Introduction

Sterilization of medical devices is an important

means of reducing the incidence of iatrogenic diseases (1). Recent developments in sterilization

methods are aimed at improving the effectiveness, applicability and

cost-effectiveness of the process. One such sterilization technique

involves treatment with gas plasma, which is generated by removing

electrons from gases to produce a highly excited mixture of charged

nuclei and free electrons. Gas plasma treatment is particularly

suitable for the sterilization of thermolabile medical devices

(2–4).

Recently, a nitrogen gas plasma instrument

(BLP-TES), which generates nitrogen gas plasma using a fast

high-voltage pulse from a static induction (SI) thyristor power

supply was developed (5–11). Our previous studies (5–11)

have demonstrated that nitrogen gas plasma can be utilized to

inactivate various microorganisms. However, the mechanisms of

action of gas plasma on microorganisms remain to be elucidated.

Previous studies have demonstrated that treatment of microorganisms

with nitrogen gas plasma may induce changes in their lipids

(5), proteins (7) and carbohydrates (8). These findings suggest that the

changes induced by sterilizing factors produced during the

generation of nitrogen gas plasma may contribute to the

inactivation of microorganisms.

Previous studies have demonstrated that nitrogen gas

plasma treatment using BLP-TES efficiently inactivates bacteria and

viruses as well as endotoxins (5–11).

Furthermore, Geobacillus stearothermophilus, which is often

used as a biological indicator for gas plasma and is one of the

most resistant microbes against physical and chemical treatments,

was inactivated by treatment with BLP-TES (6,12).

However, it remains unclear how the nitrogen gas plasma generated

by BLP-TES inactivates this bacterial spore. In the present study,

G. stearothermophilus spores on a stainless steel (SUS) disk

and filter paper were treated with nitrogen gas plasma using

BLP-TES and any changes to the genomic DNA were analyzed.

Furthermore, the effect of various sterilizing factors generated

during operation of the BLP-TES instrument were also

investigated.

Materials and methods

Nitrogen gas plasma measurement and

treatment

BLP-TES produces nitrogen gas plasma by means of a

fast high-voltage pulse applied using a SI thyristor power supply

as described in our previous studies (5–7).

Cathode electrodes (earth electrodes) were placed between the anode

electrodes (high voltage electrodes). All bacterial spore samples

and chemical indicators were placed on a plastic net on the earth

electrodes during nitrogen gas plasma treatment. First, the chamber

box containing the sample was decompressed and degassed, and then

nitrogen gas (99.9995%, Okano, Co., Ltd., Kadena, Japan) was

introduced. The pressure in the box was maintained at ~0.5

atmospheres during the discharge at 1.5 kilo pulse/sec (kpps).

Bacterial spores and culture

A filter paper strip and SUS disk coated with G.

stearothermophilus ATCC7359 (SGM Biotech Inc., Bozeman, MT,

USA) were used for treatment. In certain experiments, a tablet

containing G. stearothermophilus EZ-SPORE (Microbiologics,

Inc., St. Cloud, MN, USA) was used. Each tablet was suspended in 1

ml of hydration buffer (Microbiologics, Inc.) in accordance with

the manufacturer's protocols and then spotted and dried onto a

cover glass. The SUS disk, filter paper, or cover glass were

treated with nitrogen gas plasma. In all cases, the treated and

untreated G. stearothermophilus was mixed with tryptic soy

broth (TSB) pH 7.3±0.2 (Raven Japan Co., Ltd., Koshigaya, Japan)

and pH indicator bromocresol purple (BCP) prior to incubation at

56°C. A color change in the medium as a result of proliferation of

the bacteria served as an index of viability.

Polymerase chain reaction (PCR)

Plasma-treated or untreated G.

stearothermophilus samples on paper filters or SUS disks were

resuspended in distilled water and genomic DNA was then eluted by

heat treatment at 100°C for 15 min. The liberated DNA samples were

subjected to PCR amplification comprising 40 cycles of 94°C for 1

min, 55°C for 1 min, and 72°C for 1 min, followed by a final

incubation at 72°C for 10 min. GEOBAC primers (GEOBAC-F and

GEOBAC-R) were used in the amplification and based on the 16S-23S

rRNA gene internal transcribed spacer (ITS) region sequences.

GEOBAC-F (5′-TAAGCGTGAGGTCGGTGGTTC-3′) targeted the gene of

tRNAIle, and GEOBAC-R (5′-GCGCTCTCGGCTTCTTCCTT-3′)

targeted the 3′ end region of Geobacillus ITS (13). Gstearo-16S primers were targeted to

16S rRNA of G. stearothermophilus and designed to the DNA

sequence with Genbank Accession no. EU484358 (www.ncbi.nlm.nih.gov/genbank). The primer

sequences were as follows: Forward, 5′-CTTCGGGTCGTAAAGCTCTG-3′

termed F1′ and reverse, 5′-CCTTTGAGTTTCAGCCTTGC-3′ termed R1 and

5′-GAATTCCGCTCTCCTCTCCT-3′ termed R2. All the amplifications were

performed using a PC320 model thermocycler (Astec Co. Ltd., Kasuya,

Japan). The PCR products were initially analyzed by agarose gel

electrophoresis and then subsequently verified by DNA sequencing.

