Introduction

According to epidemiological and clinical studies

reviewed in the report by the FAO and WHO, dietary preferences and

physical activity exert critical effects on the risk of developing

certain chronic diseases and cancers. By considering the energy

density of foods in the diet, reducing the intake of added sugar,

high fat/saturated fats and sodium, and increasing the intake of

dietary fiber and bioactive compounds, can prevent the risk of

developing chronic and degenerative diseases. This can aid

individuals in the maintenance of their body weight, and can help

protect cognitive and physiological health (1). However, according to statistical data

including 46 European countries, 1 in 3 children between the ages

of 6 and 9 years is either overweight [body mass index (BMI),

25-30] or obese (BMI ≥30). The number of obese children in Europe

was 41 million in 2016 and is expected to reach 70 million by

2025(2). In the childhood and

adolescence period, snacks with high-calorie and unbalanced

nutrients are creating dietary issues. The majority of dietary

guidelines describe all high-calorie foods and beverages consumed

between main meals as ‘snacks’. In some recommendations, ‘snack

foods’ are defined as foods with a low nutrient density, but high

calories, saturated fats and added sugar (3-6).

Studies indicate a positive association between snack food

consumption and the risk of developing chronic diseases, such as

cardiovascular diseases, obesity, type-2 diabetes and insulin

resistance (7). Nutrition in

childhood plays a critical role in the prevention of obesity in

both childhood and adulthood. The United States Department of

Agriculture (USDA) has issued A Guide to Smart Snacks in School; in

this standard, there are limits to the ingredients, nutrients and

energy value of snacks (8). As a

result of this new standard, it has become increasingly popular to

employ snack designs that incorporate healthier recipes (containing

added proteins, fibers, unsaturated fats, vitamins and mineral

sources), as opposed to solely oil and/or sugar. Whey protein

concentrate (WPC), natural sweeteners, dietary fibers, such as

inulin and pectin, omega-3 fatty acids, resistant starch or certain

bioactive compounds, such as gallic acid and ellagic acid are used

in new product designs or enrichment studies (9-12).

However, the nutritional quality of food does not only depend on

its nutrient profile, but the matrix and physicochemical properties

of food are also important for the fate properties and metabolic

responses of nutrients and bioactive compounds in the digestive

system. Research has indicated that foods of the same composition

have differences in their digestion and responses, such as on the

glycemic index (GI) or satiety, depending on its structural

properties and applied technological processes (13). Another study proposed a method to

evaluate the impact of complex food matrix structures on digestion

kinetics (14). This method

combines the pH-stat technique with a static in vitro

digestion protocol based on the INFOGEST guidelines (15). That method was used to investigate

the digestion behavior of two emulsion-type food matrices that have

the same compositions (10 wt% fat, 15 wt% whey proteins), but have

different structures at the macroscopic and microscopic scales.

However, studies on the structural effects of real food matrices on

both lipolysis and proteolysis kinetics and hydrolysis degrees are

required (14).

The present study aimed to develop healthier snacks

and evaluate the in vitro hydrolysis of macronutrients

within a real food matrix, utilizing a combined approach of pH-stat

titration technique and the INFOGEST in vitro digestion

protocol. A total of five snack prototypes were formulated

following the Smart Snack criteria (8). These prototypes were then assessed

for their compliance with nutrient content claims permitted by

Regulation (EC) No. 1924/2006 (http://data.europa.eu/eli/reg/2006/1924/2014-12-13).

Various foods (dry nuts, dry fruits, kefir, eggs, butter and

sunflower oil) or ingredients rich in bioactive compounds and

nutrients (whey protein, chickpea flour, green tea, inulin,

cinnamon and honey) were used in the formulations. Of note, three

of the snacks were baked and two of them were prepared as

ready-to-eat. In all the snacks, the sensory evaluation, the

approximate and fatty acid compositions, the degree of protein and

lipid hydrolysis in vitro using pH-stat and in vitro

starch hydrolysis were determined.

Materials and methods

Foods, ingredients and chemicals

All foods and ingredients were purchased from local

suppliers. Goat kefir was purchased from Baltali Food Company. The

80% purity WPC (WPC80) was provided by Dr. Oetker Türkiye Food

Company (https://www.droetker.com.tr/kunye). The vacuum dried

vegetables; red pepper, beet roots, spinach, leeks, zucchini and

carrot were a kind gift from Eregli AgroSan Company. Pullulanase

(EC-3.2.1.41), pepsin (≥2500U/mg protein, EC 232-629-3), pancreatin

(EC 232-468-9), α-amylase (EC 232-565-6), α-chymotrypsin (C 4129),

trypsin (T 030) and bile salt (B 8638) were purchased from

MilliporeSigma. The D-glucose measurement kit was purchased from

Megazyme.

Lyophilized goat kefir, resistant

starch flour and brewed green tea

Goat kefir was freeze-dried using a freeze-dryer

(Model-FT33, Armfield) and the dry matter ratio of goat kefir was

increased from 12 to 96%, while the total fat ratio was increased

from 4 to 28%.

Chickpea flour was diluted at a ratio of 1:8 with

water and pre-gelatinized for 10 min. The autoclave was then held

for 15 min at 121˚C. Subsequently, pullulanase (80 U/g sample) was

added followed by incubation in a water bath (60˚C, 6 h). The

retrogradation process was then repeated and the samples were dried

at 55˚C for 7 h. The dried samples were kept at 4˚C in powder form

until the resistant starch content was analyzed (16).

Dried green tea leaves (0.8 g) were added to 250 ml

of boiling water and kept for 4 min for infusion. The leaves were

filtered, and the tea was stored at 4˚C until use.

Snack preparation

The classic homemade shortbread (R) was used as a

control and its recipe was used as the basis for the five snacks.

The ingredient list of the prepared snacks is presented in Table I. For snacks 1-3, the dry

ingredients were mixed and green tea was then added. The dough was

kneaded (7 min) by hand and shaped 5.5 cm width, 15 cm length and

2.5 cm in height before the pre-baking process in the convection

oven (9629 CMS, Beko) for 40 min at 150˚C, without a fan.

