., Ltd. (Fuzhou, China). All chemicals were from Jiete'ao

Biotechnology Co., Ltd. (Beijing, China). MTT was purchased from

Sigma-Aldrich (Merck KGaA, Darmstadt, Germany). Eagle's minimum

essential medium (EMEM), fetal bovine serum (FBS), penicillin and

streptomycin were obtained from Gibco (Thermo Fisher Scientific,

Inc., Waltham, MA, USA).

Preparation of PPC polymer loaded with

sirolimus

Various ratios of PPC and sirolimus were used to

produce PPC-sirolimus polymers and cell growth experiments,

performed by MTT assay as previously described (18), demonstrated that the polymer made

with 900 mg PPC and 100 mg sirolimus resulted in the greatest cell

inhibitory effect; therefore, this ratio was used in the present

study. The polymer solution was as follows: 1,000 mg PPC alone (PPC

polymer) or 900 mg PPC plus 100 mg sirolimus (PPC-sirolimus

polymer) was dissolved in 10 ml acetonitrile following stirring for

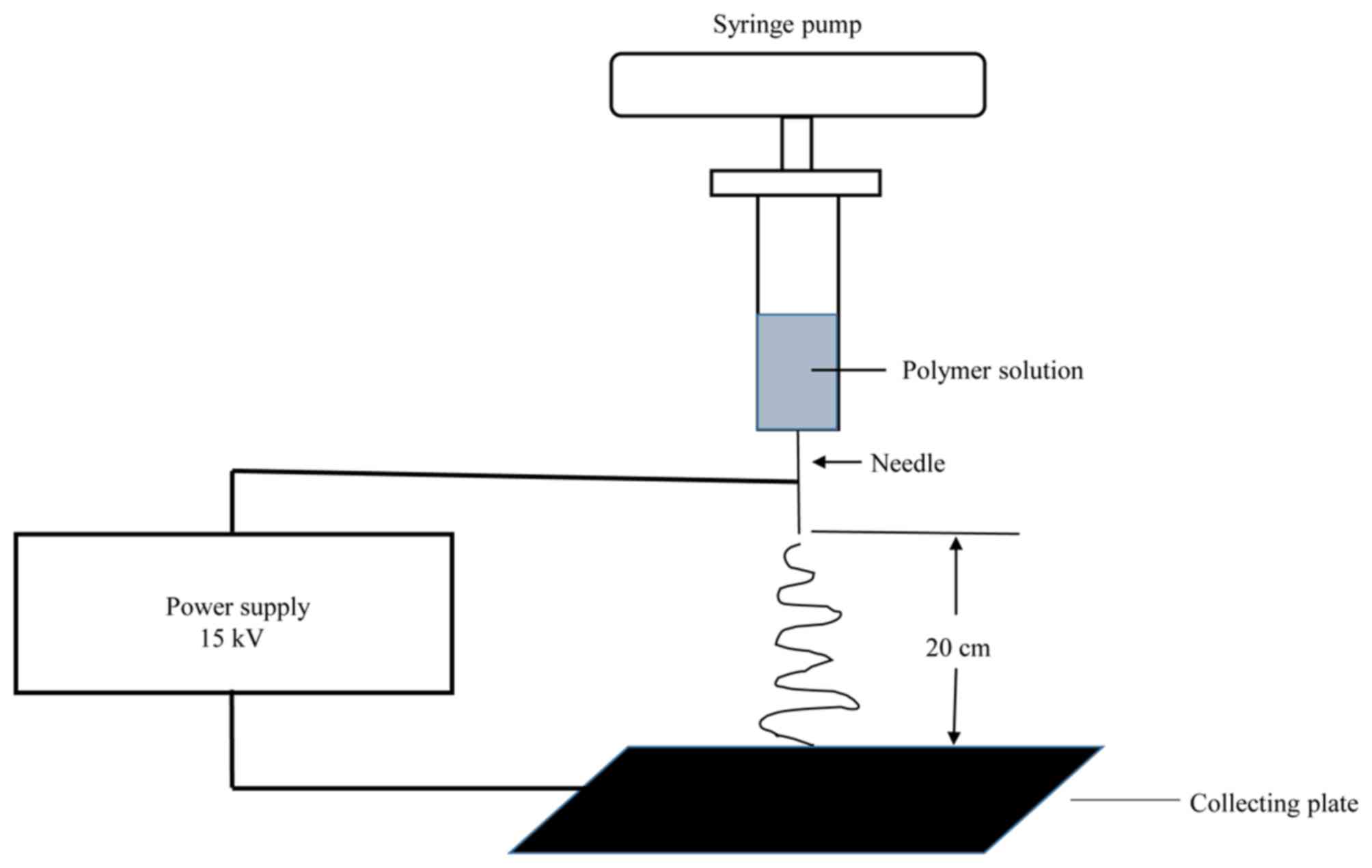

6 h. Electrospinning was performed using the electrospinning

apparatus (Model ET2535; Beijing Ucalery Technology and Development

Co., Ltd., Beijing, China). The polymer solution was transferred

into a syringe attached with a blunt tipped needle. The anode of

the power supply was clamped to the needle tip and the cathode was

connected to the grounded collector plate (Fig. 1). Electrospinning was performed

according to the established protocol (Institute of Polymer

Science, Tsinghua University, Beijing, China) (19).

