Introduction

Additive manufacturing (AM) has become integral to

modern rapid prototyping. Based on computer-aided design (CAD), AM

uses layer-based manufacturing technology to directly produce end

products (1,2). In medicine, by utilizing digital

slicing of CAD, a 3D scan (generated by Mimics or InVesalius

software programs) and microcomputed tomography (µCT) data, AM

enables direct fabrication of customized biological models for

various clinical applications (3,4). These

biological models can be used in disease diagnosis, surgical

planning, clinical teaching and patient communication (5,6). The

process of AM is continuously evolving with advances in the design

and manufacturing of customized implants according to patient needs

(7). AM provides a bridge that

transfers the simulated surgical plan accurately to the surgical

site. Therefore, high accuracy, and efficiency in planning and

execution of surgical procedures are achieved (8–10). There

are >20 individual AM processes, which vary in their method of

layering and manufacturing (1,2). Among

these processes, both selective laser melting and electron-beam

melting (EBM) have been extensively developed and improved upon for

fabrication of surgical metal implants in various clinical settings

(11,12).

Metallic biomaterials, such as 316L stainless steel,

cobalt-chromium-based alloy and titanium, have been used

extensively in manufacturing of surgical implants (13). In contrast to other biocompatible

metals, titanium has improved fatigue resistance and a modulus of

elasticity comparable to bone (14).

Ti6AI4V extra low interstitial (ELI) is an α-β alloy containing 6%

aluminum and 4% vanadium. Controlled interstitial element levels

are designated as an ELI; hence the designation Ti6Al-4V ELI

(15,16). Ti6Al-4V ELI is one of the most widely

used titanium alloys in the production of surgical implants

(17). A previous study has shown

that Ti6AI4V ELI exhibits a number of advantages compared with pure

titanium, including higher tensile strength and improved fatigue

resistance (14). Furthermore,

Ti6AI4V ELI has improved tensile strength, suitable stiffness, a

high degree of resistance to corrosion and an enhanced porous

structure that possesses excellent mechanical properties similar to

those of human bone (18).

Considerable research efforts have been undertaken to evaluate the

biocompatibility of Ti6AI4V ELI using EBM (Ti6AI4V ELI EBM) in the

physiological environment (19,20).

Ti6AI4V ELI EBM exhibits promise for fabrication of hip joints and

knee joints for use clinically (21,22).

The mandible is the largest bone in the human skull,

and it holds the lower teeth in place, assists in mastication and

forms the lower jawline (23). The

mandible is composed of the body and the ramus, and is located

inferior to the maxilla. The body is the horizontally curved

portion that creates the lower jawline (24). Mandibular defects caused by

inflammation, trauma and maxillofacial tumors can cause

dysfunctions in chewing and facial deformities, and may severely

affect a patient's quality of life (25). Due to various sizes of defects and

the effect of radiation therapy (in case of cancer treatment) on

the blood supply of the surrounding tissues, the repair and

reconstruction of mandibular defects has always been a challenging

task for surgeons (26). With the

development of modern medicine, significant progress has been made

in the reconstruction of mandibular defects. At present, there are

a variety of repair methods, including commercial reconstruction

titanium plates (for example the Stryker Leibinger universal

system), non-vascularized autogenous bone grafts, pedicled bone

grafts and vascularized fibula free grafts (27,28);

however, the existing repair methods often do not perfectly restore

the continuity and integrity of the mandible, which may result in a

second trauma (29). Using digital

medical imaging technology and metal 3D printing technology,

according to CT scan data of patients, porous titanium alloy bone

tissue substitute materials that are similar in shape, size and

weight to the bone defect area can be designed and manufactured to

achieve personalized repair and reconstruction of bone defects

(30). At present, this technology

has been applied in the field of hip, knee, spine and skull

reconstruction (31,32); however, to the best of our knowledge,

there are limited studies reporting its use in oral and

maxillofacial defects (33). The

present study included 4 patients with individualized titanium

alloy implants and the outcomes were compared with 16 patients who

received traditional reconstructed titanium plates and vascularized

fibula free flaps through a retrospective controlled study. The

conclusion of the present study may provide clinicians with a

powerful design and manufacturing technique, to improve the

availability of implantable mandibular solutions that overcome the

shortcomings of typical fixation plate-based treatment options,

thereby improving overall patient outcomes.