Subsequently, the pre-baked dough was removed from the oven and cut

into rectangular shapes, which were 1-cm-thick, and baked again for

10 min at 150˚C, with a fan. For snacks 4 and 5, dried nuts were

ground in the kitchen grinder (BH259CG, Blue House) for 10 sec and

transferred to a bowl. The dried fruits were then mixed with WPC80

for snack 5 and with inulin for snack 4. All ingredients in the

bowl were then kneaded by hand for 180 sec with the addition of

honey, cinnamon, glycerol or sunflower lecithin. Baking was not

applied to these snacks and they were prepared as ready-to-eat. For

this, the dough was formed into a bar and stored at 4˚C for 2 h in

the refrigerator, to obtain its firmness. All snacks were stored at

-18˚C until analyses were performed.

| Table IList of ingredients of the snacks (100

g samples). |

Table I

List of ingredients of the snacks (100

g samples).

| | Snack sample |

|---|

| Ingredients | R | 1 | 2 | 3 | 4 | 5 |

|---|

| Whole wheat

flour | 49.75 | 35.56 | 30.10 | 30.10 | - | - |

| Chickpea flour

(RS) | - | 8.47 | 6.02 | 4.32 | - | - |

| Butter (82%

fat) | 15.40 | 7.62 | 10.16 | 10.16 | - | - |

| Sunflower oil | - | 2.54 | - | - | - | - |

| Egg (whole) | 12.90 | 25.4 | 18.07 | 24.9 | - | - |

| Desiccated

coconut | - | - | - | - | 8.55 | 8.55 |

| Goat kefir

powder | - | 3.11 | 3.11 | 3.11 | - | - |

| Sugar (beet) | 12.15 | - | 4.81 | 3.00 | - | - |

| WPC 80 | - | 6.35 | 6.35 | 3.18 | - | 21.40 |

| Nut mix | 7.35 | - | 4.51 | 4.51 | 28.06 | 27.36 |

|

Hazelnuts | 2.45 | - | - | - | 14,03 | - |

|

Almonds | 4.90 | - | 4.51 | 4.51 | - | - |

|

Walnuts | - | - | - | - | 14.03 | 13.68 |

|

Peanuts | - | - | - | - | - | 13.68 |

| Dried fruits | 2.45 | - | 6.30 | 9.16 | 44.70 | 38.50 |

|

Raisin

(sultanas) | - | - | 3.15 | 4.58 | 29.80 | 25.65 |

|

Blueberry | - | - | - | - | 8.77 | - |

|

Cranberry | 2.45 | - | 3.15 | 4.58 | - | 8.55 |

|

Sour

cherry | - | - | - | - | 6.13 | 4.30 |

| Dried

vegetables | - | 3.56 | - | - | - | - |

| Inulin | - | 3.05 | 3.65 | 2.53 | 13.80 | - |

| Brewed green

tea | - | 4.23 | 6.82 | 4.23 | - | - |

| Cinnamon

(powder) | - | - | - | 0.70 | - | - |

| Salt (sea) | 0.10 | 0.10 | 0.10 | 0.10 | - | - |

| Honey (pine) | - | - | - | - | - | 1.24 |

| Other ingredients

(glycerol, sunflower lecithin) | - | - | - | - | 4.89 | 2.95 |

Proximate composition

Fat, total sugar, moisture and ash analyses were

determined according to AOAC (17). The water activities (aw)

of the snacks were determined with a precision humidity measuring

instrument (Testo 650, Testo SE & Co. KGaA). The total

carbohydrate amount (CHO) was determined using the difference

method. The energy values of the snacks were calculated using

Atwater calorie constants (18).

The fatty acid composition of the snacks was measured using gas

chromatography (Agilent Technologies, Inc.) with a FID detector at

235˚C.

Sensory evaluation

The standard hedonic scale (5-point scale; from 1,

dislike; to 5, like, ISO 11136:2014; https://www.iso.org/standard/50125.html) was used to

assess the sensory attributes and overall acceptance of the

developed snacks. A total of 80 panelists (aged between 18-55

years) were randomly selected and asked to evaluate the snacks

according to their taste preferences. Overall acceptability was

calculated as the mean of scores describing each attribute and

multiplied by the importance factor. Snacks >70% points were

considered successful.

In vitro hydrolysis of protein and

lipids using pH-stat

The in vitro digestion of snacks was

performed according to the INFOGEST standardized static digestion

protocol (15). The preparation of

digestive solutions; simulated saliva fluid (SSF), simulated

gastric fluid (SGF) and simulated intestinal fluid (SIF) and enzyme

activity assays were performed according to this protocol. The oral

and gastric phases of the protocol were applied the same as in

INFOGEST protocol (15). According

to this protocol, samples containing starch are mixed with saliva

containing α-amylase enzymes and treated for 2 min. At this stage,

starch digestion begins and dextrin form is formed. The digestion

continues with the stomach and intestinal phases. In the present

study, after performing the mouth and stomach stages according to

this protocol, the method of Mat et al (14) was used to monitor fat and protein

hydrolysis with pH-stat (14). For

oral digestion, 3 g of the sample was mixed with 4 ml SSF and 0.025

ml of 0.3 M CaCl2 and the volume was adjusted to 10 ml

using ultrapure water. Subsequently, the mixture was incubated in a

shaking incubator operated at 200 rpm and 37˚C for 2 min. Following

mouth digestion, 8 ml SGF and 0.005 ml CaCl2 were added

to the bolus. The pH was then adjusted to 3 using 6 M HCl and 1 ml

pepsin enzyme (2,000 U/ml) was added to the mixture. The gastric

digestion was performed in a shaking incubator operated at 200 rpm

and 37˚C for 2 h. Following the gastric phase, some modifications

were made in the SIF formulation (with NaCl instead of

NaHCO3) to prevent buffering effect during intestinal

digestion (14). The volume of

gastric bolus was completed to 20 ml with SIF and pancreatin added

with pancreatic lipase (100 U/ml trypsin activity and 2,000 U/ml

lipase activity in the final mixture). For the intestinal phase, an

automatic titrator (Kyoto KEM AT-510, Kyoto Electronics

Manufacturing Co., Ltd.) with a pH-stat program was then used to

record the reaction kinetics by maintaining the pH at 7.0 with

addition of 0.1 N NaOH as a titrant and determined with the action

of enzymes release protons, and subsequently a decrease in pH. The

analysis was performed in two steps. In the first step, the

determination of the total degree of hydrolysis

(DHtotal) (proteolysis + lipolysis), intestinal

digestion was performed with the action of pancreatin (100 U/ml

final solution based on trypsin activity), which can hydrolyze both

proteins (peptides and remaining proteins after gastric phase) and

lipids. The volume of NaOH consumed during the titration was

recorded (V1). In the second step, for the determination of only

the degree of proteolysis, intestinal digestion was conducted with

trypsin (100 U/ml final mixture) and chymotrypsin (25 U/ml final

mixture). The volume of NaOH consumed during the titration was

recorded (V2). Following 2 h of digestion of the small intestine,

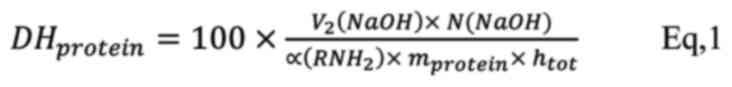

the degree of proteolysis was calculated using the following

equation (Eq. 1):

