Introduction

Alveolar bone defect is a common clinic issue, which

may be caused by multiple factors, including inflammation, trauma,

tumor, or congenital and developmental disorders (1). It may have a serious impact on

chewing and pronunciation, and may even lead to serious facial

dysfunction and deformities (2).

Therefore, efficient alveolar bone restoration is required to

restore function and appearance. Although bone grafts are commonly

used in alveolar bone reconstruction, these methods have numerous

drawbacks, including inducing new defects, immune rejections and

potential infection (3).

Three-dimensional printed (3DP) scaffolds combined

with osteogenic cells and/or osteo-inductive molecules have emerged

as a promising alternative to grafts in bone tissue regeneration

(4,5). The fused deposition modeling (FDM)

technique, a type of 3DP technique, has been successfully used in

bone tissue engineering. Scaffolds are fabricated based on the

extrusion of molten polymer fibers in a layer-by-layer manner,

using the data collected from a computer-aided design program and

computer-aided medical imaging including computed tomography or

X-ray (6). Therefore, an FDM

scaffold is able to highly match the external morphology of the

defect and accurately restore the internal structure of the tissue,

and thus represents a powerful approach for complex tissue

engineering, particularly for cranio-maxillofacial constructs

(1).

The ideal scaffold should be biodegradable and

biocompatible. It should additionally possess a highly porous

interconnected network with excellent surface characteristics for

cell affinity and tissue regeneration (7). Selecting suitable materials for 3DP

scaffold production remains challenging. U. S. Food and Drug

Administration-approved synthetic polymers poly (ε-caprolactone)

(PCL) and poly-lactic-co-glycolic acid (PLGA) have the advantages

of being relatively low cost, with the possibility of long-term

storage and superior bioactivity, thus these polymers have received

considerable attention in bone regeneration (8). PCL is flexible and used in various

fabrication techniques; however, it has been demonstrated to have

low degradability and inferior bioactivity (9). PLGA is hydrophilic, biodegradable and

highly biocompatible; however, is more brittle (10,11).

The combined use of PCL and PLGA may overcome the shortcomings of

single use and become an excellent biocompatible composite, which

has been extensively applied in the clinic for various tissue

restoration procedures (12–18).

Previous studies have primarily focused on the biocompatibility of

the PCL/PLGA composite scaffold; however, the biodegradable

properties and surface characteristics of PCL/PLGA composite

scaffolds have rarely been reported. Furthermore, few studies have

examined the application of PCL/PLGA composite scaffold in alveolar

bone regeneration.

Human periodontal ligament stem cells (hPDLSCs)

possess immense potential in bone tissue engineering, owing to

their various sources, easy attainability (19), high rates of proliferation,

multi-lineage differentiation ability (20), and great capacity for alveolar bone

(21) and tendon regeneration

(22). In order to investigate a

suitable material for alveolar bone regeneration, scaffolds with

different ratios of PCL and PLGA were fabricated via 3DP and their

surface characteristics and degradative properties, along with the

response of hPDLSCs on these scaffolds, were subsequently

assessed.

Materials and methods

Fabrication of PCL/PLGA scaffolds

The scaffolds were fabricated using a 3DP system

(Bioplotter; EnvisionTEC GmbH, Gladbeck, Germany). PCL (molecular

weight 50,000; Polysciences, Inc., Warrington, PA, USA) and PLGA

(polylactic acid/polyglycolic acid 50:50; molecular weight

50,000–75,000; Sigma-Aldrich; Merck KGaA, Darmstadt, Germany) were

used and the ratios of PCL/PLGA were 1:9, 5:5 and 9:1. The blended

powder of PCL/PLGA was melted in a chamber at 130°C, centrifuged at

100 × g for 10 min at a temperature range of 130–150°C, and

dispensed through a 27-gauge metal needle at 135°C to create fully

interconnected structures with diameters and heights of 15 and 1

mm, respectively. The XY dispensing head speed was 100 mm/min and

the dispensing pressure was ~650 kPa.

Surface characteristics

The microscopic appearance of the scaffolds was

observed using scanning electron microscopy (SEM; LEO 1530 variable

pressure field emission SEM; Zeiss GmbH, Jena, Germany) at a

magnification of 75 and ×1,000. The surface roughness of the

scaffolds was determined using a profilometer of laser scanning

confocal microscope (LSM700; Zeiss GmbH) at a magnification of ×50

and ×200. The arithmetic average of the 3D roughness (Sa) and the

quadratic average of the 3D roughness (Sq) was measured. The

wettability of the scaffolds was evaluated by measuring the water

contact angle (CA), using a CA video-based system (OCAl5;

DataPhysics, Filderstadt, Germany) and SCA20 software (version 1.0;

DataPhysics).

Degradation characteristics

Scaffolds were cut into pieces weighing 50 mg and

were immersed separately in PBS (pH 7.4; Thermo Fisher Scientific,

Inc., Waltham, MA, USA) at 37°C over 12 weeks. PBS was changed

every 3 weeks. At 3, 6, 9 and 12 weeks, the scaffolds were removed,

rinsed with distilled water and air-dried at room temperature for

24 h. The weight loss was measured using a sensitive scale (ME103;

Mettler-Toledo GmbH, Greifense, Switzerland). The pH value of the

PBS following removal of the scaffolds was measured using a pH

meter (SevenMulti; Mettler-Toledo). Five specimens were examined

for each scaffold at each time point and the average value was

calculated and recorded.

Cell culture and identification

The protocol was approved by the Ethics Committee of

the Hospital of Stomatology, Sun Yat-sen University (Guangzhou,

China). Informed consent from each patient was obtained. A total of

16 healthy premolars were acquired from four orthodontic patients

aged 14–18 years (two males and two females) at the Hospital of

Stomatology, Sun Yat-sen University from September 2016 to October

2016. Teeth extracted for orthodontic treatment were included in

the present study. Teeth with cavities, periodontitis, broken

sputum or not fully developed apical foramens were excluded. As

previously described (23),

hPDLSCs were isolated from the periodontal ligament of the teeth,

and cultured at 37°C with a limited dilution method in complete

culture medium, containing α modified eagle medium (MEM; Gibco;

Thermo Fisher Scientific, Inc.), 10% fetal bovine serum, 100 U/ml

penicillin and 100 µg/ml streptomycin (all Gibco; Thermo Fisher

Scientific, Inc.). The osteogenic and adipogenic differentiation

potential of the hPDLSCs was investigated by alizarin red S

staining and oil red O staining, respectively. After 1 day of

culture, hPDLSCs were cultured with osteoblast-inducing medium (0.1

µM dexamethasone, 50 µg/ml ascorbic acid and 10 mM β-glycerol

phosphate) or adipogenic medium (100 nM dexamethasone, 10 µg/ml

insulin, 0.5 mM 3-isobutyl-1-methylxanthine and 50 mM

indomethacin). After 2 weeks, adipogenic induced cells were fixed

in 4% paraformaldehyde for 15 min at room temperature and stained

with Oil Red O staining solution (Nanjing Jiancheng Bioengineering

Institute, Nanjing, China) at room temperature, according to the

manufacturer's protocol. Briefly, cells were stained with reagent 1

for 15 min, washed with distilled water for 20 sec and subsequently

stained with reagent 2 for 5 min. Furthermore, after 4 weeks, the

osteoblast induced cells were fixed in 4% paraformaldehyde and

stained with Alizarin Red S staining solution (Sigma-Aldrich; Merck

KGaA) for 3 min at room temperature. All dishes were subsequently

dried at room temperature and observed under an optical light

microscope at ×200 magnification.

The colony-forming ability was assessed using

colony-forming assays as previously described (23). Briefly, human PDLSCs (P3) were

seeded in 10 cm diameter culture dishes at a density of

1×103 cells per dish and cultured in complete medium.

After 12 days of incubation, cells were fixed in 4%

paraformaldehyde for 15 min at room temperature and stained with

0.1% crystal violet (Sigma-Aldrich; Merck KGaA) for 15 min at room

temperature. The dishes were subsequently washed twice with PBS and

observed under an inverted microscope at ×30 magnification. An

aggregate of 50 or more cells were considered colony unit and were

included in the final statistical analysis; aggregates of fewer

cells were excluded. Cloning formation efficiency was assessed by

examining the ratio of colony units and seeding cell number.