The PCR products obtained by standard PCR and qPCR were subcloned

into pT7Blue T-vector (EMD Millipore, Billerica, MA, USA) and

subjected to DNA sequencing (ABI PRISM 3100 Genetic Analyzer;

Applied Biosystems; Thermo Fisher Scientific, Inc.) to verify the

identity of the amplified product.

Quantitative PCR (qPCR)

The extracted genomic DNA samples were subjected to

quantitative PCR using SYBR Premix Ex TaqII (Tli RNase H Plus;

Takara Bio Inc., Otsu, Japan) and the following primers for 16S

rRNA of G. stearothermophilus (Genbank Accession no.

EU484358): Forward, 5′-CACACTGGGACTGAGACACG-3′ and reverse,

5′-CATTGCGGATTCCCTAC-3′ for region 1; forward,

5′-ACGGTACCTCACGAGAAAGC-3′ and reverse, 5′-TCGCCCCCTACGTATTACC-3′

for region 2; and forward, 5′-CATTCGGTTGGGCACTCTA-3′ and reverse,

5′-AAGGGGCATGATGATTTGAC-3′ for region 3. The thermocycling

conditions used for the quantitative PCR were as follows: 95°C for

30 sec, followed by 40 cycles of 95°C for 5 sec and 60°C for 1 min.

Relative quantification was performed using the 2−∆∆Cq

method (14).

Scanning electron microscopy

(SEM)

The G. stearothermophilus-contaminated paper

strips were treated with nitrogen gas plasma (1.5 kpps) for 0 and

15 min, and then fixed with 2% glutaraldehyde/0.1 M phosphate

buffer (pH 7.4) overnight at 4°C. The cover glasses were

subsequently treated with 2% osmium tetroxide at 4°C for 3 h.

Samples were dehydrated through a graded ethanol series (50–100%

ethanol) at room temperature. Finally, the samples were subjected

to critical point drying and evaporation coating by osmium plasma

ions. SEM was performed using a JSM-6320F (JEOL Ltd., Tokyo, Japan)

instrument at 5 kV using a magnification of ×20,000.

Temperature measurements

The temperature in the box during operation of the

instrument was measured using THERMO LABEL 5E (NiGK Corporation,

Kawagoe, Japan), which was placed on the earth electrode. The

ambient temperature in the nitrogen gas plasma instrument box was

measured using a fiber optic thermometer (FT1420A; Takaoka Electric

MFG. Co. Ltd., Tokyo, Japan) during nitrogen gas plasma

treatment.

Measurement of ultraviolet (UV)

radiation

Indicator label-H (NiGK Corporation) was placed on

the earth electrode and treated with nitrogen gas plasma (1.5 kpps)

for 0–30 min. Analysis of emission during operation of the nitrogen

gas plasma instrument was performed using a USB multichannel

spectrophotometer (S-2431; Soma Optics, Ltd., Tokyo, Japan).

Oxidative stress measurements

Chemical indicators were used to estimate the

respective concentration of 2–80 mg/l NO2−

(nitrite; Kyoritsu Chemical-Check Lab., Corporation, Tokyo, Japan),

10–500 mg/l NO3− (nitrate; Kyoritsu

Chemical-Check Lab. Corporation) and 0.5–25 mg/l

H2O2 (Merck Ltd. Tokyo, Japan). The following

indicators were used: Quantofix Nitrite (Macherey-Nagel, GmbH &

Co. KG, Düren, Germany), Quantofix Nitrite 3000, Quantofix Peroxide

25, Quantofix Peroxide 100, Nitrite, Quantofix Nitrate and

Quantofix Active oxygen, all obtained from Macherey-Nagel GmbH,

Duren, Germany), which were placed on a plastic net on the earth

electrodes prior to treatment with nitrogen gas plasma using a

BLP-TES device at 1.5 kpps for 0–30 min.