where V1 (NaOH) is the total volume of

NaOH consumed (mL), N (NaOH) is the normality of NaOH (Eq/L),

mprotein is the protein content of the sample (g),

α(RNH2) is the mean degree of dissociation of α-amino

groups, htot is the number of peptide bonds with respect

to the origin of the protein (meqv/g protein). Since the recorded

data from the pH-stat device in the intestinal phase is the result

of all physical and enzymatic actions throughout the digestion, it

is assumed that both total degree of hydrolysis and degree of

proteolysis calculations represent the entire digestion procedure,

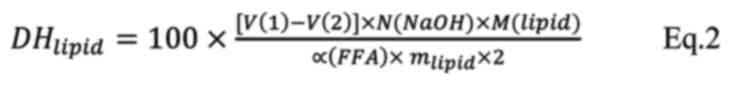

consisting of oral, gastric, and intestinal phases (14). For the in vitro degree of

lipolysis calculation, the following equation was used (Eq. 2):

where V2 (NaOH) is the total consumption

of NaOH in the presence of pancreatin enzymes at the intestinal

phase. V1 (NaOH) is the total amount of NaOH consumed

(ml) during the intestinal phase of in vitro proteolysis, N

(NaOH) is the normality of NaOH, m(lipid) is the oil

mass of the sample (g), Mlipid is the molecular weight

of the triglycerides in the oil fraction of the sample (g/mol) and

α(FFA) is the mean degree of dissociation of the carboxylic groups

of FFA.

In vitro starch hydrolysis and

estimated GI (eGI)

All stages, namely oral, gastric and intestinal were

applied according to the method suggested in the study by Minekus

et al (15). Starch

digestion begins in the mouth with α-amylase and dextrin is formed.

The glucose measurements were taken by sampling at the beginning of

the oral phase (t0) and every 30 min of the intestinal

phase for each snack. The end of the oral stage (t0) was accepted

as the initial moment for glucose measurement, to subtract the

naturally available glucose (if accessible) derived from raw

materials in the recipe, such as dry fruits. Additionally, these

data would be used to subtract from the further glucose

measurements during digestion to calculate starch hydrolysis. With

this approach, it is expected to prevent a potential error in the

calculation of starch hydrolysis stemming from the available

glucose in the recipe. Enzymatic reactions in the samples were then

terminated by the addition of 1 M HCl and centrifuged at 6,500 x g,

20˚, 20 min. The samples were diluted with water then treated using

GOPOD reactive solution and incubated in a water bath for 20 min at

45˚C. The D-glucose analysis kit (cat. no 700004297, Megazyme) was

used for the determination of the absorbance of sample at a 510 nm

wavelength in UV visible spectrophotometer (Cary 50 Scan, Varian).

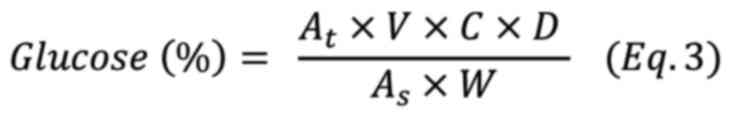

Glucose was calculated according to following equation (Eq 3)

(19):

where At is the absorbance of the sample,

ΔAs is the absorbance of the glucose standard solution,

V is the volume of the measured sample (ml), C is the concentration

of the glucose standard solution (mg/ml), D is the dilution factor,

W is the weight of the sample (mg).

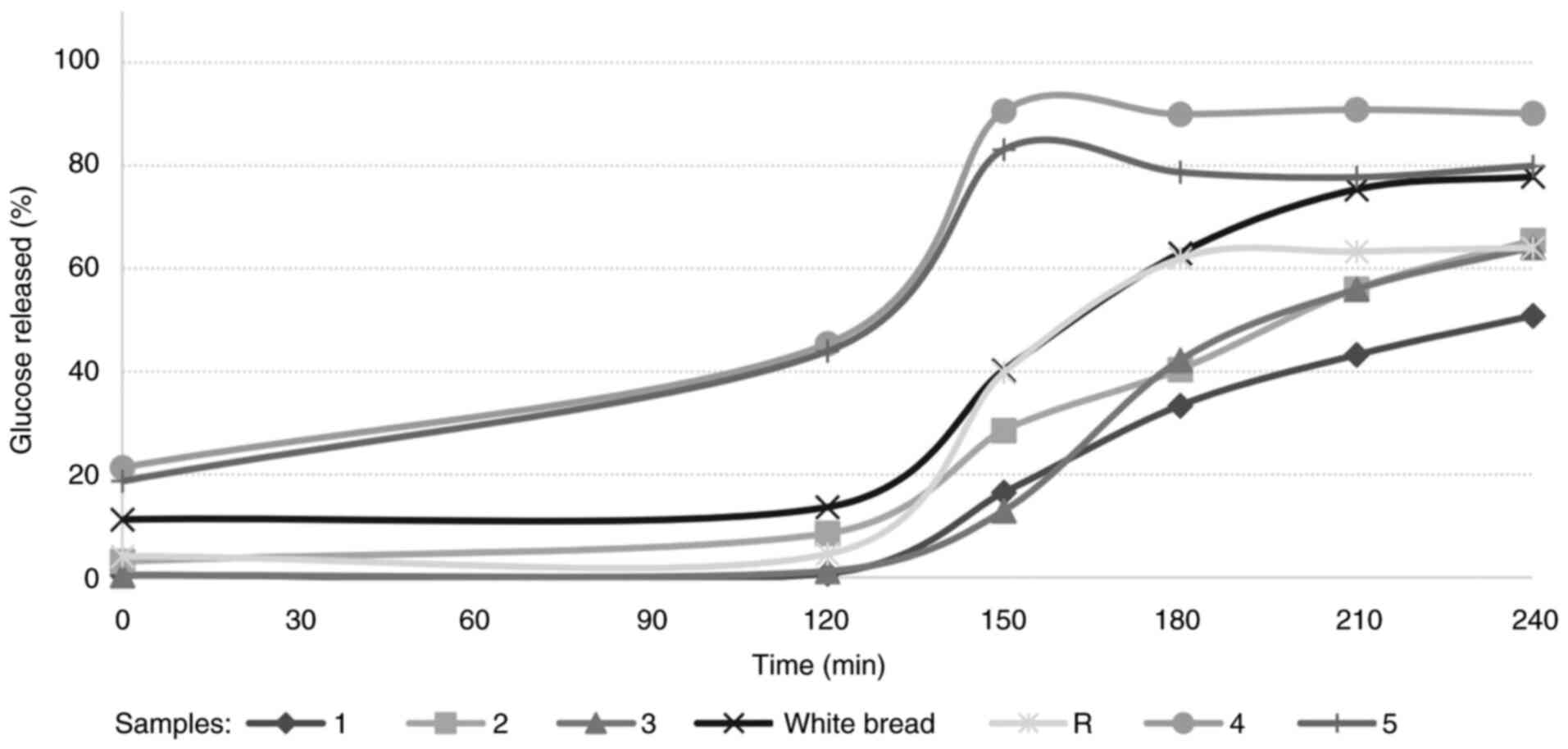

The rate of released glucose from sample starch

digestion was expressed at different times and the hydrolysis index

(HI) was obtained by dividing the area under the curve of the

sample to the area of control (white bread). The eGI was calculated

using equations 3, 4 and 5 respectively (20). The HI of white bread was accepted

as 100. Calculations using equations 4 and 5 are the best

correlated formulas for in vitro measurements when they are

compared with in vivo glycemic responses according to

reference study (21).

