Introduction

The repair of peripheral nervous system (PNS) damage

resulting from trauma, excessive stretching and even iatrogenic

injury is a tremendous challenge for clinical medicine as the

recovery of nerve function may be poor due to broken end distortion

following nerve anastomosis and scar ingrowth, ineffective nerve

regeneration and slow regeneration. Among several current therapies

for PNS damage, for example, neurosuture and nerve grafting, the

combined application of nerve regeneration-promoting drugs is a

promising technology that has few adverse reactions (1). Tacrolimus (FK506) is a macrolide

immunosuppressant approved by the US Food and Drug Administration.

It plays a role not only in immunosuppression but also in the

effective promotion of nerve regeneration. However, at present, the

systemic application of FK506 has certain side-effects, such as

nephrotoxicity, gastrointestinal dysfunction and hypertension

(2–5). In current research, the local

application of FK506 is regarded as a feasible method for reducing

side-effects. However, no accurate test is available to evaluate

the effective concentration for local application (6). A newly emerging technology known as

microfluidics has been demonstrated to be very useful for screening

the dosages of drugs. A stable cell culture environment can be

constituted and maintained by a continuous medium supply and waste

removal system that resembles the human circulatory system.

Furthermore, it reduces the number of cells required and the

requirement for large volumes of culture medium and costly

reagents, which makes the microfluidic device an attractive

platform for high-throughput screening (7,8).

In the present study, an integrated microfluidic

device was designed and fabricated that may provide an ideal

platform for cell level manipulation and analysis in vitro.

Furthermore, rat Schwann cells (SCs) were loaded into the device

and the optimum concentration of FK506 was determined with the aim

of providing an experimental and theoretical reference for the

therapy of peripheral nerve injury.

Materials and methods

Materials

FK506 (molecular weight, 804.02 g/mol) was purchased

from Purac Biochem Co. (Gorkum, The Netherlands), and used without

further purification. Rat SCs (RSC96 cell line) were purchased from

ScienCell Research Laboratories (Carlsbad, CA, USA).

