Introduction

Meniscus has limited potential of self-repair, and

menisci injury may lead to long-term degenerative joint changes

(1,2). In addition to other therapies,

meniscal regeneration using tissue engineering techniques has been

attempted, based on the loading and culture of suitable cells into

appropriate scaffolds (3,4). With regards to the cell source,

meniscal chondrocytes, mesenchymal cells and pluripotential

fibroblasts have all been identified as possible sources for the

repair of meniscal tissue (5–7).

Compared with the cell sources mentioned above, myoblasts are a

promising source for meniscal engineering, as they are relatively

abundant and easily accessible with minimal donor site morbidity.

Myoblasts may also be good candidates for tissue engineering as

they have a higher cell yield and proliferate rapidly during in

vitro expansion (8).

With regards to the scaffold, a variety of natural

or artificial biomaterials have been investigated for use in

tissue-engineered meniscus. Due to the poor biomechanical

properties and the rapid degradation of fibrin and alginate,

polymer scaffolds with a stable, biodegradable and permeable pore

network were used to support cell attachment, proliferation and

nutrient exchange and to provide stability (5,9).

In this study, non-woven PLGA scaffolds were seeded

with myoblasts and transplanted into subcutaneous pockets of 24

combined immunodeficiency (SCID) mice. It was hypothesized that

such cell-seeded constructs would demonstrate a cartilage-like

morphology with expression of chondrocyte-specific molecules, while

also conserving sufficient biomechanical characteristics, after 12

weeks in vivo.

Materials and methods

Isolation, culture and induction of

myoblasts

Canine myoblasts were isolated and cultured as

previously described (10).

Primary cells were seeded on a culture dish at a density of

5×105 cells/cm2 in Dulbecco’s modified

Eagle’s medium (DMEM; Gibco-BRL, Grand Island, NY, USA) containing

10% fetal bovine serum (FBS; Gibco-BRL), 300 μg/ml of L-glutamine,

50 μg/ml vitamin C, 100 U/ml penicillin G, 100 μg/ml streptomycin

and amphotericin B 0.25 μg/ml (all from Sigma, St. Louis, MO, USA).

After medium change, cultured myoblasts were subjected to

chondrogenic induction with culture medium containing 50 ng/ml

CDMP-2 and 20 ng/ml TGF-β1 (Sigma). The myoblasts were cultured at

37°C in a humidified atmosphere of 95% air and 5% CO2.

The medium was changed every third day, and this washed out all

non-adherent cells. Cells were subcultured at a density of

1.0×104 cells/cm2 and treated with 0.25%

trypsin plus 0.02% EDTA (Gibco-BRL) when they reached 80%

confluence. The study was approved by the ethics committee of

Tongji University, Shanghai, China.

Immunocytochemistry assay of collagen

II

To determine the in vitro chondrogenic

induction effect, induced myoblasts were examined for type II

collagen expression using immunocytochemical staining. Briefly,

cells were incubated at 37°C for 1 h with mouse anti-collagen-II

monoclonal antibody (IgG1; BD Biosciences Clontech, Franklin Lakes,

NJ, USA) diluted in phosphate-buffered saline (PBS, 1:200),

followed by incubation with 1:100 diluted horseradish peroxidase

(HRP)-conjugated anti-mouse antibody (Dako, Carpinteria, CA, USA)

for 30 min and color development with diaminobenzidine

tetrahydrochloride (DAB). Normal menisci served as positive

controls.

Preparation of PLGA scaffold and cell

seeding

A non-woven copolymer scaffold of L-lactide and

glycolide (90/10, PLGA) in the form of fibers was generously

provided by Shanghai Ju Rui Biomaterials Co., Inc., (China). The

scaffolds were cylindrical, with a diameter of 10 mm and a

thickness of 2 mm. The pore sizes of the non-woven fibers were on

average 75 μm, the pore volume accounted for 97% of the total

volume, and the filament diameter was 13 μm. The PLGA constructs

were treated using the low-pressure plasma technique at the end of

the production process. A partially ionized gas reacted with the

surface of the scaffolds and formed reactive particles. Prior to

cell seeding, the scaffolds were immersed in DMEM/F12 medium

containing 10% (v/v) FBS for 12 h to enhance cell adhesion onto the

scaffold.

Chondrogenically induced myoblasts at passage 3

(1.5×107 in 0.3 ml) were harvested and placed onto PLGA

scaffolds, respectively, to form cell-scaffold constructs and the

constructs were cultured at 37°C in a humidified atmosphere of 5%

CO2 for 5 h, which allowed the complete adhesion of

myoblasts to the scaffold. The cell-PLGA constructs in inductive

media were subsequently cultured in vitro for 14 days.

Medium was changed three times a week. As an experimental control,

scaffolds with non-induced myoblasts were cultured for the same

lengths of time.

Surgical procedure

Six-week-old athymic nude mice were used in this

study, and were obtained from the Agricultural Institute of

Shanghai Jiaotong University, China. Animal care and experimental

procedures were in accordance with the guidelines of the

Administrative Panel on Laboratory Animal Care of China. Under

general intraperitoneal anesthesia and after disinfection of the

back of each of the 24 mice, two subcutaneous pockets were bluntly

created through a 1.5-cm incision in the back. A construct (induced

cell-PLGA construct or non-induced cell-PLGA construct control) was

inserted in each subcutaneous pocket. The wound was closed using a

single interrupted suture. No animal died during the experimental

period. The animals were sacrificed and the implants were harvested

at 8 and 12 weeks, respectively.

Histological and immunohistochemical

analyses

Eight and 12 weeks after implantation, the implants

were retrieved and analyzed histologically and

immunohistochemically, respectively. For histological analyses,

specimens were fixed in 10% (v/v) buffered formalin, dehydrated

with a series of graded alcohol and embedded in paraffin. Tissue

sections (4-μm thick) were stained with hematoxylin and eosin for

morphological analysis.