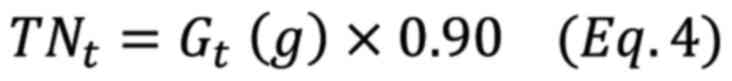

where HI is the percentage of total starch

hydrolysis, TNt is the total amount of hydrolyzed starch

at the time of t (g), and Gt is the amount of glucose in

the sample at the time of t (g).

Statistical analysis

All analyses were performed in triplicate. Data were

analyzed using one-way analysis of variance (ANOVA) with Tukey's

post hoc test using SPSS Statistics 20 software (IBM Corp.). The

confidence interval was selected at 95%. All results are presented

as the mean ± standard deviation. A P-value <0.05 was considered

to indicate a statistically significant difference.

Results and Discussion

Proximate composition

The chemical composition and energy value of the

snacks are presented in Table II.

The percentages of cooking loss of R (recipe), and snacks 1, 2 and

3 were 16, 28, 18 and 17%, respectively. The final percentage

calculations of chemical compositions and caloric values for the

snacks were adjusted to account for the mass loss incurred during

the cooking process. The energy values of all snacks apart from R

(control) were <135 kcal when they were evaluated on a serving

size (30 g) basis. While the amounts of total CHO in the snacks

varied between 14.4 and 16.56 g, the reference was found as 18.3 g

per serving (Table II). The

highest total sugar content was determined at 17.4% for the control

formula (R). The main fatty acids were palmitic (16:0), oleic

(18:1) and linoleic acid (18:2) in all snacks (Table III). The values of water activity

(aw) of all snacks were measured <0.6 (Table II), which provides the minimum

limit to prevent microbial growth and plays a crucial role in

biochemical reactions during storage. The water activities of the

baked snacks (snacks 1-3) were found to be lower than those of the

ready-to-eat snacks (snacks 4 and 5) (Table II), resulting from the heat

treatment applied to snacks1-3 and the glycerol and lecithin

involved in the ready-to-eat snacks.

| Table IIChemical composition and energy value

of the snacks. |

Table II

Chemical composition and energy value

of the snacks.

| Sample | Moisture (%) | Ash (%) | Protein (%) | Fat (%) | Water activity

(aw) | Total sugar

(%) | Total CHO (%) | Energy (kcal/30

g) |

|---|

| R | 3.60±1.01 | 1.22±0.04 | 8.7±0.26 | 21.90±0.34 | 0.354±0.08 | 17.42±2.48 | 62.7±0.74 | 148 |

| 1 | 3.10±1.01 | 2.70±0.06 | 20.5±0.31 | 18.30±0.60 | 0.308±0.07 | 2.20±0.93 | 55.2±0.34 | 134 |

| 2 | 3.29±1.12 | 2.18±0.04 | 17.7±0.68 | 16.05±0.11 | 0.309±0.09 | 10.95±2.72 | 59.5±0.22 | 127 |

| 3 | 3.34±0.43 | 1.97±0.15 | 16.5±0.26 | 17.10±0.34 | 0.323±0.06 | 8.66±5.95 | 61.0±0.22 | 129 |

| 4 | 7.30±0.29 | 2.20±0.08 | 5.7±0.69 | 24.30±0.51 | 0.520±0.04 | 17.08±3.45 | 60.2±0.71 | 119 |

| 5 | 7.70±0.26 | 2.20±0.04 | 22.6±0.21 | 19.00±2.01 | 0.509±0.03 | 15.40±2.32 | 48.3±2.06 | 110 |

| Table IIIFatty acid composition of the samples

(%). |

Table III

Fatty acid composition of the samples

(%).

| | Snack samples |

|---|

| Fatty acids | 1 | 2 | 3 | 4 | 5 |

|---|

| C10:0 | 1.99 | 4.13 | 2.44 | 0.20 | 0.95 |

| C12:0 | 2.84 | 4.23 | ND | 5.67 | 8.31 |

| C14:0 | 9.73 | 13.20 | 8.62 | 2.01 | 3.71 |

| C16:0 | 29.90 | 32.44 | 28.32 | 9.49 | 6.09 |

| C18:0 | 8.04 | 8.66 | 9.34 | ND | ND |

| C18:1 | 33.89 | 23.72 | 35.41 | 41.97 | 42.39 |

| C18:2 | 10.18 | 5.62 | 10.59 | 32.83 | 30.41 |

| C18:3 | ND | ND | ND | 6.17 | 5.51 |

Sensory evaluation

The results of sensory analysis on the hedonic scale

are expressed with a score >100. For snacks 1, 2, 3, 4 and 5,

the scores were 70.9, 80.8, 81.8, 71.5 and 77.1, respectively. The

snack preferences were in the following order:

3>2>5>4>1. The consumer preference for snacks 3 and 2

may be attributed to the presence of dried fruits and a higher

butter content. Additionally, the lower utilization of retrograded

chickpea flour in these snack samples compared to snack 1 may

contribute to a more pleasant aroma. Conversely, the lower

preference for snacks 4 and 5 is likely due to their higher content

of dietary fiber (13.80% in sample 4) and WPC (21.40% in sample 5)

compared to the preferred samples (2 and 3). These ingredients may

have resulted in a less favorable sensory perception. Finally,

snack 1, containing retrograded chickpea flour with no added sugar

or dried fruits, may have been perceived as the least favorable due

to its relative dryness and potentially strong salty taste.

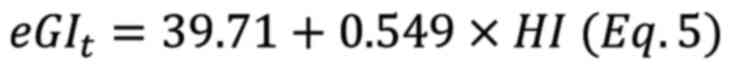

Degree of proteolysis

Proteolysis was evaluated by decreasing the pH value

of the protons of the carboxyl ends of amino acids and peptides,

which are released following GI digestion. According to the data

obtained from pH-stat during the intestinal digestion of the

snacks, the kinetics of all snacks, apart from snack 2 were similar

in shape, exhibiting a rapid rising rate at the beginning (first 45

min) followed by a gradual attenuation, leading to a plateau. Snack

2 reached the highest degree of hydrolysis with an increasing speed

up to 115 min, but did not exhibit a tendency to plateau; probably

the reaction was continuing at this moment (Fig. 1). Apart from snack 4, all snacks