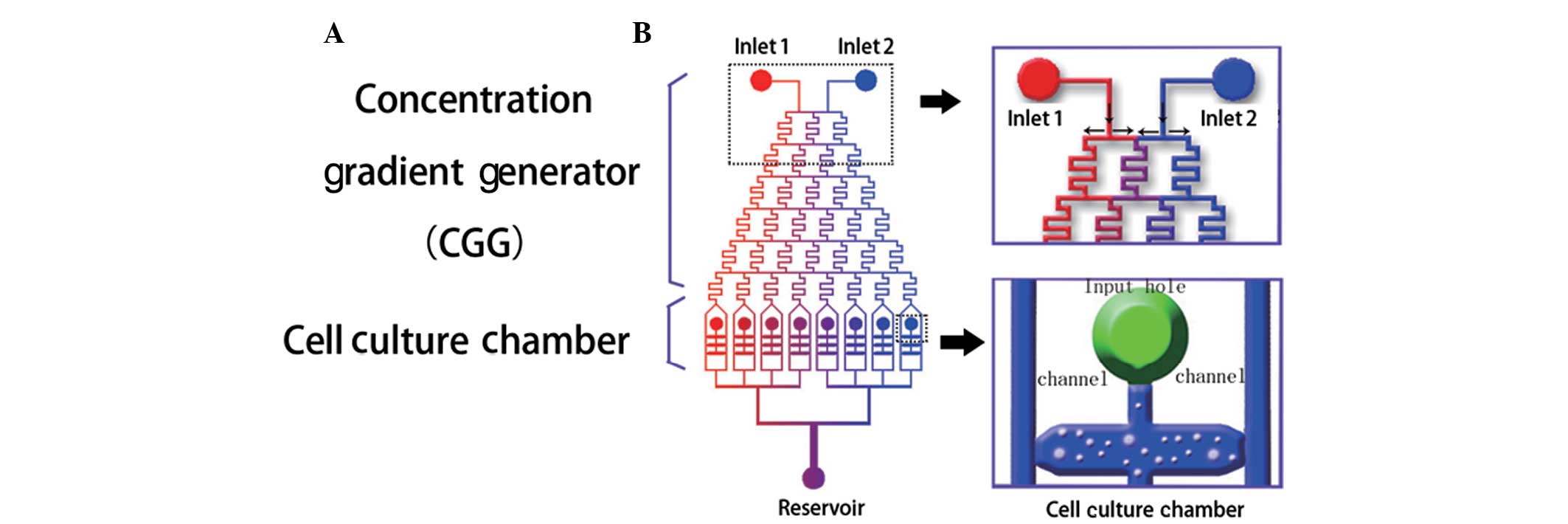

Design and fabrication of the

microfluidic device

The microfluidic device was designed using

computer-aided design (CAD) software, to provide a continuous

concentration gradient for the chemical stimulation of a cell

culture (9). The device included

two parts (Fig. 1A), namely a

pyramid shaped concentration gradient generator (CGG) and a cell

culture chamber. In accordance with the Reynolds effect, the

Reynolds number can be very low when the capillary diameter is ~100

nm to several hundred micrometers, and liquid will show a laminar

flow when it passes through the serpentine channels of the

microfluidic chip. When using this chip, if one solution

(concentration A) and a second solution (concentration 0) are

injected into the CGG via the two inlets, they are split at the

nodes, combined with neighboring streams in a laminar fashion, and

mixed by diffusion in the serpentine channels, and the

concentrations in the eight outlets are, respectively, 0, 1/7A,

2/7A, 3/7A, 4/7A, 5/7A, 6/7A and A.

Three cell culture chambers of the same function

were connected between two parallel channels of each outlet of the

CGG. The volume of each chamber was 0.4 μl (length, 800 μm; width,

500 μm; height, 100 μm). The SCs were loaded into a chamber through

an input hole. When solutions flow down the parallel channels,

substances contained in them, such as FK506, diffuse into the

chamber by osmosis until saturation is achieved.

The microfluidic devices were fabricated in

poly-dimethylsiloxane (PDMS) using rapid prototyping and soft

lithography (11). Firstly, a

transparency mask was generated by a high resolution printer from

the CAD file. The mask was used in 1:1 contact photolithography

with an SU-8 photoresist (MicroChem, Newton, MA, USA) to generate a

negative master consisting of a patterned photoresist on a silicon

wafer. Positive replicas with embossed channels were fabricated by

molding PDMS against the master. Secondly, the inlets and outlets

(ϕ=1 mm) for the fluids were punched out of the PDMS using a

sharpened needle. Then, an ultrasonically cleaned glass substrate

and the PDMS molding were irreversibly combined together to form a

system of microfluidic channels in the PDMS-glass composite chip.

The channels were 100 μm wide and 30 μm deep.