Expression of collagen type II was detected using

monoclonal antibodies (Dako). Briefly, after deparaffinization,

sections were predigested with trypsin at 37°C for 30 min to

facilitate antibody access, endogenous peroxidase was removed by

the treatment of 0.3% H2O2 in methanol at

room temperature for 30 min, and non-specific antibody binding was

blocked by incubation of sections in 10% normal goat serum at 37°C

for 30 min. Mouse anti-canine collagen type II diluted 1:100 in

0.01 M PBS (pH 7.4) was applied as a primary antibody at 4°C

overnight. Sections were then incubated with the secondary

antibody, rabbit anti-mouse immunoglobulin (Dako) for 60 min,

followed by application of mouse PAP kit (Dako). Collagen type II

was visualized by the reactions with 0.05% diaminobenzidine

containing 0.01% H2O2.

Analysis of mRNA for extracellular

matrices and collagen with reverse transcriptase-polymerase chain

reaction

RNA samples were obtained after 12 weeks and

transcribed into cDNA by real-time reverse transcriptase-polymerase

chain reaction (RT-PCR) for gene expression of type I collagen,

type II collagen and aggrecan. After explantation, the constructs

were digested with Ultraturax™ and total mRNA was prepared using

TRIzol reagent according to the manufacturer’s instructions

(Gibco-BRL). Total RNA (1 μg) was treated with 1 unit of

deoxyribonuclease I (DNase I; Gibco-BRL) in order to digest genomic

DNA contamination. Random-primed cDNA synthesis was performed using

1 μg of DNase I-treated total RNA and 50 units of StrataScript

reverse transcriptase according to the manufacturer’s instructions

(Stratagene, La Jolla, CA, USA). TaqMan™ PCR assays were performed

in 96-well optical plates on an ABI Prism 7700 Sequence Detection

system (Applied Biosystems, Forster City, CA, USA) using ABsolute

QPCR ROX Mix (Abgene, Hamburg, Germany) according to the

manufacturer’s instructions. The thermal cycling conditions were

95°C for 15 min followed by 40 cycles at 95°C for 15 sec and 60°C

for 1 min. The PCR products were analyzed by electrophoresis in 2%

agarose gels and stained with ethidium bromide. The mRNAs analyzed

were collagen I (681 bp), collagen II (447 bp), aggrecan (321 bp)

and glyceraldehyde-3-phosphate dehydrogenase (GAPDH) (211 bp).

Primer sequences for GAPDH, aggrecan, collagen I and collagen II

were as follows: GAPDH, sense 5′-CCTCTATGCCAACACAGTGC-3′ and

antisense 5′-GTACTCCTGCTTGCTGATCC-3′; aggrecan, sense 5′-TAG

AGAAGAAGAGGGGTTAGG-3′ and antisense 5′-AGCACT AGGAGCCAGGGTTAT-3′;

collagen I, sense 5′-ATGCCC AAGACTACCAGTGG-3′ and antisense

5′-TCCTGG AAGCTCTTCTCAGT-3′; collagen II, sense 5′-TTTCCC

AGGTCAAGATGGTC-3′ and antisense 5′-CTTCAGCAC CTGTCTCACCA-3′.

Biomechanical analysis of engineered

cartilage

Eight and 12 weeks after implantation, the

biomechanical properties of the engineered cartilage were tested by

measuring the compressive modulus. Briefly, the specimens were

harvested and trimmed to fit in a test chamber (5 mm diameter) of a

biomechanical analyzer (Instron, Canton, MA, USA). A constant

compressive strain rate of 1 mm/min was used until the maximal

force of 450 N was reached, and thus a force-displacement curve was

obtained. The compressive moduli of tested tissues were

automatically calculated by the machine and further verified by

manual calculation with the formula: ΔP/A × L/ΔL

(ΔP, the compressive force margin of the 2 points on the

linear segment of the load-displacement curve before the first

break point; ΔL, the displacement margin of the

corresponding two abovementioned points; A, the area of

tested tissue; L, the thickness of tested tissue). In

addition, the normal canine menisci were tested as a control. ANOVA

analysis was applied and P<0.05 was considered to indicate a

statistically significant result.

Glycosaminoglycan (GAG) quantification of

engineered cartilage

GAG quantitative analysis of 8- and 12-week

specimens was performed. Briefly, the specimens were minced and

triturated to prepare the protein solution. A series of reagents

was added step by step to ensure the specific binding of Alcian

blue and polysulfated molecules of GAGs in engineered cartilage.

All GAGs were precipitated specifically in guanidine-HCl by using a

low pH in combination with detergent and a high salt concentration.

The precipitate was dissolved in a mixture of guanidine-HCl and

propanol. For quantification, the absorbance was recorded in a

microplate reader with a 600-nm filter, and a linear standard curve

between 0.5 and 20 μg was generated by adding known amounts of

proteoglycans. The results were analyzed using the ANOVA test. A

P-value <0.05 was considered statistically significant. Since no

neocartilage was generated we did not analyse the quantitive GAG in

the control group. The positive control was also tested as a normal

meniscus.

Statistical analysis

The presence of type II collagen in the repaired

meniscus tissue from the different groups was noted and

statistically compared using the Fisher’s exact test. Compressive

modulus and GAG content in the different groups were analyzed with

ANOVA. For all evaluations, the level of statistical significance

was set at a probability value of <0.05.