The specific surface markers of hPDLSCs, including

integrin β-1 [cluster of differentiation (CD)29], cell surface

glycoprotein MUC18 (CD146), CD44 (antigen CD44), thy-1 membrane

glycoprotein (CD90), hematopoietic progenitor cell antigen (CD34)

and receptor-type tyrosine-protein phosphatase C (CD45) were

identified by flow cytometry. Briefly, once 90% confluence was

reached, hPDLSCs were trypsinized and incubated with all antibodies

diluted at 1:100, CD146 (cat. no. sc-53369), CD29 (cat. no.

sc-59827), CD44 (cat. no. sc-65265), CD90 (cat. no. sc-53116), CD34

(cat. no. sc-133082) and CD45 (cat. no. sc-53045) at 4°C for 16 h

in the dark, all of which were mouse IgG-flourescein isothiocyanate

(FITC) antibodies purchased from Santa Cruz Biotechnology, Inc.

(Dallas, TX, USA). Cell suspensions incubated with served as

controls. Finally, cells were fixed with 4% paraformaldehyde for 15

min at room temperature, washed three times with PBS and analyzed

via fluorescence-activated cell sorting with a flow cytometer (BD

Biosciences, San Jose, CA, USA) and BD Cell Quest Pro software

(version 5.1; BD Biosciences). Cells passaged to P4 were used in

the following experiments.

Cell seeding

Prior to seeding hPDLSCs, the scaffolds were

immersed in 70% ethanol for 12 h, air-dried in a clean workstation

for 1 day and incubated with α-MEM in 24-well plates for 7 days.

Subsequently, hPDLSCs were seeded on the scaffolds at a density of

1×106 cells/well.

Cell adhesion

Following 1 and 2 days of culture, the adherent

cells were fixed in 3% paraformaldehyde for 15 min and stained with

DAPI (Beyotime Institute of Biotechnology, Shanghai, China) for 10

min at room temperature. The cell numbers on each scaffold were

counted in five random fields, under an epifluorescence microscope

(Observer.Z1; Zeiss GmbH) at ×50 magnification.

Cell proliferation

Following culturing for 1, 3, 5, and 7 days, the

cell proliferation of hPDLSCs was assessed using a Cell Counting

Kit (CCK)-8 assay (Beyotime Institute of Biotechnology). At each

time point, medium was replaced with serum-free medium containing

CCK-8 solution (0.5 mg/ml) at 37°C under 5% CO2 for 2 h.

The optical density (OD) at 450 nm was measured using a

spectrophotometer (Dojindo Molecular Technologies, Inc., Kumamoto,

Japan).

Cell morphology

Following 3 days of incubation, the cell morphology

of the hPDLSCs was observed under SEM. The samples were fixed in

2.5% (w/w) glutaraldehyde for 4 h at 4°C, dehydrated in a 30, 50,

70, 90 and 100% ethanol series (15 min for each step), freeze-dried

and sputter coated with gold for SEM observation.

Cell adhesion morphology

Following culturing for 7 and 14 days, the

cytoskeletal morphology of the hPDLSCs was observed using confocal

laser scanning microscopy (CLSM: LSM780; Zeiss GmbH) at a

magnification of ×50 and ×200, and SEM at a magnification of ×75

and ×1,000. Samples for CLSM observation were fixed in 3%

paraformaldehyde for 10 min at room temperature, and immersed in

0.1% TritonX-100 for 10 min. The cells were subsequently stained

with 1:100 Actin-Tracker Green (Beyotime Institute of

Biotechnology) and DAPI at 37°C for 1 h. Samples for SEM

observation were prepared by the same protocol as for cell

morphology observation.

Alizarin Red S staining

Subsequent to 14 days of osteogenic induction, the

hPDLSCs on scaffolds were fixed in 3% paraformaldehyde for 10 min,

and stained with Alizarin Red S staining solution (Beyotime

Institute of Biotechnology) for 1 min, both at room temperature.

The scaffolds were subsequently washed twice with PBS until no more

color appeared and observed under an optical microscope at ×30

magnification. Finally, 2% cetylpyridinium chloride was added to

the samples to dissolve the mineralized nodules. The OD at 562 nm

was measured using a spectrophotometer.

Alkaline phosphatase (ALP)

activity

Subsequent to seeding for 1 day, the hPDLSCs were

cultured with osteoblast-inducing medium containing 0.1 µM

dexamethasone, 50 µg/ml ascorbic acid and 10 mM β-glycerol

phosphate. On day 7 and 14, protein concentration and ALP activity

were determined using a bicinchoninic acid protein assay kit

(Beijing ComWin Biotech Co., Ltd., Beijing, China) and an ALP kit

(Nanjing Jiancheng Bioengineering Institute), respectively,

according to the manufacturer's protocols. OD values were measured

at 560 and 520 nm, correspondingly, using a spectrophotometer. ALP

activity was normalized to the total protein amount.

Expression of osteogenic

biomarkers

hPDLSCs were cultured with osteoblast-inducing

medium for 7 and 14 days. Total RNA was extracted from hPDLSCs

using the RNAzol RNA extraction reagent (GeneCopoeia, Inc.,

Rockville, MD, USA; cat. no. RN190). The reverse transcription (RT)

reactions were performed using Prime Script RT Master Mix (cat. no.

RR037; Takara Bio, Inc., Otsu, Japan). The RT was performed at 37°C

for 15 min and 85°C for 5 sec. A quantitative polymerase chain

reaction (qPCR) was conducted using a SYBR PCR Master Mix kit (cat.

no. 4367218; Thermo Fisher Scientific, Inc.) and 10 µM specific

primers in 20 µl, consisting of 40 cycles at 95°C for 10 min, 95°C

for 15 sec, 60°C for 60 sec, and 72°C for 30 sec. The data were

acquired using the LightCycler480 System (Bio-Rad Laboratories,

Inc., Hercules, CA, USA). β-actin was used to normalize the

expression level of ALP, osteocalcin (OCN) and runt-related

transcription factor 2 (RUNX2). The primers are presented in

Table I. Relative expression was

calculated using the 2−ΔΔCq method (24).

| Table I.Primer nucleotide sequences for the

reverse transcription-quantitative polymerase chain reaction. |

Table I.

Primer nucleotide sequences for the

reverse transcription-quantitative polymerase chain reaction.

| Gene | Primer nucleotide

sequence |

|---|

| β-actin | Forward: |

5′-GCCTTCAAGGTGGTAGCCC-3′ |

|

| Reverse: |

5′-CGTTACCCGCCATGACAGTA-3′ |

| ALP | Forward: |

5′-CATGAAATACGAGATCCACCGAGAC-3′ |

|

| Reverse: |

5′-ATGCGACCACCCTCCACGAAG-3′ |

| OCN | Forward: |

5′-CCCAGGCGCTACCTGTATCAA-3′ |

|

| Reverse: |

5′-GGTCAGCCAACTCGTCACAGTC-3′ |

| RUNX2 | Forward: |

5′-TGGTTACTGTCATGGCGGGTA-3′ |

|

| Reverse: |

5′-TCTCAGATCGTTGAACCTTGCTA-3′ |

Statistical analysis

Data are presented as the mean ± standard deviation

(n=5) and were statistically analyzed using SPSS 13.0 (SPSS, Inc.,

Chicago, IL, USA). The difference among groups was analyzed by

one-way analysis of variance followed by the Student-Newman-Keuls

post hoc test. P<0.05 was considered to indicate a statistically

significant difference.