Treatment with reagents, heating or

UV

For heat treatment, a suspension of G.

stearothermophilus at 3.1×104 colony-forming unit

(CFU)/ml was incubated at temperatures ranging from 40–100°C for 30

min using a block incubator (BI-516S; Astec Co. Ltd). For UV

treatment, filter papers contaminated with G.

stearothermophilus (2.1×106 CFU) were exposed to

long wavelength UV-A and short wavelength UV-C radiation from a

handheld UV transilluminator (UVGL-58; UVP, Inc., Upland, CA) for

30 min on each side of the paper strip (distance from lamp to paper

strip, 1.3 cm). The energy (mJ/cm2) of UV-A and UV-C was

estimated on the basis of a color change of UV indicator (UV

label-H). Samples of G. stearothermophilus suspension

(3.1×104 CFU/ml) were subjected to oxidative stress by

incubation in the presence of hydrogen peroxide (0–3%; Wako Pure

Chemical Industries, Ltd., Osaka, Japan), peroxynitrite (0–4.92 mM;

Dojindo Molecular Technologies, Inc., Kumamoto, Japan) or

3-(4-morpholinyl)sydnonimine hydrochloride (SIN-1; 1.0

mM-1.0×10−5 mM; Dojindo Molecular Technologies, Inc.),

which produces superoxide anions and nitric oxide resulting in the

generation of peroxynitrite.

Analysis of DNA oxidation by

enzyme-linked immunosorbent assay (ELISA)

G. stearothermophilus samples on filter

papers were frozen at −80°C overnight and dipped into 500 µl of

High Molecular Weight (HMW) buffer containing 10 mM Tris-HCl (pH

8.0), 0.1 M ethylenediaminetetraacetic acid (pH 8.0), and 0.5%

sodium dodecyl sulfate prior to boiling for 10 min. Following

centrifugation at 10,000 × g for 15 min, an aliquot (50 µl)

of the supernatant was subjected to the ELISA. To detect

8-hydroxy-2′-deoxyguanosine (8-OHdG), Highly Sensitive 8-OHdG Check

ELISA kit (Japan Institute for the Control of Aging, NIKKEN SEIL

Co., Ltd., Fukuroi, Japan) and 8-OHdG Assay Preparation reagent set

(Wako Pure Chemical Industries, Ltd.) was used in accordance with

the manufacturer's protocols. In this kit, a competitive ELISA

utilizing monoclonal antibody (clone N45.1), which is highly

specific for 8-OHdG, was employed. The concentrations of 8-OHdG was

quantified by comparison of absorbance at a wavelength of 450 nm

with standards of 8-OHdG diluted with HMW buffer.

Statistical analysis

The results are presented as the mean ± standard

deviation of replicate experiments (n=6). The statistical analysis

of significant difference between plasma-treated and untreated

samples was performed by Mann-Whitney U test. P<0.05 was

considered to indicate a statistically significant difference.

Results

Nitrogen gas plasma treatment

decreased the number of viable bacteria spores

The inactivation efficiency of the nitrogen gas

plasma was investigated (Fig. 1).

The bacterial spores of G. stearothermophilus were spotted

and dried onto a SUS disk or filter paper and treated with nitrogen

gas plasma at 1.5 kpps for 0, 5, 15 or 30 min. The spores were then

incubated in TSB medium containing BCP at 56°C for 6, 24 and 48 h

and the change in pH of the culture broth was used as the index of

bacterial proliferation. The results after 6 h incubation of the

spores taken from the SUS disk (initial population,

1.9×106 CFU) and filter paper (initial population,

1.4×106 CFU) indicated that nitrogen gas plasma

treatment decreased the number of viable bacterial spores on the

surface of the two materials. However, longer incubation of the

samples (24 and 48 h) demonstrated that the inactivation efficiency

was greater for the spores recovered from the filter paper compared

with those from the SUS disk.

| Figure 1.Inactivation of Geobacillus

stearothermophilus by nitrogen gas plasma treatment. A total of

ten filter papers (strip) and ten SUS disks (disk) contaminated

with spores of G. stearothermophilus at 1.4×106

CFU and 1.9×106 CFU, were treated with nitrogen gas

plasma at 1.5 kpps for 0, 5, 15 and 30 min using a BLP-TES device.

The BLP-TES instrument generates gas plasma by a short high-voltage

pulse generated from a static induction thyristor power supply. The

treated bacterial spores were incubated in tryptic soy broth

medium, which included the pH indicator bromocresol purple, at 56°C

for 6, 24 and 48 h. Proliferation of G. stearothermophilus

in the medium was monitored by the development of a yellow color

due to acidification. The proliferation of G.

stearothermophilus following nitrogen gas plasma treatment (1.5

kpps) was then carefully monitored. The growth of the bacteria

following a 6 h incubation was 100% for the untreated samples and

0% for samples treated with nitrogen gas plasma (5–30 min treatment

period) recovered from filter papers and SUS disks. However,

prolonged incubation (24 and 48 h) of the spores recovered from

filter papers gave 100% growth for the untreated sample and sample

treated for 5 min, 10% after 15 min treatment and 0% after 30 min

treatment. By contrast, all G. stearothermophilus samples

recovered from SUS disks, even those subjected to 30 min nitrogen

gas plasma treatment, proliferated to 100% after 24 and 48 h

incubation. SUS, stainless steel; CFU, colony-forming units. |

The fraction negative method, calculated using the

Halvorson-Ziegler formula (15)

and Stumbo-Murphy-Cochran procedure (16), indicated the decimal reduction time

(D-value) for the filter paper samples was 2.48 min at 15

min of treatment, while the D value for the SUS disk could

not be calculated, suggesting lower inactivation efficiency in the

SUS disk.