Materials and methods

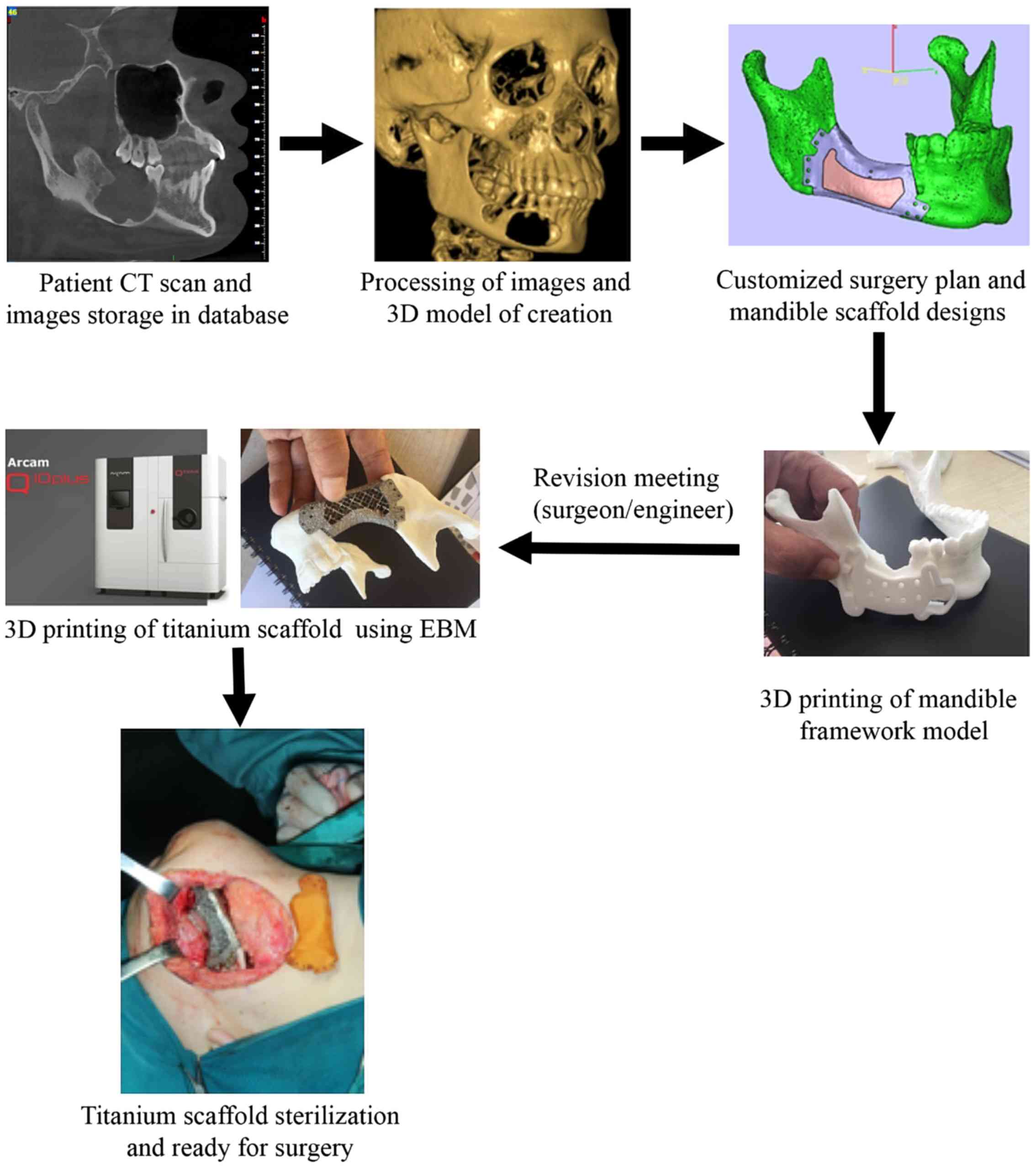

Workflow

The workflow of reconstruction of mandibular

discontinuity using AM technology consisted of several stages: i)

3D digital imaging; ii) data transfer; iii) processing and

segmentation; iv) evaluation of design; and v) AM model production

and evaluation. In the present study, pre-operative preparations,

surgical procedures and post-operative treatment outcomes were

compared among patients who received mandibular reconstruction

using a customized 3D titanium implant, and two other conventional

approaches; titanium reconstruction plates and vascularized

autologous fibular grafting (Fig.

1).

Selection criteria

The present study included patients with mandibular

defects caused by non-malignant tumors. These tumors have a clear

invasive pattern and margin, and radical therapy is recommended,

which has high immediate cure success rates (34). Furthermore, patients who did not

exhibit tumor recurrence within 1 year of surgery and did not

receive radiation therapy were also included. Cases with any

condition of uncontrolled inflammation were excluded. The surgical

outcome in the prospective cohort of patients was compared with the

retrospective cohort of patients who received mandibular

reconstruction using two other conventional approaches: Titanium

plates or vascularized autologous fibular grafting. The same

inclusion and exclusion criteria were also applied to the

retrospective cohort cases. The surgical pathology database from

Stomatological Hospital of Jiangsu was searched for reported cases

of benign oral tumors between January 2014 and February 2017. A

total of 16 retrospective cases were identified and follow-up time

periods were recorded (Table SI).

Among these retrospective cases, 6 patients received implantation

of titanium plates, and 10 patients received vascularized

autologous fibular grafting. All patients underwent mandibular

reconstruction, and their patient files containing pre- and

post-operative µCT scans were reviewed. All patients were

introduced different types of implants including advantages and

disadvantages for each type. The treatment was based on the

patient's preference after consultation with surgeons.

Written informed consent for participation in the

study was obtained from participants according to the policy of the

Stomatological Hospital of Jiangsu Ethical Review Board, and the

data were anonymized for analysis and research publication. The

present study was approved by the Stomatological Hospital of

Jiangsu Ethical Review Board (approval no. PJ2016-003-01).

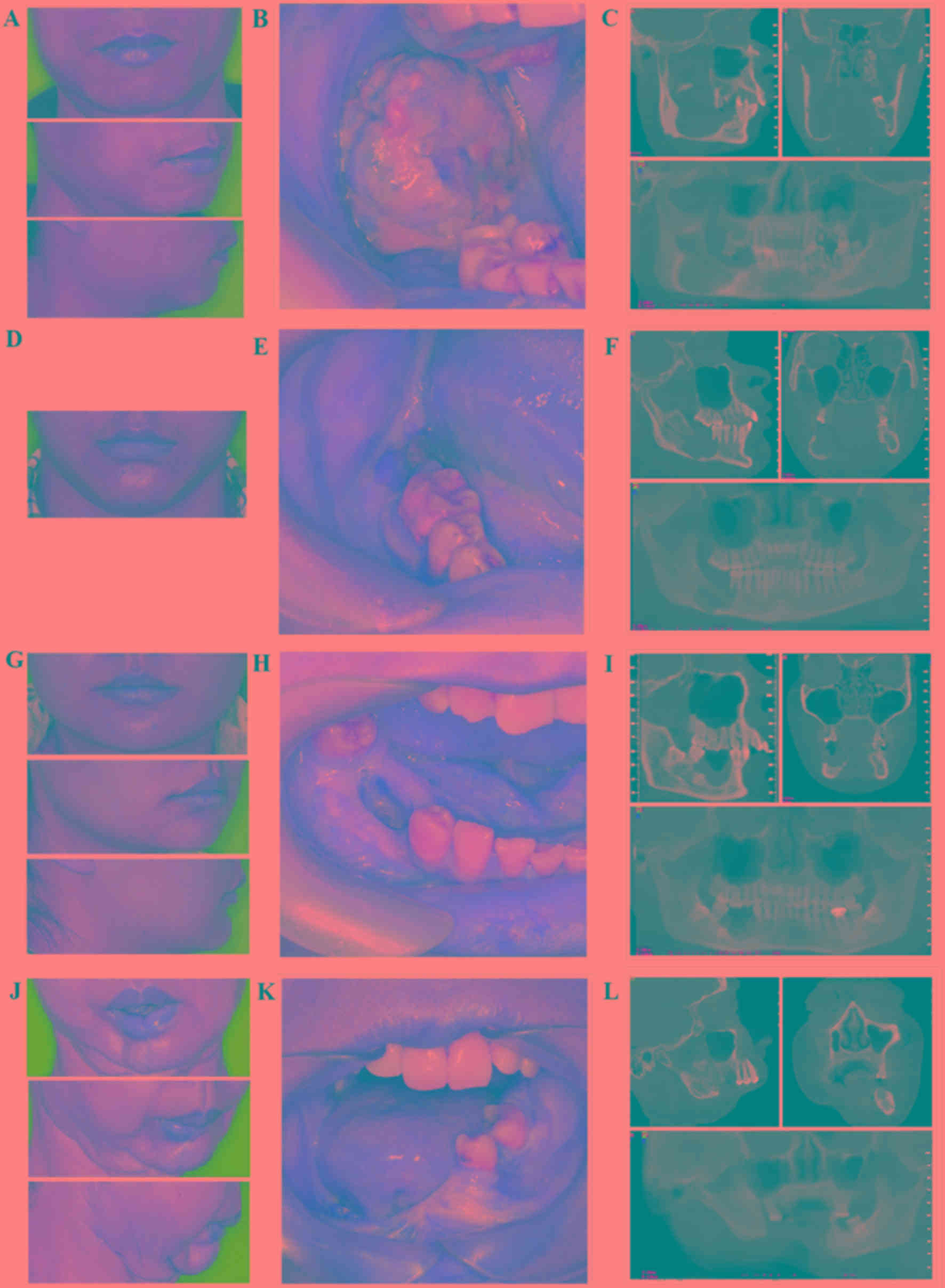

Patient information

A total of 4 patients (mean age, 33 years; age

range, 21–50 years) were recruited prospectively at The Affiliated

Hospital of Stomatology of Nanjing Medical University (Nanjing,

China) between March 2016 and March 2017. The patients included 2

men and 1 woman who developed recurring ameloblastoma, and another

woman who was diagnosed with squamous cell carcinoma. According to

the classification scheme proposed by Urken et al (35), the 2 males were classified as having