Scanning electron microscopy

(SEM)

The polymers were coated with silver using the

vacuum evaporator (HUS 5GB; Hitachi Ltd., Tokyo, Japan) following

an established protocol at the Imaging Center, Shandong University

(Jinan, China) (20). The silver

coated polymers were analyzed using a scanning electron microscope

(H-8010; Hitachi, Ltd., Japan) operated at 15 kV, and images were

captured.

Differential scanning calorimetry

(DSC)

The thermal behavior of the PPC-sirolimus polymers

was assessed by DSC analysis using the DSC822e differential

scanning calorimeter (Mettler Toledo, Greifensee, Switzerland). A

total of 4 mg sample (pure sirolimus or PPC-sirolimus polymer) was

weighed in a 40 µl aluminum pan and placed in the sample chamber of

the calorimeter, and an empty pan was used as the reference. A flow

of nitrogen gas was maintained over the sample to eliminate air

oxidation of the sample at high temperatures, and to create a

reproducible and dry atmosphere. DSC analysis was performed using

the STARe software version 8.10 (Mettler Toledo) with the

temperature range 20–300°C and the temperature increase being set

at a rate of 10°C/min. The endothermic or exothermic peak was

automatically recorded.

In vitro PPC-sirolimus polymer

degradation assessment

A PPC-sirolimus polymer of 1×1 cm was placed in a

5-ml test tube and soaked in PBS (pH 7.2). The tube was gently

shaken (60 rpm) at 37°C for 4 weeks. Subsequently, the structure of

the polymer was examined using SEM.

Determination of drug loading and

entrapment efficiency

The efficiency of drug loading and entrapment was

determined as follows: 1,000 mg PPC-sirolimus polymer was dissolved

in dichloromethane by stirring for 2 h followed by addition of 0.1

M hydrochloric acid. Following mixing by vortex, lower

dichloromethane and upper hydrochloric acid layers were formed. The

hydrochloric acid layer was collected, centrifuged at 1,000 × g for

5 min at room temperature and the supernatant was collected. The

precipitate was mixed with 0.1 M hydrochloric acid containing 0.1%

EDTA. When the precipitate was completely dissolved, the solution

was added to the previously collected hydrochloric acid

supernatant. The sirolimus in the combined solution was measured by

high pressure liquid chromatography as described previously

(21). The sirolimus loading

efficiency (%) was calculated using the following formula: (Total

sirolimus amount in the combined solution/polymer weight) × 100.

Drug entrapment efficiency was calculated using the following

formula: [Total sirolimus amount in the combined solution/total

sirolimus amount used for polymer preparation (100 mg)] × 100. A

total of three PPC-sirolimus polymer preparations were used to

determine the drug loading and entrapment efficiency.

In vitro measurement of sirolimus

release from polymers

A total of 5 mg PPC-sirolimus polymer was placed in

14 separate 5-ml test tubes. The polymer was immersed in 4 ml

PBS/tube and gently shaken (60 rpm) at 37°C. At day 2, 4, 6, 8, 10,

12, 14, 16, 18, 20, 22, 24, 26 and 28 following shaking, the

polymer was removed and the sirolimus contained in the polymer was

isolated and measured as described in the determination of drug

loading and entrapment efficiency section. At each time point, the

amount of released sirolimus was calculated using the following

formula: Total sirolimus in the original 5 mg polymer-total

sirolimus in the soaked polymer. The release percentage was

calculated using the following formula: (Amount of released

sirolimus/total sirolimus in the original 5 mg polymer) × 100.