Results

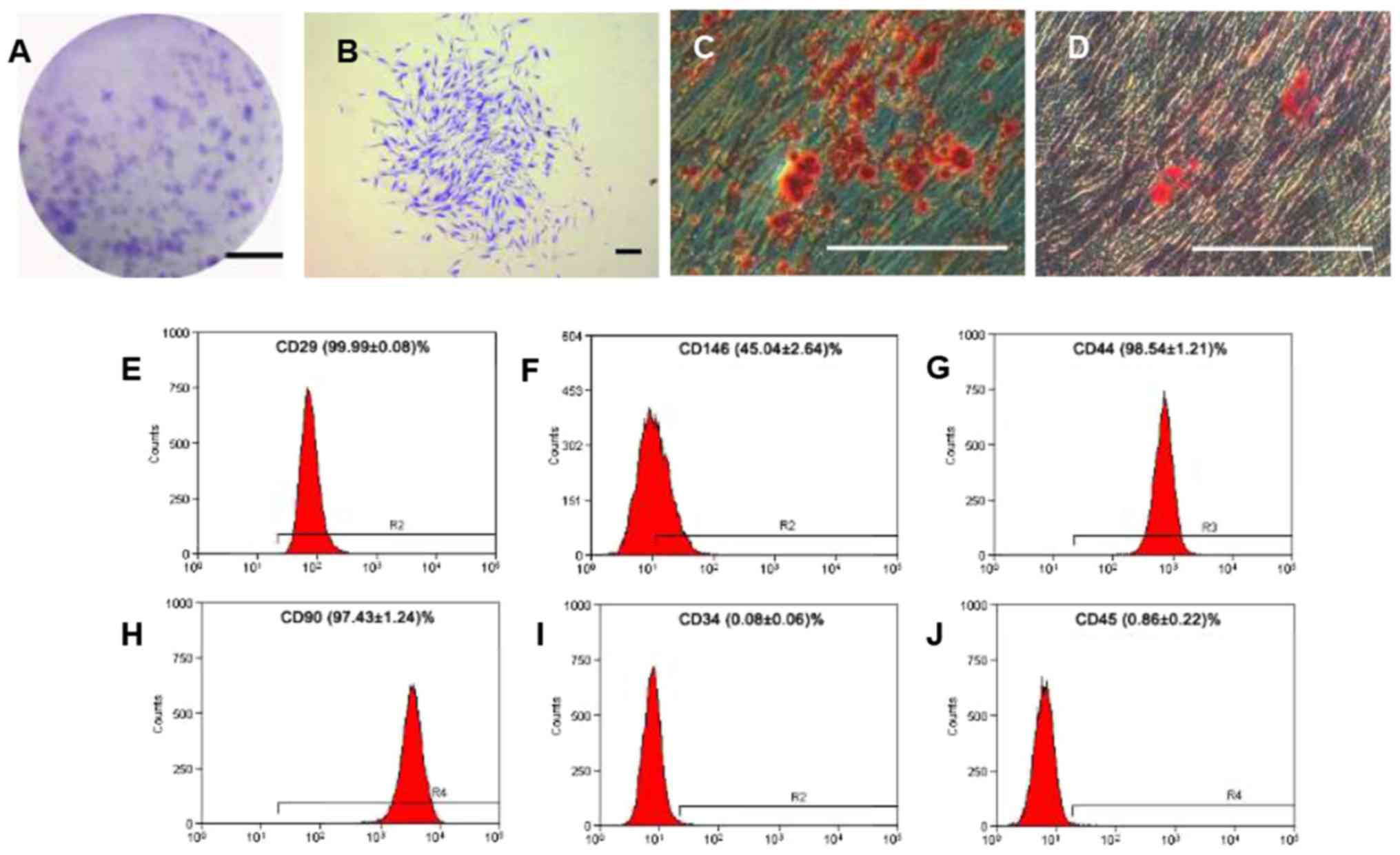

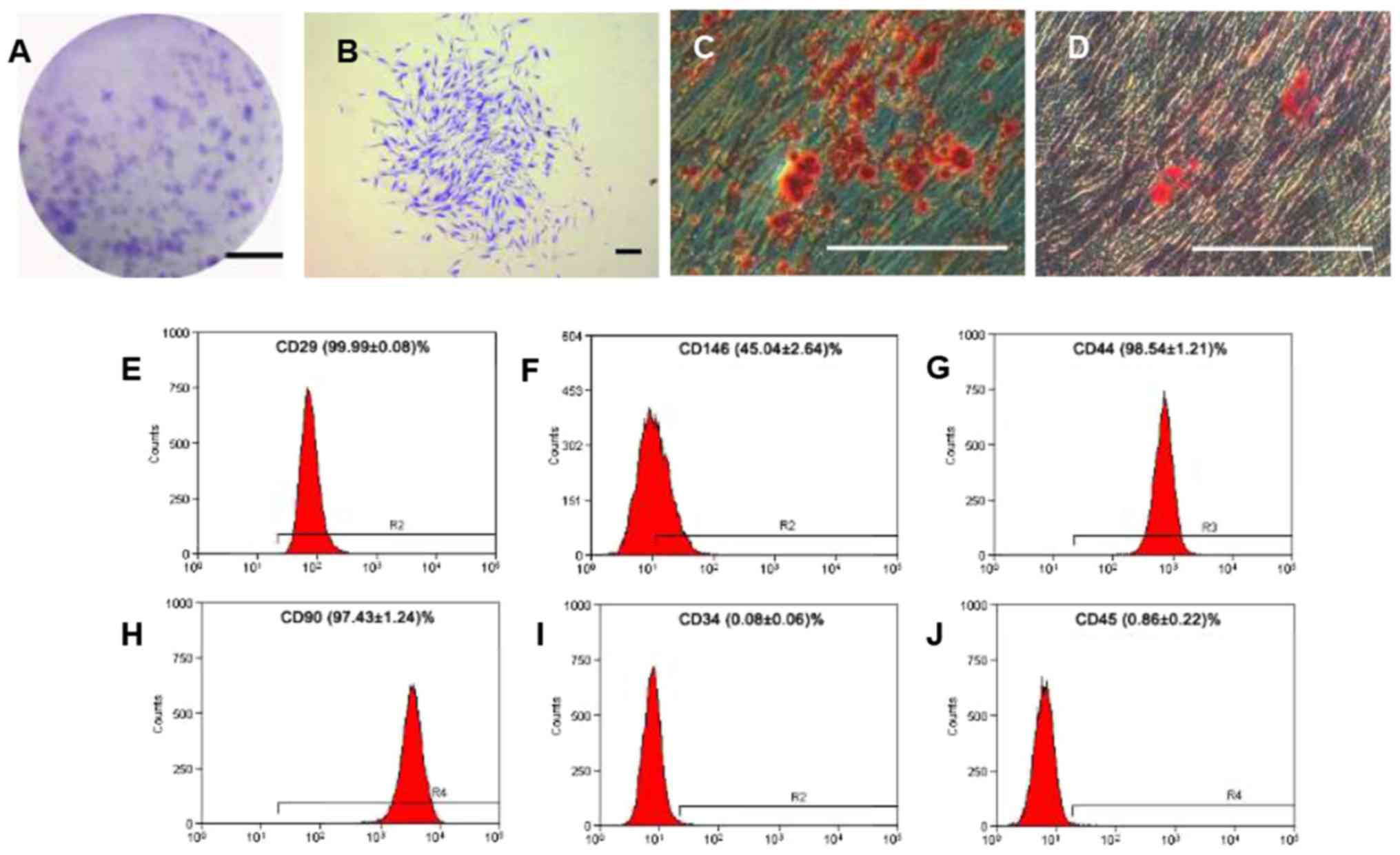

hPDLSC culture and identification

Colony-forming units of the hPDLSCs were counted and

the colony formation efficiency was 30.2% (Fig. 1A and B). The hPDLSCs displayed long

spindle morphology, and demonstrated the ability for osteogenic

(Fig. 1C) and adipogenic

differentiation (Fig. 1D). The

flow cytometric analyses demonstrated that the hPDLSCs were

positive for CD29 (adhesion molecule), CD146 (mesenchymal stem cell

marker), CD44 (receptor molecule) and CD90 (extracellular matrix

protein); however, they were negative for CD34 and CD45

(hematopoietic and angiogenic lineage markers) (Fig. 1E-J).

| Figure 1.Cell culture and identification of

hPDLSCs. (A) Colony forming units of hPDLSCs after cultivation for

12 days. Scale bar, 2 cm (B) Single clone of hPDLSCs. (C)

Mineralized nodules identified by alizarin red S staining following

osteogenic induction for 28 days. (D) Oil red O-positive lipid

clusters identified following adipogenic induction for 14 days.