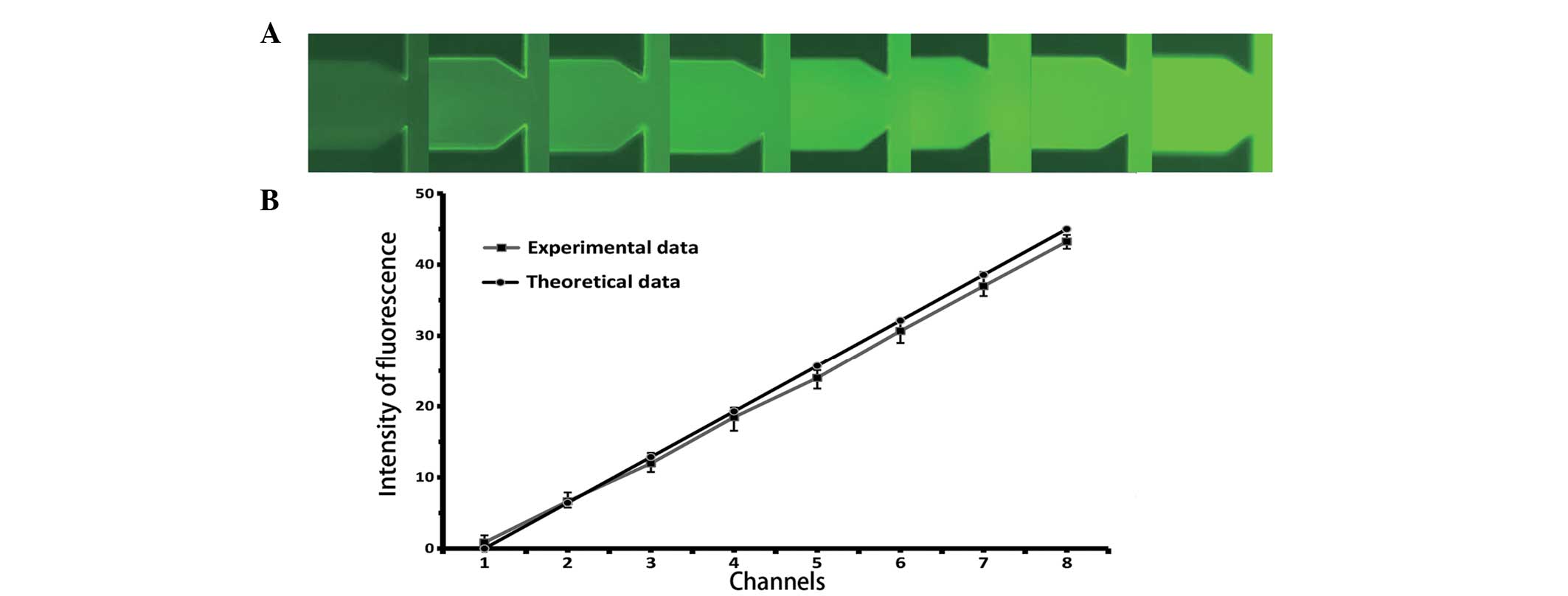

CGG performance validation

Fluorescein isothiocyanate-dextran (FITC-dextran;

Nanocs, Boston, MA, USA) was used as an indicator for evaluating

the gradient generated by the CGG. By injecting FITC-dextran and

phosphate-buffered saline into the two inlets, respectively, the

FITC-dextran was continuously diluted. A series of concentrations

of FITC-dextran were thus acquired in the CGG and then flowed into

the corresponding downstream cell culture devices. As the intensity

of fluorescence of FITC-dextran is proportional to its

concentration, the concentration was positively associated with the

intensity of fluorescence of FITC-dextran in the CGG (10). The intensities of FITC-dextran at

the eight outlets of the CGG were imaged by confocal laser scanning

microscopy (Leica Microsystems, Wetzlar, Germany) and quantified

using Image-Pro Plus software (version 6.0 for Windows 7; Media

Cybernetics, Inc., Rockville, MD, USA). All experiments were

repeated three times. The measured values were compared with

theoretical values (9),

whereafter, their relativity was analyzed.