had >40% proteolysis within 30 min. At the end of the intestinal

digestion, the degree of hydrolysis was estimated >80% for

snacks 2 and 5. The degree of hydrolysis of all the snacks at the

end of the intestinal phase is presented in Table IV. There was no significant

difference between snacks 1 (65.17%) and 3 (63.12%) (P>0.05),

while snack 4 had the lowest degree of hydrolysis (57.37%), and

snacks 2 and 5 had high degrees of hydrolysis (84.84 and 84.46%,

respectively; P<0.05). In the recipe for snack 4, a high amount

(13.8%) of inulin was used; thus, it could be a distinct difference

compared to snacks 1, 2 and 3 (inulin contents: 3.05, 3.65 and

2.53%, respectively). In snack 5 which had the highest degree of

hydrolysis, inulin was not used. On the other hand, it could be

said that resistant starch had no effect on protein hydrolysis in

snacks 1, 2 and 3 (P<0.05). Sciarini et al (22) examined the in vitro

digestibility of gluten-free bread enriched with inulin. They noted

that the protein hydrolysis of bread decreased when inulin was

added at 10% to the bread and increased at the level of 5%. The

addition of fiber can cause a different structure between protein

and starch in bread, which could make starch and protein less

accessible to enzyme hydrolysis and influence protein aggregation

(13,23). Inulin as a viscous soluble dietary

fiber increases digesta viscosity and decreases the kinetics of

enzyme reactions due to reducing the rate of mixing with

proteolytic enzymes released in the stomach or small intestine

during digestion (23,24). However, this physicochemical

barrier for enzyme reactions can be evaluated with the view that it

provides a low GI due to lower carbohydrate digestion. This effect

will be explained in further detail below in the subsection

entitled ‘Degree of starch hydrolysis and eGI’.

| Table IVIn vitro protein, lipid

hydrolysis, released glucose, HI and eGI values of the snack

samples. |

Table IV

In vitro protein, lipid

hydrolysis, released glucose, HI and eGI values of the snack

samples.

| | Snack sample |

|---|

| Hydrolysis (%) | White bread | R | 1 | 2 | 3 | 4 | 5 |

|---|

|

DHproteolysis | - | - |

65.17±3.91a |

84.84±5.39b |

63.12±10.95a |

57.37±3.44c |

84.46±7.96b |

|

DHlipolysis | - | - |

76.85±1.76d |

62.63±12.68d |

74.65±7.07d |

80.94±1.54e |

91.92±5.07f |

| RG% | 77.83 | 64.02 | 50.84 | 65.46 | 64.13 | 90.13 | 79.93 |

| HI | 100 | 105.57g |

61.54±1.76h |

105.12±12.68i |

107.19±7.07i | NM | NM |

| eGI | 70 | 73.04j | 56.21k | 69.03l | 68.33l | NM | NM |

Starch hydrolysis

Another reason for the highest hydrolysis degree

found in snack 5 may be the presence of WPC in the recipe; snack 5

had the highest amount of WPC (21.40%) among the snacks. This

result is consistent with the findings in the literature (13,25),

reporting that the denatured form of the whey protein structure is

easily hydrolyzed with intestinal protease enzymes. However, a

previous study found that the proteolysis results of biscuits

enriched with 20% whey protein and pea protein is was not altered

compared with the control (23).

Furthermore, different proteolysis rates have been reported when

heat-induced whey protein gel structures are subjected to simulated

intestinal digestion. It has been observed that the gel structure

may affect the reaction rate and hydrolysis mechanisms, and the

differences in the diffusion of the enzyme into the chyme during

proteolysis may result from the steric barrier created by the gel

structure (26,27). In the present study, the use of

enriched whey protein without the use of heat treatment may

correspond to high levels of enzyme activity.

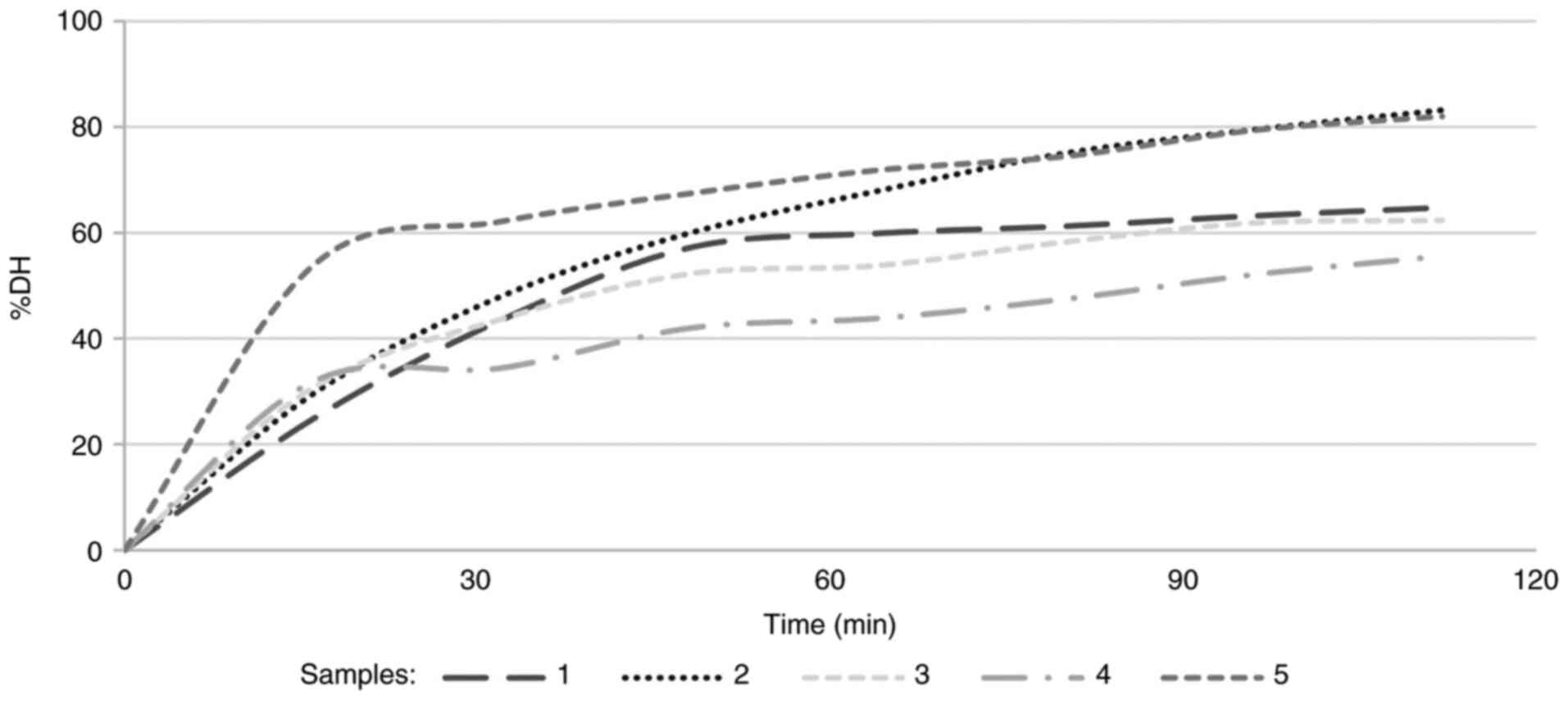

Degree of lipolysis

Lipolysis was calculated using data obtained by the

subtraction of the DH values obtained in the presence of

proteolytic enzymes, from DH values obtained in the presence of

pancreatin enzymes (Fig. 2). In

snacks 4 and 5 (ready-to-eat samples), a lipolysis >80% was

observed, which was higher than that of the baked snacks (snacks 1,

2 and 3) (P<0.05; Table IV);