(B-D) Scale bar, 300 µm. Flow cytometric analyses for surface

markers of hPDLSCs: (E) CD29; (F) CD146; (G) CD44; (H) CD90; (I)

CD34; and (J) CD45. hPDLSCs, human periodontal ligament stem cells;

CD, cluster of differentiation; CD29, integrin β-1; CD146, cell

surface glycoprotein, CD44, antigen CD44; CD90, thy-1 membrane

glycoprotein; CD34, hematopoietic progenitor cell antigen; CD45,

receptor-type tyrosine-protein phosphatase C. |

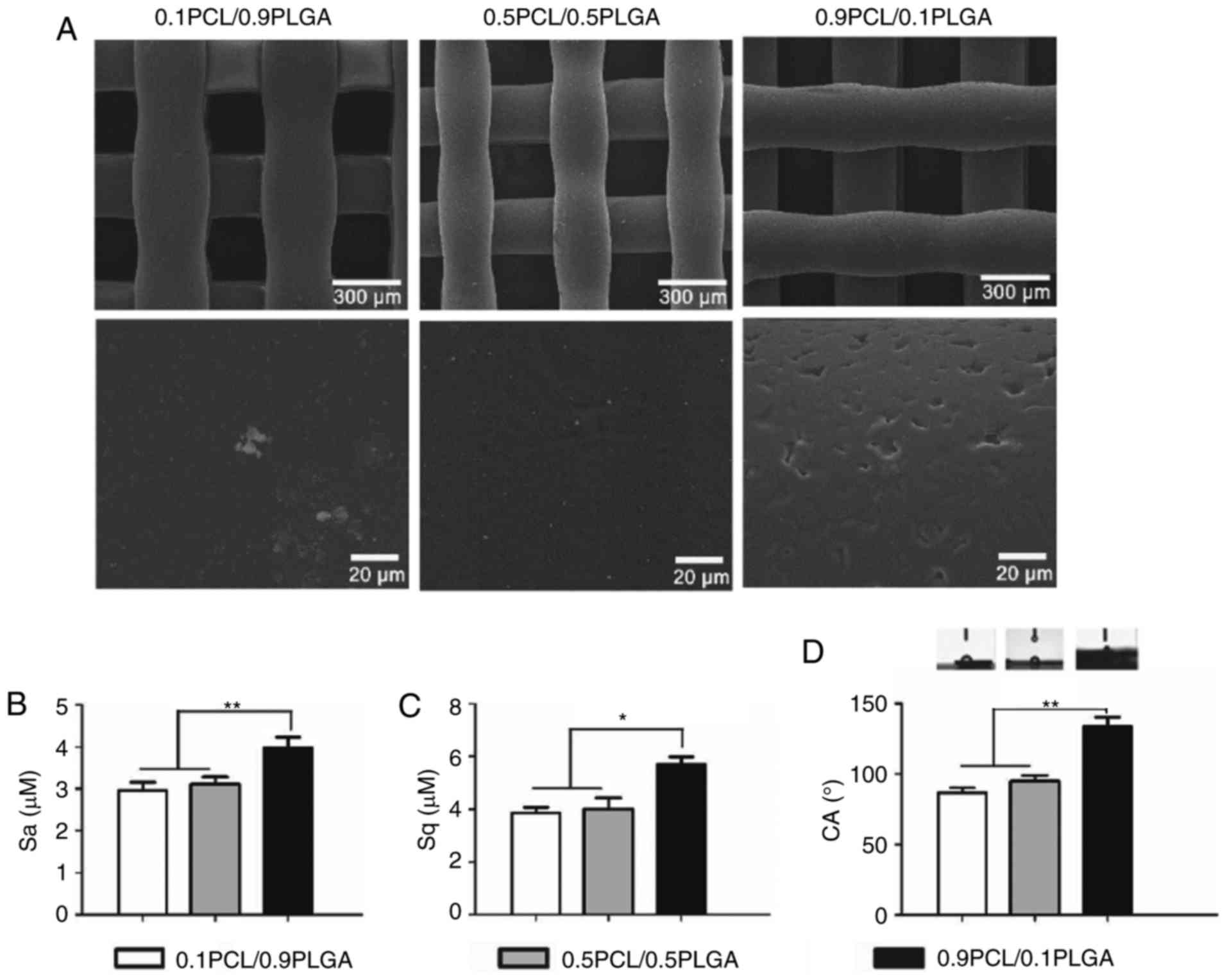

Surface characteristics (morphology,

surface roughness and wettability)

As demonstrated in Fig.

2A, the surface of the 0.9PCL/0.1PLGA scaffold was rough and

exhibited micro-sized pores. By comparison, the surfaces of the

0.1PCL/0.9PLGA and 0.5PCL/0.5PLGA scaffold were smooth.

Surface roughness is exhibited in Fig. 2B and C. The introduction of PLGA

into PCL decreased the Sa and Sq. The Sa value of 0.9PCL/0.1PLGA

was significantly higher compared with the other two groups

(P<0.01). Sq values shared the same tendency as Sa (Fig. 2C).

Water contact angle images are illustrated in

Fig. 2D. The water angle of the

composites decreased and the surface hydrophilicity increased with

the increasing proportion of PLGA. The average values of the CAs of

0.1PCL/0.9PLGA (86.60±3.60°) and 0.5PCL/0.5PLGA (94.93±4.14°) were

significantly lower compared with 0.9PCL/0.1PLGA (133.83±6.53°)

(P<0.01; Table II). There was

no significant difference observed between the two lower

groups.

| Table II.Surface roughness and hydrophilicity

of the tested scaffolds (n=5). |

Table II.

Surface roughness and hydrophilicity

of the tested scaffolds (n=5).

| Group | Sa, µm | Sq, µm | CA, ° |

|---|

| 0.1PCL/0.9PLGA |

2.97±0.19c |

3.85±0.12c |

86.60±3.60c |

| 0.5PCL/0.5PLGA |

3.12±0.06c |

4.01±0.42c |

94.93±4.14c |

| 0.9PCL/0.1PLGA |

3.99±0.04a,b |

5.70±0.68a,b |

133.83±6.53a,b |

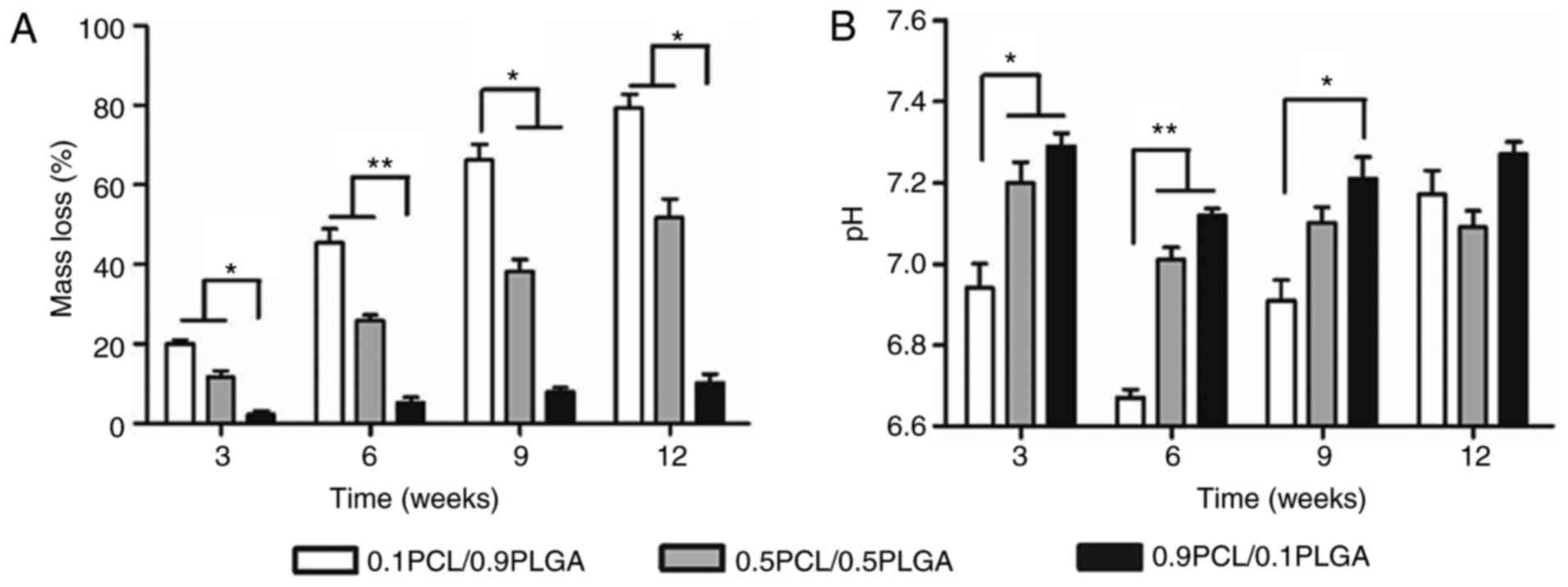

Degradation properties/alterations in

mass and pH

As demonstrated in Fig.

3A, PLGA addition may adjust the degradation rates of PCL/PLGA

scaffolds. The presence of PLGA significantly accelerated the mass

loss of the composites. Following 12 weeks, the mass loss was

79.20±4.22, 51.89±4.56 and 10.21±2.16% for the 0.1PCL/0.9PLGA,

0.5PCL/0.5PLGA and 0.9PCL/0.1PLGA scaffolds, respectively.