a ‘RB’ mandibular defect, 1 female was classified as having a ‘BS’

mandibular defect, and the other female was classified as having a

‘BSS’ mandibular defect. Based on CT scans, the 2 male cases

exhibited local invasion in the lower mandibular ridge and the

buccal, and the lingual walls were notably resorbed (Fig. 2A and B). The tumors had spread to the

anterior mandibular ascending branch and the soft tissue of the

posterior molar. The treatment plans included a combination of

mandibular segmental resection and reconstruction following tumor

removal. In the case of the female patient with recurring

ameloblastoma, the tumor had spread to the mandibular canal, and

the treatment plan included a mandibular osteotomy preserving the

lower mandibular ridge (Fig. 2C).

The female case with squamous cell carcinoma involved large

segmental defects within the jaw due to invasion by the gingival

squamous cell carcinoma (Fig. 2D).

No tumor recurrences were observed within 1 year after surgery, and

therefore this patient was recommended for customized titanium

mandibular implantation.

In the present study, the four prospective patients

who received customized titanium implants were included in group A

(Table SI). Of the remaining cases

that were analyzed retrospectively, 6 cases underwent titanium

plate implantation and were included in group B, and 10 cases

underwent vascularized autologous fibular grafting and were

included in group C (Fig. S1 and

Table SI). Group B included 3 males

and 3 females, and the age range was 18–77 years, with a mean age

of 41.5 years. Group C consisted of 8 males and 2 females, and the

age range was 19–65 years, with a mean age of 36.8 years. The

breakdown of the benign oral tumor subtypes is presented in

Figure S1 nad Table SI. Among all cases, mandibular

ameloblastoma was the most common subtype (14 cases), followed by

osteofibroma (2 cases), keratocystic odontogenic tumor (2 cases),

mandibular cyst (1 case), and squamous cell carcinoma (1 case). The

diagnosis of benign oral tumor was confirmed in each case.

3D medical imaging acquisition

Full 3D digital dental models were obtained using

integrating cone-beam computed tomography (CBCT; NewTom VG, SRL

Company). These data were handled, stored and transmitted according

to the standards of Digital Imaging and Communications in Medicine

(36). The geometric data obtained

from the CBCT scans were imported into medical image processing

software, including Materialise's interactive medical image control

system (Mimics®; version 15.0; Materialise) and

Analyze® (Mayo Foundation). Using Mimics®, a

3D digital anatomical model comprising the patient's mandible was

constructed by imaging processing and segmentation. This was

followed by construction of a triangular model of bone structure

from the volume data by performing a series of computed steps,

including region growing, mask formation and 3D model calculation.

The anatomical region of mandibular defects was isolated from the

entire data, and the selected bone structure was imported and

processed using Unigraphics NX (version 10.0; Siemens AG) or

Solidworks (version 2014; Dassault Systèmes) for prosthesis design,

including refinement of the internal porous structures and the

patient-specific 3D mesh structure through topology optimization.

The position and model of the personalized implant was designed and

determined according to the patient's mandible and occlusion

defects. Furthermore, the surgical guide was customized and refined

for each reconstruction. After the corresponding stereolithography

(STL) file was generated, the obtained STL file was imported into

Magics (version 20; Materialize) for data error fixing, positing

the part in the build envelop, and for creating the scaffold and

slicing. Finally, the corrected STL file was sent for production of

implants using Ti6AL4V ELI (Arcam AB; model 2016), which meets the

national standards GB/T 13810 of titanium alloy for surgical

implants in China. The implants were produced by Beijing Aikang

Co., Ltd., and were casted in titanium alloy according to the

design of position during printing. (Fig. 3) The entire design and manufacturing

process of personalized porous titanium alloy implant took ~3

weeks.

Surgery

All patients received pre-operative antiseptic oral

rinsing and treatment was maintained with intravenous antibiotics

(Cefazolin Sodium Pentahydrate Inj Pwd F/Sol; 1 g). For patients in

group A (Figs. 4 and 5), customized titanium implants were

designed using computer-aided software and constructed using an EBM

system (37). Prior to surgery, the

titanium implants were cleaned using ultrasonic vibration and then

sterilized using high temperature steam. During the operation,

osteotomy was performed according to the surgical guide, which

controlled the position and direction of resection. Segmental

resection of the mandible including the benign tumor was removed.

After the customized titanium plate was inserted and fixed with 4–8

titanium screws (10-mm; Stryker Leibinger GmbH & Co.), the oral

tissues were stitched back into place using dissolvable stitches.

Patients received antibiotics after surgery [Cefoxitin, 1 g,

intravenously (i.v.), once a day for 5 days]. For patients in group

B, the mandibulectomy area was measured and confirmed based on µCT

images. The sterilized titanium reconstruction plate was pre-bent

to fit the resected mandible. After the benign tumor was removed,

the prebent titanium reconstruction plate was fixed on residual

bone using 3–4 titanium screws on each side. Patients received

antibiotics after surgery as aforementioned. For patients in group

C, the defects were confirmed by µCT scans. A two-team approach was

used for the surgery; one team focused on resection of the benign

tumor; the other team focused on mandibular reconstruction using

vascularized free fibular flap grafting. Harvesting and contouring

of the fibula free flap took ~120 min. The modelled fibula flap was

placed between the mandibular stumps and fixed to the titanium

plate with multiple screws. Finally, the micro-anastomoses were

constructed and the skin was sutured into its definitive position.

Patients received immediate post-operative special care

(Ceftriaxone, 1 g, IV, once a day for 5 days; Ornidazole, 0.5 g,

IV, twice a day for 3 days) with anti-inflammatory (dexamethasone

sodium phosphate injection, 10 mg, i.v., once a day for 3 days) and

anti-coagulant medications (hemocoagulase injection, 1 KU,

intramuscular injection, once a day for 3 days).

Post-operative outcome assessment

The main clinical outcome was evaluated using

assessment scale and measures referring to the EORTC

QLQ-C30/QLQ-H&N35 questionnaires (38,39), and

the University of Washington Quality of Life questionnaire

(40,41). The items related to head and neck

tumors were selected, and modified to the specific situation to

formulate the prognostic evaluation form (Table SII). The questionnaire contained

seven categories: Facial appearance, occlusal force and chewing,

pain [as determined by verbal rating scale (42)], opening degree, speech,

swallowing/eating and mentality. Each category was given a score.

The total score of seven categories ranged between 7–28, and was

subsequently divided into 4 grades. Higher scores corresponded to

worse symptoms and, consequently, a worse quality of life. The

prognosis was classified into one of four grades (grade I–IV).