No major changes to spores were

observed following nitrogen gas plasma treatment

SEM analysis was performed to investigate the effect

of nitrogen gas plasma treatment on the structure of the bacterial

spore surface (Fig. 2). Careful

examination indicated no evidence of shrunken or aggregated spores

after nitrogen gas plasma treatment. However, spores subjected to

nitrogen gas plasma treatment for 15 min exhibited a slight

increase in surface roughness compared with untreated spores.

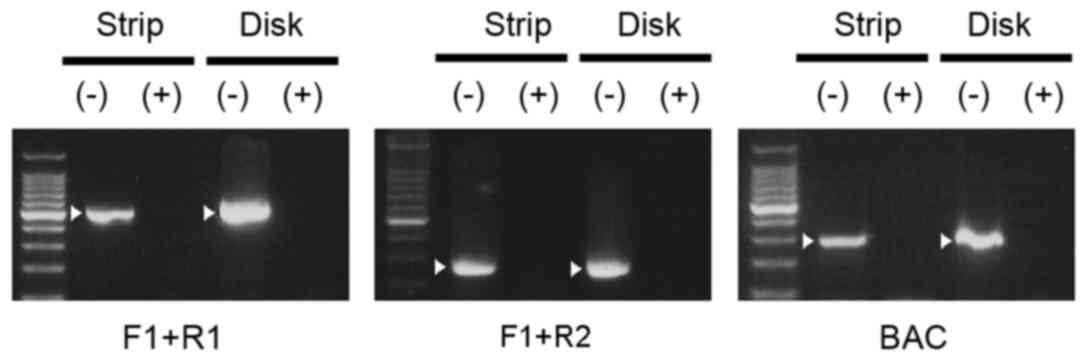

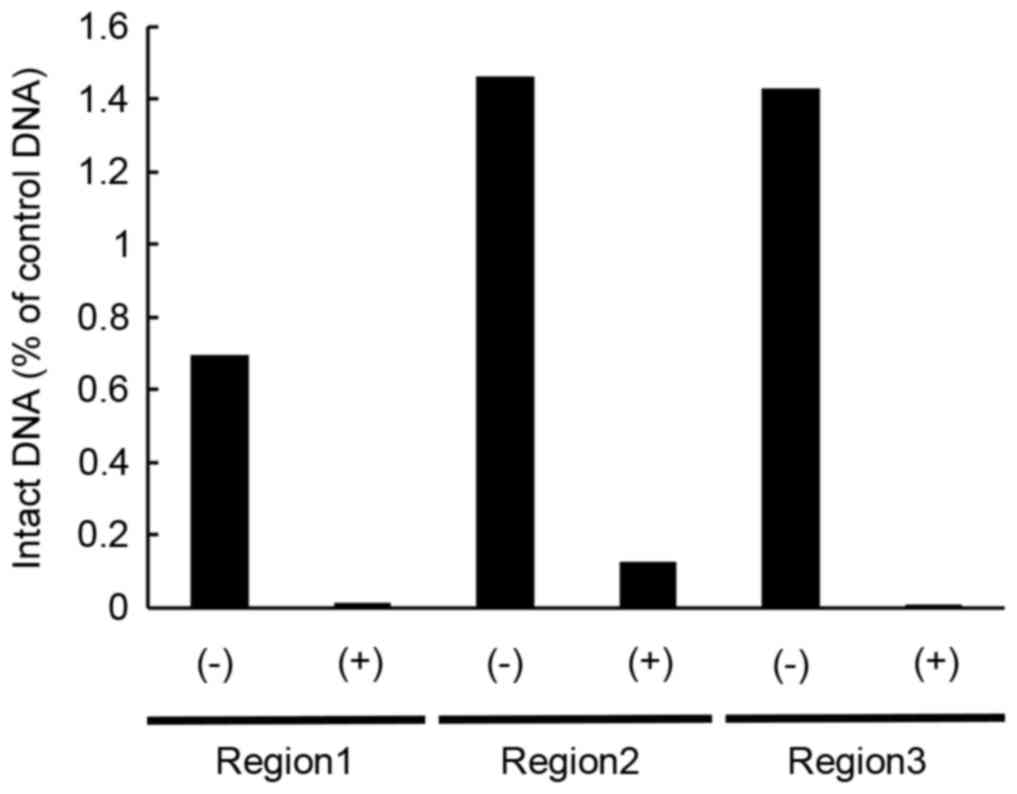

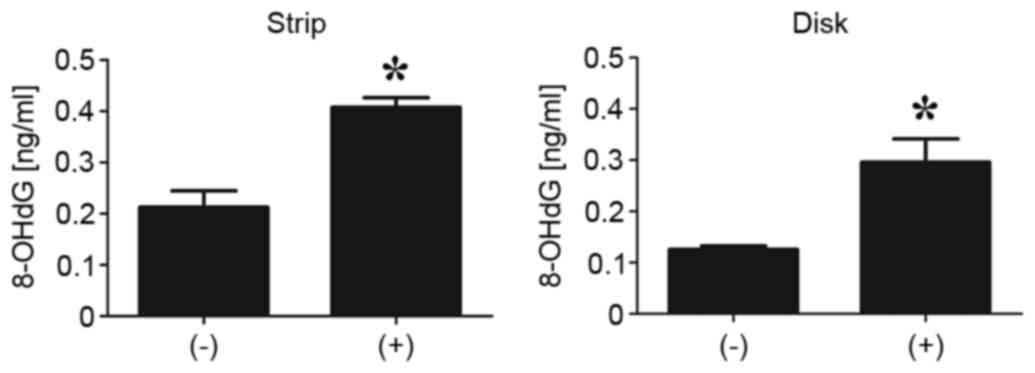

DNA oxidation was induced by nitrogen

gas plasma treatment

Potential changes to the bacterial genomic DNA

induced by nitrogen gas plasma treatment were observed (Figs. 3 and 4). SUS disks (disk) and filter papers

(strip) were treated with nitrogen gas plasma for 0 and 15 min and

then subjected to PCR analysis using the three pairs of primers

designed against the sequence of G. stearothermophilus 16S

rRNA (F1+R1, F1+R2, and GEOBAC-F+GEOBAC-R; Fig. 3). Agarose gel electrophoresis

indicated that no PCR products were amplified from genomic DNA

samples of G. stearothermophilus after 15 min treatement

with nitrogen gas plasma on a SUS disk or filter paper. By

contrast, PCR products of the anticipated size were generated from

the untreated samples. Quantitative analysis using qPCR, which

employed three pairs of primers designed against three different

regions of 16S rRNA (region 1–3), demonstrated a decrease of intact

genomic DNA in the nitrogen gas plasma treated bacterial spores of

G. stearothermophilus compared with untreated samples

(Fig. 4). The quantity of intact

DNA detected in the nitrogen gas plasma treated samples was ~1/10

that of the untreated samples. DNA sequence analysis demonstrated

that in each case the anticipated product had been amplified.