Overall, the pH values of the composites decreased

with the increasing ratio of PLGA at each time point (Fig. 3B). At 6 weeks of degradation, the

pH values of the three different scaffolds reached the minimum,

which was 6.67±0.02, 7.01±0.06 and 7.12±0.02 for 0.1PCL/0.9PLGA,

0.5PCL/0.5PLGA and 0.9PCL/0.1PLGA, respectively. Additionally, a

significant difference was observed in the pH values between

0.1PCL/0.9PLGA and the other two scaffolds following 3 (P<0.05)

and 6 weeks (P<0.01) of degradation, and between 0.1PCL/0.9PLGA

and 0.9PCL/0.1PLGA at 9 weeks of degradation (P<0.05).

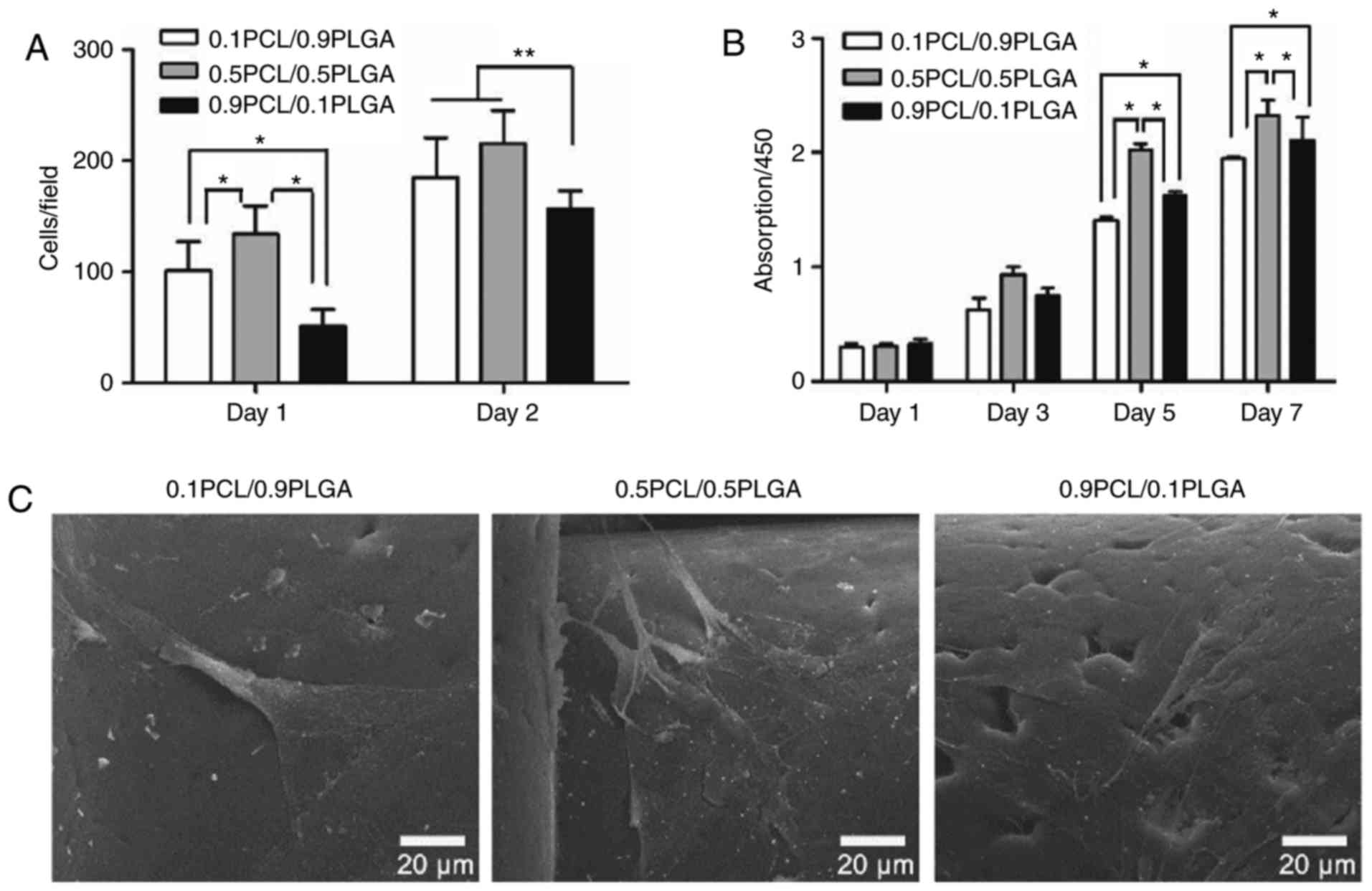

Cell adhesion

As demonstrated in Fig.

4A, the initial adherent number of hPDLSCs on 0.1PCL/0.9PLGA

and 0.5PCL/0.5PLGA was significantly higher compared with

0.9PCL/0.1PLGA on day 1 (P<0.05) and day 2 (P<0.01). No

significant difference between 0.1PCL/0.9PLGA and 0.5PCL/0.5PLGA

was revealed on day 2.

Cell proliferation

As presented in Fig.

4B, the proliferation of the hPDLSCs on different scaffolds

demonstrated a specific order at each time point with the exception

of day 1, with the ranking 0.5PCL/0.5PLGA >0.9PCL/0.1PLGA

>0.1PCL/0.9PLGA. On day 1 and day 3, no significant difference

was observed among the groups (P>0.05). On day 5 and day 7, the

proliferation level was significantly higher in 0.5PCL/0.5PLGA

(OD5d=2.03±0.05; OD7d=2.33±0.13) and

significantly lower in 0.1PCL/0.9PLGA (OD5d=1.62±0.04;

OD7d=2.11±0.20) compared with 0.9PCL/0.1PLGA

(OD5d=1.41±0.03; OD7d=1.95±0.01)

(P<0.05).

Cell morphology

The morphology of the hPDLSCs was demonstrated in

Fig. 4C following 3 days of

culture. Cells on 0.5PCL/0.5PLGA were highly branched, polygonal

shaped and exhibited clear nuclei; whereas, cells were flat on the

0.1PCL/0.9PLGA scaffold, and spindle-like with fewer branch points

on the 0.9PCL/0.1PLGA scaffold.