Inhibition of cell growth by

PPC-sirolimus polymers

An MTT assay was performed to examine the anti-cell

proliferative effect of the PPC-sirolimus polymer. Rat aortic

adventitial fibroblast cells (RAAFCs) were isolated as described

previously (22,23). A total of 4 Wistar rats (2 males

and 2 females, ~ 7 weeks old, weighing 180–220 g) were used for

RAAFC isolation. The animals were purchased from Shandong

Experimental Animal Center (Jinan, China), housed in the Shandong

University (Jinan, China) Animal Room with temperature at 20±2°C,

and fed with standard chow. The use of animals was approved by the

Research Ethics Committee of Shandong University in compliance with

the Guidelines for the Care and Use of Laboratory Animals issued by

the Ministry of Science and Technology, China. Cells were cultured

in EMEM with 10% FBS, 50 IU/ml penicillin and 100 µg/ml

streptomycin at 37°C in a humidified atmosphere containing 5%

CO2. For the MTT assay, 5×103 cells suspended

in 100 µl culture medium were seeded into each well of a 96-well

plate, into which had previously been added 2 mg of PPC or

PPC-sirolimus polymer (each sample in triplicate). Cells seeded in

wells with no polymer were taken as the control. Following

culturing for 1 and 3 days, the MTT assay was performed as follows:

10 µl MTT solution was added into each well and incubated at 37°C

for 4 h, followed by the addition of 50 µl dimethyl sufoxide/well.

Following gentle shaking for 10 min, absorbance at a wavelength of

570 nm was measured using a 96-well plate reader (Model 680,

Bio-Rad Laboratories, Inc., Hercules, CA, USA). The relative cell

viability (%) of each sample was calculated using the following

formula: (Average sample absorbance/average control absorbance) ×

100.

Statistical analysis

Cell growth data are expressed as the mean ±

standard error of the mean. The SPSS 17.0 software (SPSS, Inc.,

Chicago, IL, USA) was used for statistical analysis. Statistical

significance was determined using the Student's t-test. P<0.05

was considered to indicate a statistically significant

difference.

Results

Electrospinning and polymer

characterization

Electrospinning conditions were optimized and used

as follows: The voltage was set at 15 kV; the distance from the

needle tip to the collector was 20 cm, and the flow rate of the

spinning solution was controlled at 0.2 ml/h by a syringe pump

(TJ-3A/W0109-1B; Longer Precision Pump Co., Ltd., Baoding, China)

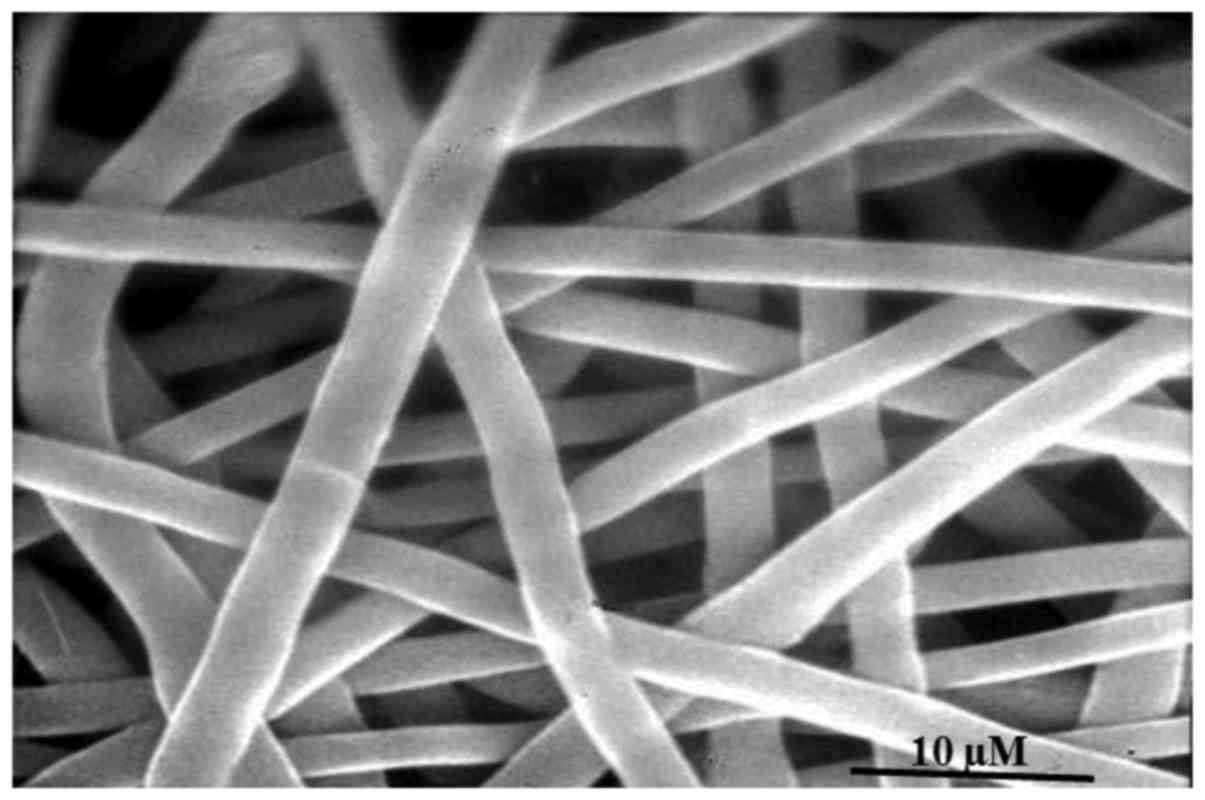

(Fig. 1). SEM analysis

demonstrated that the polymer exhibited a regular

three-dimensional, grid-intertwined, net-like structure with a

smooth surface, and the diameter was ~3 µm (Fig. 2). DSC analysis demonstrated that