Specifically, 99–87% (F1+R1), 99–96% (F1+R2) for Genbank Accession

no. EU484358, and 100% (GEOBAC-F+GEOBAC-R) for Genbank Accession

no. EU157949, 99% (region 1), 100% (region 2) and 100% (region 3)

for Genbank Accession no. KJ722527. Furthermore, the ELISA

demonstrated a significant increase in the level of 8-OHdG in G.

stearothermophilus containing filter paper and SUS disk

following nitrogen gas plasma treatment (P<0.01; Fig. 5). 8-OHdG is a product of oxidative

damage to DNA formed by hydroxyl radicals, singlet oxygen and

direct photodynamic action (17).

Thus, the results indicate nitrogen gas plasma treatment of G.

stearothermophilus spores induces oxidation of the DNA.

Generation of heat, UV-A and oxidative

stress in the BLP-TES instrument

Previous studies have confirmed that at least three

variables are generated during operation of the nitrogen gas plasma

instrument BLP-TES that may be responsible for its sterilizing

action, namely heat, UV-A and oxidative stress (10). This is similar to other gas plasma

instruments (18,19). Temperature measurement of the

sample box in the BLP-TES instrument using a fiber thermometer gave

readings of 65°C at 7.5 min, 75°C at 15 min, and 85°C at 30 min

during operation of the device. UV measurements using a paper

indicator indicated a color change in a time-dependent manner

(equivalent to 0 mJ/cm2 at 0 min, 25 mJ/cm2

at 7.5 min, and 50 mJ/cm2 at 30 min). Consistent with

these findings, UV-A was detected by analysis of the emission using

a spectrophotometer (S-2431; data not shown). In addition, the

levels of chemicals were further estimated by the index of color

change. The increase of hydrogen peroxide depended on treatment

time and was estimated to be 7.5±0.9 mg/l at 30 min. Production of

nitrite was also observed during operation of the instrument and

was estimated to be 5.5±0.7 mg/l at 30 min, while that of nitrate

was 92.7±19.0 mg/l at 30 min (data not shown).

