Introduction

The three essential elements of tissue engineering

are seed cells, scaffold materials and cytokines (1–3). The

selection of tissue engineering scaffold material is directly

associated with the effect of the material implanted in the animal

or human body. Most importantly, the scaffold materials should have

good biocompatibility (4–6). Scaffold materials can provide a good

adsorption interface for the adhesion of seed cells, in order to

facilitate cell proliferation. In addition, the scaffold material

must have a certain level of biomechanical strength (7,8) and

maintain a controlled degradation rate once implanted into the

animal or human body. The material should have no cytotoxic,

immunogenic, tumorigenic or teratogenic effects on animals or

humans. In addition, the scaffold materials are required to

integrate cytokines and to activate the expression of various

specific genes, Runt-related transcription factor 2, osteocalcin

(9), peroxisome

proliferator-activated receptor-γ (10) and α-smooth muscle actin (11) in order to maintain the normal

phenotype of the seed cells on the scaffold surface (12).

Classes of scaffold materials include natural

biological scaffold materials, synthetic biodegradable polymer

scaffolds materials (13–15), composite scaffold materials

(16–18) and nano-scaffold materials (16–18).

Natural biological scaffolds have good biocompatibility but poor

mechanical properties (19).

Synthetic biodegradable polymer scaffolds tend to have strong

mechanical properties (20), but

lack good cellular compatibility. Nano-scaffold materials have been

widely studied in recent years, but are expensive to produce

(21). Currently, the most widely

used scaffold materials are composite scaffold materials. These

benefit from the good cellular compatibility of natural biological

scaffolds and the strong mechanical properties of synthetic

biodegradable polymer scaffolds (22).

In our previous studies, human-like collagen I

(HLC-I) (23) was combined with

the acellular vascular matrix (ACVM) (23,24)

to construct the ACVM-0.25% HLC-I scaffold material (25). This process involved combining a

polymer material with natural degenerative biomaterials to

construct a composite tissue engineering scaffold material. This

material supports the growth of seed cells with a three-dimensional

ultrastructure of protein space to promote the formation of

functional tissue, but it also possesses compressive mechanical

properties required for vascular tissue engineering (25). A previous study demonstrated that

vascular endothelial cells and vascular smooth muscle cells are

induced and differentiated by human gingival fibroblasts (HGFs)

(25). Combining these cells with

ACVM-0.25% HLC-I scaffold materials supported successful tissue

engineering of vessels that possessed the morphological and immune

characteristics of vascular tissue. The structure of the

tissue-engineered vascular tissue was intact following 9 weeks in

nude mice (25). Thus, the

aforementioned results demonstrated the feasibility of ACVM-0.25%

HLC-I scaffold material for tissue engineering.

The present study compares the biological

characteristics of different ACVM-0.25% HLC-I scaffold materials

with Acellular Dermal Matrix (ADM) (26,27),

Small Intestinal Submucosa (SIS) (28,29)

and Bio-Gide scaffolds in tissue engineering. The aim of the

present study was to confirm the advantages of ACVM-0.25% HLC-I

composite scaffolds and lay a foundation for the research of tissue

engineering scaffold materials.

Materials and methods

Preparation of vascular scaffolds

Preparation of ACVM-HLC-I

scaffolds

Female 12-week-old New Zealand white rabbits,

weighing 1.8–2.0 kg, were provided by the Animal Center of Hebei

Medical University (Shijiazhuang, China; license no. SCXK

2013-1-003; certification no. 1505098). The rabbits were housed in

plastic cage (1 rabbit per cage) and were allowed free access to

food and water. The housing conditions were maintained at

temperature of 25°C, relative humidity of 40–70%, under a 12-h

light/dark cycle. Animal experiments were approved by the Ethics

Committee of Southwest Medical University (Sichuan, China).

ACVM-HLC-I scaffolds were prepared as described previously

(23). Briefly, the blood vessels

of New Zealand white rabbits were isolated and washed in saline

solution eight times. Sections of blood vessel 2 cm in length were

immersed in PBS containing 1% benzalkonium bromide (Lircon) for 1 h

at room temperature and then in PBS for 5 min. The vessels were

then placed in a liquid mixture with 1% trypsin and 0.01% EDTA for

24 h at 37°C and 5% CO2. Following washing with PBS for

5 min, samples were incubated in PBS containing 1% Triton-X-100 for

72 h at room temperature. Finally, blood vessels were immersed in

sterile PBS solution at 4°C for subsequent experiments.

Then, the ACVM scaffolds were prepared as follows:

The bio-activation of ACVM-HLC-I was performed by firstly using a

solution of acrylic acid to reduce the dissolved oxygen on the

surface of the ACVM scaffolds. The scaffolds were then exposed to

UV radiation for 30 min and placed in a Petri dish. The scaffolds

were washed with distilled water to remove the excess homo-polymer

and placed to dry in a vacuum desiccator. Immobilization of HLC-I

was performed once the surface of the scaffolds was modified with

acrylic acid. The ACVM-acrylic acid scaffolds were immersed at 4°C

for 1 h in PBS, which also contained 5 mg/ml water-soluble

carbodiimide in order to activate the carboxyl groups on the

surface of the ACVM scaffolds. Secondly, various concentrations of

HLC-I (0.10, 0.25, 0.50, 0.75 and 1.00 mg/ml) were added to combine

with the surface of the ACVM for 5 h at room temperature. Thirdly,

the scaffolds were washed with PBS at room temperature for 1 h to

remove the excess HLC-I that was physically adsorbed on the surface

of the scaffold. Finally, ACVM-HLC-I scaffolds were dried under

reduced pressure and stored at 4°C.

Preparation of SIS, ADM and Bio-Gide

scaffolds

Serosa and muscle of the jejunum were removed using

gauze. Then, the jejunum was immersed in PBS that contained 1%

penicillin and 1% streptomycin for 3 h at room temperature. Trypsin

(0.25%) was added to the jejunum for 24 h at room temperature and

then it was immersed in 0.5% SDS for 24 h. The jejunum was washed

with distilled water twice. Finally, the jejunum was sterilized in

sterile water containing 20% ethanol and 0.1% peracetic acid for 10

h at room temperature, then freeze-dried for use. The ADM scaffold

was purchased from Beijing Qingyuanweiye Bio-Tissue Engineering,

Co., Ltd., (Beijing, China), and the Bio-Gide scaffold was

purchased from Geistlich Pharma AG (Wolhusen, Switzerland).

Cell isolation and culture of primary

cells

HGFs were used for cell studies. HGFs were isolated

from healthy gingival tissue, which was harvested from clinical

donors undergoing mandibular third impact molar extraction as

described previously (30). The

acquisition of normal human gingival tissues from patients was

approved by the Hospital of Stomatology at Hebei Medical University

(Hebei, China), and written informed consent was obtained from all

patients. Following the removal of the epithelial layer, human

gingival tissues were cut into 1×1 mm2 pieces and placed

in low-glucose Dulbecco's modified Eagle medium (L-DMEM; Hyclone;

GE Healthcare Life Sciences, Logan, UT, USA) containing 10% fetal

bovine serum (Gibco; Thermo Fisher Scientific, Inc., Waltham, MA,

USA), 100 U/ml penicillin (Shenzhen Huayao Nanfang Pharmaceutical

Co., Ltd., Shenzhen, China), and 100 U/ml streptomycin (Shenzhen

Huayao Nanfang Pharmaceutical Co., Ltd.). Cells at the second or

the third passage were from 6 different donors in the present

study.

Immunofluorescence staining of

HGFs

HGFs were immersed in acetone and washed with PBS.