the crystalline pure sirolimus produced an endothermic peak at

~230°C, the melting point of sirolimus (Fig. 3A). By contrast, the PPC-sirolimus

polymer exhibited a glass transition temperature of ~40°C for PPC

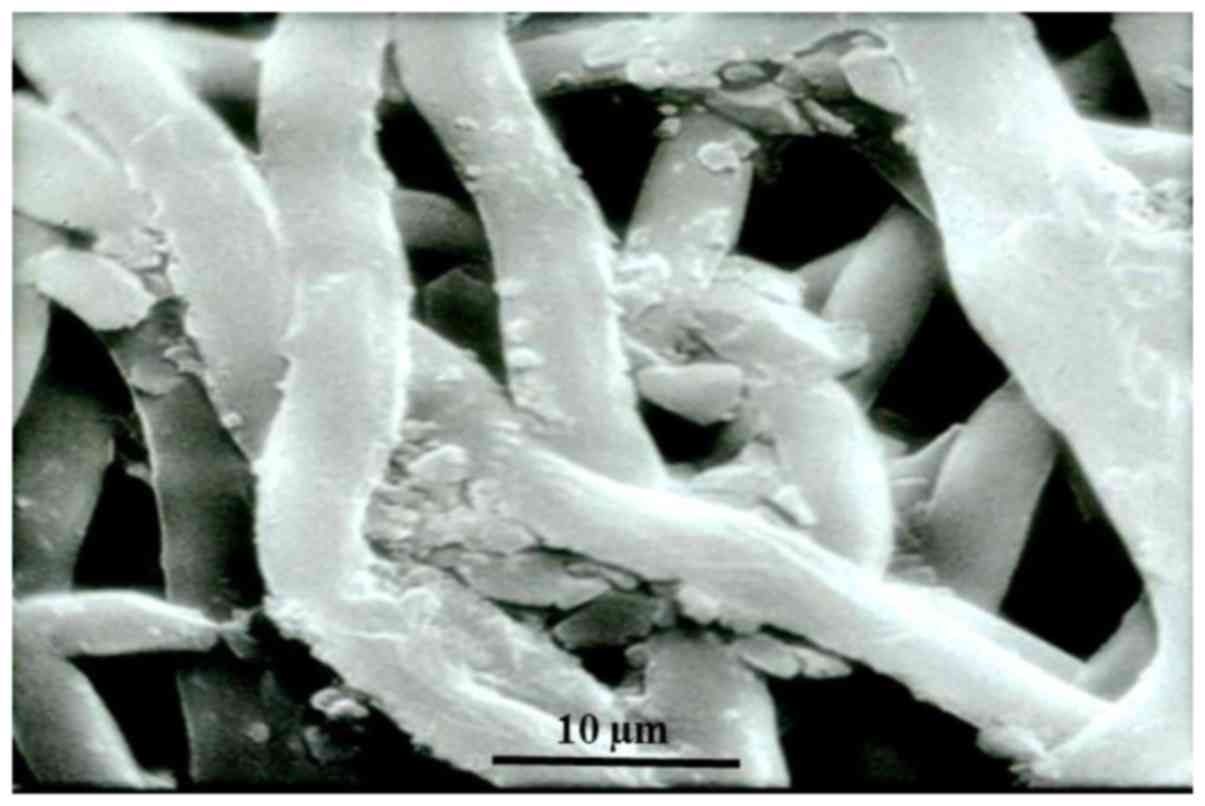

(Fig. 3B). The in vitro

degradation experiment demonstrated that, following soaking in PBS

for 4 weeks, the polymer swelled and the regular three-dimensional

grid-intertwined structure broke down and fragmented (Fig. 4).