Briefly, grade I (score 7–12) was characterized as satisfied facial

appearance, balanced mandibular contour symmetry, normal occlusal

force and chewing efficiency, no temporomandibular joint related

pain and normal maximum mouth opening. Grade II (score 13–17) was

characterized as slightly unilateral facial depression or bulging,

restored occlusal function with chewing efficiency of 60–80%, mild

temporomandibular joint related pain, two finger mouth opening, and

slight difficulty to communicate, eat and socialize. Grade III

(score 18–22) was characterized as unilateral facial asymmetry with

obvious depression or bulging, implant fracture, reduced occlusal

force with chewing efficiency of 40–60%, one finger mouth opening

and a high degree of masticatory difficulty, and difficulty to

communicate, eat and socialize. Grade IV (score 23–28) was

characterized as extreme facial asymmetry with significant

depression or bulging, significantly reduced occlusal force

associated with <40% chewing efficiency, severe pain, severely

limited mouth opening, and considerable difficulty communicating,

eating and socializing, implant removal due to post-operative

infection, implant loosening and tumor recurrence. Patients with a

total score between 7 and 12 were classified as grade I (best

outcome); patients with a total score between 13 and 17 were

classified as grade II; patients with a score between 18 and 22

were classified as grade III; and patients with a total score of 23

and 28 were classified as grade IV (the worst outcome).

Statistical analysis

Associations between groups were analyzed using SPSS

version software 19.0 (IBM Corp.). The post-operative outcomes

among group A, B and C were scored according to prognostic

evaluation (Table SII) and analyzed

using Kruskal-Wallis H non-parametric test followed by Dunn's test

for intergroup comparisons. P<0.05 was considered to indicate a

statistically significant difference.

Results

In group A, mandibular defects were repaired using

customized titanium implants in patients. The mean operative time

of group A was ~130 min (range, 90–160 min), and the mean length of

follow-up was 12 months (range, 3–19 months). In group A, all

patients had post-operative µCT scans verifying the accuracy of

positioning of customized titanium implants and complete tumor

removal (Fig. 4). The continuity of

the mandible of all 4 patients was restored (Fig. 4). Furthermore, they almost fully

recovered the ability to ingest the same foodstuffs they were able

to ingest prior to surgery, along with normal maximum mouth opening

(25–40 mm) (Fig. 5). Among these 4

patients, 2 males and 1 female had good postoperative dental

restoration (Fig. 5). One female

(case 4) had a significantly shorter follow-up time. This female

patient had a smaller range of maximum opening range due to scar

formation from a previous operation, but the continuity of the

mandibula was restored, and the patient was satisfied with their

facial appearance (Fig. 5). Overall,

postoperative dental rehabilitation was completed with satisfactory

results in all patients in group A. No tumor recurrences were

observed.

According to the criteria on facial appearance,

occlusal force and chewing, pain, opening degree, speech,

swallowing/eating and mentality, the prognosis was classified into

four different grades (Table SII).

Group A patients had improved post-operative outcomes compared with

both groups B and C (Table I). In

group A (n=4), 3 patients were grade I and 1 patient was grade II;

however, groups B and C rarely obtained a grade I clinical outcome

score (Table I). In group B (n=6), 3

patients were grade II, 2 patients were grade III and 1 patient was

grade IV. In group C (n=10), 1 patient was grade I, 5 patients were

grade II, 3 patients were grade III and 1 patient was grade IV. The

outcomes among groups A, B and C were analyzed using Kruskal-Wallis

H non-parametric test, which revealed that post-operative treatment

outcomes were significantly different among the three groups

(P=0.033). Subsequently, the outcomes were compared between two

groups by Dunn's test (Table II).

This demonstrated that operative treatment outcomes were

significantly different between groups A and B (P=0.0191), and

between groups A and C (P=0.0378). However, no significant

difference was identified between groups B and C (P=0.873).

| Table I.Summary and analysis of

post-operative outcomes among group A, B and C. |

Table I.

Summary and analysis of

post-operative outcomes among group A, B and C.

|

| Four-grade clinical

outcome |

|---|

|

|

|

|---|

| Group | I | II | III | IV |

|---|

| A | 3 | 1 | 0 | 0 |

| B | 0 | 3 | 2 | 1 |

| C | 1 | 5 | 3 | 1 |

|

| Total | 4 | 8 | 5 | 2 |

| Table II.Statistical analysis of the

post-operative outcomes among groups A, B and C. |

Table II.

Statistical analysis of the

post-operative outcomes among groups A, B and C.

| Group | A | B | C |

|---|

| B | 0.0191 | NA | NA |

| C | 0.0378 | 0.873 | NA |

In summary, patients who underwent mandibular

reconstruction using a customized titanium implant exhibited

improved mandibular contour symmetry, restored occlusal function, a

normal range of mouth opening and no temporomandibular joint

related pain (Table SIII). This was

in contrast to the increased risk of unilateral facial asymmetry,

limited mouth opening, decreased chewing function as well as

implant loosening observed in patients who received one of the

other two conventional approaches (Table SIII).

Discussion

The mandible serves a critical role in several

physiological aspects, including craniofacial growth and

development, mastication, swallowing and breathing (23). Accurate mandibular reconstruction has

always been a challenge (43).

Mandibular defects may result from radioactive osteonecrosis,

trauma, inflammation, oral cavity carcinoma and cysts. The

reconstruction of mandibular defects following surgical extirpation

of oral cavity carcinoma accounts for 80% of clinical cases

(40,41). The goals of mandibular reconstruction

are re-establishment of mandibular continuity and completeness,

correction of mandibular deformity and restoration of mandibular

functions (44). Current trends in

mandibular reconstruction with modern medical applications aim to

take into consideration several factors, including accurate

reconstruction of the normal anatomy, the degree of occlusion and

proper biomechanical compatibility with the surrounding bone

tissues (45).

The use of titanium plates in mandibular

reconstruction has been widely implemented (46–48). The

primary advantages of this approach are: i) Lower-complexity

surgical procedures; ii) reduced fatigue of the metal; and iii)

improved adaptation of reconstruction plates (49,50).

However, disadvantages include, decreased rigidity and fracturing

of titanium plates (51,52). Furthermore, if any radiotherapy

patient has inadequate soft tissue coverage over the operative

site, the individual may be at high-risk for plate protrusion and

thus infection, requiring removal of implant and thus surgical

failure (51,53). Although titanium plate systems for

maxillofacial surgery are currently available from several

different manufacturers, the choice of systems from various

manufacturers always results in differences in clinical outcome.

Several of the placed titanium implants later negatively influence

denture repair (54). Autologous

bone grafting can be categorized as non-vascularized and

vascularized. Non-vascularized autologous bone grafting is less

demanding, less invasive and has fewer common complications

(55–57). However, the major limitation of this

approach is that the implant has no blood supply of its own, which

is followed by severe graft resorption. A notable reduction in bony

height further complicates predictable implant rehabilitation

(58). Furthermore, the bone graft

is avascular making it susceptible to delayed union and infection,

and may result in permanent damage to soft tissues thereby

increasing the chances of failure in patients (59,60). By

contrast, vascularized autologous bone grafting overcomes these

limitations by virtue of its inherent own vasculature and can be

harvested with soft tissues (61).