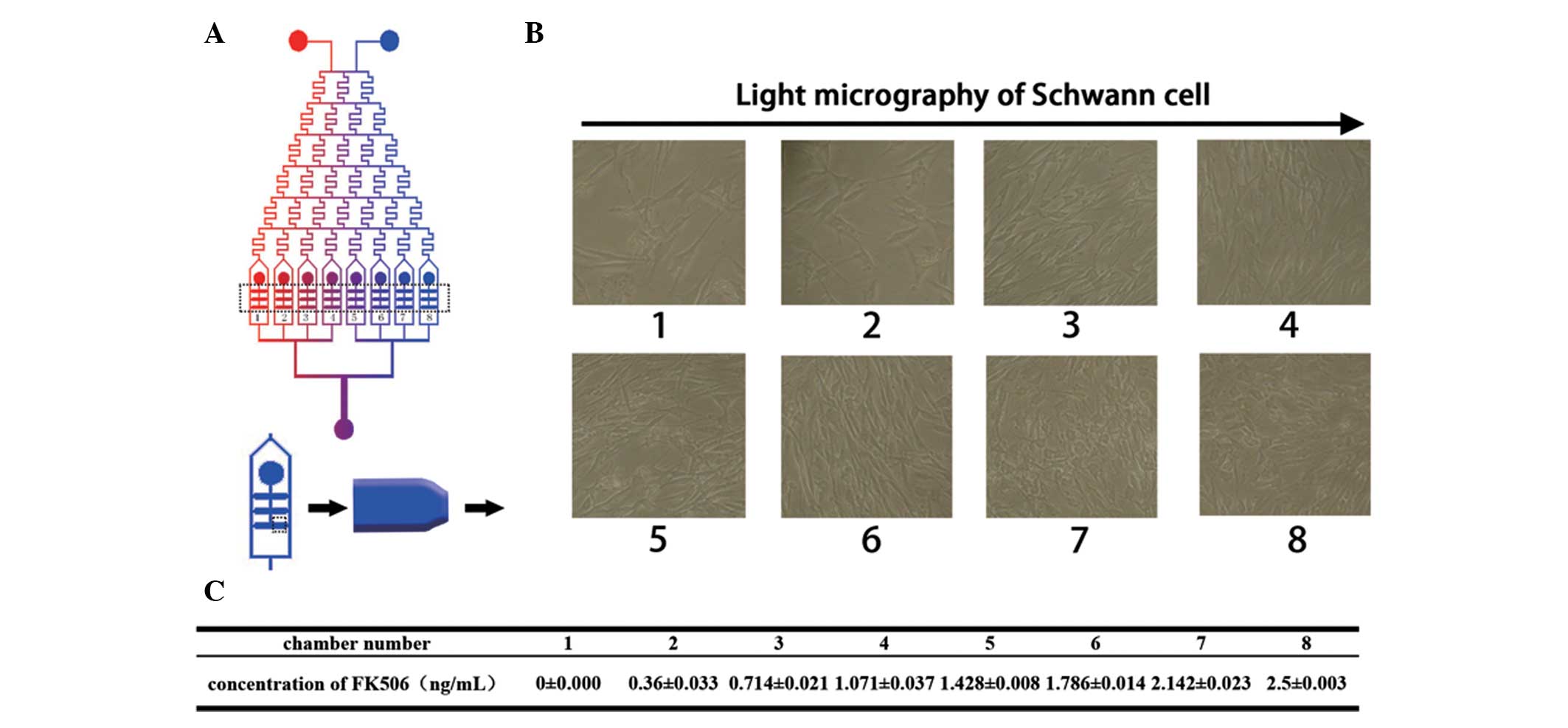

Screening of the effective concentration

of FK506

Culture media with and without FK506 were

simultaneously infused into the microfluidic device. The fluid was

driven by a medical syringe pump, and the flow speed was controlled

at 0.1 μl/min (Fig. 2). The

concentration gradient of FK506 was established at the eight

outlets of the CGG 30 min later following the repeated splitting,

mixing, and recombination of the fluid streams as they traveled

through the channels of the CGG. In each cell culture chamber to

which the SCs had been loaded, a culture medium with different

concentrations of FK506 was obtained when the solution flowed in

the parallel channels of each outlet (12). To prevent the washing out of cells,

a 3-h incubation step was conducted prior to infusion of the

culture media since SCs loaded inside the chambers attach to FK506

after a while and their locations remain relatively stable. The

device was then kept in an incubator at 37°C, 5% CO2 and

100% humidity for an additional 1, 3, 5, 7 and 9 days. At every

indicated time interval, the extent of the cell proliferation was

evaluated using a cell counting kit 8 (CCK-8) assay (Dojindo,

Tokyo, Japan) (13). Then, the

concentration of FK506 was analyzed by liquid chromatography-mass

spectrometry (3200QTRAP®; Applied Biosystems, Foster

City, CA, USA). All cell proliferation assays were repeated in

96-well plates with the same concentrations.

Statistical analysis

All quantitative data were analyzed and expressed as

the mean ± standard deviation. Cell proliferation assay results

were assessed by one way analysis of variance (ANOVA). The

comparison between two means was analyzed using Tukey’s test, and

P<0.05 was considered to indicate a statistically significant

difference.

Results

CGG performance validation

Figs. 1 and

2 are images of the microfluidic

device. As streams of dye traveled down the network, they were

repeatedly split, combined with neighboring streams in laminar mode

at the nodes, and mix by diffusion in the serpentine channels. A

series of solutions with different concentrations of FITC-dextran

were formed at the cell culture chamber (Fig. 3A). The fluorescent intensities of

FITC-dextran in the junctions between the CGG and the cell culture

module were quantified, corrected by subtraction of the background

fluorescence, and compared with the theoretical data. As shown in

Fig. 3B, there was a good

coherence (correlation coefficient = 0.9948) between the

experimental and theoretical data.