Sirolimus loading, entrapment

efficiency and release from polymer

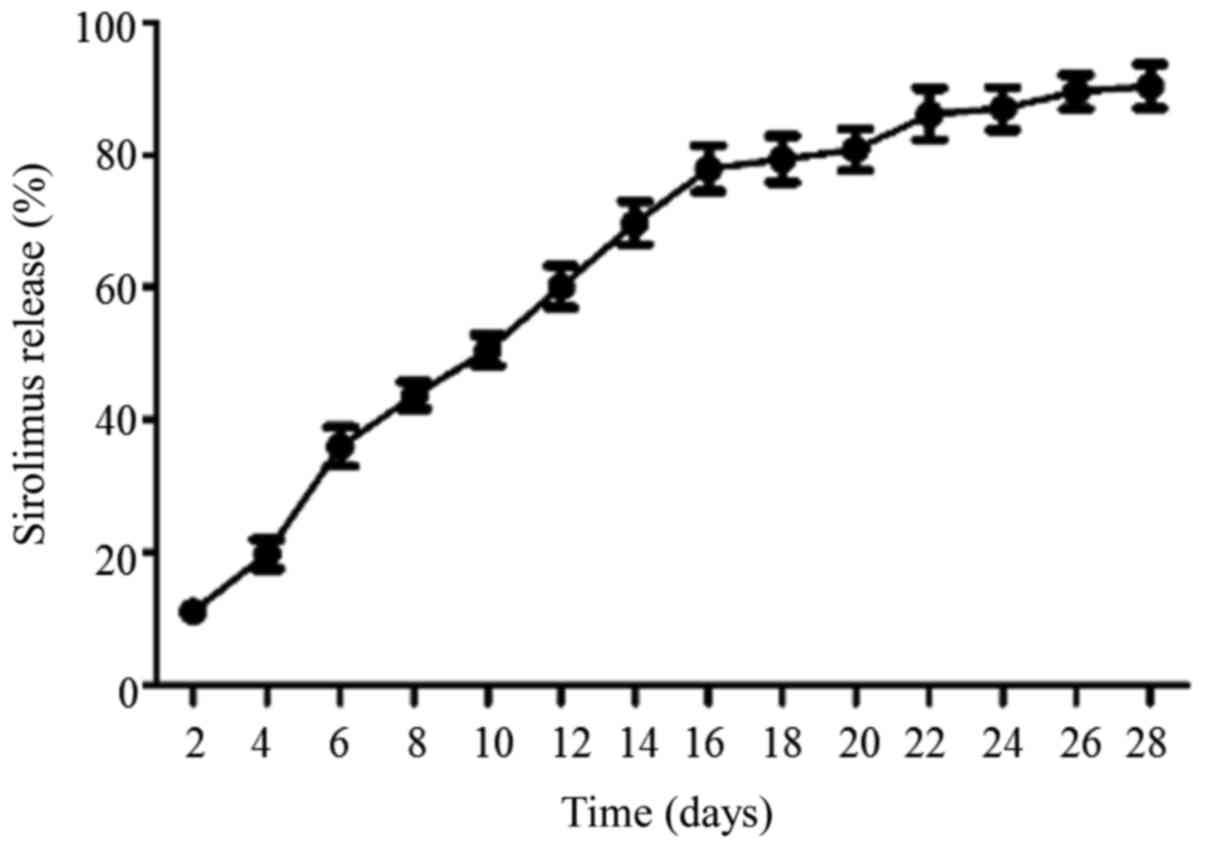

Sirolimus loading and entrapment efficiency were

10.3±3.2 and 95.1±10.6%, respectively. The release of sirolimus was

measured for 28 days. As presented in Fig. 5, sirolimus was gradually released

from the PPC-sirolimus polymer in a linear-like fashion,

particularly for the first 3 weeks. A total of ~90% of the

sirolimus entrapped in the polymer was released after 28 days.