The individual contribution of these three variables

(heat, UV, and oxidative stress) to inactivation efficiency was

examined. Following exposure to each of these variables, at a level

equivalent to that observed during operation of the gas plasma

device, spores of G. stearothermophilus (3.1×104

CFU) were incubated for 48 h. The change in color of the medium was

then checked against an index to determine the bacterial

proliferation. The results indicated that heating at 40–100°C for

30 min did not affect the viability of the bacterial spores

(Table I). UV-C treatment for 30

min (>300 mJ/cm2) using a transilluminator (UVGL-58)

completely inactivated bacterial spores (100%), while UV-A

treatment (75–142 mJ/cm2) for the same length of time

did not (Table II). In the case

of oxidative stress, treatment with peroxynitrite

(4.92–4.92×10−5 mM), SIN-1 (1.0–1.0×10−5 mM)

or hydrogen peroxide (3×2−5-3×2−9%) for 30

min did not inactivate the bacterial spores (Tables III–V). However, exposure of the spores to an

elevated level of hydrogen peroxide (3–3×2−4%) resulted

in their complete inactivation (Table III).

| Table I.Effect of heat treatment for 30 min on

the viability of G. stearothermophilus. |

Table I.

Effect of heat treatment for 30 min on

the viability of G. stearothermophilus.

|

|

Temperature

(°C) |

|---|

|

|

|

|---|

| Viability | 40 | 50 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 |

|---|

| Cell growth | + | + | + | + | + | + | + | + | + | + | + |

| Table II.Effect of UV treatment for 30 min on

the viability of G. stearothermophilus. |

Table II.

Effect of UV treatment for 30 min on

the viability of G. stearothermophilus.

| Viability | UV-A | UV-C |

|---|

| Cell growth

(%) | 100 (3/3) | 0 (0/3) |

| Table III.Effect of hydrogen peroxide treatment

for 30 min on the viability of G. stearothermophilus. |

Table III.

Effect of hydrogen peroxide treatment

for 30 min on the viability of G. stearothermophilus.

|

|

H2O2 (%) |

|---|

|

|

|

|---|

| Viability | 3 |

3×2−1 |

3×2−2 |

3×2−3 |

3×2−4 |

3×2−5 |

3×2−6 |

3×2−7 |

3×2−8 |

3×2−9 |

|---|

| Cell growth | − | − | − | − | − | + | + | + | + | + |

| Table V.Effect of SIN-1 treatment for 30 min

on the viabilty of G. stearothermophilus. |

Table V.

Effect of SIN-1 treatment for 30 min

on the viabilty of G. stearothermophilus.

|

| SIN-1 [mM] |

|---|

|

|

|

|---|

| Viability | 1.0 |

1.0×10−1 |

1.0×10−2 |

1.0×10−3 |

1.0×10−4 |

1.0×10−5 |

|---|

| Cell growth | + | + | + | + | + | + |

Discussion

The inactivation rates of bacterial spores on the

SUS disks were low compared to those on the filter papers following

nitrogen gas plasma treatment at a frequency of 1.5 kpps,

indicating that different surfaces elicit a different effect on

spore viability. These findings are consistent with a previous

study, which reported the inactivating efficiency of G.

stearothermophilus spores on SUS disks was low compared to

spores placed on filter papers (12).

In the present study, the D value determined

by nitrogen gas plasma treatment of G. stearothermophilus on

filter papers (D-value=2.48 min) was similar to that of

hydrogen peroxide vapor (2 mg/l; D-value=2.1 min; G.

stearothermophilus SUS disk) or steam sterilization (121°C;

D-value=2.2 min; G. stearothermophilus filter strip).

Thus, the nitrogen gas plasma instrument enables efficient

inactivation of bacterial spores, equivalent to that observed by

exposure to hydrogen peroxide vapor or steam sterilization in the

case of samples on filter paper. Hydrogen peroxide vapor is one of

the major sterilization methods for thermolabile medical devices

(20), while steam sterilization

is the conventional sterilization method. However, hydrogen

peroxide vapor treatment is not compatible with numerous materials

due to its powerful oxidizing activity (21). By contrast, as gas plasma

penetration at the surface of the material is slight at ~10–20 nm

(6), the sterilization procedure

does not reduce the functional integrity of the medical instrument.

However, as certain surface materials, such as SUS, may reduce

inactivation efficiency, compatibility of materials should be

checked prior to employing nitrogen gas plasma treatment.

One of the sterilization factors is UV-A radiation

emitted during the generation of nitrogen gas plasma (10). Thus, it was assumed that gas plasma

treatment may elicit its sterilizing action by damaging the genomic

DNA of microorganisms. The present study assessed potential damage

to the genomic DNA by analyzing the 16S rRNA gene of gas plasma

treated and untreated spores by PCR and qPCR. The results

demonstrated clear evidence that DNA in the bacterial spores is

damaged by nitrogen gas plasma treatment. Furthermore, increased

levels of 8-OHdG following nitrogen gas plasma suggested that the

DNA damage is the result of oxidation. The present study also

assessed whether UV-A emitted during the operation of nitrogen gas

plasma contributes, at least in part, to the sterilization process.