Cell proliferation and effective

concentration of FK506

To measure the effective concentration of FK506, SCs

were loaded into the microfluidic device and exhibited a polygonal

morphology after nine days in the presence of different

concentrations of FK506 solution (Fig.

4B). The effective concentration was screened over a large

range, and it was confirmed that the highest proliferation rate was

obtained at a concentration between 1.786±0.014 and 2.5±0.003

ng/ml. The concentrations of FK506 from chamber 1 to chamber 8 are

shown in Fig. 4C. The

concentration-dependency of SC proliferation in the presence of

FK506 was apparent between 0 and 2.5±0.003 ng/ml as shown in

Fig. 4B. The proliferation rate

reached a maximum in the 1.786±0.014 ng/ml group (Fig. 5), which was statistically

significantly different from the proliferation rates in the groups

of lower FK506 concentrations (P<0.01). These results were

consistent with the light micrographs shown in Fig. 4B. There was no statistically

significant difference between the proliferation rate in the

1.786±0.014 ng/ml group and that in the groups of higher FK506

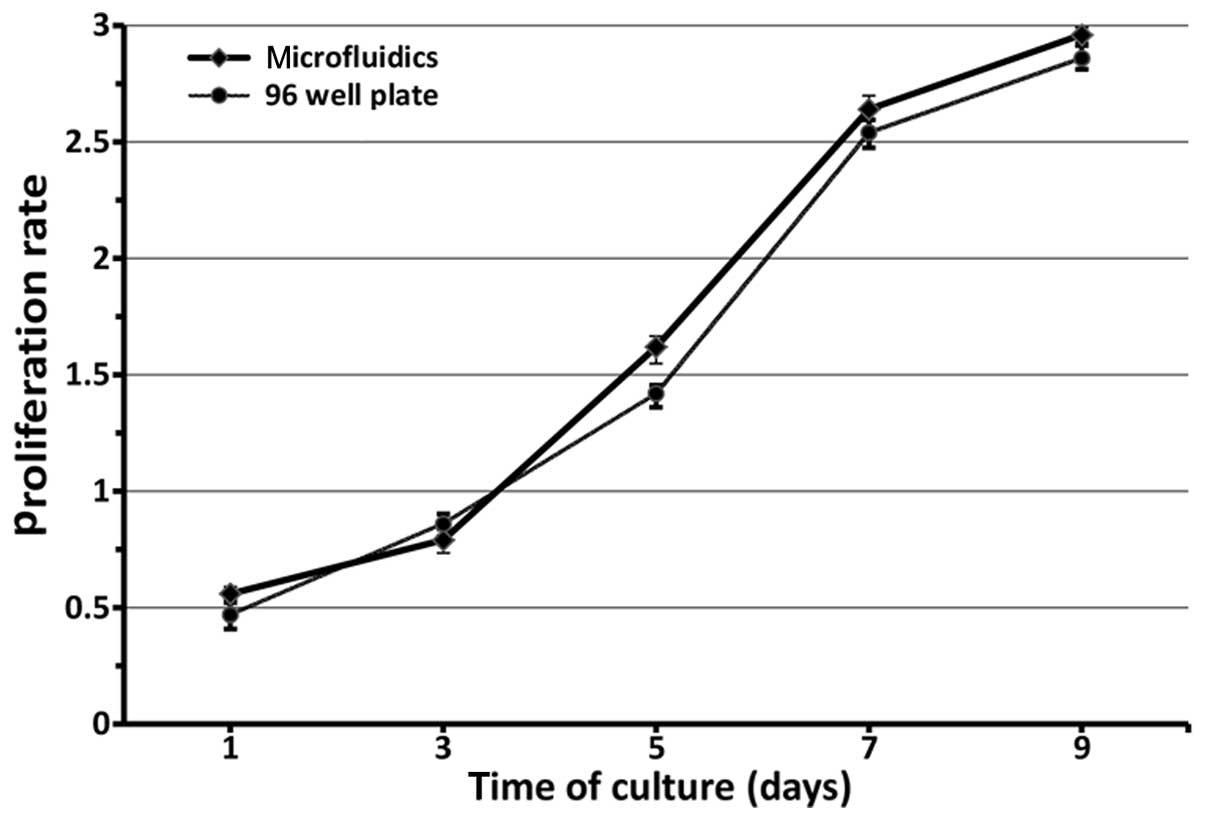

concentration (P>0.05). Furthermore, in Fig. 6, the proliferation of RSCs was

evaluated by CCK-8 quantitative assay after culturing for nine

days. The RSCs in the microfluidic device and 96-well plate

continued to proliferate as the culture time was prolonged. There

were no statistically significant differences between the

microfluidic chips and 96-well plate with regard to proliferation

rate in each corresponding group (F=121.366, P>0.05). Thus, it

is considered that the effective local concentration of FK506 is in

the vicinity of 1.786±0.014 ng/ml.