snacks 4 and 5 exhibited rapid digestion at the beginning; however,

the release rate of fatty acids then gradually decreased, and the

lipolysis rate remained relatively constant after 75 min, until the

end of intestinal digestion. However, in the baked snacks, the rate

of lipolysis was slower, with hydrolysis occurring in the first 25

min at ~30%; this value was >65% in snacks 4 and 5. There were

no marked differences between snacks 1, 2 and 3 (P>0.05);

however, the lipolysis values of snacks 4 and 5 differed

significantly (P<0.05) (Table

IV). The difference between snacks 4 and 5 can be explained by

the degree of lipolysis being negatively affected due to the

interaction of dietary fibers with molecules, such as bile salts,

fatty acids and calcium during gastro-intestinal digestion

(28). Furthermore, the lower

lipolysis values of the baked samples compared with the

ready-to-eat snacks may be based on the presence of starch that

negatively affects lipolysis. A previous study investigated the

influence of intestinal conditions, non-lipid components and food

matrix on lipolysis with a selection of 52 real foods. The results

were then statistically processed using factors such as energy,

protein, total lipid, starch, saturated fatty acid, monounsaturated

fatty acid, polyunsaturated fatty acid, fiber, iron, calcium,

sodium content of the foods; and lipid structures (complex solid,

continuous aqueous phase and continuous lipid phase) in the food

matrix (28). The authors of that

study pointed out that lipid-protein and lipid-starch interactions

negatively affected lipolysis in real foods when using the INFOGEST

(15) static in vitro

digestion method. Notably, high-fat foods were not affected by

these macronutrient interactions (29). In the present study, snacks 4 and 5

that had a total lipid content of 24 and 19%, respectively, the

lipolysis values were higher than those of the baked snacks

(P<0.05). It was found that snack 5, which had the highest

protein content (22.6%), had the highest lipolysis value (91.9%;

P<0.05; Table IV) compared

with the other snacks. Additionally, the high unsaturated fatty

acid content in the snacks positively affected the lipolysis

values, resulting in the uncooked snacks (ready-to-eat) having

higher lipolysis values than the baked snacks (P<0.05; Table IV). On the contrary, the content

of mono or polyunsaturated fatty acids has been reported to have no

effect on lipolysis in real foods (29).

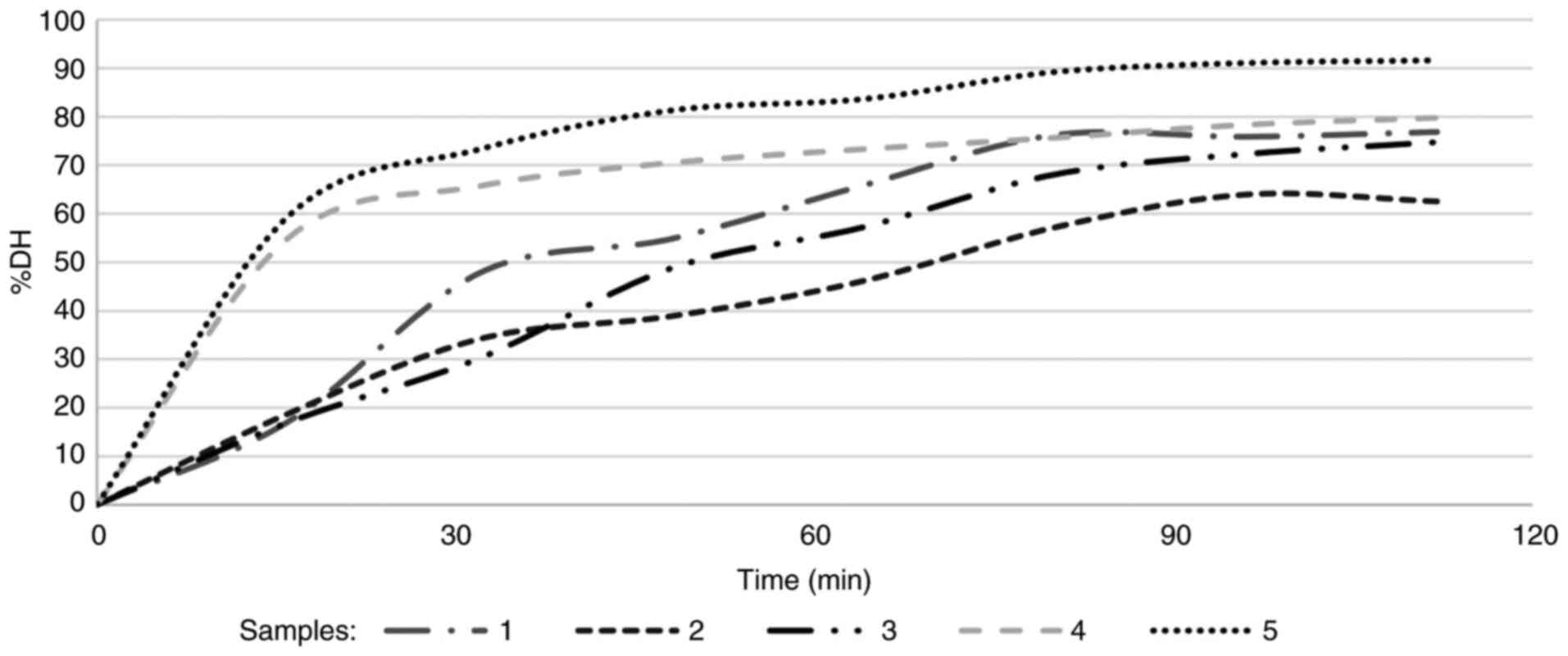

Degree of starch hydrolysis and

eGI

The glucose released during the hydrolysis of the

sample during simulated gastrointestinal digestion is illustrated

in Fig. 3. Starch hydrolysis was

examined in R (control recipe), white bread and baked snacks

(numbered as 1, 2 and 3) that contain a certain amount of complex

carbohydrates (Fig. 3). The

calculated HI and eGI values of the samples are presented in

Table IV. The eGI values were

correlated to 70 (white bread) (≤55: Low; 56<eGI<69:

Moderate; 70≥eGI: High) and although the control (R) was on the

border, it was found to have a high GI, while snacks 1, 2 and 3

were evaluated as having a moderate GI. The hydrolysis rate (HI) of

snack 1 was significantly lower than that of the other snacks

(P<0.05). According to the eGI calculations, all baked snacks

differed significantly compared with R (P<0.05). This is

particularly crucial for assisting the regulation of the blood

glucose level for insulin resistance, type-2 diabetes and obesity

(20). The glucose released during

in vitro digestion of snacks was measured by sampling at the

beginning of the oral phase (t0) and every 30 min of the intestinal

phase. According to the results (Fig.