Results

Morphological and immunohistochemical

analysis

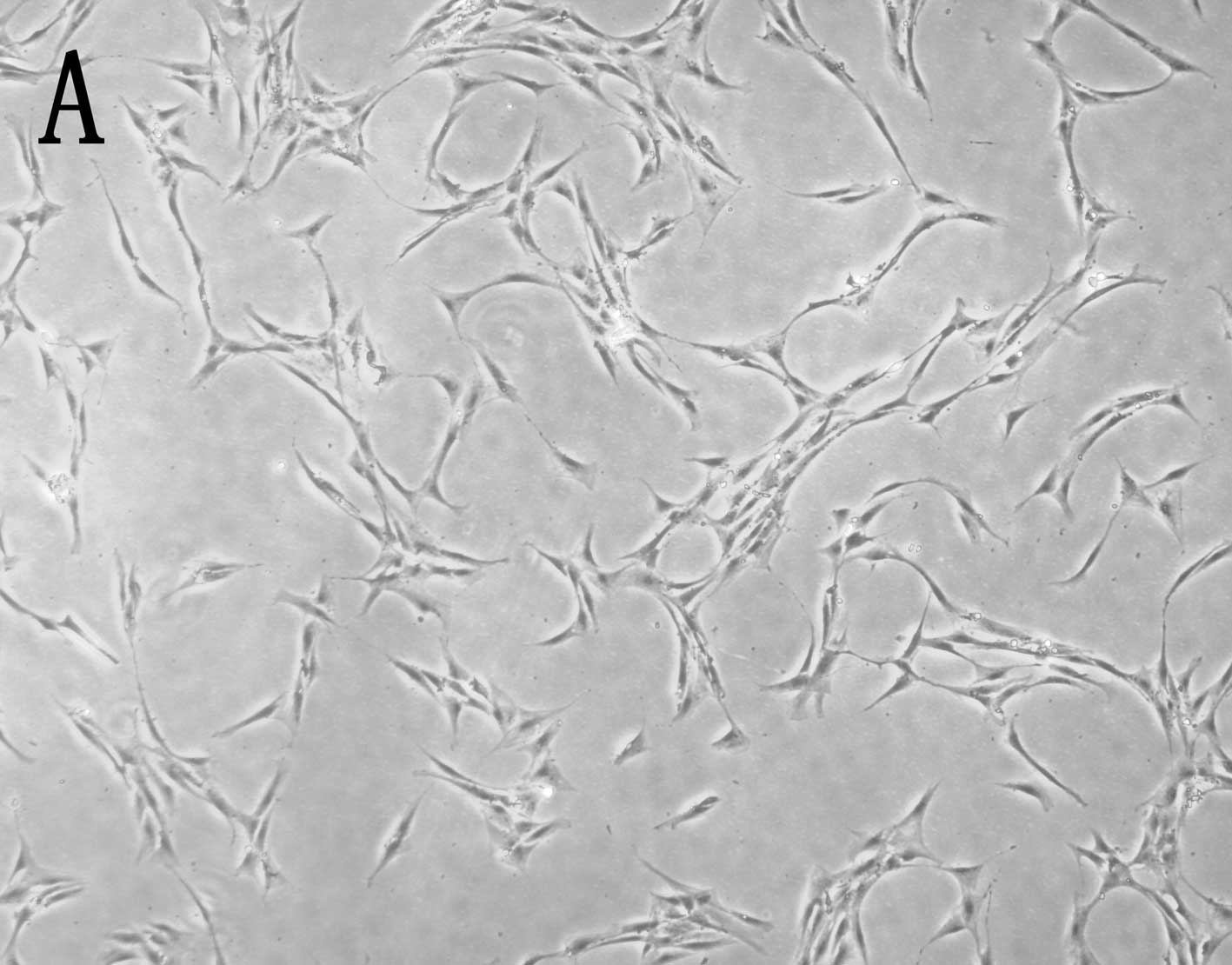

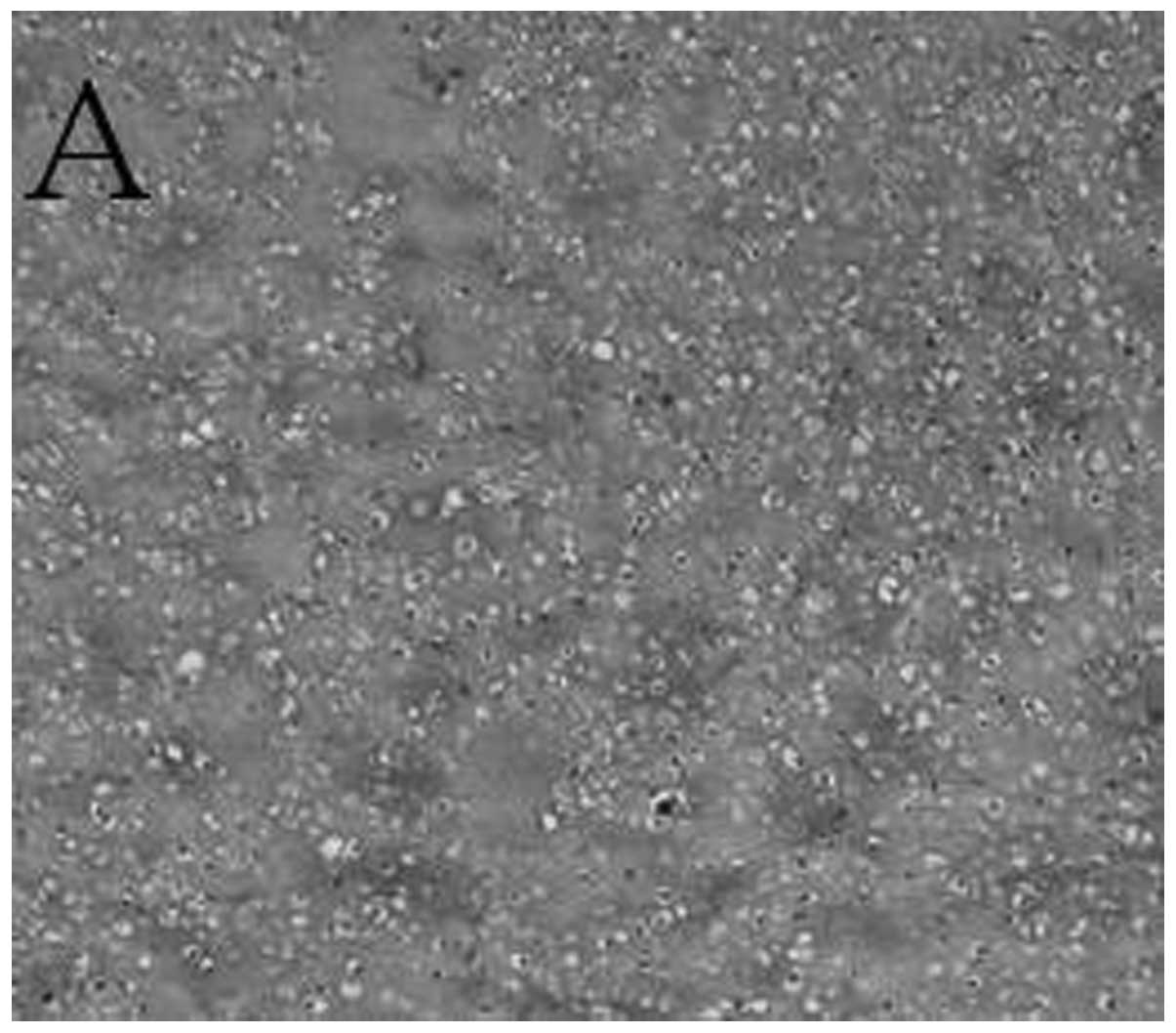

As shown in Fig. 1,

myoblasts induced with CDMP-2 and TGF-β1 underwent a morphological