Then, HGFs were fixed in 4% paraformaldehyde at 4°C overnight and

washed with PBS three times. The following primary antibodies were

used for cell incubation at 37°C for 2 h: Vimentin (1:100; ZM-0260;

Beijing Zhongshan Golden Bridge Biotechnology Co., Ltd., Beijing,

China) and S100A4 (1:100; ZA-0257; Beijing Zhongshan

Golden Bridge Biotechnology Co., Ltd.). H2O2

(3%) was added to blocking protease for 20 min at room temperature

and then 30 µl sheep serum blocking buffer (ZC-02125; Beijing

Zhongshan Golden Bridge Biotechnology Co., Ltd.) was added for 1 h

at room temperature. Following three washes with PBS, the cells

were incubated with the following secondary antibodies at 37°C for

1 h: Fluorescein isothiocyanate-conjugated goat anti-mouse

immunoglobulin G (IgG; 1:100, ZF-0312; Beijing Zhongshan Golden

Bridge Biotechnology Co., Ltd.) and rhodamine-conjugated goat

anti-rabbit IgG (1:100; ZF-0316; Beijing Zhongshan Golden Bridge

Biotechnology Co., Ltd.). Cell nuclei were stained with

4′,6-diamidino-2-phenylindole for 10 min at room temperature.

Finally, the cells were photographed under a laser confocal

microscope (Olympus Corporation, Tokyo, Japan).

Optimal concentration of HLC-I

crosslinking with ACVM scaffolds measured by MTT

ACVM scaffolds with various concentrations of HLC-I

(ACVM-HLC-I scaffolds) were cut into smaller blocks of 10.0 mm

diameter. Scaffolds were placed in a 24-well culture plate. A

volume of 100 µl L-DMEM containing 1×105 HGFs was placed

on each scaffold. The seeded scaffolds were placed in a 37°C

incubator for 2 h and then transferred to another 24-well plate,

following which 2 ml culture medium was added to each well. The

culture medium was replaced every 2 days. The number of cells of

each scaffold were tested by MTT assay following culture for 1, 4

and 7 days.

For the MTT assay, HGFs on each scaffold were

incubated with L-DMEM for 12 h at 37°C. Then, 10 µl of 5 mg/ml MTT

(Beijing Zhongshan Golden Bridge Biotechnology Co., Ltd.) was added

to each well. A well without cells was used as the blank control.

The plate was incubated at 37°C for 3.5 h. Then, 100 µl DMSO was

added to each well and incubated at room temperature for 10 min.

Absorbance at 490 nm was measured by microplate reader to calculate

the concentration of cells on ACVM-HLC-I scaffolds.

Observation analysis of the vascular

scaffolds

Histological analysis

Sections of scaffold (5 cm) were mounted on light

microscope slides and Masson Trichrome staining (HT15;

Sigma-Aldrich; Merck KGaA, Darmstadt, Germany) was performed. The

slides were stained with Masson complex staining for 5 min at room

temperature and washed with 0.2% acetic acid water. Then, the

slides were immersed in 5% phosphotunfstic acid for 5 min and

washed with 0.2% acetic acid water twice. Following

deparaffinization, the slides were stained with Bouin's solution at

56°C for 15 min. Hematoxylin and eosin (H&E) staining was used

to investigate the basic structure of ACVM-0.25% HLC-I scaffold

compared with SIS, ADM and Bio-Gide scaffolds, and to observe the

four different biodegradable scaffolds following seeding with HGFs.

After dewaxing, the slides were stained with hematoxylin for 5 min

at room temperature, following by washing with water for 2 min.

Then, the slides were stained with eosin for 30 sec, and next

washed with water for 2 min. Masson staining was performed to

evaluate the fiber composition of the ACVM-0.25% HLC-I, SIS, ADM

and Bio-Gide scaffolds.

Water absorption capacities

The water absorption capacities of the four

scaffolds were determined by the degree of swelling in PBS at room

temperature. A known weight of the scaffold material was placed in

PBS for 12 h. The wet weight of the scaffold was determined as the

weight of the scaffold after blotting the surface with filter paper

to remove the extra PBS. The percentage of water absorption of the

scaffolds was calculated using the following equation (23):

W1-W0/W0 ×100%, where

W1 represents the wet weight of the scaffolds after 24 h

and W0 is the initial weight of the scaffolds.

Measurement of scaffold mechanical

ability

The stress-time and stress-strain curves of the

scaffolds were tested using a universal material testing machine

(Zwick Roell Z020; Zwick Roell Group, Ulm, Germany). The scaffolds

were divided into four groups: ACVM-0.25% HLC-I scaffold, ADM

scaffold, Bio-Gide scaffold and SIS scaffold groups. During the

whole experiment, PBS was used to keep the samples moist. All

samples were pre-adjusted prior to testing. The length of the

specimen was 1 cm and it was stretched at a speed of 10 mm/min

until it snapped. The stress and strain were subsequently recorded.

Stress is the mechanical state describing every direction of every

point within an object. It is described as the force per unit area.

Strain is the amount of change in the shape of a material under

external force. The stress-strain curves were plotted on the basis

of stress as the ordinate and strain as the abscissa. The breaking

strength and elongation at break were also calculated. Breaking

strength = maximum stress when the material breaks /

cross-sectional area. Elongation at break (%) = displacement value

of material when it breaks/original length of material.

Scanning electron microscope (SEM)

imaging

The samples were fixed in a metal and coated with a

thin layer of gold, using an Edwards EXC 120 Turbo Pump Controller.

A SEM (JSM-5310; JEOL, Ltd., Tokyo, Japan) was used to investigate

the surface morphology of the four scaffolds.

Observation analysis of the vascular

scaffolds following seeding with HGFs

Histological analysis

Scaffold sections (5 cm) were mounted on light

microscope slides and Masson Trichrome staining was performed at

room temperature. The slides were stained with Masson complex

staining for 5 min and after washed with 0.2% acetic acid water.

Then, the slides were immersed in 5% phosphotunfstic acid for 5 min

and washed with 0.2% acetic acid water twice. Following dewaxing,

the slides were stained with Bouin's solution at 56°C for 15 min.

H&E staining was used to evaluate ACVM-0.25% HLC-I, SIS, ADM

and Bio-Gide scaffolds after seeding with HGFs. Tissue samples for

histology were fixed in 4% paraformaldehyde at 4°C for 24 h and

embedded in paraffin. After dewaxing, the slides were stained with

hematoxylin for 5 min at room temperature, following by washing

with water for 2 min. Then, the slides were stained with eosin for

30 sec, then with water for 2 min.

SEM imaging

The surface morphology of HGFs on the four different

biodegradable scaffolds was observed using an JSM-6320F SEM (JEOL,

Ltd.), as aforementioned.

Growth kinetics of HGFs on

scaffolds

Cell Counting Kit-8 (CCK-8) was used to evaluate the

growth kinetics of HGFs on the four scaffolds. A total of

2×103 HGFs/well were seeded on the four scaffolds

inoculated in 96-well microplates. CCK-8 solution (10 µl) was added

to each well and incubated at 37°C for 1 h. Subsequently, the

absorbance of each well was measured by a microplate reader at 450

nm on days 1, 4 and 7 after cell seeding. The absorbance values at

different time points were used to construct a growth curve to

indicate the growth kinetics of HGFs on the four scaffolds.

Changes in the diameter of the

scaffolds following HGF seeding

A vernier caliper was used to measure the diameter

of the ACVM-0.25% HLC-I, ADM, Bio-Gide and SIS scaffolds prior to

seeding with HGFs. The diameters of all scaffolds were measured to

be 10 mm. The density of 2×105 HGFs were placed on the

surface of each scaffold and cultured in a 37°C incubator for 48 h.

Then, the scaffolds were removed and the culture fluid was

aspirated with sterile filter paper. The diameter of each scaffold

was measured using a vernier caliper following compounding of

HGFs.