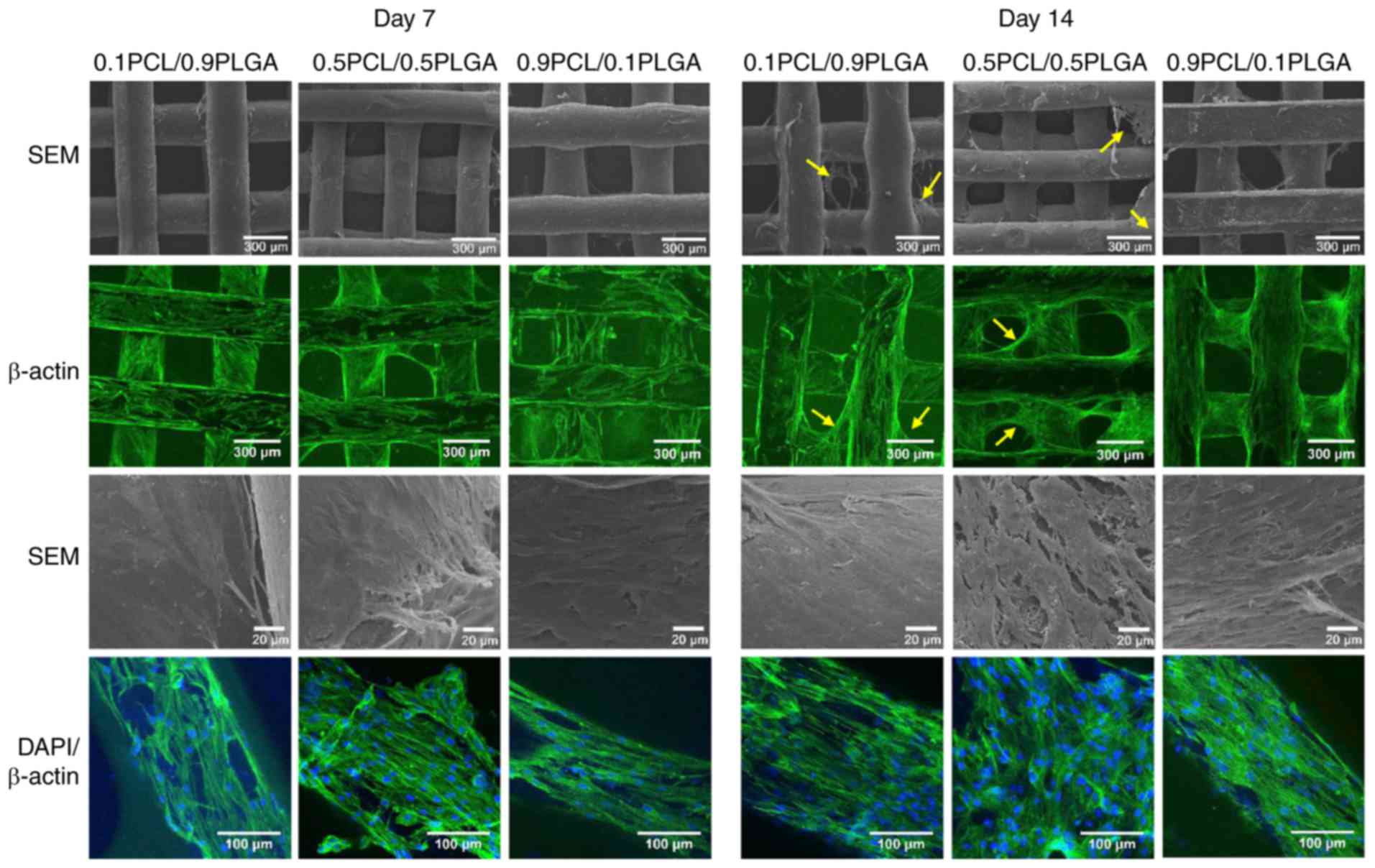

Cell adhesion morphology

The cell adhesion morphology of the hPDLSCs was

observed following 7 and 14 days of incubation on the scaffolds

(Fig. 5). SEM and CLSM images at

low magnification demonstrated that with culture time, hPDLSCs

gradually grew on the scaffold surface and formed cell layers.

Subsequent to 14 days of culture, hPDLSCs grew on the struts and

additionally over the porous structure of the 0.1PCL/0.9PLGA and

0.5PCL/0.5PLGA scaffolds (yellow arrows); whereas, hPDLSCs only

covered the struts and not the porous structure of the

0.9PCL/0.1PLGA scaffolds.

SEM images at high magnification revealed that

hPDLSCs were well adhered to the surfaces of all scaffolds. The

hPDLSCs formed denser cell layers on the 0.5PCL/0.5PLGA scaffolds

compared with on the 0.1PCL/0.9PLGA and 0.9PCL/0.1PLGA scaffolds.

CLSM images at high magnification revealed that abundant stress

fibers and actin microfilaments were observed on the 0.5PCL/0.5PLGA

scaffolds with fewer cellular junctions revealed on the

0.1PCL/0.9PLGA and 0.9PCL/0.1PLGA scaffolds.

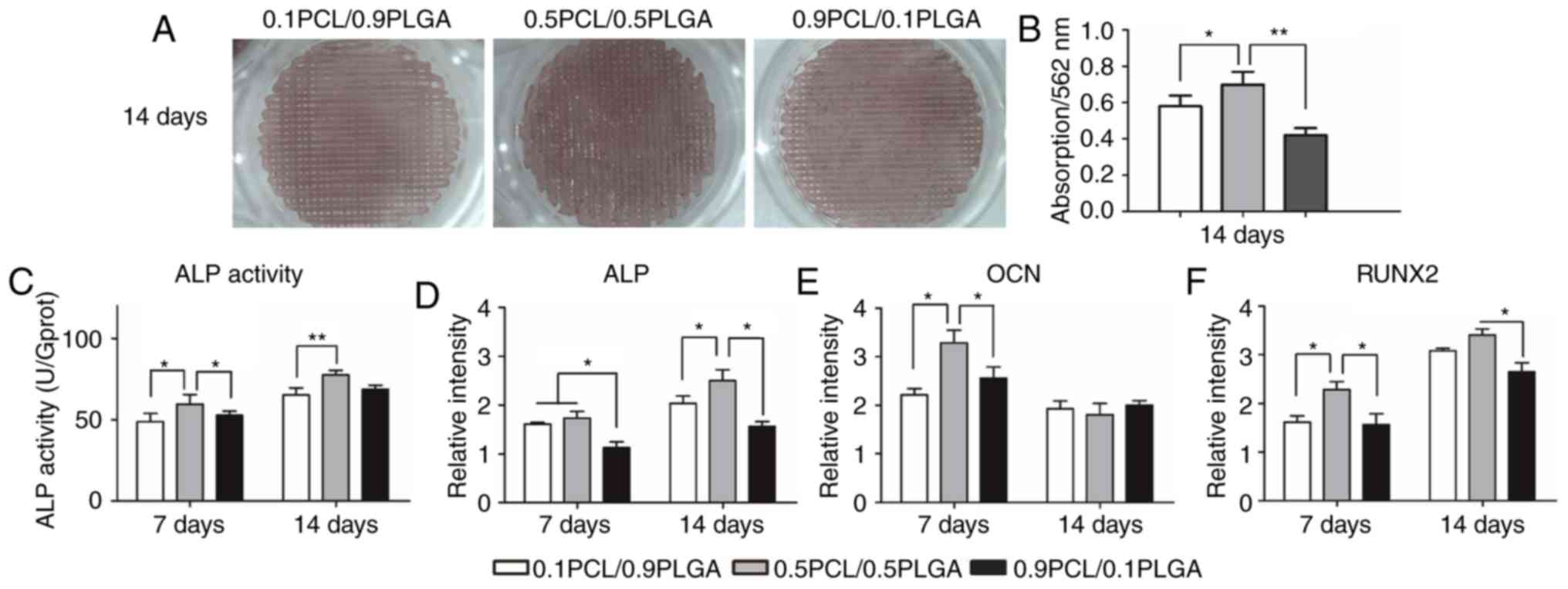

Osteogenic differentiation

Extracellular matrix mineralization of hPDLSCs on

scaffolds following 14 days of osteogenic induction is demonstrated

in Fig. 6A. Markedly dense red

color in the struts of the 0.5PCL/0.5PLGA scaffolds was observed,

with pale red color on the 0.1PCL/0.9PLGA and 0.9PCL/0.1PLGA

scaffolds. The semi-quantitative analysis (Fig. 6B) demonstrated that hPDLSCs

cultured on the 0.5PCL/0.5PLGA (OD562=0.70±0.07)

scaffolds produced a higher level of deposited calcium compared

with the 0.1PCL/0.9PLGA (OD562=0.58±0.06) and

0.9PCL/0.1PLGA (OD562=0.42±0.04) scaffolds

(P<0.05).

ALP activity was determined to assess the early

osteogenic capacity of the hPDLSCs on the scaffolds (Fig. 6C). The overall ALP activity of the

hPDLSCs on the 0.5PCL/0.5PLGA surface was significantly higher

compared with the other two groups on day 7 and day 14 (P<0.05),

apart from no significant difference compared with 0.1PCL/0.9PLGA

on day 14.

The expression of osteogenic biomarkers of hPDLSCs

on scaffolds was detected using a qPCR (Fig. 6D-F). Overall, the mRNA expression

of ALP and RUNX2 was higher on day 14 compared with on day 7, while

the expression of OCN mRNA demonstrated the opposite trend.

Following culturing for 7 days, the OCN and RUNX2 mRNA expression

of the cells grown on the 0.5PCL/0.5PLGA scaffolds was

significantly higher compared with the other two groups

(P<0.05). Additionally, the expression level of ALP mRNA was

significantly higher in the 0.1PCL/0.9PLGA and 0.5PCL/0.5PLGA

groups compared with the 0.9PCL/0.1PLGA group (P<0.05).

Subsequent to 14 days of culture, the mRNA expression of ALP and

RUNX2 were the highest, and the difference between the

0.5PCL/0.5PLGA scaffolds and the 0.9PCL/0.1PLGA scaffolds was

statistically significant (P<0.05).

Discussion

In the present study, PCL/PLGA blended scaffolds

with highly porous interconnected networks were successfully

created using the FDM technique. The topological structure of the

scaffolds directly affects cell activity and tissue regeneration

(25). Karageorgiou and Kaplan

(26) reported that a scaffold

with 300–500 µm pores optimized vascularization, and enhanced cell

adhesion and new tissue integration. Levenberg et al

(27) suggested that the size of

the struts should not exceed 400 µm in any dimension; otherwise, it

may inhibit the O2 diffusion and result in local tissue

hypoxia and necrosis. The pore diameter and the cross-section of

the beam and column of the scaffolds in the present study was 300

µm, suitable for bone regeneration.