change after chondrogenic induction, approaching the shape of

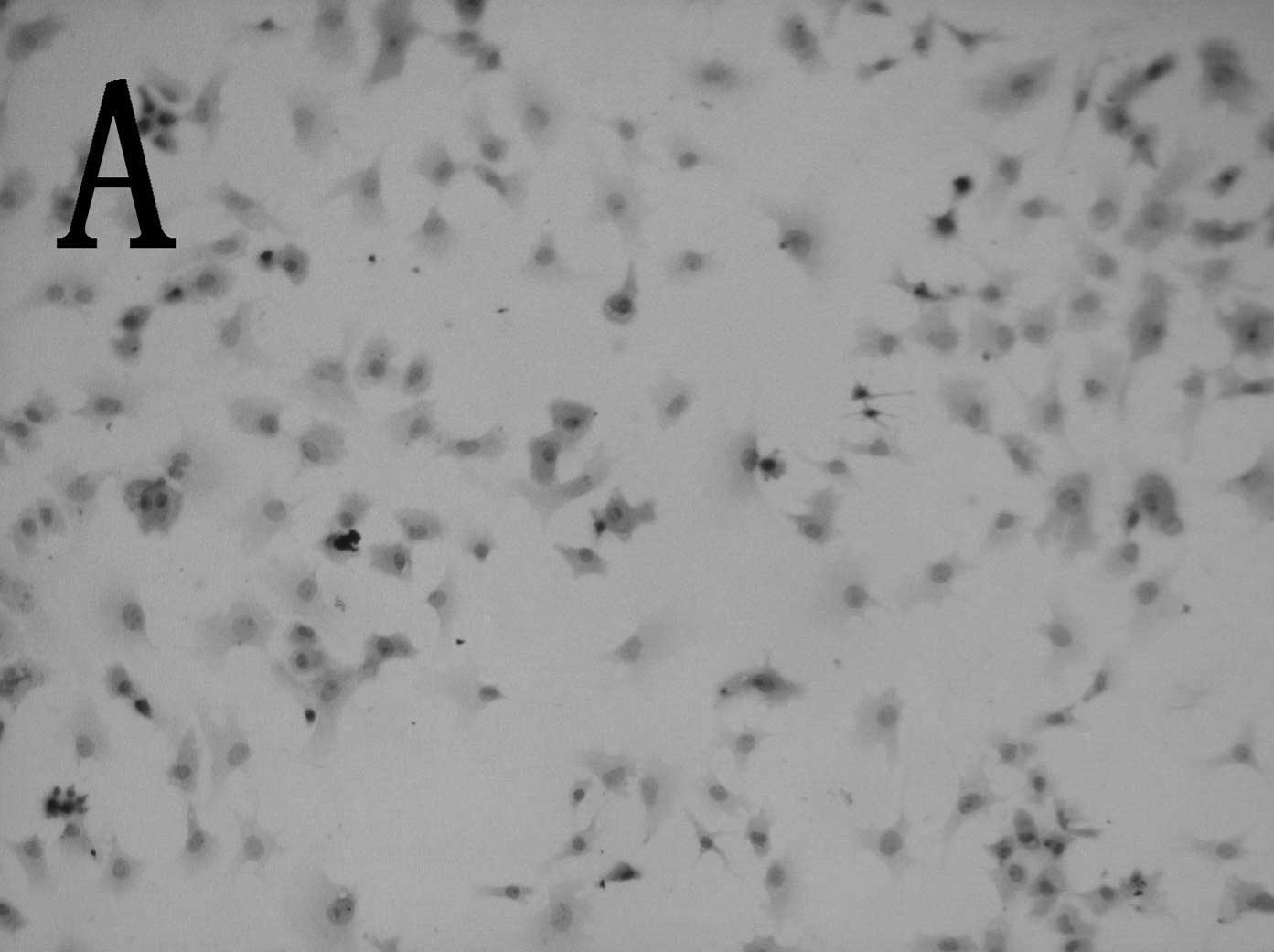

native chondrocytes. In addition, the induced cells showed

significantly enhanced collagen II expression compared to control

cells (Fig. 2).