Inhibition of RAAFC growth by the

PPC-sirolimus polymer

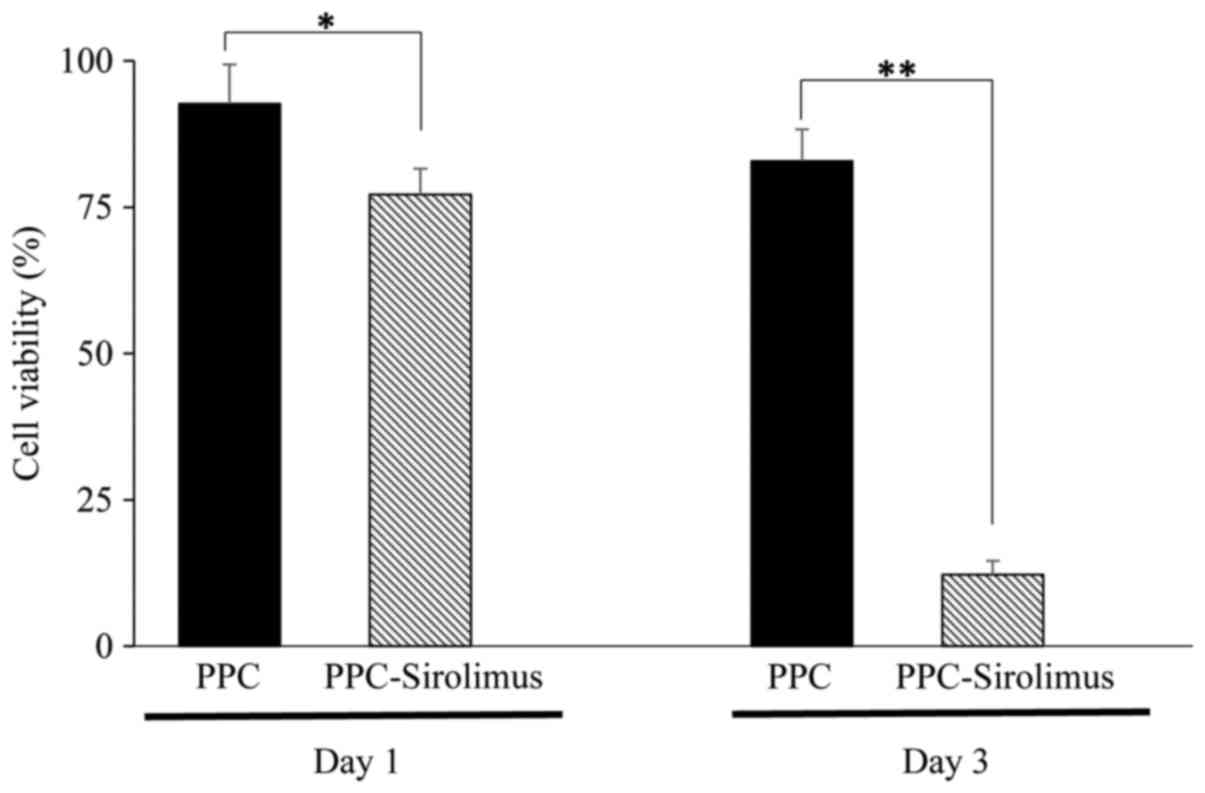

An MTT assay was performed in order to evaluate the

effect of the PPC-sirolimus polymer on RAAFC growth. The viability

of control cells (without the addition of any polymer) was

arbitrarily set at 100%. As presented in Fig. 6, following culture for 1 day, the

viability of cells treated with PPC and PPC-sirolimus was 92.7±6.7

and 77.2±4.4%, respectively. At day 3, the viability of cells

treated with PPC and PPC-sirolimus was 82.9±5.4 and 12.2±2.4%,

respectively. Statistical analysis demonstrated that the

PPC-sirolimus polymer significantly inhibited the growth of RAAFCs

at the two time points, while the PPC polymer did not (Fig. 6).

Discussion

Subsequent to the first investigations into

polymer-controlled drug release in cancer therapy (8,24,25),

the field has rapidly expanded and applied to the treatment of

other diseases (18,26,27).

Aliphatic polyesters, particularly PLGA, have been extensively

explored for local drug delivery. However, one disadvantage of

traditional aliphatic polyesters is that they generate acidic

products following degradation in vivo, which may cause

aseptic inflammation and tissue necrosis (10,28–30).

By contrast, PCC, a novel aliphatic polyester, is distinct in that

it primarily produces H2O and CO2 following

degradation, eliminating the side effects caused by PLA, PGA and

PLGA (14). Additionally, PPC

exhibits an increased bioadhesive capacity compared with PLA, PGA

and PLGA (21), enabling PPC-drug

conjugates to be retained in the target area and exert prolonged

therapeutic effects.

Using electrospinning technology, PPC fibers

containing sirolimus were generated in the present study. As

examined by SEM, the PPC-sirolimus polymer formed a uniform

three-dimensional and grid-intertwined net-like structure. The

structure formed in electrospun fibers is hypothesized to exhibit a

large surface area which is ideal for drug release (31). DSC analysis demonstrated that the

endothermic peak for sirolimus was not present in PPC-sirolimus

polymer, indicating that sirolimus may exist in the polymer in an

amorphous state. Notably, DSC sensitivity may be affected by the

low concentration of the drug in the polymer fibers. It is thought

that the amorphous state enhances the release of the drug from the

polymers (32). In a previous

study, PLGA was used to load sirolimus, and the entrapment and drug

loading efficiencies were reported to be ~80 and ~5%, respectively

(21), slightly lower compared

with what was observed with PPC in the present study.

It is desirable that entrapped therapeutic agents in

a polymer are able to be released for a period of time, thus

maintaining a sustained action and decreasing the number of

administration procedures required. The results of the present

study demonstrate that sirolimus encapsulated in a PPC polymer was

released in a linear-like manner, particularly for the first 3

weeks. At week 4, ~90% of the sirolimus had been released. Zou

et al (21) demonstrated

the application of PLGA with carbopol, a compound which enhances

PLGA bioadhesion, for local sirolimus delivery; it was observed in

an in vitro experiment that sirolimus was able to be

released for 4 weeks. Kang et al (33) observed that the release of

doxorubicin from polyorganophosphazene hydrogels lasted 20–30 days,

which is consistent with the results of the present study. In

vitro experiments in the present study demonstrated that PPC

did not affect the growth of RAAFCs. However, the PPC-sirolimus

polymer significantly reduced cell viability, warranting further

in vivo investigation of the effects of PPC-sirolimus.