3), glucose was not detected in snack 1 at the beginning (t120)

of the intestinal phase. The release of glucose molecules was

finished in unbaked snacks after the first 30 min (t150) of the

intestinal phase. However, glucose hydrolysis continued in baked

snacks until the time interval of t210 and t240. This difference

may have been caused by inhibitory and delaying effects of

ingredients such as whole wheat, resistant starch, and inulin

(30). Besides, the food matrix

could affect starch digestibility by creating interactions such as

starch-protein, starch-fiber and starch-lipid (31). In snacks 1, 2 and 3, brewed green

tea was used in ratios 4.23, 6.8 and 4.23%, respectively. In

another study, gallic acid and epigallocatechin gallate in green

tea extract may have inhibitory effects on enzymes that hydrolyze

starch (32). However, that

inhibitory effect was not observed in our study. Using brewed tea

instead of extract could be the reason for this result.

Evaluation of snacks as ‘Smart Snacks,

SS’ and nutritional claims

According to the Smart Snacks (SS) standard

(8), SS must meet certain

criteria. There must be a grain product with whole grains as the

main ingredient (≥50% by weight) or contain fruit and vegetables,

milk, dairy products or protein as the main ingredient, or a

combination of foods that provides at least 0.25 cups of fruit

and/or vegetables by weight. Additionally, there are five more

nutritional requirements based on the snacks' composition (8). When comparing the data from the

present study with these requirements, all snacks met the mandatory

criteria outlined in the Smart Snacks standard. These criteria

include having ≤200 calories, with ≤35% of the calories derived

from fat, <10% of the calories derived from saturated fat, and

35% of the weight derived from total sugars. The sources of sugar

and fat in the snacks complied with the exceptions specified in the

standard, such as dried fruits, dried vegetables, nuts and

seeds.

Furthermore, according to the Annex of Regulation

(EC) No. 1924/2006 (http://data.europa.eu/eli/reg/2006/1924/2014-12-13).

on labeling standards, all snacks can be nutritionally claimed as a

source of omega-3, containing a high amount of monounsaturated

fatty acids, rich in polyunsaturated fatty acids, and as a source

of protein. For snacks 1, 4 and 5 as ‘no sugar added’,

‘high amount of protein’ was amended by the Regulation (EU)

No. 1047/2012 (https://eur-lex.europa.eu/eli/reg/2012/1047).

The calorie target of the snacks in the present

study was set at 135 calories per serving. Additionally,

investigating the bioaccessibility of macronutrients in the samples

was critical for understanding the impact of the food matrix.

Chriqui et al (33)

observed in their study that implementing Smart Snacks policies in

school food environments effectively influenced the consumption of

fruits, vegetables, and healthier choices among young individuals.

The snacks developed in the present study were well-liked by the

panelists, which is a crucial criterion for replacing fatty,

sugary, or salty snacks with healthier alternatives.

In the present study, sensory successful products

with Smart Snack criteria, which can be sold in school canteens,

were developed considering the portion size. In the future, a

better approach perhaps would be to develop these standards

considering the bioaccessibility/bioavailability of proteins,

lipids and carbohydrates, and understanding the effects of the food

matrix and interactions of these macronutrients in food.

The healthy eating recommendations strive to enhance

overall well-being by focusing on specific dietary improvements.

These include reducing saturated fat intake, while increasing the

consumption of complex carbohydrates, such as dietary fiber and

bioactive compounds found in legumes, cereals, vegetables and

fruits. To further promote health and nutrition, the introduction

of Smart Snack standards has revolutionized snack choices by

evaluating them based on their positive impact. These new criteria

ensure that snacks available in school canteens align with health

goals. To address the diverse needs of consumers, the present study

successfully developed sensory appealing products that meet the

Smart Snack criteria, taking into account appropriate portion

sizes. However, to enhance these standards further, it would be

beneficial to consider the bioaccessibility/bioavailability of

essential nutrients, such as protein, lipids and carbohydrates

along with further standard updates on vitamins, minerals and trace

elements. This would involve the understanding of how these

macronutrients interact within the food matrix and their effects on

the body. By incorporating bioaccessibility/bioavailability factors

and assessing the intricate interactions among macronutrients,

future standards can better optimize the nutritional value of food

products. This approach will ensure that the snacks offered in

school canteens not only meet the smart snack criteria but also

provide optimal nutrient absorption and utilization. Consequently,

individuals will benefit from improved health outcomes and overall

well-being.

Acknowledgements

The present study is a part of the thesis of CD for

a Master of Science degree on nutrition section of food

engineering, under the supervision of SNE from the Food Engineering

Department of Ege University, Bornova, Turkey.

Funding

Funding: The present study received financial support from Ege

University (Project no: 16MUH022).

Availability of data and materials

The datasets used and/or analyzed during the current

study are available from the corresponding author on reasonable

request.

Authors' contributions

CD and SNE worked collectively on the study design.

CD conducted the literature review, all the experiments, the

statistical analysis and participated in the discussion of the

results. SNE participated in the discussion of the results and

contributed to the structure and grammar of the whole article. CD

and SNE confirm the authenticity of all the raw data in that study.

Both authors have read and approved the final manuscript.

Ethics approval and consent to

participate

Not applicable.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

World Health Organization (WHO):

Sustainable healthy diets: guiding principles. WHO, Rome, 2019.

https://www.who.int/publications/i/item/9789241516648.

|

|

2

|

United European Gastroenterology (UEG):

The Survey of Digestive Health Across Europe Highlighting changing

trends and healthcare. UEG, Wien, 2016.

|

|

3

|

Bellisle F: Meals and snacking, diet

quality and energy balance. Physiol Behav. 134:38–43.

2014.PubMed/NCBI View Article : Google Scholar

|

|

4

|

Grunert KG, Brock S, Brunsø K,

Christiansen T, Edelenbos M, Kastberg H, Krogager SGS, Mielby LH

and Povlsen KK: Cool snacks: A cross-disciplinary approach to

healthier snacks for adolescents. Trends Food Sci Technol.

47:82–92. 2016.

|

|

5

|

Hess JM, Jonnalagadda SS and Slavin JL:

What Is a Snack, Why Do we snack, and how can we choose better

snacks? A review of the definitions of snacking, motivations to

snack, contributions to dietary intake, and recommendations for

improvement. Adv Nutr. 7:466–475. 2016.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Zizza CA: Healthy snacking

recommendations: One size does not fit all. Physiol Behav.

134:32–37. 2014.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Prapkree L, Uddin R, Jaafar JAA, Baghdadi

M, Coccia C, Huffman F and Palacios C: Snacking behavior is

associated with snack quality, overall diet quality, and body

weight among US college students. Nutr Res. 114:41–49.