Gross morphology of engineered

cartilage

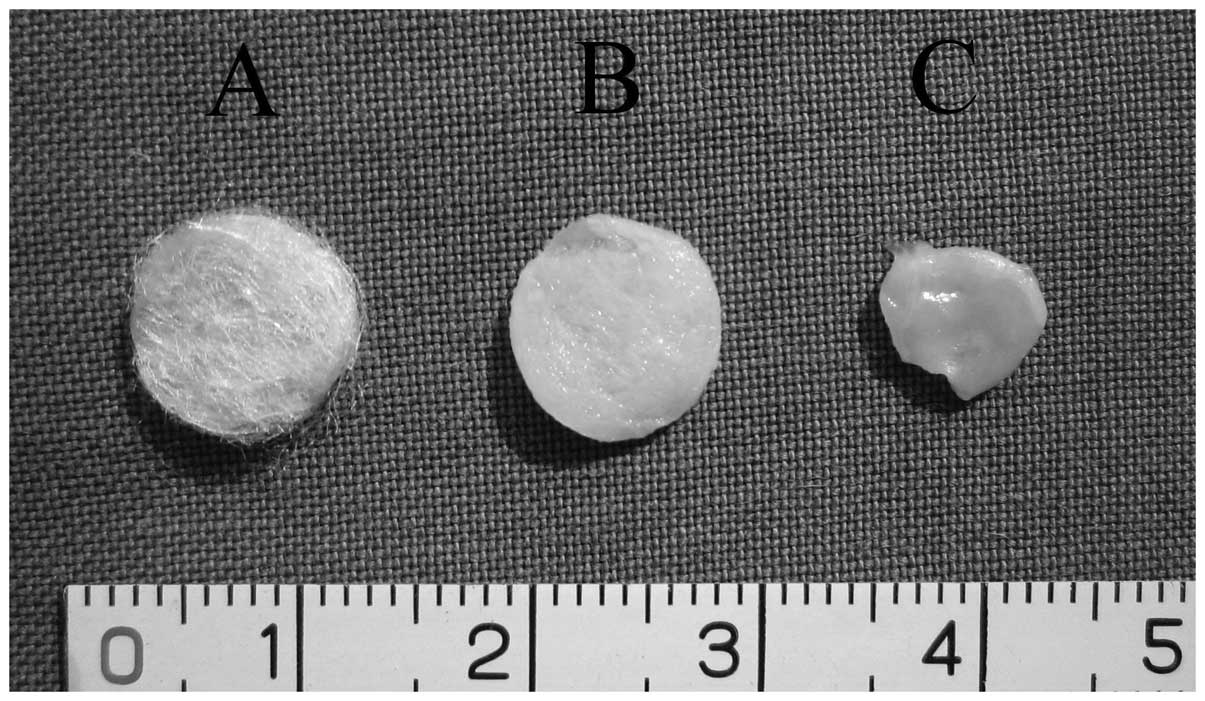

Specimens harvested after 8 weeks of in vivo

culture showed that all induced cell-PLGA constructs maintained the

approximate original scaffold shape and size, and had a compact

consistency (Fig. 3). The

non-induced cell-PLGA constructs showed a failure to maintain the

shape and size of the original scaffold. Twelve-week specimens

showed a more cartilaginous appearance. However, no construct was

identified in the control group, indicating that the scaffold was

degraded completely at 12 weeks.

Histological and immunohistochemical

assessment of engineered cartilage

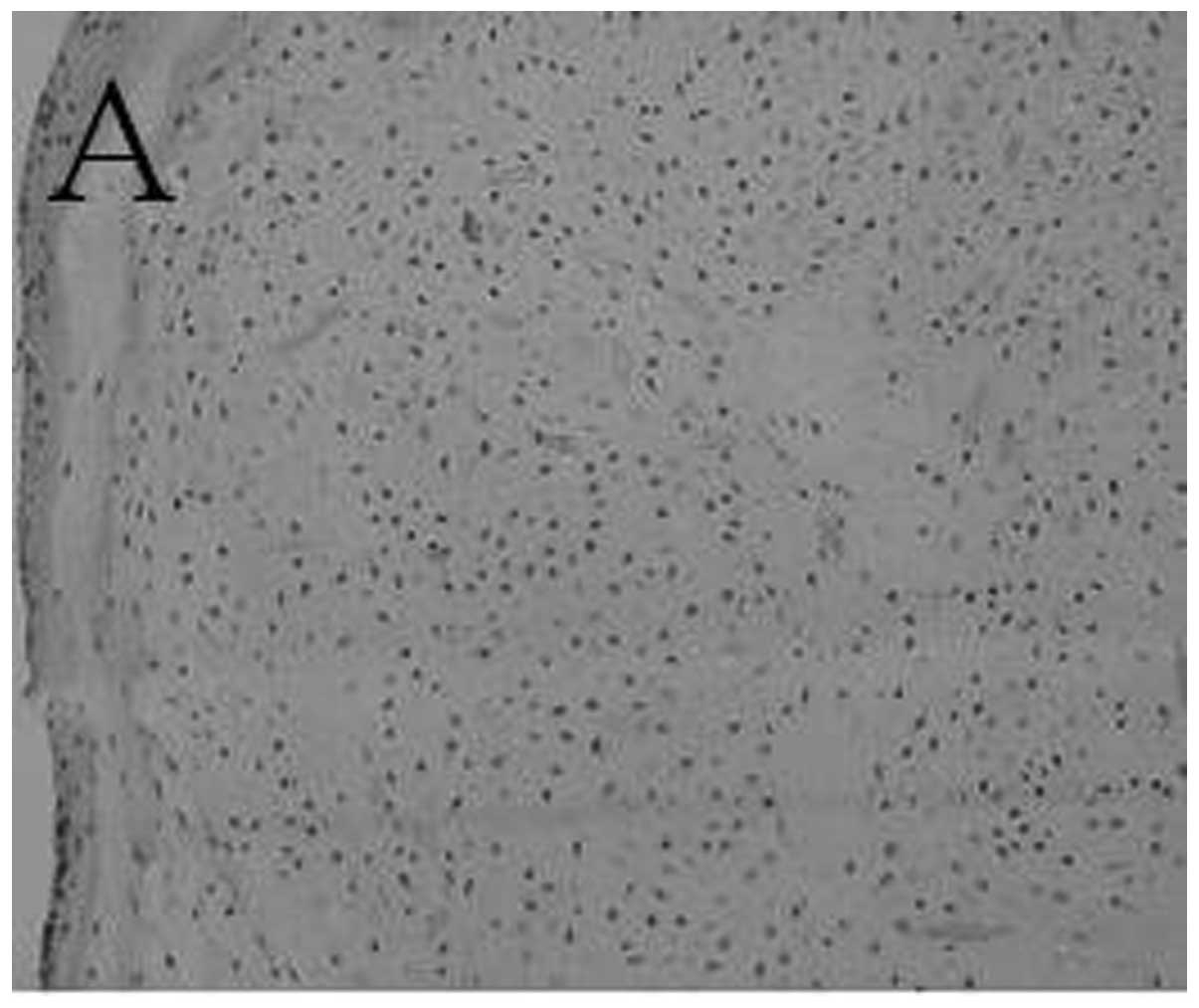

A histological section of engineered cartilage at 8

weeks had the appearance of fibrocartilage with

fibrochondrocytic-like cells (Fig.