Discussion

Microfluidic devices integrate the preparation of

pharmaceutical compositions, separation, detection, cell culture

and other basic operations into a very small chip (14). Compared with traditional methods of

pharmaceutical analysis, microfluidic chips are characterized by

minimal sample demand and a significant improvement of detection

sensitivity. The use of such chips may reduce consumption and costs

significantly. Due to the characteristics of integration,

miniaturization and automation, it is also known as ‘lab-on-a-chip’

(15). In the present study, the

high throughput screening of the effective concentration of FK506

was determined using very small amounts of cells and drugs. The

experimental conditions were easily controlled by changing the

concentration of the FK506 solution, and the risk of contamination

was minimal. More importantly, a stable culture environment was

constituted and maintained by the continuous medium supply and

waste removal system (16).

Furthermore, FK506 diffused into the cell culture chamber, and the

metabolic waste generated by cell growth was drained away

simultaneously. This bionic design was used to test different

concentrations of FK506 for their ability to improve SC growth. The

design of parallel pipelines through from the side of the cell

culture chamber kept cells away from the direct flushing effect of

solution. Due to the low consumption of cells in microfluidic

devices, cell loss can influence the result significantly. The

small but effective design of the device in the present study may

reduce the influence of cell loss. The consistency of the cell

proliferation between the microfluidic chip and 96-well plates

(Fig. 6) demonstrates that the

microfluidic device performs excellently in the high throughput

screening of effective drug concentrations. Due to the

aforementioned advantages, microfluidic devices are ideal platforms

for cell level manipulation and analysis in vitro.

FK506 is widely used clinically as an

immunosuppressant following liver and kidney transplantations. By

combining with FK506 binding protein-1 and suppressing the immune

responses induced by nerve injury, it creates a suitable

microenvironment for nerve regeneration (17,18).

Although the effectiveness of FK506 for the promotion of nerve

regeneration is known (19), at

present, due to the fact that systemic application may lead to

opportunistic infections and tumors and is not generally accepted

for the treatment of peripheral nerve injury, FK506 has not been

widely used for the treatment of simple peripheral nerve injury.

The systemic application of FK506 has certain side-effects such as

nephrotoxicity, gastrointestinal dysfunction and hypertension.

These factors restrict the application of FK506. The method of

local application of FK506 to avoid side-effects from systemic

application has been widely approved by clinics (20). However, no accurate test is

available to determine the effective concentration for local

application. For the purpose of testing the effective

concentration, a series of FK506 concentrations were established

and their effects on rat SCs were investigated using the

microfluidic device in the present study. It was shown that the

cell proliferation rate increased as the FK506 concentration

increased and reached a peak at 1.786±0.014 ng/ml. As the

concentration of FK506 increased from 1.786±0.014 to 2.5±0.003

ng/ml, no further increase occurred, which indicates that higher

concentrations have no additional promoting effect. Accordingly, it

is considered that FK506 shows a maximum capacity for stimulating

peripheral nerve regeneration at a concentration of 1.786±0.014

ng/ml. The risk of adverse effects is likely to be greatly

increased at higher dosages.

In the present study, FK506 synergistically promoted

SC proliferation. The effective FK506 concentration for local

application was determined to be 1.786±0.014 ng/ml. A microfluidic

device was fabricated from PDMS. The device design was developed in

order to adapt to the cell culture and the effectiveness for

high-throughput screening was demonstrated by the intensity of

fluorescence of FITC-dextran. The data obtained revealed that the

microfluidic device described in the present study is a candidate

for cell level manipulation and analysis in vitro. The

advantages of miniaturization and high integration indicate that

microfluidic technology holds great promise for use in high-through

screening at the cellular level.