However, UV-A exposure did not efficiently inactivate the bacterial

spores. Thus, other factors appear to be predominantly responsible

for the microbial inactivation. SEM images demonstrated an

irregular surface structure of bacterial spores following treatment

with nitrogen gas plasma. The observed changes in cell surface

structures are possibly due to oxidative stress produced during gas

plasma generation. Therefore, inactivation of bacterial spores

during nitrogen gas plasma treatment may the result of changes in

the cell surface components, as well as damage to genomic DNA as a

result of oxidative stress. In summary, the nitrogen gas plasma

instrument produces at least three variables, heat, UV-A and

oxidative stress, during its operation, which may be responsible

for bacterial inactivation. Among these factors, hydrogen peroxide

is the most effective for inactivation of G.

stearothermophilus. However, there may be a synergistic effect

involving the other factors that contribute to the bactericidal

activity of nitrogen gas plasma treatment.

Hydrogen peroxide, similarly to formaldehyde or

chlorine, exhibits good cell permeability, and may act to reduce

the water content of the spores by hydrating dipicolinic acid in

the core of the spore (22–24).

Thus, hydrogen peroxide generated from the nitrogen gas plasma

instrument, in addition to oxidizing the bacterial spore surface,

may exert its effect by reducing the water content in the

cytoplasm. In addition, other reactive chemical species may be

produced during operation of the BLP-TES device. Indeed, the

preliminary data indicated a change in the color of the chemical

indicator Quantofix Active oxygen which reacts with a broad range

of oxidants, including potassium monopersulfate triple salt

(KHSO5, KHSO4 and

K2SO4) and hydrogen peroxide, bromine

(Br2), hypochlorite (OCl−), peracetic acid

(CH3COOOH) and chlorine (Cl2) (25). Thus, other reactive chemical

species in addition to hydrogen peroxide may contribute to the

observed bacterial inactivation and may indicate a synergistic

inactivating effect. Thus, further studies are required in order to

identify other reactive chemical species that contribute to the

bactericidal action of the BLP-TES instrument.

In conclusion, nitrogen gas plasma treatment is an

effective means of sterilization and disinfection, suggesting this

methodology has practical potential for sterilization of medical

devices in the fields of medicine and dentistry, as well as

disinfection in the food industry.

Acknowledgements

The authors of the present study would like to thank

Ms. Haruna Ohshiro and Ms. Rika Imamura (Laboratory of Biometabolic

Chemistry, School of Health Sciences, University of the Ryukyus,

Nishihara, Japan) for their technical assistance and Dr. Naohiro

Shimizu (NGK Insulators, Mizuho-ku, Japan) for their technical

support. The current study was supported by a Grant-in-Aid for the

Promotion of Basic Research Activities for Innovative Biosciences

from the Bio-oriented Technology Research Advancement Institution,

the Science and Technology Research Promotion Program for

Agriculture, Forestry, Fisheries and Food Industry (grant no.

26015A), and a Grant-in-Aid from the Amano Institute of Technology,

as well as Grants-in-Aid for Scientific Research on Innovative

Areas (grant nos. 22110514, 24110717 and 16K04997) from the Japan

Society for the Promotion of Science.

References

|

1

|

McDonnell GE: Antisepsis, Disinfection,

and Sterilization: Types, Action, and Resistance. ASM Press;

Washington, D.C: 2007

|

|

2

|

Sakudo A and Shintani H: Sterilization and

disinfection by plasma: Sterilization mechanisms, biological and

medical applications. Nova Science Publishers, Inc.; New York:

2011

|

|

3

|

Laroussi M: Low temperature plasma-based

sterilization: Overview and state-of-the-art. Plasma Process Polym.

2:391–400. 2005. View Article : Google Scholar

|

|

4

|

Moisan M, Barbeau J, Crevier MC, Pelletier

J, Philip N and Saoudi B: Plasma sterilization: Methods and

mechanisms. Pure Appl Chem. 74:349–358. 2002.

|

|

5

|

Sakudo A, Shimizu N, Imanishi Y and Ikuta

K: N2 gas plasma inactivates influenza virus by inducing

changes in viral surface morphology, protein, and genomic RNA.

Biomed Res Int. 2013:6942692013.PubMed/NCBI

|

|

6

|

Shintani H, Shimizu N, Imanishi Y, Sekiya

T, Tamazawa K, Taniguchi A and Kido N: Inactivation of

microorganisms and endotoxins by low temperature nitrogen gas

plasma exposure. Biocontrol Sci. 12:131–143. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Sakudo A, Higa M, Maeda K, Shimizu N,

Imanishi Y and Shintani H: Sterilization mechanism of nitrogen gas

plasma: Induction of secondary structural change in protein.