Statistical analysis

Statistical analysis was performed by using SPSS

software (v. 21.0; IBM Corp., Armonk, NY, USA). The measurement

data are presented as the mean ± standard deviation and were

analyzed by one-way analysis of variance, followed by a

Student–Newman–Keuls multiple comparison test. P<0.05 was

considered to indicate a statistically significant difference.

Results

General observations of the four

scaffold materials

The ACVM-HLC-I scaffold presented as an ivory-white,

translucent, non-elastic vascular wall with folded and damaged

lumen (Fig. 1A). The ADM scaffold

was ivory-white, translucent and exhibited a honeycomb structure

with a rough surface (Fig. 1B).

The thickness of ADM was 0.4–0.6 mm. Bio-Gide presented as pale

yellow-white, translucent, rectangular patches with a smooth

surface (Fig. 1C). SIS presented

as a pale ivory, translucent membrane (Fig. 1D).

| Figure 1.Observation of scaffold materials.

(A) ACVM-HLC-I, (B) ADM, (C) Bio-Gide and (D) SIS. ACVM-HLC-I

scaffold presented as an ivory-white, translucent and non-elastic

vascular wall with a folded and damaged lumen. ADM presented with

an ivory-white, translucent, honeycomb structure with a rough

surface. Bio-Gide was pale yellow-white, with translucent

rectangular patches and a smooth surface. SIS presented as a pale

ivory, translucent membrane. ACVM-HLC-I, acellular vascular

matrix-human-like collagen I; ADM, acellular dermal matrix; SIS,

small intestinal submucosa. |

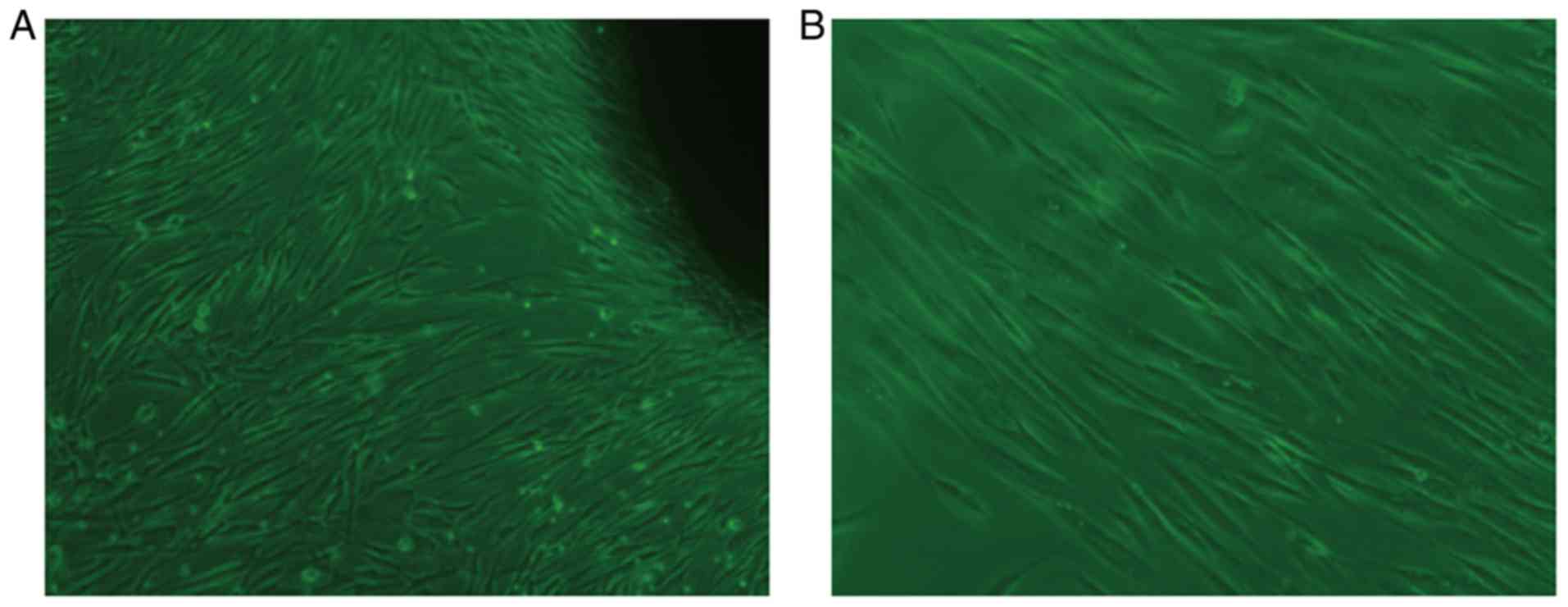

Observation of HGFs by inverted

microscope

Following 7 days of primary culture of HGFs,

fibroblast-like cells with clear and large outlines, spherical or

elliptic nuclei were observed (Fig.

2A). At an average of 15 days, a large number of cells were

available to harvest the fibroblast-like cells. As shown in

(Fig. 2B), the second generation

of cells was tightly adhered, spindle-shaped and well-spread, and

fibroblast-like in appearance.

Identification of HGFs by

immunofluorescent staining

The characteristics of HGFs were identified by

immunofluorescent staining of vimentin and S100A4, markers for

mesenchymal cells. It was observed that the protein expression of

vimentin and S100A4 was positive in the cytoplasm of HGFs (Fig. 3).

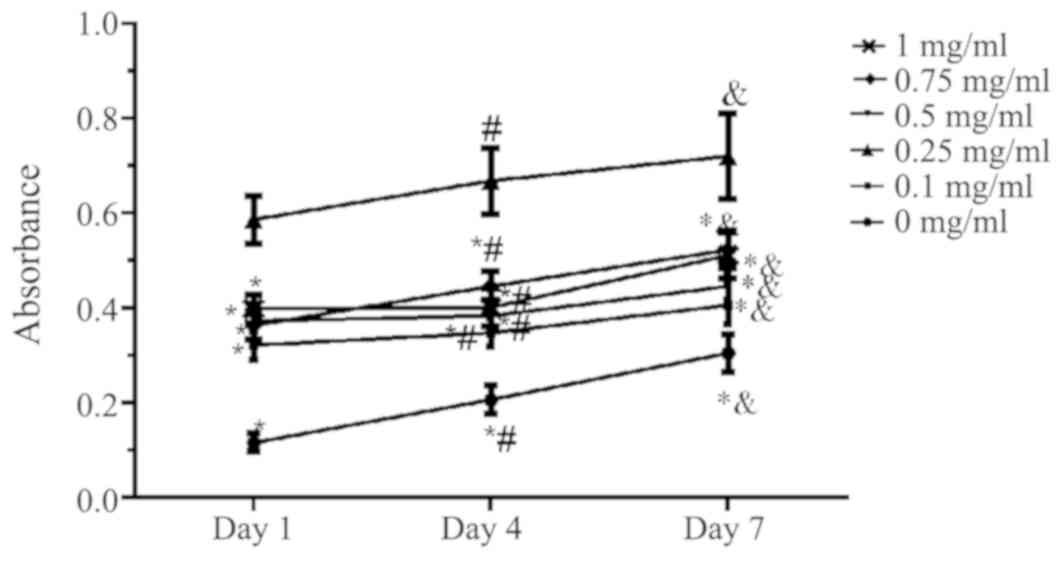

Cell adherence ability by MTT

assay

The results demonstrated that compared with the ACVM

scaffold without HLC-I, the ACVM-HLC-I scaffold had better cell

adherence. In addition, the ACVM scaffold coated with 0.25% HLC-I

presented the highest cell adherence at all time points (Fig. 4).