2023.PubMed/NCBI View Article : Google Scholar

|

|

8

|

U.S. Department of Agriculture, Food and

Nutrition Service: A Guide to Smart Snacks in School. United States

Department of Agriculture, Washington, DC, 2016.

|

|

9

|

Mridula D, Singh KK and Barnwal P:

Development of omega-3 rich energy bar with flaxseed. J Food Sci

Technol. 50:950–957. 2013.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Aggarwal D, Sabikhi L and Sathish Kumar

MH: Formulation of reduced-calorie biscuits using artificial

sweeteners and fat replacer with dairy-multigrain approach. NFS J.

2:1–7. 2016.

|

|

11

|

Colantuono A, Ferracane R and Vitaglione

P: In vitro bioaccessibility and functional properties of

polyphenols from pomegranate peels and pomegranate peels-enriched

cookies. Food Funct. 7:4247–4258. 2016.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Stamataki NS, Nikolidaki EK, Yanni AE,

Stoupaki M, Konstantopoulos P, Tsigkas A and Karathanos VT:

Function Evaluation of a high nutritional quality snack based on

oat flakes and inulin : Effects on postprandial glucose, insulin

and ghrelin responses of healthy subjects. Food Funct. 7:3295–3303.

2016.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Hiolle M, Lechevalier V, Floury J,

Boulier-Monthéan N, Prioul C, Dupont D and Nau F: In vitro

digestion of complex foods: How microstructure influences food

disintegration and micronutrient bioaccessibility. Food Res Int.

128(108817)2020.PubMed/NCBI View Article : Google Scholar

|

|

14

|

Mat DJL, Le Feunteun S, Michon C and

Souchon I: In vitro digestion of foods using pH-stat and the

INFOGEST protocol: Impact of matrix structure on digestion kinetics

of macronutrients, proteins and lipids. Food Res Int. 88:226–233.

2016.

|

|

15

|

Minekus M, Alminger M, Alvito P, Balance

S, Bohn T, Bourlieu C, Carrière F, Boutrou R, Corredig M, Dupont D,

et al: A standardised static in vitro digestion method suitable for

food-an international consensus. Food Funct. 5:1113–1124.

2014.PubMed/NCBI View Article : Google Scholar

|

|

16

|

Simsek S and El SN: Production of

resistant starch from taro (Colocasia esculenta L. Schott)

corm and determination of its effects on health by in vitro

methods. Carbohydr Polym. 90:1204–1209. 2012.PubMed/NCBI View Article : Google Scholar

|

|

17

|

Association of Official Analytical

Chemists (AOAC): Official Methods of Analysis. 18th edition.

Association of Official Analytical Chemists, Gaithersburg,

2007.

|

|

18

|

Schakel SF, Jasthi B, Van Heel N and

Harnack L: Adjusting a nutrient database to improve calculation of

percent calories from macronutrients. J Food Comp Analysis. 22

(Suppl):S32–S36. 2009.

|

|

19

|

Englyst KN, Englyst HN, Hudson GJ, Cole TJ

and Cummings JH: Rapidly available glucose in foods: An in vitro

measurement that reflects the glycemic response. Am J Clin Nutr.

69:448–454. 1999.PubMed/NCBI View Article : Google Scholar

|

|

20

|

Goñi I, Valdivieso L and Gudiel-Urbano M:

Capacity of edible seaweeds to modify in vitro starch digestibility

of wheat bread. Nahrung. 46:18–20. 2002.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Isabel G, Garcia-Alonso A and

Saura-Calixto F: A starch hydrolysis procedure to estimate glycemic

index. Nut Res. 17:427–437. 1997.

|

|

22

|

Sciarini LS, Bustos MC, Vignola MB,

Paesani C, Salinas CN and Pérez GT: A study on fibre addition to

gluten free bread: Its effects on bread quality and in vitro

digestibility. J Food Sci Technol. 54:244–252. 2017.PubMed/NCBI View Article : Google Scholar

|

|

23

|

Villemejane C, Denis S, Marsset-Baglieri

A, Alric M, Aymard P and Michon C: In vitro digestion of

short-dough biscuits enriched in proteins and/or fibres using a

multi-compartmental and dynamic system (2): Protein and starch

hydrolyses. Food Chem. 190:164–172. 2016.PubMed/NCBI View Article : Google Scholar

|

|

24

|

Jin Y, Yu Y, Qi Y, Wang F, Yan J and Zou

H: Peptide profiling and the bioactivity character of yogurt in the

simulated gastrointestinal digestion. J Proteomics. 141:24–46.

2016.PubMed/NCBI View Article : Google Scholar

|

|

25

|

Lorieau L, Halabi A, Ligneul A, Hazart E,

Dupont D and Floury J: Impact of the dairy product structure and

protein nature on the proteolysis and amino acid bioaccessiblity

during in vitro digestion. Food Hydrocoll. 82:399–411. 2018.

|

|

26

|

Dégen L, Halas V and Babinszky L: Effect

of dietary fibre on protein and fat digestibility and its

consequences on diet formulation for growing and fattening pigs: A

review. Acta Agric Scand A Anim Sci. 57:1–9. 2007.

|

|

27

|

Nyemb K, Guérin-Dubiard C, Pézennec S,

Jardin J, Briard-Bion V, Cauty C and Nau F: The structural

properties of egg white gels impact the extent of in vitro protein

digestion and the nature of peptides generated. Food Hydrocoll.

54:315–327. 2016.

|

|

28

|

Espinal-Ruiz M, Parada-Alfonso F,

Restrepo-Sánchez LP, Narváez-Cuenca CE and McClements DJ: Impact of

dietary fibers [methyl cellulose, chitosan, and pectin] on

digestion of lipids under simulated gastrointestinal conditions.

Food Funct. 5:3083–3095. 2014.PubMed/NCBI View Article : Google Scholar

|

|

29

|

Zhang H, Jiang Y, Pan J, Lv Y, Liu J,

Zhang S and Zhu Y: Effect of tea products on the in vitro enzymatic

digestibility of starch. Food Chem. 243:345–350. 2018.PubMed/NCBI View Article : Google Scholar

|

|

30

|

Calvo-Lerma J, Fornés-Ferrer V, Heredia A

and Andrés A: In vitro digestion of lipids in real foods: Influence

of lipid organization within the food matrix and interactions with

nonlipid components. J Food Sci. 83:2629–2637. 2018.PubMed/NCBI View Article : Google Scholar

|

|

31

|

Singh J, Dartois A and Kaur L: Starch

digestibility in food matrix: A review. Trends Food Sci Technol.

21:168–180. 2010.

|

|

32

|

Vujić L, Vitali Čepo D and Vedrina

Dragojević I: Impact of dietetic tea biscuit formulation on starch

digestibility and selected nutritional and sensory characteristics.

LWT-Food Sci Technol. 62:647–653. 2015.

|

|

33

|

Chriqui JF, Leider J, Turner L,

Piekarz-Porter E and Schwartz MB: State wellness policy requirement

laws matter for district wellness policy comprehensiveness and

wellness policy implementation in the United States. Nutrients.

13(188)2021.PubMed/NCBI View Article : Google Scholar

|