4A). In the control group, only a band of fibrous tissue was

observed (Fig. 4B). The engineered

cartilage at 12 weeks had histological structures more similar to

those of normal cartilage than those at 8 weeks (Fig. 4C).

Immunohistological staining indicated that

engineered cartilage was positively stained for type II collagen at

8 weeks post-implantation (Fig.

5A). With the maturation of engineered cartilage, the

expression and distribution of collagen II was found to be similar

to that of the neighboring native meniscus at 12 weeks

post-implantation (Fig. 5C).

However, no expression of collagen II was observed in all specimens

of the control group at 8 weeks (Fig.

5B).

Expression of cartilage-specific genes by

RT-PCR

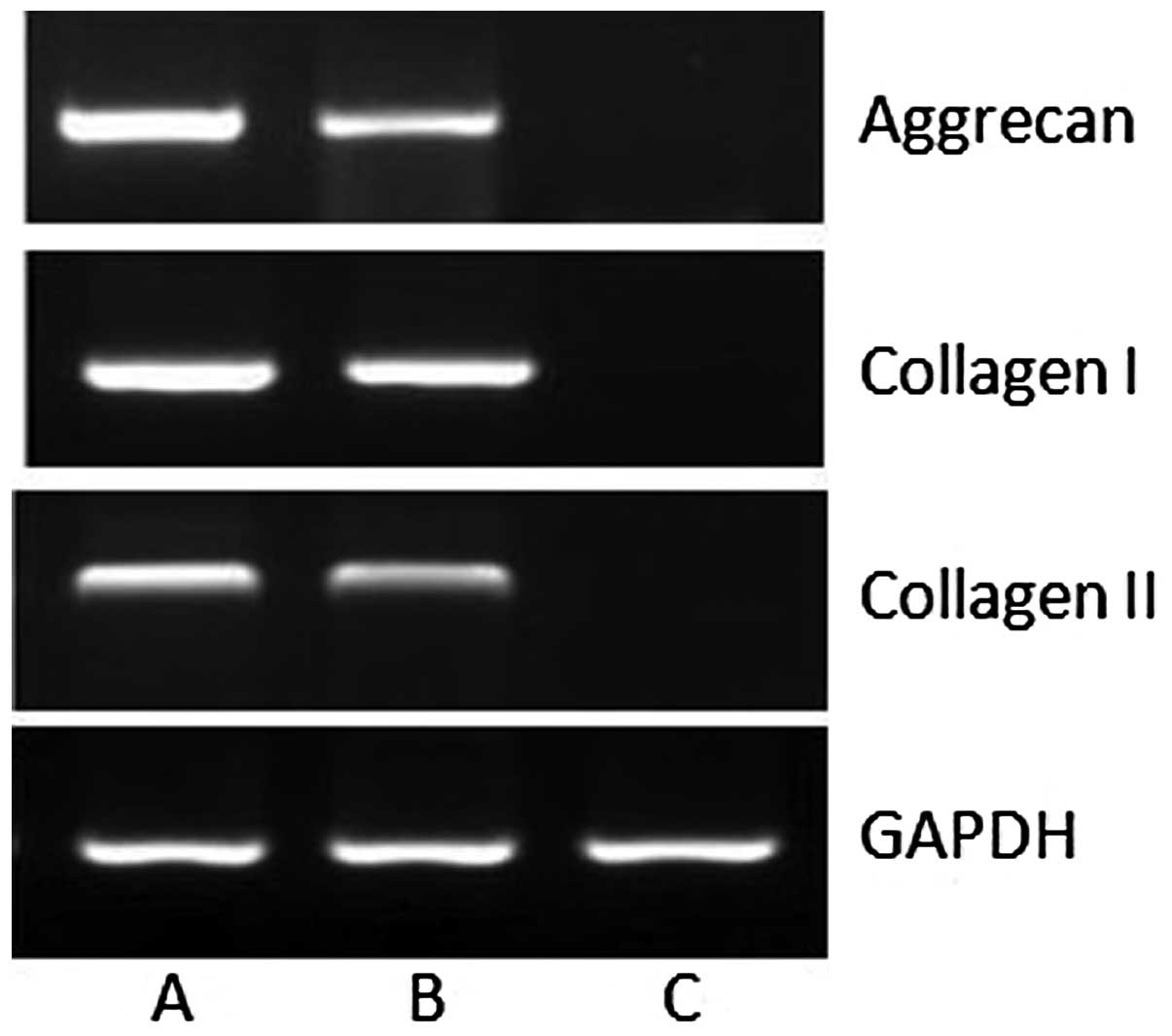

To investigate the chondrogenic differentiation of

the engineered cartilage, mRNA expression of type I collagen, type

II collagen and aggrecan was assessed using RT-PCR. At 12 weeks,

expression of mRNAs for type I collagen, type II collagen and

aggrecan was detected. By contrast, none of the assessed genes were

expressed in the control tissue (Fig.

6). Gene expression of the normal meniscus was assessed as a

positive control.

Biomechanical properties of engineered

cartilage

As summarized in Table

I, the compressive moduli increased with length of

transplantation time. At 8 weeks, the moduli reached 50.41 and

23.16% of the normal meniscus level, respectively, in the

experimental and control groups, and the experimental group

increased further to 85.72% at 12 weeks. Statistical analysis

demonstrated that the compressive modulus was higher in the induced

group (Exp) than in the non-induced group (Ctrl) (P<0.05),

indicating that in vitro chondrogenic induction is helpful

for improving biomechanical properties of myoblast-engineered

cartilage.

| Table IThe compressive moduli of repaired

cartilage. |

Table I

The compressive moduli of repaired

cartilage.

| 8 weeks (n=12) | 12 weeks (n=12) |

|---|

|

|

|

|---|

| Groups | Moduli (MPa) | Percentage of normal

(%) | Moduli (MPa) | Percentage of normal

(%) |

|---|

| Normal | 27.12±0.69 | | 28.92±1.35 | |

| Exp | 13.67±1.830 | 50.41±2.93 | 24.79±2.78 | 85.72±4.23 |

| Ctrl | 6.28±1.52 | 23.16±2.49 | | |

GAG content quantification

The GAG deposition of the engineered cartilage was

further quantified by biochemical analysis and also compared with

that of the normal meniscus. As shown in Table II, it was found that the amount of