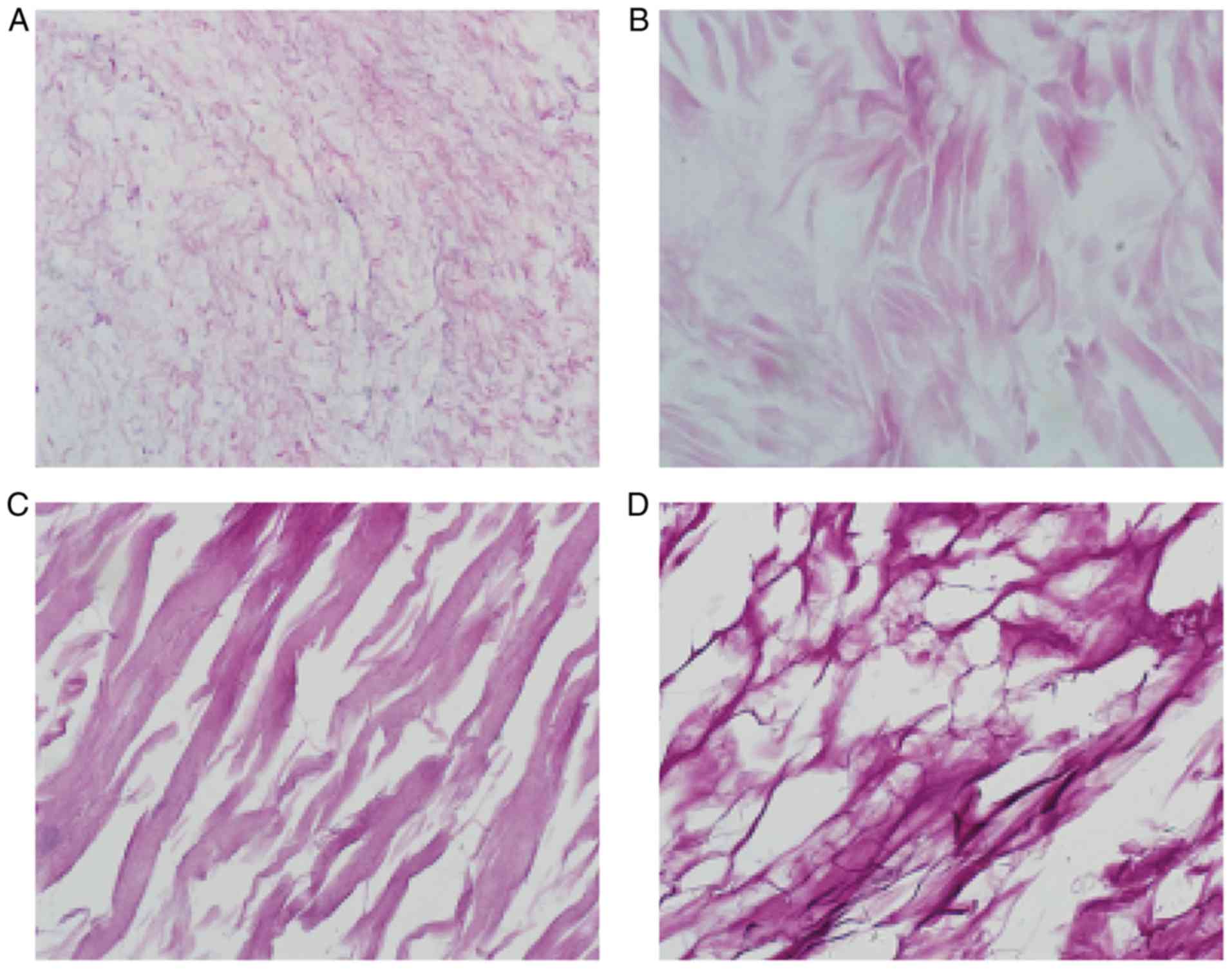

Observation of vascular scaffolds

H&E staining

H&E staining of the ACVM-0.25% HLC-I scaffold

revealed the reticular and collagen fibers without cell nuclei,

cell debris and media layer smooth muscle cells. The inner membrane

was mainly distributed in the reticular fiber and media layer, the

outer membrane was mainly distributed in the collagen fibers. The

gap between collagen fibers was large, and collagen near the outer

membrane was relatively concentrated (Fig. 5A). H&E staining of the ADM

scaffolds revealed that the mesh structure of collagen fibers was

looser and fewer cells were present (Fig. 5B). H&E staining of the Bio-Gide

scaffolds exhibited a loose and thick mesh structure of collagen

fibers and complete absence of cells (Fig. 5C). In addition, it was observed

that in the SIS scaffold, interlaced irregular collagen fibers

produced a mesh with a large aperture and compact structure

(Fig. 5D).

Masson staining

Masson staining of the four scaffolds suggested that

the majority of them were composed of collagen fibers and were dyed

green. In each layer of ADM, a large number of muscle fibers were

dyed red, and the structure of the collagen fiber was thin. In the

Bio-Gide group, the majority of the collagen fibers were dyed

green, and the collagen fibers were thick and sparse. In the SIS

scaffold only a small number of muscle fibers were dyed red

(Fig. 6).

SEM

SEM images of the surfaces of the four scaffolds are

presented in Fig. 7. The surfaces

of the ADM, Bio-Gide, SIS and ACVM-0.25% HLC-I scaffolds exhibited

dense collagen fiber bundles. The material surface of the

ACVM-0.25% HLC-I scaffold was more slender and softer compared with

those of the SIS, ADM and Bio-Gide scaffolds. In addition, compared

with the Bio-Gide scaffold, the surface fiber structure of the ADM

scaffold was dense, while the surface fiber structure of the SIS

scaffold was relatively sparse and hard. The ACVM-0.25% HLC-I

scaffold surface appeared to have the smallest fibers, but no

statistically significant difference was observed between SIS and

ADM scaffolds.

Water absorption capacities of the

scaffold materials

Following 24 h, the ACVM-0.25% HLC-I scaffold

exhibited the best water absorption performance, followed by the

SIS and Bio-Gide scaffolds, and then the ADM scaffold. The water

absorption of the four scaffolds is presented in Table I. ACVM-0.25% HLC-I scaffolds had

significantly improved water absorption when compared with SIS,

Bio-Gide and ADM scaffolds (P<0.05).

| Table I.Comparison of water absorption for

four different biodegradable scaffolds. |

Table I.

Comparison of water absorption for

four different biodegradable scaffolds.