This explains the increased popularity of vascularized autologous

bone grafting as the standard option (62). Multiple reconstructive options have

emerged for mandibular reconstruction, including iliac crest, rib

and fibula (63). The fibula was

first utilized by Hidalgo et al (64) for mandibular reconstruction in 1989.

Compared with other options, the fibula has gained widespread use,

owing to its versatility by offering great length and thickness of

bone, intraosseous and segmental blood supply, and reliable skin

paddle for simultaneous soft tissue reconstruction (65,66).

Therefore, the use of the fibula for mandibular reconstruction is

well accepted among numerous oral maxillofacial surgeons (62). However, despite its merits,

harvesting and contouring of the fibula demands tremendous skill

and expertise. Furthermore, post-operative facial symmetry is an

important aesthetic aspect, which is very difficult to achieve

(67). Previous studies have

reported that harvesting the fibula increases the risk of

donor-site morbidity, and lowers walking endurance in the

short-term and decrease the ability to do strenuous activity in the

long-term (68,69). Certain patients may also experience

mild lameness, and the loss of bony height always results in

notable challenges to post-operative denture restoration (70). Although there have been some

successes, tissue engineering is not yet ready for mandibular

reconstruction in terms of clinical outcomes. Current obstacles

remain to develop an ideal biocompatible bone repair scaffold that

possesses suitable microstructure. Natural biological materials,

such as chitosan-fibrin and hydroxyapatite, possess excellent cell

adhesion and growth support properties (71,72).

However, these polymers lack mechanical strength and physical

stability, which limit their application in reconstruction of

load-bearing areas of the mandible, and are thus likely to result

in the implant failure (70).

Recent advances in digital imaging and CAD have made

it possible to create customized 3D models from medical images

(73). AM technology, also known as

3D printing, allows the use of patient-specific digital models to

manufacture anatomically-specific 3D mesh titanium scaffolds for

the reconstruction of mandibular defects (74). AM technology offers a new level of

control over the architecture of porosity and hardness of titanium

to match the Young's modulus to that of the bone tissue. As a

result, the resulting titanium product has improved

stress-shielding effects, which may stimulate osteogenesis, thereby

significantly enhancing implant-bone interface stability and

reducing the risk of implant loosening (75). Furthermore, titanium with microporous

structure allows better cell adhesion and increased bone in-growth

to achieve biological fixation (76). 3D printing can build complex porous

features inside the implant to enhance biocompatibility (77), and allows the clinician the

capability to design these implants to aesthetically enhance the

cosmetic outcome. Indeed, improved post-operative denture

restoration was observed in patients with customized mandibular

implants in the present study. When compared with other

conventional approaches, the operative time was reduced. Among all

the treatment groups, group A were the most satisfied in regard to

their facial symmetry, and exhibited the most improved maximum

mouth opening and occlusal function. Furthermore, high-precision 3D

printed titanium alloy implants can be quickly positioned and fixed

during surgery, instead of applying traditional finished

reconstructed titanium plates to repair, it takes less time during

the operation to bend to fit the mandible ends and restore

maxillofacial appearance. Overall, in contrast to other treatment

options, patients who received the customized titanium implant

showed improved post-operative life quality.

The strength of AM technology lies in the areas

where traditional implantation approaches are limited, including

personalization. However, customized implants should be designed

with exacting parameters, which require high-resolution imaging

techniques to optimize the bone-to-implant interface. The design

and manufacture of high-quality customized implants for mandibular

reconstruction are complicated, and require close collaboration

between clinicians and engineers. Although the use of AM technology

in mandibular reconstruction is promising, the widespread

application of this technology is limited by several important

factors, including i) Costly materials and equipment maintenance;

ii) sub-optimal porous structure and mechanical performance; iii)

available techniques for implant surface modification; and iv) low

resistance to clinically relevant cumulative radiation doses in

patients with malignant tumors (78).

In conclusion, 3D printing has been applied in the

medical field, including in complex surgical procedure design,

surgical simulation, surgical guide fabrication, implant design and

manufacturing (79). For the

reconstruction of mandibular defects, treatment options include

reconstruction of titanium plates and vascularized autologous bone

grafts, but each method has its advantages and disadvantages

(80). With advances in 3D printing

technology, it has become possible to manufacture custom titanium

implants for mandibular reconstruction. By obtaining digital image

data of patients through CT scans, it is possible to construct 3D

models, optimize surgical schemes, design and manufacture custom

titanium alloy implants, improve the accuracy of the surgical

procedure, reduce the operation time and improve the effect of

repair and reconstruction (81).

Advancements in AM technology within oral and maxillofacial surgery

are positively affecting the health of these patients. The present

study has elucidated a detailed approach of using customized

titanium implants for reconstruction of mandibular defects.

Patients with customized titanium implants exhibited improved

mandibular contour symmetry and functions, with minimum

post-operative complications. Taken together, the present study has

provided a more detailed picture of development of customized

implants. This will aid future studies to take a more efficient and

feasible route to the manufacture of such products in order to

achieve the implant's desired outcomes and complexity. Based on the

results of the present study, surgeons may be able to formulate

adequate strategies and contingency plans to control post-operative

complications. Notably, this work will lead to heightened

confidence in this emerging AM technology for its application in

oral and maxillofacial surgery.

Supplementary Material

Supporting Data

Acknowledgements

Not applicable.

Funding

This work was supported by the Priority Academic

Program Development of Jiangsu Higher Education Institutions (grant

no. ZCB2012010).

Availability of data and materials

The datasets used and/or analyzed during the present

study are available from the corresponding author on reasonable

request.

Authors' contributions

YX and HL contributed to the conception, design and

data acquisition. YX, ZCF, CL and HL contributed to data analysis

and interpretation, and drafted and critically revised the

manuscript. HW, CT and LW contributed to data acquisition and

analysis, and critically revised the manuscript. All authors read

and approved the final manuscript.

Ethics approval and consent to

participate

Written informed consent for participation in the

study was obtained from participants according to the policy of the

Stomatological Hospital of Jiangsu Ethical Review Board, and the

data were anonymized for analysis and research publication. The

present study was approved by the Stomatological Hospital of

Jiangsu Ethical Review Board (approval no. PJ2016-003-01).

Patient consent for publication

Participants provided informed consent for

publication of identifying information/images in an online

publication.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Jiménez M, Romero L, Domínguez I, Espinosa

M and Domínguez M: Additive Manufacturing Technologies: An Overview

about 3D Printing Methods and Future Prospects. Complexity.

2019:302019. View Article : Google Scholar

|

|

2

|

Berman B: 3-D printing: The new industrial

revolution. Bussiness Horizons. 55:155–162. 2012. View Article : Google Scholar

|

|

3

|

Truscott M, Beer D, Vicatos G, Hosking K,

Barnard L, Booysen G and Ian Campbell R: Using RP to promote

collaborative design of customised medical implants. Rapid

Prototyping J. 13:82007. View Article : Google Scholar

|

|

4

|

Khan SF and Dalgarno KW: Design of

customised bioceramic medical implants by layered manufacturing.