Microbiol Immunol. 57:536–542. 2013.PubMed/NCBI

|

|

8

|

Sakudo A, Misawa T, Shimizu N and Imanishi

Y: N2 gas plasma inactivates influenza virus mediated by

oxidative stress. Front Biosci (Elite Ed). 6:69–79. 2014.PubMed/NCBI

|

|

9

|

Shintani H, Sakudo A, Burke P and

McDonnell G: Gas plasma sterilization of microorganisms and

mechanisms of action. Exp Ther Med. 1:731–738. 2010.PubMed/NCBI

|

|

10

|

Maeda K, Toyokawa Y, Shimizu N, Imanishi Y

and Sakudo A: Inactivation of Salmonella by nitrogen gas plasma

generated by a static induction thyristor as a pulsed power supply.

Food Control. 52:54–59. 2015. View Article : Google Scholar

|

|

11

|

Sakudo A, Toyokawa Y and Imanishi Y:

Nitrogen Gas Plasma Generated by a Static Induction Thyristor as a

Pulsed Power Supply Inactivates Adenovirus. PLoS One.

11:e01579222016. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Kawamura K, Sakuma A, Nakamura Y, Oguri T,

Sato N and Kido N: Evaluation of bactericidal effects of

low-temperature nitrogen gas plasma towards application to

short-time sterilization. Microbiol Immunol. 56:431–440. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Kuisiene N, Raugalas J, Stuknyte M and

Chitavichius D: Identification of the genus Geobacillus using

genus-specific primers, based on the 16S-23S Rrna gene internal

transcribed spacer. FEMS Microbiol Lett. 277:165–172. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Livak KJ and Schmittgen TD: Analysis of

relative gene expression data using real-time quantitative PCR and

the 2(−Delta Delta C(T)) Method. Methods. 25:402–408. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Halvorson HO and Ziegler NR: Application

of Statistics to Problems in Bacteriology: I. A Means of

Determining Bacterial Population by the Dilution Method. J

Bacteriol. 25:101–121. 1933.PubMed/NCBI

|

|

16

|

Stumbo CR, Murphy JR and Cochran J: Nature

of Thermal Death Time Curves for P.A. 3679 and Clostridium

botulinum [1950]. Food Technol. 4:321–326. 1950.

|

|

17

|

Valavanidis A, Vlachogianni T and Fiotakis

C: 8-hydroxy-2′- deoxyguanosine (8-OhdG): A critical biomarker of

oxidative stress and carcinogenesis. J Environ Sci Health C Environ

Carcinog Ecotoxicol Rev. 27:120–139. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Laroussi M and Leipold F: Evaluation of

the Roles of Reactive Species, Heat and UV radiation in the

Inactivation of bacterial Cells by Air Plasmas at Atmospheric

Pressure. Int J Mass Spectrom. 233:81–86. 2004. View Article : Google Scholar

|

|

19

|

Laroussi M, Mendis DA and Rosenberg M:

Plasma Interaction with Microbes. New J Phys. 5:1–41. 2003.

|

|

20

|

Shintani H: Application of vapor phase

hydrogen peroxide sterilization to endoscope. Biocontrol Sci.

14:39–45. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Shintani H: Simultaneous Achievement of

Sterility Assurance Level (SAL) of 10−6 and Material and

Functional Compatibility in Gas Plasma Sterilization Running Title:

Simultaneous SAL and Compatibility. Pharm Regul Aff. 4:1312015.

|

|

22

|

Eskenazi S, Bychkowski OE, Smith M and

MacMillan JD: Evaluation of glutaraldehyde and hydrogen peroxide

for sanitizing packaging materials of medical devices in sterility

testing. J Assoc Off Anal Chem. 65:1155–1161. 1982.PubMed/NCBI

|

|

23

|

Kenar L, Ortatatli M, Yaren H,

Karayilanoglu T and Aydogan H: Comparative sporicidal effects of

disinfectants after release of a biological agent. Mil Med.

172:616–621. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Setlow B, Yu J, Li YQ and Setlow P:

Analysis of the germination kinetics of individual Bacillus

subtilis spores treated with hydrogen peroxide or sodium

hypochlorite. Lett Appl Microbiol. 57:259–265. 2013.PubMed/NCBI

|

|

25

|

MACHEREY-NAGEL GmbH & Co. KG, .

QUANTOFIX® Active oxygen. simpleftp://ftp.mn-net.com/english/Instruction_leaflets/QUANTOFIX/91349en.pdf#search=%27Quantofix+Active+oxygen%27Accessed

25 August 2015.

|