Scaffolds should break down at a rate that is

harmonious with the rate of cell growth and tissue maturation

(28). The degradation rate of the

PCL/PLGA scaffolds was adjustable by altering the concentration of

PLGA. The 0.5PCL/0.5PLGA composite scaffold demonstrated an ideal

degradation rate; the degradation of the 0.1PCL/0.9PLGA scaffold

was too fast and the 0.9PCL/0.1PLGA scaffold was too slow. PLGA is

hydrophilic, and hence is able to accelerate the hydrolytic

degradation of hybrid PCL/PLGA (29). However, PLGA had acidic byproducts

during degradation, which may consequently inhibit cell viability

and induce tissue inflammation (30). It was revealed in the present study

that with the proportion of PLGA decreasing, the scaffolds

exhibited fewer acidic byproducts, demonstrating their potential

use in biomedical applications.

Biomaterials are required to allow cell attachment,

which is termed biocompatibility (31). Following cell attachment and

proliferation, the material should break down and be replaced by

the extracellular matrix (32,33).

A previous study indicated that hybrid PCL/PLGA may facilitate the

adhesion and proliferation of stem cells (34). The present data demonstrated that

hPDLSCs on the 0.5PCL/0.5PLGA and 0.1PCL/0.9PLGA scaffolds had a

significantly higher rate of attachment and proliferation compared

with the 0.9PCL/0.1PLGA scaffolds. Furthermore, hPDLSCs on

0.5PCL/0.5PLGA presented a uniform appearance resembling

mesenchymal stem cells and exhibited enhanced cell bridging

following 7 and 14 days of seeding. The differences may be due to

the different roughness and hydrophilicity of the scaffolds

(35).

Additionally, 0.5PCL/0.5PLGA demonstrated a superior

osteogenic capacity compared with the other two scaffolds,

confirmed with higher ALP activity and higher expression of

bone-related markers, including ALP, OCN and RUNX2, consistent with

a previous study reported by Makadia and Siegel (29), who discovered that a PCL/PLGA

composite may induce differentiation of osteoblasts. The promotion

of osteogenic capacity may be due to improved early cell attachment

and proliferation on the 0.5PCL/0.5PLGA scaffold. Cell morphology

may be another reason for osteogenesis, as stretching of cells may

affect intracellular communication and upregulate osteogenic gene

expression (36,37).

Biological behavior is associated with the surface

characteristics of the scaffolds. Generally, scaffolds must possess

adequate roughness, hydrophilicity and specific surface topography,

which are widely accepted to affect cell attachment, proliferation

and differentiation (38,39). The present data revealed that the

surface roughness of composite scaffolds increased with the

increased proportion of PCL. Thapa et al (40) discovered a rougher surface of PCL

compared with PLGA following dissolution and deposition. Other

researchers reported that different surface topographies resulted

from pores with various sizes (5–40 nm) formed on the polymer

surface during the crystallization process following deposition

(41), and the size of pores was

strongly influenced by the polymer blend ratio (42).

Another study suggested that the increased surface

roughness provides a larger surface area, and thus leads to

increased cell adhesion (43).

However, in the present study, early cell attachment and

proliferation did not alter correspondingly with the increase in

surface roughness. This result was in accordance with studies

reported by Liao et al (44) and Deng et al (45). Therefore, superior hPDLSC responses

on the PCL/PLGA scaffolds may be attained by modifying surface

roughness with different ratios of PCL/PLGA.

Surface wettability was additionally responsible for

the cell response on the material. Highly hydrophilic surfaces

facilitate the initial attachment of water molecules, promoting the

adsorption of proteins, including fibronectin (46). Furthermore, hydrophilic surfaces

demonstrate high surface energies and enhanced cell adhesion

(47,48). It was observed that the

hydrophilicity of PLGA/PCL hybrid scaffolds increased with the

higher PLGA ratio, which was positively associated with cell

attachment, viability and differentiation.

In summary, the present study demonstrated that

PCL/PLGA composite scaffolds exhibited good degradation properties,

surface characteristics and cellular activities, demonstrating

potential in alveolar bone restoration, and 0.5PCL/0.5PLGA (w/w)

possessed superior bioactivity. Further studies are required to

examine the in vivo effect in animal models.

Acknowledgements

Not applicable.

Funding

This study was supported by the Natural Science

Foundation of Guangdong Province (China; grant no.

2015A030313083).

Availability of data and materials

The data sets used and/or analyzed during the

current study are available from the corresponding author on

reasonable request.

Authors' contributions

LW, JZ and CP conceived and designed the

experiments. XZ, LD and CP performed the experiments. CP, ZC and DC

analyzed the data. CP drafted the manuscript. CP and LW critically

revised the manuscript.

Ethics approval and consent to

participate

The protocol was approved by the Ethics Committee of

the Hospital of Stomatology, Sun Yat-sen University (Guangzhou,

China; approval no. PKUSSIRB-201311103). Informed consent from each

patient was obtained.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Asa'ad F, Pagni G, Pilipchuk SP, Gianni

AB, Giannobile WV and Rasperini G: 3D-printed scaffolds and

biomaterials: Review of alveolar bone augmentation and periodontal

regeneration applications. Int J Dent. 2016:12398422016.PubMed/NCBI

|

|

2

|

Teven CM, Fisher S, Ameer GA, He TC and

Reid RR: Biomimetic approaches to complex craniofacial defects. Ann

Maxillofac Surg. 5:4–13. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Sheikh Z, Hamdan N, Ikeda Y, Grynpas M,

Ganss B and Glogauer M: Natural graft tissues and synthetic

biomaterials for periodontal and alveolar bone reconstructive

applications: A review. Biomater Res. 21:92017. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Obregon F, Vaquette C, Ivanovski S,

Hutmacher DW and Bertassoni LE: Three-dimensional bioprinting for

regenerative dentistry and craniofacial tissue engineering. J Dent

Res. 94 9 Suppl:143S–152S. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Hung BP, Naved BA, Nyberg EL, Dias M,

Holmes CA, Elisseeff JH, Dorafshar AH and Grayson WL:

Three-dimensional printing of bone extracellular matrix for

craniofacial regeneration. ACS Biomater Sci Eng. 2:1806–1816. 2016.

View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Lu T, Li Y and Chen T: Techniques for

fabrication and construction of three-dimensional scaffolds for

tissue engineering. Int J Nanomedicine. 8:337–350. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Nyberg EL, Farris AL, Hung BP, Dias M,

Garcia JR, Dorafshar AH and Grayson WL: 3D-printing technologies

for craniofacial rehabilitation, reconstruction, and regeneration.

Ann Biomed Eng. 45:45–57. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Chia HN and Wu BM: Recent advances in 3D

printing of biomaterials. J Biol Eng. 9:42015. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Rasperini G, Pilipchuk SP, Flanagan CL,

Park CH, Pagni G, Hollister SJ and Giannobile WV: 3D-printed

bioresorbable scaffold for periodontal repair. J Dent Res. 942 9

Supp:153S–157S. 2015. View Article : Google Scholar

|

|

10

|

Chou SF and Woodrow KA: Relationships

between mechanical properties and drug release from electrospun

fibers of PCL and PLGA blends. J Mech Behav Biomed Mater.

65:724–733. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Li X, Yang C, Li L, Xiong J, Xie L, Yang

B, Yu M, Feng L, Jiang Z, Guo W and Tian W: A therapeutic strategy

for spinal cord defect: Human dental follicle cells combined with

aligned PCL/PLGA electrospun material. Biomed Res Int.

2015:1971832015.PubMed/NCBI

|

|

12

|

Jensen T, Blanchette A, Vadasz S, Dave A,

Canfarotta M, Sayej WN and Finck C: Biomimetic and synthetic

esophageal tissue engineering. Biomaterials. 57:133–141. 2015.

View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Zong C, Wang M, Yang F, Chen G, Chen J,

Tang Z, Liu Q, Gao C, Ma L and Wang J: A novel therapy strategy for

bile duct repair using tissue engineering technique: PCL/PLGA

bilayered scaffold with hMSCs. J Tissue Eng Regen Med. 11:966–976.

2017. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Trajano VCC, Costa KJR, Lanza CRM,

Sinisterra RD and Cortes ME: Osteogenic activity of

cyclodextrin-encapsulated doxycycline in a calcium phosphate PCL

and PLGA composite. Mater Sci Eng C Mater Biol Appl. 64:370–375.

2016. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Franco RA, Nguyen TH and Lee BT:

Preparation and characterization of electrospun PCL/PLGA membranes

and chitosan/gelatin hydrogels for skin bioengineering

applications. J Mater Sci Mater Med. 22:2207–2218. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Baker SC, Rohman G, Southgate J and

Cameron NR: The relationship between the mechanical properties and

cell behaviour on PLGA and PCL scaffolds for bladder tissue

engineering. Biomaterials. 30:1321–1328. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Subramanian A, Krishnan UM and Sethuraman

S: Fabrication, characterization and in vitro evaluation of aligned

PLGA-PCL nanofibers for neural regeneration. Ann Biomed Eng.