2009. View Article : Google Scholar

|

|

5

|

Rodby KA, Turin S, Jacobs RJ, Cruz JF,

Hassid VJ, Kolokythas A and Antony AK: Advances in oncologic head

and neck reconstruction: Systematic review and future

considerations of virtual surgical planning and computer aided

design/computer aided modeling. J Plast Reconstr Aesthet Surg.

67:1171–1185. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Rengier F, Mehndiratta A, von

Tengg-Kobligk H, Zechmann CM, Unterhinninghofen R, Kauczor HU and

Giesel FL: 3D printing based on imaging data: Review of medical

applications. Int J Comput Assist Radiol Surg. 5:335–341. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Tack P, Victor J, Gemmel P and Annemans L:

3D-printing techniques in a medical setting: A systematic

literature review. Biomed Eng Online. 15:1152016. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Salmi M, Tuomi J, Paloheimo KS,

Björkstrand R, Paloheimo M, Salo J, Kontio R, Mesimäki K and

Mäkitie A: Patient-specific reconstruction with 3D modeling and

DMLS additive manufacturing. Rapid Prototyp J. 18:209–214. 2012.

View Article : Google Scholar

|

|

9

|

Philippe B: Custom-made prefabricated

titanium miniplates in Le Fort I osteotomies: Principles, procedure

and clinical insights. Int J Oral Maxillofac Surg. 42:1001–1006.

2013. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Zeng C, Xing W, Wu Z, Huang H and Huang W:

A combination of three-dimensional printing and computer-assisted

virtual surgical procedure for preoperative planning of acetabular

fracture reduction. Injury. 47:2223–2227. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Prochor P and Mierzejewska ZA: Influence

of the surface roughness of PEEK GRF30 and Ti6Al4V SLM on the

viability of primary human osteoblasts determined by the MTT Test.

Materials (Basel). 12:41892019. View Article : Google Scholar

|

|

12

|

Vaezi M, Drescher P and Seitz H: Beamless

metal additive manufacturing. Materials (Basel). 13:9222020.

View Article : Google Scholar

|

|

13

|

Chen Q and Thouas GA: Metallic implant

biomaterials. Materials Science Engineering. 87:1–57. 2015.

View Article : Google Scholar

|

|

14

|

Vandenbroucke B and Kruth JP: Selective

laser melting of biocompatible metals for rapid manufacturing of

medical parts. Rapid Prototyp J. 13:196–203. 2007. View Article : Google Scholar

|

|

15

|

Zhou C, Lei F, Chodosh J and Paschalis EI:

The role of titanium surface microtopography on adhesion,

proliferation, transformation, and matrix deposition of corneal

cells. Invest Ophthalmol Vis Sci. 57:1927–1938. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Traini T, Mangano C, Sammons RL, Mangano

F, Macchi A and Piattelli A: Direct laser metal sintering as a new

approach to fabrication of an isoelastic functionally graded

material for manufacture of porous titanium dental implants. Dent

Mater. 24:1525–1533. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Abdelrhman Y, Gepreel MA, Kobayashi S,

Okano S and Okamoto T: Biocompatibility of new low-cost (α+β)-type

Ti-Mo-Fe alloys for long-term implantation. Mater Sci Eng C Mater

Biol Appl. 99:552–562. 2019. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Ponader S, von Wilmowsky C, Widenmayer M,

Lutz R, Heinl P, Körner C, Singer RF, Nkenke E, Neukam FW and

Schlegel KA: In vivo performance of selective electron beam-melted

Ti-6Al-4V structures. J Biomed Mater Res A. 92:56–62. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Parthasarathy J, Starly B, Raman S and

Christensen A: Mechanical evaluation of porous titanium (Ti6Al4V)

structures with electron beam melting (EBM). J Mech Behav Biomed

Mater. 3:249–259. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Murr LE, Amato KN, Li SJ, Tian YX, Cheng

XY, Gaytan SM, Martinez E, Shindo PW, Medina F and Wicker RB:

Microstructure and mechanical properties of open-cellular

biomaterials prototypes for total knee replacement implants

fabricated by electron beam melting. J Mech Behav Biomed Mater.

4:1396–1411. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Cronskär M, Rännar LE and Bäckström M:

Production of Customized Hip Stem Prostheses: A Comparison Between

Machining and Additive Manufacturing. Rapid Prototyp J. 19:365–372.

2011. View Article : Google Scholar

|

|

22

|

Jardini AL, Larosa MA, Maciel Filho R,

Zavaglia CA, Bernardes LF, Lambert CS, Calderoni DR and

Kharmandayan P: Cranial reconstruction: 3D biomodel and

custom-built implant created using additive manufacturing. J

Craniomaxillofac Surg. 42:1877–1884. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Breeland G, Aktar A and Patel BC: Anatomy,

Head and Neck, Mandible. In: StatPearls. (Treasure Island (FL)).

2020.

|

|

24

|

Zhang J, Liu M, Wang L, Chen S, Yuan P, Li

J, Shen SG, Tang Z, Chen KC, Xia JJ and Shen D: Context-guided

fully convolutional networks for joint craniomaxillofacial bone

segmentation and landmark digitization. Med Image Anal.

60:1016212020. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Lee S, Choi D, Shim JH and Nam W: Efficacy

of three-dimensionally printed polycaprolactone/beta tricalcium

phosphate scaffold on mandibular reconstruction. Sci Rep.

10:49792020. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Alfotawi R and Ayoub A: Reconstruction of

maxillofacial bone defects: Contemporary methods and future

techniques. Am J Adv Med Sci. 2:18–27. 2014.

|

|

27

|

Ansari E, Chargi N, van Gemert JTM, van Es

RJJ, Dieleman FJ, Rosenberg AJWP, Van Cann EM and de Bree R: Low

skeletal muscle mass is a strong predictive factor for surgical

complications and a prognostic factor in oral cancer patients

undergoing mandibular reconstruction with a free fibula flap. Oral

Oncol. 101:1045302020. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Mesgarzadeh AH, Abadi A and Keshani F:

Seven-year follow-up of spontaneous bone regeneration following

segmental mandibulectomy: Alternative option for mandibular

reconstruction. Dent Res J (Isfahan). 16:435–440. 2019. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Tatara AM, Koons GL, Watson E,

Piepergerdes TC, Shah SR, Smith BT, Shum J, Melville JC, Hanna IA,

Demian N, et al: Biomaterials-aided mandibular reconstruction using

in vivo bioreactors. Proc Natl Acad Sci USA. 116:6954–6963. 2019.

View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Zhang M, Lin R, Wang X, Xue J, Deng C,

Feng C, Zhuang H, Ma J, Qin C, Wan L, et al: 3D printing of

Haversian bone-mimicking scaffolds for multicellular delivery in

bone regeneration. Sci Adv. 6:eaaz67252020. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Tsukamoto Y, Akagi T and Akashi M:

Vascularized cardiac tissue construction with orientation by

layer-by-layer method and 3D printer. Sci Rep. 10:54842020.