GAG in the experimental group at 8 weeks reached 47.39% of that in

the normal meniscus, as compared with 23.26% for the control group

(P<0.05). However, with the maturation of the engineered

cartilage to 12 weeks, GAG content was increased, reaching 91.35%

of that in the normal meniscus (P<0.05). A significant

difference was also observed between the amount of GAG in the

engineered cartilage at 8 and 12 weeks (P<0.05).

| Table IIGAG contents (wet weight) of repaired

cartilage. |

Table II

GAG contents (wet weight) of repaired

cartilage.

| 8 weeks (n=12) | 12 weeks (n=12) |

|---|

|

|

|

|---|

| Groups | GAG content

(mg/g) | Percentage of normal

(%) | GAG content

(mg/g) | Percentage of normal

(%) |

|---|

| Normal | 12.07±0.37 | | 12.95±1.23 | |

| Exp | 5.72±0.87 | 47.39±2.37 | 11.83±3.05 | 91.35±5.27 |

| Ctrl | 2.81±1.03 | 23.26±4.76 | | |

Discussion

Meniscal injury is one of the most common injuries

to the knee. The menisci are important for normal knee function. A

meniscus injury increases the risk of subsequent development of

degenerative changes in the knee (11). Repairing meniscus injuries remains

a challenge in sports medicine, since meniscus usually does not

regenerate by itself following injury. The emergence of a tissue

engineering technique may provide a satisfactory solution to the

problem.

Tissue engineering is based on a unique combination

of exogenous cells, specific stimuli and matrix scaffold in an

in vitro or in vivo environment. In the present

study, myoblasts were used. Myoblasts, which are adult stem cells

and include skeletal muscle cell precursors, have been shown to

possess multipotential mesenchymal stem cell activity and are

capable of forming chondrocytes, osteocytes and adipocytes as well

as myocytes (12–14). Previous reports suggest that a

degree of plasticity remains prior to terminal myoblastic

differentiation. Therefore, myoblasts may prove useful for the

development of new therapeutic approaches aimed at the regeneration

of damaged or diseased tissues. Myoblasts have been investigated as

a candidate cell source for tissue engineering (15–17).

In comparison with other stem cell sources, myoblasts represent a

more promising source for cartilage engineering, as they are

relatively abundant and easily accessible, with minimal donor site

morbidity (18,19). Studies have shown that myoblasts

have a higher cell yield and more rapid proliferation ability

during in vitro expansion (8,20).

In this study, we observed a chondrogenic response with a dose of

50 ng/ml CDMP-2 and 20 ng/ml TGF-β1 provided continuously with each

medium change. Chondrogenic differentiation, analyzed using

immunohistochemistry and gene expression profiles, was observed.

This suggests that key events responsible for the commitment of

myoblasts to the chondrogenic lineage occur during the early

initial period of cell growth and proliferation.

PGA is a commonly used synthetic polymer in

cartilage tissue engineering. In order to maintain its dimensional

stability and enhance its mechanical properties, fibrous PGA meshes

are coated with solutions of PLA. Evaporation of the solvent for

PLA leads to the formation of PLGA composites with specific shapes.

The feasibility of using a PLGA composite as a scaffold to engineer

cartilage tissue has been documented in a number of studies

(21,22). It was also shown that adhesion and

proliferation of chondrocytes on PGA fibers was significantly

suppressed when an increased amount of PLA was added (21,22).

Therefore, the concentration of PLA solution to be added needs to

be lowered but still sufficient to function as glue to maintain the

structural stability of the PGA 3D scaffold. In the present study,

1.5% PLA in dichloromethane was used. Any further lowering would

cause an unstable configuration of the scaffold. Scanning electron

microscopy revealed that PLA at this concentration is capable of

wrapping PGA fibers together and that the shape of scaffold was

maintained when they were kept in culture medium for as long as 5

weeks (22).

The main advantage of using a PLGA scaffold for

meniscal tissue engineering is its suitable degradation rate, which

matches the kinetics of new meniscal formation in

vivo(5). The degradation of

non-woven PGA scaffold is reported to be complete over a period of

2 months in vivo(23). In

the present study, no undegraded PLGA fibers were observed

histologically in the experimental or control groups at 12 weeks

post-implantation. Due to its rapid degradation, PLGA scaffold was

found to accelerate chondrogenesis of constructs prepared from

dedifferentiated chondrocytes and PLGA, as the accumulation of the

deposited cartilage-specific extracellular matrix (ECM) and

expression of marker genes both in vitro and in vivo

were significantly enhanced compared with those of constructs

prepared from PGA. It was also proposed that early degradation of

PLGA fibers may have a positive effect on chondrogenesis by leaving

new spaces for cells to further fill in and produce new

intercellular matrix, which in turn may facilitate the formation of

more cell-matrix and cell-cell contact.

In this study, the specimens showed a cartilaginous

appearance. However, no construct was identified in all control

groups after 8 weeks of in vivo culture. As shown by the

histological analysis, the section of engineered cartilage had the

appearance of fibrocartilage with fibrochondrocytic-like cells at 8

and 12 weeks. In the control group, only a band of fibrous tissue

was observed. Immunohistological staining indicated that engineered

cartilage was positively stained for type II collagen compared with

the control group at 8 and 12 weeks post-implantation. At 12 weeks,

expression of mRNAs for type I collagen, type II collagen and

aggrecan was detected by RT-PCR. By contrast, no assessed genes

were expressed in the control tissue. In addition, the

biomechanical properties (compressive modulus) and biochemical

composition (GAG quantification) of engineered cartilage at 12

weeks post-implantation were similar to those of corresponding

normal cartilage, which indicated that the engineered cartilage was

formed both structurally and functionally.

In conclusion, we showed chondrogenic

differentiation of myoblasts seeded into PLGA scaffolds following

implantation in a subcutaneous pocket of nude mice. Further studies

are required to investigate implanted myoblast-seeded PLGA

scaffolds in a joint, including biomechanical stress for the

evaluation of a possible positive stimulus by mechanical loading

after implantation.