In conclusion, compared with PLGA, the most widely

studied aliphatic polyester for drug delivery, PPC exhibits a

similar drug release curve and slightly increased loading and

entrapment efficiency with respect to sirolimus encapsulation. As

PPC exhibits increased bioadhesion and primarily produces

H2O and CO2 following degradation in

vivo, causing minimal side effects, PPC may be a promising

alternative polymer to PLGA for controlled drug delivery.

Acknowledgements

The present study was supported by the Independent

Innovation Foundation of Shandong University (grant no. 2012TS171)

and the Research Award Fund for Outstanding Young Scientists of

Shandong Province (grant no. 2006BS03014).

References

|

1

|

Lendlein A: Polymers in biomedicine.

Macromol Biosci. 10:993–997. 2010. View Article : Google Scholar

|

|

2

|

Chattopadhyay S and Raines RT: Review

collagen-based biomaterials for wound healing. Biopolymers.

101:821–833. 2014. View Article : Google Scholar :

|

|

3

|

Williams CK: Synthesis of functionalized

biodegradable polyesters. Chem Soc Rev. 36:1573–1580. 2007.

View Article : Google Scholar

|

|

4

|

Gunatillake P, Mayadunne R and Adhikari R:

Recent developments in biodegradable synthetic polymers. Biotechnol

Annu Rev. 12:301–347. 2006. View Article : Google Scholar

|

|

5

|

Fambri L, Pegoretti A, Fenner R, Incardona

SD and Migliaresi C: Biodegradable fibres of poly(L-lactic acid)

produced by melt spinning. Polymer. 38:79–85. 1997. View Article : Google Scholar

|

|

6

|

Peyton SR, Raub CB, Keschrumrus VP and

Putnam AJ: The use of poly(ethylene glycol) hydrogels to

investigate the impact of ECM chemistry and mechanics on smooth

muscle cells. Biomaterials. 27:4881–4893. 2006. View Article : Google Scholar

|

|

7

|

Kapoor DN, Bhatia A, Kaur R, Sharma R,

Kaur G and Dhawan S: PLGA: A unique polymer for drug delivery. Ther

Deliv. 6:41–58. 2015. View Article : Google Scholar

|

|

8

|

Langer RS and Peppas NA: Present and

future applications of biomaterials in controlled drug delivery

systems. Biomaterials. 2:201–214. 1981. View Article : Google Scholar

|

|

9

|

Middleton JC and Tipton AJ: Synthetic

biodegradable polymers as orthopedic devices. Biomaterials.

21:2335–2346. 2000. View Article : Google Scholar

|

|

10

|

Seyednejad H, Ghassemi AH, Van Nostrum CF,

Vermonden T and Hennink WE: Functional aliphatic polyesters for

biomedical and pharmaceutical applications. J Control Release.

152:168–176. 2011. View Article : Google Scholar

|

|

11

|

Cameron DJ and Shaver MP: Aliphatic

polyester polymer stars: Synthesis, properties and applications in

biomedicine and nanotechnology. Chem Soc Rev. 40:1761–1776. 2011.

View Article : Google Scholar

|

|

12

|

Jain R, Shah NH, Malick AW and Rhodes CT:

Controlled drug delivery by biodegradable poly(ester) devices:

Different preparative approaches. Drug Dev Ind Pharm. 24:703–727.

1998. View Article : Google Scholar

|

|

13

|

Li XH, Meng YZ, Chen GQ and Li RKY:

Thermal properties and rheological behavior of biodegradable

aliphatic polycarbonate derived from carbon dioxide and propylene

oxide. J Appl Polym Sci. 94:711–716. 2004. View Article : Google Scholar

|

|

14

|

Zhong X and Dehghani F: Solvent free

synthesis of organometallic catalysts for the copolymerisation of

carbon dioxide and propylene oxide. Appl Catal B. 98:101–111. 2010.

View Article : Google Scholar

|

|

15

|

Li WJ, Laurencin CT, Caterson EJ, Tuan RS

and Ko FK: Electrospun nanofibrous structure: A novel scaffold for

tissue engineering. J Biomed Mater Res. 60:613–621. 2002.

View Article : Google Scholar

|

|

16

|

Ji Y, Ghosh K, Shu XZ, Li B, Sokolov JC,

Prestwich GD, Clark RA and Rafailovich MH: Electrospun three

dimensional hyaluronic acid nanofibrous scaffolds. Biomaterials.