View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Belaid H, Nagarajan S, Teyssier C, Barou

C, Barés J, Balme S, Garay H, Huon V, Cornu D, Cavaillès V and

Bechelany M: Development of new biocompatible 3D printed graphene

oxide-based scaffolds. Mater Sci Eng C Mater Biol Appl.

110:1105952020. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Pacifici A, Polimeni A and Pacifici L:

Additive manufacturing and biomimetic materials in oral and

maxillofacial surgery: A topical overview. J Biol Regul Homeost

Agents. 32:1579–1582. 2018.PubMed/NCBI

|

|

34

|

Rink B: Mandibular resection in cancer of

the tongue and/or mouth floor. HNO. 39:224–226. 1991.(In German).

PubMed/NCBI

|

|

35

|

Urken ML, Weinberg H, Vickery C,

Buchbinder D, Lawson W and Biller HF: Oromandibular reconstruction

using microvascular composite free flaps. Report of 71 cases and a

new classification scheme for bony, soft-tissue, and neurologic

defects. Arch Otolaryngol Head Neck Surg. 117:733–744. 1991.

View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Burgess J: Digital DICOM in dentistry.

Open Dent J. 9:330–336. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Parthasarathy J: 3D modeling, custom

implants and its future perspectives in craniofacial surgery. Ann

Maxillofac Surg. 4:9–18. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

38

|

Wan Leung S, Lee TF, Chien CY, Chao PJ,

Tsai WL and Fang FM: Health-related quality of life in 640 head and

neck cancer survivors after radiotherapy using EORTC QLQ-C30 and

QLQ-H&N35 questionnaires. BMC Cancer. 11:1282011. View Article : Google Scholar : PubMed/NCBI

|

|

39

|

Tschudi D, Stoeckli S and Schmid S:

Quality of life after different treatment modalities for carcinoma

of the oropharynx. Laryngoscope. 113:1949–1954. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Boyapati RP, Shah KC, Flood V and Stassen

LF: Quality of life outcome measures using UW-QOL questionnaire v4

in early oral cancer/squamous cell cancer resections of the tongue

and floor of mouth with reconstruction solely using local methods.

Br J Oral Maxillofac Surg. 51:502–507. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

41

|

Viana TSA, Silva PGB, Pereira KMA, Mota

MRL, Alves APNN, de Souza EF and Sousa FB: Prospective evaluation

of quality of life in patients undergoing primary surgery for oral

cancer: Preoperative and postoperative analysis. Asian Pac J Cancer

Prev. 18:2093–2100. 2017.PubMed/NCBI

|

|

42

|

Williamson A and Hoggart B: Pain: A review

of three commonly used pain rating scales. J Clin Nurs. 14:798–804.

2005. View Article : Google Scholar : PubMed/NCBI

|

|

43

|

Dimitroulis G: Mandibular reconstruction

following ablative tumour surgery: An overview of treatment

planning. Aust N Z J Surg. 70:120–126. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Bak M, Jacobson AS, Buchbinder D and Urken

ML: Contemporary reconstruction of the mandible. Oral Oncol.

46:71–76. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

45

|

Zhang M, Rao P, Xia D, Sun L, Cai X and

Xiao J: Functional reconstruction of mandibular segment defects

with individual preformed reconstruction plate and computed

tomographic angiography-aided iliac crest flap. J Oral Maxillofac

Surg. 77:1293–1304. 2019. View Article : Google Scholar : PubMed/NCBI

|

|

46

|

Kumar BP, Venkatesh V, Kumar KA, Yadav BY

and Mohan SR: Mandibular Reconstruction: Overview. J Maxillofac

Oral Surg. 15:425–441. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

47

|

Bowerman JE: A review of reconstruction of

the mandible. Proc R Soc Med. 67:610–614. 1974.PubMed/NCBI

|

|

48

|

Gullane PJ and Holmes H: Mandibular

reconstruction. New concepts. Arch Otolaryngol Head Neck Surg.

112:714–719. 1986. View Article : Google Scholar : PubMed/NCBI

|

|

49

|

Schusterman MA, Reece GP, Kroll SS and

Weldon ME: Use of the AO plate for immediate mandibular

reconstruction in cancer patients. Plast Reconstr Surg. 88:588–593.

1991. View Article : Google Scholar : PubMed/NCBI

|

|

50

|

Vuillemin T, Raveh J and Sutter F:

Mandibular reconstruction with the titanium hollow screw

reconstruction plate (THORP) system: evaluation of 62 cases. Plast

Reconstr Surg. 82:804–814. 1988. View Article : Google Scholar : PubMed/NCBI

|

|

51

|

Liu YF, Xu LW, Zhu HY and Liu SS:

Technical procedures for template-guided surgery for mandibular

reconstruction based on digital design and manufacturing. Biomed

Eng Online. 13:632014. View Article : Google Scholar : PubMed/NCBI

|

|

52

|

Wikesjo UM, Susin C, Qahash M, Polimeni G,

Leknes KN, Shanaman RH, Prasad HS, Rohrer MD and Hall J: The

critical-size supraalveolar peri-implant defect model:

Characteristics and use. J Clin Periodontol. 33:846–854. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

53

|

Sadr-Eshkevari P, Rashad A, Vahdati SA,

Garajei A, Bohluli B and Maurer P: Alloplastic mandibular

reconstruction: A systematic review and meta-analysis of the

current century case series. Plast Reconstr Surg. 132:413e–427e.

2013. View Article : Google Scholar : PubMed/NCBI

|

|

54

|

Shibahara T, Noma H, Furuya Y and Takaki

R: Fracture of mandibular reconstruction plates used after tumor

resection. J Oral Maxillofac Surg. 60:182–185. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

55

|

Gadre PK, Ramanojam S, Patankar A and

Gadre KS: Nonvascularized bone grafting for mandibular

reconstruction: Myth or reality? J Craniofac Surg. 22:1727–1735.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

56

|

Handschel J, Hassanyar H, Depprich RA,

Ommerborn MA, Sproll KC, Hofer M, Kübler NR and Naujoks C:

Nonvascularized iliac bone grafts for mandibular

reconstruction-requirements and limitations. In Vivo. 25:795–799.

2011.PubMed/NCBI

|

|

57

|

Warnke PH, Wiltfang J, Springer I, Acil Y,

Bolte H, Kosmahl M, Russo PA, Sherry E, Lützen U, Wolfart S and

Terheyden H: Man as living bioreactor: Fate of an exogenously

prepared customized tissue-engineered mandible. Biomaterials.

27:3163–3167. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

58

|

Moura LB, Carvalho PH, Xavier CB, Post LK,

Torriani MA, Santagata M and Chagas Júnior OL: Autogenous

non-vascularized bone graft in segmental mandibular reconstruction:

A systematic review. Int J Oral Maxillofac Surg. 45:1388–1394.

2016. View Article : Google Scholar : PubMed/NCBI

|

|

59

|

Mericli AF, Boukovalas S, Rhines LD,

Adelman DM, Hanasono MM and Chang EI: Free Fibula Flap for

Restoration of Spinal Stability after Oncologic Vertebrectomy Is

Predictive of Bony Union. Plast Reconstr Surg. 145:219–229. 2020.