Acknowledgements

This study was funded by the National Natural

Science Foundation of China (81171464).

References

|

1

|

Terzis JK, Sun DD and Thanos PK:

Historical and basic science review: past, present, and future of

nerve repair. J Reconstr Microsurg. 13:215–225. 1997. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Varghese J, Reddy MS, Venugopal K, et al:

Tacrolimus-related adverse effects in liver transplant recipients:

its association with trough concentrations. Indian J Gastroenterol.

33:219–225. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Yamazoe K, Yamazoe K, Yamaguchi T, Omoto M

and Shimazaki J: Efficacy and safety of systemic tacrolimus in

high-risk penetrating keratoplasty after graft failure with

systemic cyclosporine. Cornea. 33:1157–1163. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Peters DH, Fitton A, Plosker GL and Faulds

D: Tacrolimus. A review of its pharmacology, and therapeutic

potential in hepaticand renal transplantation. Drugs. 46:746–794.

1993. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

van Dieren JM, van Bodegraven AA, Kuipers

EJ, Bakker EN, et al: Local application of tacrolimus in distal

colitis: feasible and safe. Inflamm Bowel Dis. 15:193–198. 2009.

View Article : Google Scholar

|

|

6

|

Udina E, Ceballos D, Gold BG and Navarro

X: FK506 enhances reinnervation by regeneration and by collateral

sprouting of peripheral nerve fibers. Exp Neurol. 183:220–231.

2003. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Yeon JH and Park JK: Microfluidic cell

culture systems for cellular analysis. Biochip J. 1:17–27.

2007.

|

|

8

|

Sittinger M, Schultz O, Keyszer G, et al:

Artificial tissues in perfusion culture. Int J Artif Organs.

20:57–62. 1997.PubMed/NCBI

|

|

9

|

Jeon NL, Dertinger SKW, Chiu DT, et al:

Generation of solution and surface gradients using microfluidic

systems. Langmuir. 16:8311–8316. 2000. View Article : Google Scholar

|

|

10

|

Xia YN: Soft lithography and the art of

patterning - A tribute to Professor George M. Whitesides. Advanced

Materials. 16:1245–1246. 2004. View Article : Google Scholar

|

|

11

|

Li Y, Qin J, Lin B, et al: The effects of

insulin-like growth factor-1 and basic fibroblast growth factor on

the proliferation of chondrocytes embedded in the collagen gel

using an integrated microfluidic device. Tissue Eng Part C Methods.

16:1267–1275. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Wei Y, Zhou J, Zheng Z, et al: An improved

method for isolating Schwann cells from postnatal rat sciatic

nerves. Cell Tissue Res. 337:361–369. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Zheng XF, Lu SB, Zhang WG, et al:

Mesenchymal stem cells on a decellularized cartilage matrix for

cartilage tissue engineering. Biotechnol Bioprocess Eng.

16:593–602. 2011. View Article : Google Scholar

|

|

14

|

Li Y, Yang M, Huang Z, et al: AxonQuant: A

microfluidic chamber culture-coupled algorithm that allows

high-throughput quantification of axonal damage. Neurosignals.

22:14–29. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Whitesides GM: The origins and the future

of microfluidics. Nature. 442:368–373. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Kane BJ, Zinner MJ, Yarmush ML and Toner

M: Liver-specific functional studies in a microfluidic array of

primary mammalian hepatocytes. Anal Chem. 78:4291–4298. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Yang RK, Lowe JB III, Sobol JB, et al:

Dose-dependent effects of FK506 on neuroregeneration in a rat

model. Plast Reconstr Surg. 112:1832–1840. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Mackinnon SE, Doolabh VB, Novak CB and

Trulock EP: Clinical outcome following nerve allograft

transplantation. Plast Reconstr Surg. 107:1419–1429. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Bavetta S, Hamlyn PJ, Burnstock G, et al:

The effects of FK506 on dorsal column axons following spinal cord

injury in adult rats: neuroprotection and local regeneration. Exp

Neurol. 158:382–393. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Konofaos P and Terzis JK: FK506 and nerve

regeneration: past, present, and future. J Reconstr Microsurg.

29:141–148. 2013. View Article : Google Scholar : PubMed/NCBI

|