40:2098–2110. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Qian Y, Chen H, Xu Y, Yang J, Zhou X,

Zhang F and Gu N: The preosteoblast response of electrospinning

PLGA/PCL nanofibers: Effects of biomimetic architecture and

collagen I. Int J Nanomedicine. 11:4157–4171. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Mrozik K, Gronthos S, Shi S and Bartold

PM: A method to isolate, purify, and characterize human periodontal

ligament stem cells. Methods Mol Biol. 666:269–284. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Zhu W and Liang M: Periodontal ligament

stem cells: Current status, concerns, and future prospects. Stem

Cells Int. 2015:9723132015. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Cha Y, Jeon M, Lee HS, Kim S, Kim SO, Lee

JH and Song JS: Effects of in vitro osteogenic induction on in vivo

tissue regeneration by dental pulp and periodontal ligament stem

cells. J Endod. 41:1462–1468. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Moshaverinia A, Xu X, Chen C, Ansari S,

Zadeh HH, Snead ML and Shi S: Application of stem cells derived

from the periodontal ligament or gingival tissue sources for tendon

tissue regeneration. Biomaterials. 35:2642–2650. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Zhang H, Liu S, Zhu B, Xu Q, Ding Y and

Jin Y: Composite cell sheet for periodontal regeneration: Crosstalk

between different types of MSCs in cell sheet facilitates complex

periodontal-like tissue regeneration. Stem Cell Res Ther.

7:1682016. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Livak KJ and Schmittgen TD: Analysis of

relative gene expression data using real-time quantitative PCR and

the 2(-Delta Delta C(T)) method. Methods. 25:402–408. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Bruzauskaite I, Bironaite D, Bagdonas E

and Bernotiene E: Scaffolds and cells for tissue regeneration:

Different scaffold pore sizes-different cell effects.

Cytotechnology. 68:355–369. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Karageorgiou V and Kaplan D: Porosity of

3D biomaterial scaffolds and osteogenesis. Biomaterials.

26:5474–5491. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Levenberg S, Rouwkema J, Macdonald M,

Garfein ES, Kohane DS, Darland DC, Marini R, van Blitterswijk CA,

Mulligan RC, D'Amore PA and Langer R: Engineering vascularized

skeletal muscle tissue. Nat Biotechnol. 23:879–884. 2005.

View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Osorio R, Alfonso-Rodriguez CA, Osorio E,

Medina-Castillo AL, Alaminos M, Toledano-Osorio M and Toledano M:

Novel potential scaffold for periodontal tissue engineering. Clin

Oral Investig. 21:2695–2707. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Makadia HK and Siegel SJ: Poly

Lactic-co-glycolic acid (PLGA) as biodegradable controlled drug

delivery carrier. Polymers (Basel). 3:1377–1397. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Rhee SH and Lee SJ: Effect of acidic

degradation products of poly(lactic-co-glycolic)acid on the

apatite-forming ability of poly(lactic-co-glycolic)acid-siloxane

nanohybrid material. J Biomed Mater Res A. 83:799–805. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Prakasam M, Locs J, Salma-Ancane K, Loca

D, Largeteau A and Berzina-Cimdina L: Biodegradable materials and

metallic Implants-a review. J Funct Biomater. 8:pii: E44. 2017.

View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Pulyala P, Singh A, Dias-Netipanyj MF,

Cogo SC, Santos LS, Soares P, Gopal V, Suganthan V, Manivasagam G

and Popat KC: In-vitro cell adhesion and proliferation of adipose

derived stem cell on hydroxyapatite composite surfaces. Mater Sci

Eng C Mater Biol Appl. 75:1305–1316. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

He HY, Zhang JY, Mi X, Hu Y and Gu XY:

Rapid prototyping for tissue-engineered bone scaffold by 3D

printing and biocompatibility study. Int J Clin Exp Med.

8:11777–11785. 2015.PubMed/NCBI

|

|

34

|

Sa M and Kim JY: Effect of various

blending ratios on the cell characteristics of PCL and PLGA

scaffolds fabricated by polymer deposition system. Int J Precis Eng

Man1. 4:649–655. 2013. View Article : Google Scholar

|

|

35

|

Shahrousvand M, Sadeghi GMM, Shahrousvand

E, Ghollasi M and Salimi A: Superficial physicochemical properties

of polyurethane biomaterials as osteogenic regulators in human

mesenchymal stem cells fates. Colloids Surf B Biointerfaces.

156:292–304. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Folkman J and Moscona A: Role of cell

shape in growth control. Nature. 273:345–349. 1978. View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Uzer G, Pongkitwitoon S, Chan Ete M and

Judex S: Vibration induced osteogenic commitment of mesenchymal

stem cells is enhanced by cytoskeletal remodeling but not fluid

shear. J Biomech. 46:2296–2302. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

38

|

Mathieu PS and Loboa EG: Cytoskeletal and

focal adhesion influences on mesenchymal stem cell shape,

mechanical properties, and differentiation down osteogenic,

adipogenic, and chondrogenic pathways. Tissue Eng Part B Rev.

18:436–444. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

39

|

Fu Y, Liu S, Cui SJ, Kou XX, Wang XD, Liu

XM, Sun Y, Wang GN, Liu Y and Zhou YH: Surface chemistry of

nanoscale mineralized collagen regulates periodontal ligament stem

cell fate. ACS Appl Mater Interfaces. 8:15958–15966. 2016.

View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Thapa A, Webster TJ and Haberstroh KM:

Polymers with nano-dimensional surface features enhance bladder

smooth muscle cell adhesion. J Biomed Mater Res A. 67:1374–1383.

2003. View Article : Google Scholar : PubMed/NCBI

|

|

41

|

Karagkiozaki V, Vavoulidis E,

Karagiannidis PG, Gioti M, Fatouros DG, Vizirianakis IS and

Logothetidis S: Development of a nanoporous and multilayer

drug-delivery platform for medical implants. Int J Nanomedicine.

7:5327–5338. 2012.PubMed/NCBI

|

|

42

|

Affrossman S, Henn G, O'Neill S, Pethrick

P and Stamm M: Surface topography and composition of deuterated

polystyrene-poly (bromostyrene) blends. Macromolecules.

29:5010–5016. 1996. View Article : Google Scholar

|

|

43

|

Baker BM, Trappmann B, Wang WY, Sakar MS,

Kim IL, Shenoy VB, Burdick JA and Chen CS: Cell-mediated fibre

recruitment drives extracellular matrix mechanosensing in

engineered fibrillar microenvironments. Nat Mater. 14:1262–1268.

2015. View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Liao J, Wei Q, Zou Y, Fan J, Song D, Cui

J, Zhang W, Zhu Y, Ma C, Hu X, et al: Notch signaling augments

BMP9-induced bone formation by promoting the

osteogenesis-angiogenesis coupling process in mesenchymal stem

cells (MSCs). Cell Physiol Biochem. 41:1905–1923. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

45

|

Deng Y, Liu X, Xu A, Wang L, Luo Z, Zheng

Y, Deng F, Wei J, Tang Z and Wei S: Effect of surface roughness on

osteogenesis in vitro and osseointegration in vivo of carbon

fiber-reinforced polyetheretherketone-nanohydroxyapatite composite.

Int J Nanomedicine. 10:1425–1447. 2015.PubMed/NCBI

|

|

46

|

Spriano S, Chandra Sarath V, Cochis A,

Uberti F, Rimondini L, Bertone E, Vitale A, Scolaro C, Ferrari M,

Cirisano F, et al: How do wettability, zeta potential and

hydroxylation degree affect the biological response of

biomaterials? Mater Sci Eng C Mater Biol Appl. 74:542–555. 2017.

View Article : Google Scholar : PubMed/NCBI

|

|

47

|

Ranella A, Barberoglou M, Bakogianni S,

Fotakis C and Stratakis E: Tuning cell adhesion by controlling the

roughness and wettability of 3D micro/nano silicon structures. Acta

Biomater. 6:2711–2720. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

48

|

Zhao G, Schwartz Z, Wieland M, Rupp F,

Geis-Gerstorfer J, Cochran DL and Boyan BD: High surface energy

enhances cell response to titanium substrate microstructure. J

Biomed Mater Res A. 74:49–58. 2005. View Article : Google Scholar : PubMed/NCBI

|