27:3782–3792. 2006. View Article : Google Scholar

|

|

17

|

Tipduangta P, Belton P, Fábián L, Wang LY,

Tang H, Eddleston M and Qi S: Electrospun polymer blend nanofibers

for tunable drug delivery: The role of transformative phase

separation on controlling the release rate. Mol Pharm. 13:25–39.

2016. View Article : Google Scholar

|

|

18

|

Zheng L, Chen J, Ma Z, Liu W, Yang F, Yang

Z, Wang K, Wang X, He D, Li L and Zeng J: Capsaicin enhances

anti-proliferation efficacy of pirarubicin via activating TRPV1 and

inhibiting PCNA nuclear translocation in 5637 cells. Mol Med Rep.

13:881–887. 2016.

|

|

19

|

Zeng J, Chen X, Xu X, Liang Q, Bian X,

Yang L and Jing X: Ultrafine fibers electrospun from biodegradable

polymers. J Appl Polym Sci. 89:1085–1092. 2003. View Article : Google Scholar

|

|

20

|

Ni S, Xia T, Li X, Zhu X, Qi H, Huang S

and Wang J: Sustained delivery of chondroitinase ABC by

poly(propylene carbonate)-chitosan micron fibers promotes axon

regeneration and functional recovery after spinal cord hemisection.

Brain Res. 1624:469–478. 2015. View Article : Google Scholar

|

|

21

|

Zou W, Cao G, Xi Y and Zhang N: New

approach for local delivery of rapamycin by bioadhesive

PLGA-carbopol nanoparticles. Drug Deliv. 16:15–23. 2009. View Article : Google Scholar

|

|

22

|

Gu M and Brecher P: Nitric oxide-induced

increase in p21(Sdi1/Cip1/Waf1) expression during the cell cycle in

aortic adventitial fibroblasts. Arterioscler Thromb Vasc Biol.

20:27–34. 2000. View Article : Google Scholar

|

|

23

|

Tsuruda T, Kato J, Cao YN, Hatakeyama K,

Masuyama H, Imamura T, Kitamura K, Asada Y and Eto T:

Adrenomedullin induces matrix metalloproteinase-2 activity in rat

aortic adventitial fibroblasts. Biochem Biophys Res Commun.

325:80–84. 2004. View Article : Google Scholar

|

|

24

|

Duncan R: Polymer conjugates as anticancer

nanomedicines. Nat Rev Cancer. 6:688–701. 2006. View Article : Google Scholar

|

|

25

|

Davis ME, Chen Z and Shin DM: Nanoparticle

therapeutics: An emerging treatment modality for cancer. Nat Rev

Drug Discov. 7:771–782. 2008. View

Article : Google Scholar

|

|

26

|

Liechty WB, Kryscio DR, Slaughter BV and

Peppas NA: Polymers for drug delivery systems. Annu Rev Chem Biomol

Eng. 1:149–173. 2010. View Article : Google Scholar :

|

|

27

|

Merkle HP: Drug delivery's quest for

polymers: Where are the frontiers? Eur J Pharm Biopharm.

97:293–303. 2015. View Article : Google Scholar

|

|

28

|

Fu K, Pack DW, Klibanov AM and Langer R:

Visual evidence of acidic environment within degrading

poly(lactic-co-glycolic acid) (PLGA) microspheres. Pharm Res.

17:100–106. 2000. View Article : Google Scholar

|

|

29

|

Danmark S, Finne-Wistrand A, Schander K,

Hakkarainen M, Arvidson K, Mustafa K and Albertsson AC: In vitro

and in vivo degradation profile of aliphatic polyesters subjected

to electron beam sterilization. Acta Biomater. 7:2035–2046. 2011.

View Article : Google Scholar

|

|

30

|

Ding AG and Schwendeman S: Acidic

microclimate pH distribution in PLGA microspheres monitored by

confocal laser scanning microscopy. Pharm Res. 25:2041–2052. 2008.

View Article : Google Scholar :

|

|

31

|

Zamani M, Prabhakaran MP and Ramakrishna

S: Advances in drug delivery via electrospun and electrosprayed

nanomaterials. Int J Nanomedicine. 8:2997–3017. 2013.

|

|

32

|

Zahedi P and Lee PI: Solid molecular

dispersions of poorly water-soluble drugs in poly(2-hydroxyethyl

methacrylate) hydrogels. Eur J Pharm Biopharm. 65:320–328. 2007.

View Article : Google Scholar

|

|

33

|

Kang GD, Cheon SH and Song SC: Controlled

release of doxorubicin from thermosensitive poly(organophosphazene)

hydrogels. Int J Pharm. 319:29–36. 2006. View Article : Google Scholar

|