View Article : Google Scholar : PubMed/NCBI

|

|

60

|

Rao Janardhan S, Kotrashetti SM, Lingaraj

JB, Pinto PX, Keluskar KM, Jain S, Sone P and Rao S: Anterior

segmental distraction osteogenesis in the hypoplastic cleft

maxilla: Report of five cases. Sultan Qaboos Univ Med J.

13:454–459. 2013.PubMed/NCBI

|

|

61

|

Wu V, Helder MN, Bravenboer N, Ten

Bruggenkate CM, Jin J, Klein-Nulend J and Schulten EAJM: Bone

tissue regeneration in the oral and maxillofacial region: A review

on the application of stem cells and new strategies to improve

vascularization. Stem Cells Int. 2019:62797212019. View Article : Google Scholar : PubMed/NCBI

|

|

62

|

Vidal L, Kampleitner C, Brennan MA,

Hoornaert A and Layrolle P: Reconstruction of large skeletal

defects: Current clinical therapeutic strategies and future

directions using 3D Printing. Front Bioeng Biotechnol. 8:612020.

View Article : Google Scholar : PubMed/NCBI

|

|

63

|

Wang MM, Flores RL, Witek L, Torroni A,

Ibrahim A, Wang Z, Liss HA, Cronstein BN, Lopez CD, Maliha SG and

Coelho PG: Dipyridamole-loaded 3D-printed bioceramic scaffolds

stimulate pediatric bone regeneration in vivo without disruption of

craniofacial growth through facial maturity. Sci Rep. 9:184392019.

View Article : Google Scholar : PubMed/NCBI

|

|

64

|

Hidalgo DA: Fibula free flap: A new method

of mandible reconstruction. Plast Reconstr Surg. 84:71–79. 1989.

View Article : Google Scholar : PubMed/NCBI

|

|

65

|

Byun SH, Lim HK, Yang BE, Kim SM and Lee

JH: Delayed reconstruction of palatomaxillary defect using fibula

free flap. J Clin Med. 9:8842020. View Article : Google Scholar

|

|

66

|

Hashemi S, Oda M, Onoue K, Basa K, Rubin

SJ, Sakai O, Salama A and Ezzat WH: Determining the optimal

osteotomy distance with the fibula free flap in mandibular

reconstruction. Am J Otolaryngol:. 41:1024362020. View Article : Google Scholar : PubMed/NCBI

|

|

67

|

Lonie S, Herle P, Paddle A, Pradhan N,

Birch T and Shayan R: Mandibular reconstruction: Meta-analysis of

iliac-versus fibula-free flaps. ANZ J Surg. 86:337–342. 2016.

View Article : Google Scholar : PubMed/NCBI

|

|

68

|

Iamaguchi RB, de Moraes MA, Silva GB, Cho

AB, Iwase FDC, Wei TH, de Rezende MR and Mattar R Jr: Is obesity a

risk factor for free vascularized fibular flap complications? Acta

Ortop Bras. 27:192–196. 2019. View Article : Google Scholar : PubMed/NCBI

|

|

69

|

Prevost R, Kimakhe J, Diep D, Drouet J,

Benateau H and Veyssiere A: The significance of computer-assisted

surgery in avoiding double-barrel fibula grafts in reconstruction

of the horizontal mandibular ramus. J Stomatol Oral Maxillofac

Surg. 120:167–171. 2019. View Article : Google Scholar : PubMed/NCBI

|

|

70

|

Bartaire E, Mouawad F, Mallet Y, Milet P,

El Bedoui S, Ton Van J, Chevalier D and Lefebvre JL: Morphologic

assessment of mandibular reconstruction by free fibula flap and

donor-site functional impairment in a series of 23 patients. Eur

Ann Otorhinolaryngol Head Neck Dis. 129:230–237. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

71

|

Vedakumari WS, Ayaz N, Karthick AS,

Senthil R and Sastry TP: Quercetin impregnated chitosan-fibrin

composite scaffolds as potential wound dressing

materials-Fabrication, characterization and in vivo analysis. Eur J

Pharm Sci. 97:106–112. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

72

|

Zhao W, Li Y, Zhou A, Chen X, Li K, Chen

S, Qiao B and Jiang D: Controlled release of basic fibroblast

growth factor from a peptide biomaterial for bone regeneration. R

Soc Open Sci. 7:1918302020. View Article : Google Scholar : PubMed/NCBI

|

|

73

|

Yuan X, Xuan M, Tian W and Long J:

Application of digital surgical guides in mandibular resection and

reconstruction with fibula flaps. Int J Oral Maxillofac Surg.

45:1406–1409. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

74

|

Foley BD, Thayer WP, Honeybrook A, McKenna

S and Press S: Mandibular reconstruction using computer-aided

design and computer-aided manufacturing: An analysis of surgical

results. J Oral Maxillofac Surg. 71:e111–e119. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

75

|

Pattanayak DK, Fukuda A, Matsushita T,

Takemoto M, Fujibayashi S, Sasaki K, Nishida N, Nakamura T and

Kokubo T: Bioactive Ti metal analogous to human cancellous bone:

Fabrication by selective laser melting and chemical treatments.

Acta Biomater. 7:1398–1406. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

76

|

Jia ZJ, Li M, Xiu P, Xu X, Cheng Y, Zheng

Y, Xi T, Wei S and Liu Z: A novel cytocompatible, hierarchical

porous Ti6Al4V scaffold with immobilized silver nanoparticles.

Mater Lett. 157:143–146. 2015. View Article : Google Scholar

|

|

77

|

Bertollo N, Da Assuncao R, Hancock NJ, Lau

A and Walsh WR: Influence of electron beam melting manufactured

implants on ingrowth and shear strength in an ovine model. J

Arthroplasty. 27:1429–1436. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

78

|

Azuma M, Yanagawa T, Ishibashi-Kanno N,

Uchida F, Ito T, Yamagata K, Hasegawa S, Sasaki K, Adachi K,

Tabuchi K, Sekido M and Bukawa H: Mandibular reconstruction using

plates prebent to fit rapid prototyping 3-dimensional printing

models ameliorates contour deformity. Head Face Med. 10:452014.

View Article : Google Scholar : PubMed/NCBI

|

|

79

|

Crafts TD, Ellsperman SE, Wannemuehler TJ,

Bellicchi TD, Shipchandler TZ and Mantravadi AV: Three-dimensional

printing and its applications in otorhinolaryngology-head and neck

surgery. Otolaryngol Head Neck Surg. 156:999–1010. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

80

|

Sweed AH, Bolzoni AR, Kadubiec A,

Beltramini GA, Cherchi A and Baj A: Factors influencing CAD/CAM

accuracy in fibula free flap mandibular reconstruction. Acta

Otorhinolaryngol Ital. 40:138–143. 2020. View Article : Google Scholar : PubMed/NCBI

|

|

81

|

Friedli L, Kloukos D, Kanavakis G,

Halazonetis D and Gkantidis N: The effect of threshold level on

bone segmentation of cranial base structures from CT and CBCT

images. Sci Rep. 10:73612020. View Article : Google Scholar : PubMed/NCBI

|