| Scaffold | n | Water absorption

(%) |

|---|

| ACVM-0.25%

HLC-I | 6 | 24.05±0.59 |

| SIS | 6 | 10.99±0.28 |

| Bio-Gide | 6 | 5.82±0.07 |

| ADM | 6 | 3.55±0.08 |

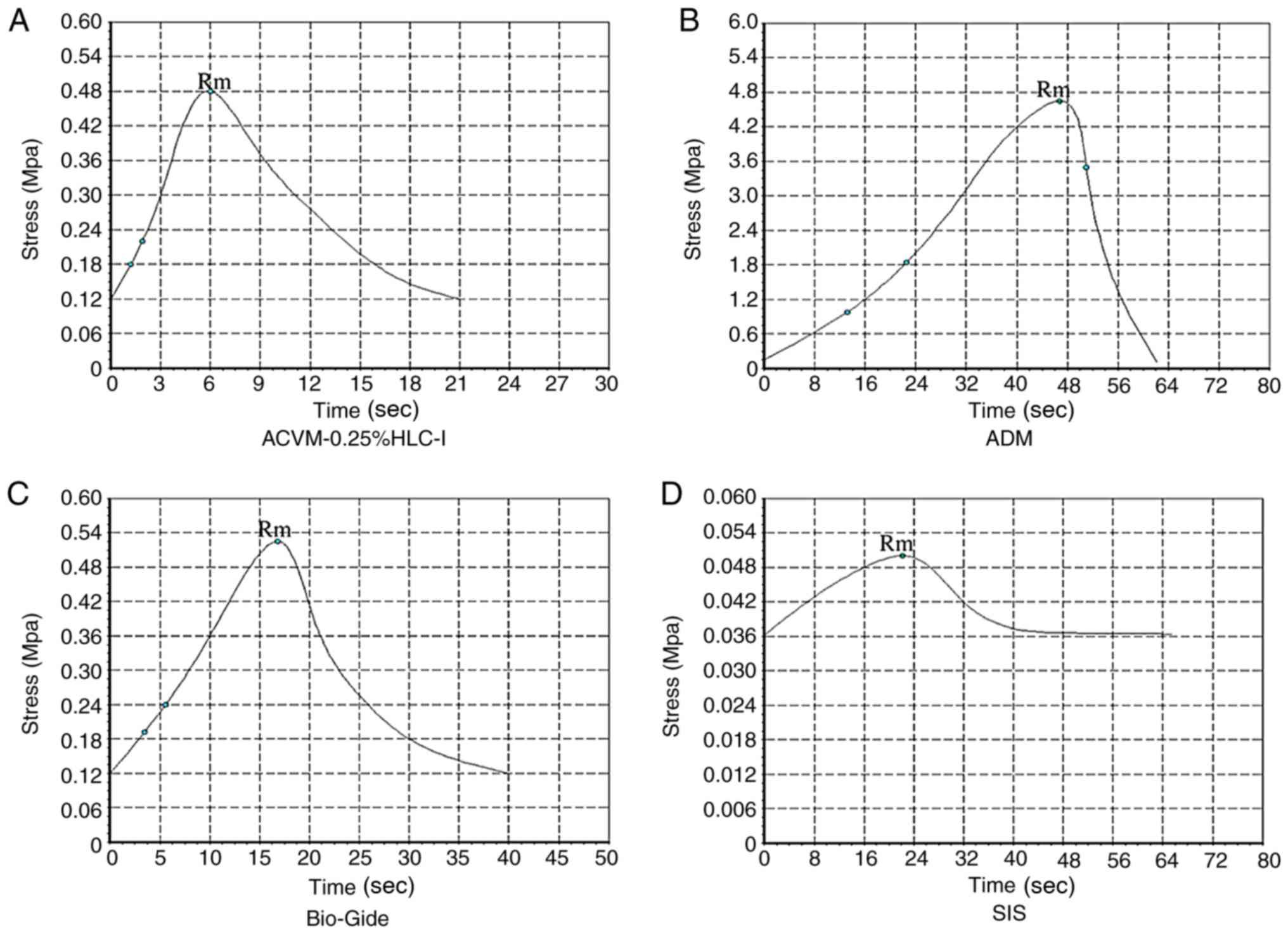

Mechanical test results of the

scaffold materials

In terms of stress, the ADM scaffold material had

the largest tensile stress and reached a peak value of 4.65±0.78

Mpa at 46 sec, which was markedly higher when compared with the

tensile stress of the ACVM-0.25% HLC-I, Bio-Gide and SIS scaffold

materials (P<0.05; Fig. 8). The

tensile stress of ACVM-0.25% HLC-I, Bio-Gide and SIS reached their

peak values at 6, 16.8 and 22 sec (0.48±0.04, 0.52±0.09 and

0.05±0.0017 Mpa), respectively. There was no notable difference in

tensile stress between the ACVM-0.25% HLC-I and Bio-Gide scaffold

materials (P>0.05), but the tensile stress of the SIS scaffold

material was markedly lower when compared with the other three

types of scaffold (P<0.05). Therefore, the tensile stress of the

ACVM-0.25% HLC-I scaffold material was not as high as the ADM

scaffold material, but was similar to the Bio-Gide scaffold

material and was increased compared with the SIS scaffold material

(Fig. 8).

In terms of strain, ADM exhibited a notably higher

value compared with the ACVM-0.25% HLC-I, Bio-Gide and SIS scaffold

materials (P<0.05; Fig. 9).

There was no notable difference between ACVM-0.25% HLC-I and

Bio-Gide scaffold materials (P>0.05), but there was a notable

difference between ACVM-0.25% HLC-I and SIS scaffold materials

(P<0.05). The stress-strain curve indicated that the ADM

scaffold had the greatest tensile strength. The tensile strength of

the Bio-Gide scaffold was similar to that of the ACVM-0.25% HLC-I

scaffold, but the tensile strength of the SIS scaffold material was

relatively poor (Figs. 8 and

9). In terms of breaking strength,

the ADM scaffold material exhibited the highest strength, while the

SIS scaffold material exhibited the lowest. There was no marked

difference between the ACVM-0.25% HLC-I and Bio-Gide scaffold

materials (P>0.05). A negative association was observed between

the elongation at break and the breaking strength (Table II). The largest value of

elongation at break was observed in the SIS scaffold, while the

smallest value was observed in the ADM scaffold. There was no

notable difference in elongation at break between the Bio-Gide and

ACVM-0.25% HLC-I scaffolds (P>0.05; Table II).

| Table II.Breaking strength and elongation at

break of the four scaffolds. |

Table II.

Breaking strength and elongation at

break of the four scaffolds.

| Group | Breaking strength

(MPa) | Elongation at break

(%) |

|---|

| ADM |

46.5±1.78a,b |

5.66±0.41a,b |

| ACVM-0.25%

HLC-I |

4.80±0.32a |

52.93±1.34a |

| Bio-Gide |

5.20±0.35a |

51.31±1.48a |

| SIS | 0.50±0.08 | 470.3±1.93 |

Observation of HGFs on vascular

scaffolds

HE staining

The histology of the ACVM-0.25% HLC-I scaffold

seeded with HGFs and cultured for 7 days is presented in Fig. 10. HGFs were abundant and

well-distributed in the central part of the ACVM-0.25% HLC-I

scaffold. The cells exhibited extending processes in various

directions, indicating that they had potential migration abilities

and cell activity. The histology of the HGFs seeded on the ADM and

Bio-Gide scaffolds are also presented in Fig. 10. Compared with the ACVM-0.25%

HLC-I scaffold, ADM and Bio-Gide scaffolds following 7 days

appeared to exhibit limited cell proliferation. The cells appeared

healthy with extended morphology. The HGFs seeded on the SIS

scaffold also presented and few cells grew on the surface of the

SIS scaffold following 7 days (Fig.

10).

SEM

SEM images of the four scaffolds seeded with HGFs

and cultured for 7 days are presented in Fig. 11. A large number of HGFs were

observed on the surface of the ACVM-0.25% HLC-I scaffold compared

with the ADM and Bio-Gide scaffolds. On the other hand, HGFs were

observed in limited numbers on the surface of the SIS scaffold.

This result was similar to the histology results of the four

different biodegradable scaffolds following seeding with HGFs.