Acknowledgements

This study was supported by the Shanghai Natural

Science Foundation (Grant No. 09ZR1425500) and Research Grant for

Health Science and Technology of Pudong Health Bureau of Shanghai

(Grant No. PW2009B-2).

References

|

1

|

Hart R, Janecek M, Siska V, Kucera B and

Stipcák V: Correlation of long-term clinical and radiological

results after meniscectomies. Acta Chir Orthop Traumatol Cech.

72:304–307. 2005.PubMed/NCBI

|

|

2

|

van der Wal RJ, Thomassen BJ and van Arkel

ER: Long-term clinical outcome of open meniscal allograft

transplantation. Am J Sports Med. 37:2134–2139. 2009.PubMed/NCBI

|

|

3

|

Yamasaki T, Deie M, Shinomiya R, Yasunaga

Y, Yanada S and Ochi M: Transplantation of meniscus regenerated by

tissue engineering with a scaffold derived from a rat meniscus and

mesenchymal stromal cells derived from rat bone marrow. Artif

Organs. 32:519–524. 2008. View Article : Google Scholar

|

|

4

|

Webber RJ, York JL, Vanderschilden JL and

Hough AJ Jr: An organ culture model for assaying wound repair of

the fibrocartilaginous knee joint meniscus. Am J Sports Med.

17:393–400. 1989. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Kang SW, Son SM, Lee JS, Lee ES, Lee KY,

Park SG, Park JH and Kim BS: Regeneration of whole meniscus using

meniscal cells and polymer scaffolds in a rabbit total meniscectomy

model. J Biomed Mater Res A. 78:659–671. 2006. View Article : Google Scholar

|

|

6

|

Ishida K, Kuroda R, Miwa M, Tabata Y,

Hokugo A, Kawamoto T, Sasaki K, Doita M and Kurosaka M: The

regenerative effects of platelet-rich plasma on meniscal cells in

vitro and its in vivo application with biodegradable gelatin

hydrogel. Tissue Eng. 13:1103–1112. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Peretti GM, Gill TJ, Xu JW, Randolph MA,

Morse KR and Zaleske DJ: Cell-based therapy for meniscal repair: a

large animal study. Am J Sports Med. 32:146–158. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Lu SH, Yang AH, Wei CF, Chiang HS and

Chancellor MB: Multi-potent differentiation of human purified

muscle-derived cells: potential for tissue regeneration. BJU Int.

105:1174–1180. 2009.PubMed/NCBI

|

|

9

|

Zhou G, Liu W, Cui L, Wang X, Liu T and

Cao Y: Repair of porcine articular osteochondral defects in

non-weightbearing areas with autologous bone marrow stromal cells.

Tissue Eng. 12:3209–3221. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Zhu W, Wang Y, Qiu G and Chen B:

Characterization of the purification and primary culture of adult

canine myoblasts in vitro. Mol Med Report. 3:463–468.

2010.PubMed/NCBI

|

|

11

|

Gu YL and Wang YB: Treatment of meniscal

injury: a current concept review. Chin J Traumatol. 13:370–376.

2010.PubMed/NCBI

|

|

12

|

Gu Y, Wang Y, Dai H, Lu L, Cheng Y and Zhu

W: Chondrogenic differentiation of canine myoblasts induced by

cartilage-derived morphogenetic protein-2 and transforming growth

factor-β1 in vitro. Mol Med Report. 5:767–772.

2012.PubMed/NCBI

|

|

13

|

Asakura A, Komaki M and Rudnicki M: Muscle

satellite cells are multipotential stem cells that exhibit

myogenic, osteogenic and adipogenic differentiation.

Differentiation. 68:245–253. 2001. View Article : Google Scholar

|

|

14

|

Matsushita T, Matsui N, Fujioka H, Kubo S,

Kuroda R, Kurosaka M and Yoshiya S: Expression of transcription

factor sox9 in rat L6 myoblastic cells. Connect Tissue Res.

45:164–173. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Goldring K, Partridge T and Watt D: Muscle

stem cells. J Pathol. 197:457–467. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Day CS, Kasemkijwattana C, Menetrey J,

Floyd SS Jr, Booth D, Moreland MS, Fu FH and Huard J:

Myoblast-mediated gene transfer to the joint. J Orthop Res.

15:894–903. 1997. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Koning M, Harmsen MC, van Luyn MJ and

Werker PM: Current opportunities and challenges in skeletal muscle

tissue engineering. J Tissue Eng Regen Med. 3:407–415. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Singh D, Nayak V and Kumar A:

Proliferation of myoblast skeletal cells on three-dimensional

supermacroporous cryogels. Int J Biol Sci. 6:371–381. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Marsano A, Millward-Sadler SJ, Salter DM,

Adesida A, Hardingham T, Tognana E, Kon E, Chiari-Grisar C, Nehrer

S, Jakob M and Martin I: Differential cartilaginous tissue

formation by human synovial membrane, fat pad, meniscus cells and

articular chondrocytes. Osteoarthritis Cartilage. 15:48–58. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Stern-Straeter J, Bran G, Riedel F, Sauter

A, Hörmann K and Goessler UR: Characterization of human myoblast

cultures for tissue engineering. Int J Mol Med. 21:49–56. 2008.

|

|

21

|

Moran JM, Pazzano D and Bonassar LJ:

Characterization of polylactic acid-polyglycolic acid composites

for cartilage tissue engineering. Tissue Eng. 9:63–70. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Cui L, Wu Y, Cen L, Zhou H, Yin S, Liu G,

Liu W and Cao Y: Repair of articular cartilage defect in non-weight

bearing areas using adipose derived stem cells loaded polyglycolic

acid mesh. Biomaterials. 30:2683–2693. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Zwingmann J, Mehlhorn AT, Südkamp N, Stark

B, Dauner M and Schmal H: Chondrogenic differentiation of human

articular chondrocytes differs in biodegradable PGA/PLA scaffolds.

Tissue Eng. 13:2335–2343. 2007. View Article : Google Scholar : PubMed/NCBI

|