Growth kinetics of HGFs on

scaffolds

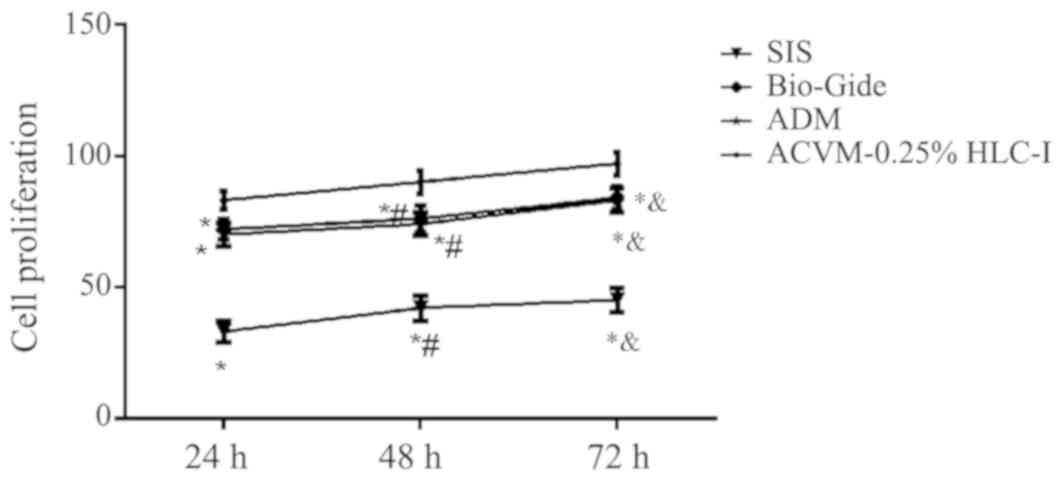

The number of HGFs in the ACVM-0.25% HLC-I, SIS, ADM

and Bio-Gide scaffolds were quantified by CCK-8 assay (Fig. 12). The ACVM-0.25% HLC-I scaffold

exhibited a larger number of cells when compared with the other

scaffolds. The ACVM-0.25% HLC-I scaffold had the fastest level of

proliferation compared with the ADM, Bio-Gide and SIS scaffolds,

with the majority of HGFs attaching following 1 h of incubation.

There was no significant difference in the number of cells between

the ADM and Bio-Gide scaffolds (P>0.05). The number of cells in

the SIS scaffold was lower when compared with the other scaffolds

at all times. With the exception of the SIS scaffold, the number of

cells collected from the scaffolds at 72 h was significantly

increased from that at 24 h (P<0.05; Fig. 12).

Scaffold diameter prior to and

following seeding with HGFs

The diameter of all scaffolds was 10 mm prior to

seeding with HGFs. Following 7 days, the ACVM-0.25% HLC-I scaffold

had contracted significantly. The ADM and Bio-Gide scaffolds seeded

with HGFs were slightly larger when compared with prior to seeding.

There was no significant change in the SIS scaffold diameter

following seeding with HGFs. The diameters of the four scaffolds

prior to and following seeding with HGFs are presented in Table III.

| Table III.Diameter of the four different

biodegradable scaffolds before and after seeding with HGFs. |

Table III.

Diameter of the four different

biodegradable scaffolds before and after seeding with HGFs.

|

| Diameter of

scaffold (mm) |

|---|

|

|

|

|---|

| Scaffold | Prior to

seeding | Following HGF

seeding for 7 days |

|---|

| ACVM-0.25%

HLC-I | 10.00 |

9.77a |

| SIS | 10.00 | 10.00 |

| Bio-Gide | 10.00 | 10.02 |

| ADM | 10.00 | 10.04 |

Discussion

The most widely used scaffold materials in tissue

engineering research are natural biological scaffold materials,

synthetic degradable polymer scaffolds and composite scaffold

materials. In the present study, the SIS (28,29)

and ADM scaffolds were used as natural biological scaffold

materials, and the Bio-Gide scaffold material was a synthetic

degradable polymer. The ACVM-HLC-I scaffold combined ACVM material

with HLC-I to form a composite scaffold material. Previous research

has indicated that composite scaffold materials possess the good

cellular compatibility of natural biological scaffolds and the

strong mechanical properties of synthetic degradable polymer

scaffolds (31). In the present

study, ACVM-HLC-I was compared with ADM, Bio-Gide and SIS, and the

aim of the study was to verify the feasibility of the composite

scaffold material ACVM-HLC-I for application as a tissue

engineering scaffold material. Preliminary findings had confirmed

that the ACVM-HLC-I composite scaffold material was feasible for

the construction of tissue-engineered blood vessels. ACVM-0.25%

HLC-I provides a three-dimensional ultrastructure space for the

growth of seeded cells and promotes the establishment of an

organized structure and function (32). It also has appropriate mechanical

properties for maintaining compressive resistance, which is

required for building blood vessel substitutes. A concentration of

0.25% HLC-I was demonstrated to be optimal (23). The preparation of ACVM-0.25% HLC-I

material supported the tissue engineering of blood vessels by

inducing vascular endothelial cells and smooth muscle cells

(33). In the present study, the

application feasibility of composite scaffold material ACVM-0.25%

HLC-I was explored further and compared with other tissue

engineering scaffold materials, ADM, Bio-Gide and SIS.

In the present study, the ADM material was a

transparent, milky-yellow film 0.4–0.6 mm thick, which was divided

into a coarse hairy surface and a translucent honeycomb smooth

surface with slightly elastic force. The Bio-Gide material was a

white membrane, which was slightly less thick than the ADM scaffold

material. Large collagen bundles could be seen protruding from the

surface of the Bio-Gide scaffold, and the elasticity was low. The

SIS scaffold material was a yellow and white translucent membrane

with low elasticity. The ACVM-0.25% HLC-I scaffold was a

homogeneous, translucent membrane with low thickness and high

elasticity. H&E staining, Masson staining and SEM indicated

that there were dense bundles of collagen fibers on the surface of

the ADM, Bio-Gide, SIS and ACVM-0.25% HLC-I scaffolds, but on the

ACVM-0.25% HLC-I scaffold these were more slender and soft compared

with those on the SIS, ADM and Bio-Gide scaffolds. In addition,

compared with the Bio-Gide scaffold, the surface fiber structure of

the ADM scaffold was dense, while the surface fiber structure of

the SIS scaffold was relatively sparse and hard.

Previous studies have indicated that scaffold

materials applied in tissue engineering should have a degree of

biomechanical strength (23,30),

also called mechanical strength, to ensure that they do not become

deformed or ruptured when implanted in the body of a human or

animal. For example, tissue-engineered blood vessels should have a

certain amount of compressive stress and shear stress to tolerate

blood flow impact without breaking. To compare the strength of ADM,

Bio-Gide, SIS and AVCM-0.25% HLC-I materials in the present study,

biomechanical test apparatus was used for various mechanical

experiments. In terms of stress, ADM scaffold materials reached a

maximum tensile stress of 4.65±0.78 Mpa at 46 sec, which was

significantly higher compared with the ACVM-0.25% HLC-I, Bio-Gide

and SIS scaffold materials. Among the groups, there was no

significant difference in tensile stress between the ACVM-0.25%

HLC-I and Bio-Gide scaffold materials, but the SIS scaffold

material had significantly lower tensile stress compared with other

three scaffold materials. There was a significant difference in

strain among the ADM, ACVM-0.25% HLC-I, Bio-Gide and SIS scaffold

materials. The ACVM-0.25% HLC-I was not significantly different

compared with the Bio-Gide scaffold, but was significantly

different compared with the SIS scaffold. A stress-strain curve was

constructed for the ADM, Bio-Gide, SIS and ACVM-0.25% HLC-I

scaffold materials. The ADM scaffold had the largest tensile

capacity. The resistance of the Bio-Gide scaffold was similar to

that of the ACVM-0.25% HLC-I, while the tensile strength of the SIS

scaffold material was relatively poor. According to the fracture

strength value, ADM scaffolds had the highest fracture strength.

The ACVM-0.25% HLC-I scaffold and Bio-Gide material had a similar

fracture strength and were weaker compared with the ADM scaffold.

The SIS scaffold had the lowest fracture strength. The elongation

at break value was highest for the SIS scaffold, followed by the

Bio-Gide and ACVM-0.25% HLC-I scaffolds. The ADM scaffold had the

lowest elongation at break value.

The aforementioned results indicated that the

breaking strength values of the ADM, Bio-Gide, ACVM-0.25% HLC-I and

SIS scaffolds were negatively associated with elongation at break.

Although ADM scaffolds had the highest breaking strength, their

elongation at break was the smallest. Although SIS scaffolds had

the smallest breaking strength, their elongation at break was the

largest. There was no significant difference between the Bio-Gide

and ACVM-0.25% HLC-I scaffolds in terms of breaking strength and

elongation at break. This suggested that although the tensile

stress, stress strain and breaking strength of the ACVM-0.25% HLC-I

scaffold were not as large as that of the ADM scaffold material, it

had similar properties to the Bio-Gide scaffold material. As

composite scaffolds, ACVM-0.25% HLC-I scaffolds have similar

mechanical properties and mechanical strength to synthetic

biodegradable polymer scaffolds; that is, ACVM-0.25% HLC-I

scaffolds have appropriate mechanical strength and other mechanical

properties to act as scaffolds for tissue engineering.

The results of the water absorption test indicated

that ACVM-0.25% HLC-I scaffolds had a significantly greater water

absorption capacity compared with the SIS, Bio-Gide and ADM

scaffolds. The SIS scaffold had the worst mechanical properties,

but its water absorption capacity was only inferior to that of the

ACVM-0.25% HLC-I scaffold. Although the mechanical capacity of

Bio-Gide scaffold was not significantly different to that of the

ACVM-0.25% HLC-I scaffold, its water absorption ability was

markedly lower compared with the ACVM-0.25% HLC-I scaffold. The

mechanical strength of the ADM scaffold was the largest, but its

water absorption capacity was the poorest. Based on the

aforementioned experimental results, it was concluded that the

ACVM-0.25% HLC-I scaffold possessed biomechanical properties and a

strong water absorption capability, further indicating its

feasibility as a tissue engineering scaffold material.

Furthermore, scaffold materials for tissue

engineering should have no cytotoxic effects in addition to

possessing biomechanical strength (34). The results indicated that the

cytotoxicity of ACVM-0.25% HLC-I scaffolds was significantly

different from that of the ADM, Bio-Gide and SIS scaffolds, while

there was no significant difference in cytotoxicity between ADM and

Bio-Gide scaffolds. The relative growth rate (RGR) of ACVM-0.25%

HLC-I, ADM and Bio-Gide scaffolds was >75% at 24, 48 and 72 h,

the cytotoxicity grade was 1, and the scaffolds were considered to

not be cytotoxic. The RGR of the SIS scaffolds was >40% at 24 h,

and the scaffolds were considered to be cytotoxic. The RGR was

>50% at 48 and 72 h, and the scaffolds were considered to not be

cytotoxic. This suggested that, as a scaffold for tissue

engineering, the ACVM-0.25% HLC-I scaffold had improved cellular

compatibility and lower cytotoxicity compared with the ADM,

Bio-Gide and SIS scaffolds, which provides a basis for screening of

the material in vivo implants. Subsequently, an experiment

was conducted to verify whether the diameter of the material

changed following seeding with HGFs. The results indicated that

following seeding with HGFs, the diameter of the ACVM-0.25% HLC-I

scaffold decreased and the diameter of the SIS scaffold had not

markedly changed. The diameters of the ADM and Bio-Gide scaffolds

increased slightly. This may be associated with good attachment and

growth of HGFs on the ACVM-0.25% HLC-I scaffold.

ACVM-0.25% HLC-I scaffold material, which combines

HLC-I (23) with ACVM (23,24),

is a composite tissue engineering scaffold formed by combining

natural acellular biomaterials with synthetic polymer materials.

Composite materials have the advantages of natural acellular

biomaterials (such as ADM scaffolds) and synthetic polymer

materials (such as Bio-Gide scaffolds). Therefore, they can provide

three-dimensional ultrastructural protein space for cell growth and

promote the formation of tissue function. They also possess

sufficient mechanical properties to maintain the compressive

ability of the tissue substitutes and the degradation rate of the

material, and can be designed and regulated (35,36).

In conclusion, the results of the present study indicate that

ACVM-0.25% HLC-I promotes cell adhesion, cell proliferation and

cell migration, and possesses good mechanical and biomechanical

properties. This suggests that the composite tissue engineering

scaffold material could be successfully applied in tissue

regeneration.

The limitations in the present study must also be

mentioned. Firstly, during the experiment, the authors did not

consider to evaluate the potential change of the scaffold material

following 7 days in mechanical properties, only testing the

mechanical properties of the scaffold material prior to planting

the cells. Secondly, no in vivo tests were performed on

animals, which was a flaw in our experimental design, thus this

will be addressed in future studies.

Acknowledgements

Not applicable.

Funding

The present study was supported by Applied basic

research found of Luzhou Science and Technology Bureau of Sichuan

province (grant no. 2018-JYJ-36); City-School-Stomatological

Hospital Introduces Doctoral Research Fund (grant no. 20186-2);

Scientific Research Fund of Sichuan Medical Association (grant no.

S17073)

Availability of data and materials

All data generated or analyzed during the present

study are included in this article.

Authors' contributions

All authors conceived and designed the experiments.

YLQ, XC and YLH performed the experiments and analyzed the data.

YJH, SBT and YHC wrote the manuscript. LY, MHN and XQL modified the

manuscript and designed the experiments.

Ethics approval and consent to

participate

Animal experiments were approved by the Ethics

Committee of Southwest Medical University (Sichuan, China). The

acquisition of normal human gingival tissues from patients was

approved by the Hospital of Stomatology at Hebei Medical University

(Hebei, China), and written informed consent was obtained from all

patients.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Gao P, Jiang D and Li Z: The application

progress of human urine derived stem cells in bone tissue

engineering. Zhonghua Wai Ke Za Zhi. 54:317–320. 2016.(In Chinese).

PubMed/NCBI

|

|

2

|

Sun Z and Li J: Research progress of

tissue engineered ligament. Zhongguo Xiu Fu Chong Jian Wai Ke Za

Zhi. 29:1160–1166. 2015.(In Chinese). PubMed/NCBI

|

|

3

|

Yang Q, Xu HW, Hurday S and Xu BS:

Construction strategy and progress of whole intervertebral disc

tissue engineering. Orthop Surg. 8:11–18. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Ge L, Cao C, Chen S, Shao B, Li Q, Li Q,

Liu L, Liang Z and Huang Y: Preparation of laminin/nidogen adsorbed

urinary bladder decellularized materials via a mussel-inspired

polydopamine coating for pelvic reconstruction. Am J Transl Res.

9:5289–5298. 2017.PubMed/NCBI

|

|

5

|

Mi HY, Jing X, Napiwocki BN, Hagerty BS,

Chen G and Turng LS: Biocompatible, degradable thermoplastic

polyurethane based on

polycaprolactone-block-polytetrahydrofuran-block-polycaprolactone

copolymers for soft tissue engineering. J Mater Chem B.

5:4137–4151. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Wang L, Yang J, Ran B, Yang X, Zheng W,

Long Y and Jiang X: Small molecular TGF-β1-inhibitor-loaded

electrospun fibrous scaffolds for preventing hypertrophic scars.

ACS Appl Mater Interfaces. 9:32545–32553. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Faulk DM, Londono R, Wolf MT, Ranallo CA,

Carruthers CA, Wildemann JD, Dearth CL and Badylak SF: ECM hydrogel

coating mitigates the chronic inflammatory response to

polypropylene mesh. Biomaterials. 35:8585–8595. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Wang W, Deng D, Wang B, Zhou G, Zhang W,

Cao Y, Zhang P and Liu W: * Comparison of autologous, allogeneic,

and cell-free scaffold approaches for engineered tendon repair in a

rabbit model-a pilot study. Tissue Eng Part A. 23:750–761. 2017.

View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Xie J, Peng C, Zhao Q, Wang X, Yuan H,

Yang L, Li K, Lou X and Zhang Y: Osteogenic differentiation and

bone regeneration of iPSC-MSCs supported by a biomimetic

nanofibrous scaffold. Acta Biomater. 29:365–379. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Baumgartner W, Schneider I, Hess SC, Stark

WJ, Märsmann S, Brunelli M, Calcagni M, Cinelli P and Buschmann J:

Cyclic uniaxial compression of human stem cells seeded on a bone

biomimetic nanocomposite decreases anti-osteogenic commitment

evoked by shear stress. J Mech Behav Biomed Mater. 83:84–93. 2018.

View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Qiu XW and Wang JH: Efficacy of dermal

scaffold for promoting repair of acute full-thickness skin defects

in pigs. Nan Fang Yi Ke Da Xue Xue Bao. 38:363–368. 2018.(In

Chinese). PubMed/NCBI

|

|

12

|

Ramanathan G, Muthukumar T and

Tirichurapalli Sivagnanam U: In vivo efficiency of the collagen

coated nanofibrous scaffold and their effect on growth factors and

pro-inflammatory cytokines in wound healing. Eur J Pharmacol.

814:45–55. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Farkas B, Rodio M, Romano I, Diaspro A,

Intartaglia R and Beke S: Fabrication of hybrid nanocomposite

scaffolds by incorporating ligand-free hydroxyapatite nanoparticles

into biodegradable polymer scaffolds and release studies. Beilstein

J Nanotechnol. 6:2217–2223. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Nasonova MV, Glushkova TV, Borisov VV,

Velikanova EA, Burago AY and Kudryavtseva YA: Biocompatibility and

structural features of biodegradable polymer scaffolds. Bull Exp

Biol Med. 160:134–140. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Perry L, Flugelman MY and Levenberg S:

Elderly patient-derived endothelial cells for vascularization of

engineered muscle. Mol Ther. 25:935–948. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Hu WW, Wu YC and Hu ZC: The development of

an alginate/polycaprolactone composite scaffold for in situ

transfection application. Carbohydr Polym. 183:29–36. 2018.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Sun T, Liu M, Yao S, Ji Y, Xiong Z, Tang

K, Chen K, Yang H and Guo XD: Biomimetic composite scaffold

containing small intestinal submucosa and mesoporous bioactive

glass exhibits high osteogenic and angiogenic capacity. Tissue Eng

Part A. 24:1044–1056. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Tohamy KM, Mabrouk M, Soliman IE, Beherei

HH and Aboelnasr MA: Novel alginate/hydroxyethyl

cellulose/hydroxyapatite composite scaffold for bone regeneration:

In vitro cell viability and proliferation of human mesenchymal stem

cells. Int J Biol Macromol. 112:448–460. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Awad NK, Niu H, Ali U, Morsi YS, Lin T, et

al: Electrospun fibrous scaffolds for small-diameter blood vessels:

A review. Membranes (Basel). 8:E152018. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Xu Y, Wu J, Wang H, Li H, Di N, Song L, Li

S, Li D, Xiang Y, Liu W, et al: Fabrication of electrospun

poly(L-lactide-co-ε-caprolactone)/collagen nanoyarn network as a

novel, three-dimensional, macroporous, aligned scaffold for tendon

tissue engineering. Tissue Eng Part C Methods. 19:925–936. 2013.

View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Feng C, Hu J, Liu C, Liu S, Liao G, Song L

and Zeng X: Association of 17-β estradiol with adipose-derived stem

cells: New strategy to produce functional myogenic differentiated

cells with a nano-scaffold for tissue engineering. PLoS One.

11:e01649182016. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Lech CJ and Phan AT: Ball with hair:

Modular functionalization of highly stable G-quadruplex DNA

nano-scaffolds through N2-guanine modification. Nucleic Acids Res.

45:6265–6274. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Liu X, Wang J, Dong F, Song P, Tian S, Li

H and Hou Y: Cytocompatibility and biologic characteristics of

synthetic scaffold materials of rabbit acellular vascular matrix

combining with human-like collagen I. J Biomater Appl. 32:463–471.

2017. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Lalka SG, Oelker LM, Malone JM, Duhamel

RC, Kevorkian MA, Raper BA, Nixon JC, Etchberger KJ, Dalsing MC,

Cikrit DF, et al: Acellular vascular matrix: A natural endothelial

cell substrate. Ann Vasc Surg. 3:108–117. 1989. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Liu X, Wang J, Dong F, Song P, Li H and

Hou Y: Study of composite vascular scaffold combining with

differentiated VSMC- and VEC-like cells in vitro and in vivo. J

Biomater Appl. 32:219–229. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Heidemann LN, Gunnarsson GL, Salzberg CA,

Sørensen JA and Thomsen JB: Complications following nipple-sparing

mastectomy and immediate acellular dermal matrix implant-based

breast reconstruction-a systematic review and meta-analysis. Plast

Reconstr Surg Glob Open. 6:e16252018. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Sobti N, Ji E, Brown RL, Cetrulo CL Jr,

Colwell AS, Winograd JM, Austen WG Jr and Liao EC: Evaluation of

acellular dermal matrix efficacy in prosthesis-based breast

reconstruction. Plast Reconstr Sur. 141:541–549. 2018. View Article : Google Scholar

|

|

28

|

Pitman MJ, Kurita T, Powell ME, Kimball

EE, Mizuta M, Chang S, Garrett CG and Rousseau B: Vibratory

function and healing outcomes after small intestinal submucosa

biomaterial implantation for chronic vocal fold scar. Laryngoscope.

128:901–908. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Zhou Q, Teng F, Zhang Y, Sun Q and Meng G:

Evaluation of transventricular placement of porcine small

intestinal submucosa stent valves in the pulmonary position in

juvenile sheep model. Interact Cardiovasc Thorac Surg. 27:295–300.

2018. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Liu X, Wang J, Dong F, Li H and Hou Y:

Induced differentiation of human gingival fibroblasts into

VSMC-like cells. Differentiation. 95:1–9. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Choi HJ, Lee JJ, Lee JB, Sung HJ, Shin JW,

Shin JW, Wu Y and Kim JK: MG-63 cells proliferation following

various types of mechanical stimulation on cells by auxetic hybrid

scaffolds. Biomater Res. 20:322016. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Zhang W, Choi JK and He X: Engineering

microvascularized 3D tissue using alginate-chitosan microcapsules.

J Biomater Tissue Eng. 7:170–173. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Wang Y, Yin P, Bian GL, Huang HY, Shen H,

Yang JJ, Yang ZY and Shen ZY: The combination of stem cells and

tissue engineering: An advanced strategy for blood vessels

regeneration and vascular disease treatment. Stem Cell Res Ther.

8:1942017. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Saberi EA, Karkehabadi H and Mollashahi

NF: Cytotoxicity of various endodontic materials on stem cells of

human apical papilla. Iran Endod J. 11:17–22. 2016.PubMed/NCBI

|

|

35

|

Wu T, Huang C, Li D, Yin A, Liu W, Wang J,

Chen J, Ei-Hamshary H, Al-Deyab SS and Mo X: A multi-layered

vascular scaffold with symmetrical structure by bi-directional

gradient electrospinning. Colloids Surf B Biointerfaces.

133:179–188. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Jiang B, Akar B, Waller TM, Larson JC,

Appel AA and Brey EM: Design of a composite biomaterial system for

tissue engineering applications. Acta Biomater. 10:1177–1186. 2014.

View Article : Google Scholar : PubMed/NCBI

|